Potentials of Explainable Predictions of Order Picking Times in

Industrial Production

Kaja Balzereit

a

, Nehal Soni

b

and Andreas Bunte

c

Fraunhofer IOSB, Industrial Automation branch, Fraunhofer Center for Machine Learning, Lemgo, Germany

Keywords:

Explainability, Prediction, Regression Analysis, Industrial Application of AI.

Abstract:

The order picking process in a manufacturing supermarket is central in many industrial productions as it

ensures that the items required for production are provided at the right time. However, the order picking

process itself often is a black box, i.e., the time it takes to pick an order and the dependencies in the process

that influence the time usually are not exactly known. In this work, we highlight the potentials of creating

explainable predictions of order picking times using Artificial Intelligence methods. The prediction is based

on the analysis of a historic database and on a linear regression analysis that learns the dependencies in the

data. From this prediction, (1) the potential of identifying features having a high and a low influence on the

order picking time, (2) the potential of optimizing the order picking process itself, and (3) the potential of

optimizing depending processes are identified. For prediction, we utilize the regression methods LASSO and

Decision Tree. These methods are compared with regard to their interpretability and usability in industrial

manufacturing.

1 INTRODUCTION

Artificial Intelligence (AI) gets more and more impor-

tant in many areas of life (European Factories of the

Future Research Association, 2019). Due to the abil-

ity of AI of handling and analyzing large data with

a high accuracy, its potential is huge (Burkart and

Huber, 2021). However, for AI to be applicable to

sensitive domains, for example when it comes to pro-

cessing data about human behavior, it needs to be ex-

plainable, i.e., the reasoning steps of the AI need to

be comprehensible for a human. But methods from

Machine Learning (ML) often comprise many mathe-

matical transformations and aggregations that prevent

an intuitive understanding. Explainable AI (XAI) al-

lows for deeper insights into AI models, and thus, al-

lows for drawing conclusions about the underlying,

unknown analyses (Balzereit et al., 2022).

Whereas explainability is crucial for AI in do-

mains such as medicine (Holzinger et al., 2019), it

is also required for the domain of manufacturing. AI

harbors a great potential throughout the whole indus-

trial production (Lu, 2019; World Intellectual Prop-

a

https://orcid.org/0000-0001-9203-5902

b

https://orcid.org/0000-0002-3149-2971

c

https://orcid.org/0000-0001-6878-0419

erty Organization, 2019). And modern computing in-

frastructures enable the collection of data about ev-

ery step of production. Nowadays, manufacturing is a

human-centered, cyber-physical process (Monostori,

2014). Hence, the data that is stored about manufac-

turing processes undoubtedly involves data about hu-

man operators. So for an AI system to be applicable to

manufacturing processes, its use and analysis of data

shall be understandable. Furthermore, many manu-

facturing processes are black-box processes, i.e., the

dependencies between different influencing factors

usually are not known to its fullest extent (Balzereit

et al., 2019). XAI allows for drawing conclusions

about these dependencies, and thus, gives deeper in-

sights into unknown processes.

In this article, we are concerned with the applica-

tion of XAI to the order picking process in a manu-

facturing supermarket. A manufacturing supermarket

is a decentralized warehouse storage that allows for

quick and easy access to items required for produc-

tion. The principle of a manufacturing supermarket

goes back to the Toyota Production System: a picker

collects those items required for production of a spec-

ified product from easily accessible shelves (Towill,

2010). The shelves are restocked as soon as required

with items from a less accessible storage, e.g., a high-

rack storage (Yang et al., 2015). The process of col-

Balzereit, K., Soni, N. and Bunte, A.

Potentials of Explainable Predictions of Order Picking Times in Industrial Production.

DOI: 10.5220/0011677000003393

In Proceedings of the 15th International Conference on Agents and Artificial Intelligence (ICAART 2023) - Volume 3, pages 405-412

ISBN: 978-989-758-623-1; ISSN: 2184-433X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

405

lecting items required is called order picking process.

The order picking process itself usually is a black-

box, i.e., the time required for picking one order is not

exactly known. Hence, in production planning, which

needs to incorporate many depending processes, order

picking time often is not considered. As nowadays in

production lot sizes tend to shrink and delivery times

shall be minimized, it can be error prone to not con-

sider order picking times (European Factories of the

Future Research Association, 2019).

For optimizing the order picking process and con-

nected processes, the order picking time needs to be

estimated from available data. But dependencies be-

tween KPIs, such as picking times and input features,

are not known (Balzereit et al., 2019; Balzereit et al.,

2022). In this article, we apply XAI to an industrial

order picking process. Our contribution is as follows:

(1) We will show an intuitive approach to predict

order picking times of new orders, based on historic

data and expert knowledge. For this purpose, fea-

tures ensuring interpretability are generated from ex-

pert knowledge. Interpretable regression methods en-

sure a directly interpretable model.

(2) We compare LASSO regression and deci-

sion tree regression towards their usability and inter-

pretability in predicting order picking times in manu-

facturing supermarkets.

(3) We outline the potential of predicting order

picking times for some AI applications in production

planning: (a) The used models allow for extracting

information about the influence of features. Thus,

information for adapting the process to reduce order

picking times can be drawn. (b) A prediction of or-

der picking times for single orders allows for optimiz-

ing the sequence of orders. Thus, load peaks can be

reduced and a homogeneous load factor of the pick-

ers can be reached. (c) Processes subsequent to order

picking can be optimized by integrating an estimation

of the order picking time.

This article is structured as follows: first, the re-

lated work is described (Section 2). Then, in Sec-

tion 3, the order picking process is described. Our

approach on predicting the order picking time is pre-

sented in Section 4. In Section 5, the results are pre-

sented. After that, the potentials of the prediction are

highlighted (Section 6). Finally, a conclusion is given

in Section 7.

2 RELATED WORK

Dovsilovic et al. (Do

ˇ

silovi

´

c et al., 2018) understand

XAI as a pedagogical system that enables humans to

understand the reasoning of complex algorithms. This

process is crucial for the wide application of AI. Fur-

thermore, as AI need to be continuously improved,

either by updating the training data or by adjusting

the hyperparameters of the model, a deep understand-

ing of the model and how it was created is essential

(Ahmed et al., 2022).

Nor et al. (Nor et al., 2021) emphasized the po-

tential of XAI in industrial applications such as prog-

nostics, diagnostics, and anomaly detection. It states

that the research interest in XAI in industrial appli-

cations rises continuously. Especially interpretable

models, rule- and knowledge-based approaches, and

attention mechanisms, which enable understanding of

image recognition, face a steep rise of interest.

Burkart and Huber (Burkart and Huber, 2021)

published an exhaustive article about recent advan-

tages in XAI. They classified approaches in inter-

pretable by nature, interpretable by design, and black-

box models. Approaches that are interpretable by na-

ture are not optimized in a special way to achieve

interpretability but interpretability is intrinsic in the

approach. For example, linear regression, least abso-

lute shrinkage and selection operator (LASSO), or the

CART algorithm that is used to train decision trees

are interpretable by nature. Interpretability by de-

sign refers to models for which the interpretability

can be controlled. Examples are Deep Neural De-

cision Trees, that combine decision trees with neu-

ral networks (Yang et al., 2015), and Ordered Rules

for Classification, an approach that creates a sequence

of decision rules that are identified using Mixed Inte-

ger Optimization. Black-box approaches, in general,

comprise all methods that do not come with an expla-

nation of their decision. For example, deep neural net-

works are black-box approaches as their decision is

based on the concatenation of mathematical transfor-

mations on the input data. An explanation of why the

specific prediction is given cannot be extracted easily.

To achieve explainability for black-box models, post-

hoc methods creating an explanation after a black-box

model has been trained, are needed.

Related work from the area of order picking is

concerned the use of convolutional neural networks

for classification (Grzeszick et al., 2017) and on the

use of different optimization techniques to increase

the efficiency of the process (Ene and

¨

Ozt

¨

urk, 2012;

Moeller, 2011). Hence, the potential in the analysis

of data about the order picking process is huge.

Our approach uses AI methods that are inter-

pretable by nature. We target an intuitive understand-

ing and a gain of insights into the industrial manufac-

turing process. Thus, hidden dependencies in the data

are identified.

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

406

3 THE ORDER PICKING

PROCESS

Order picking is an essential and cost demanding

process in the supply chain in industrial production.

Given a list of items required for manufacturing a

product, a picker walks through a manufacturing su-

permarket to collect these items. The layout of the

supermarket, the picking system, and the storage and

routing strategies are important aspects that affect the

efficiency of the order picking process (Burinskiene,

2010).

The order picking data is collected as the picker

navigates through the warehouse to collect the items.

Every time a picker starts a new order, finishes an or-

der, or picks an item, a scanner documents the partic-

ular process step. Each of these operations is assigned

with a timestamp. When picking an item, along with

the timestamp, the weight of the item and the location

of the item in the supermarket is stored. In addition,

for each picking order the type of trucks required for

transportation of the items and the lot size (amount of

order) is recorded. This data constitutes the raw data

of the order picking process.

For example, manufacturing an engine requires an

enclosure, a coil and a rotor among other items. While

a single order requires only one quantity of each item,

an order of four engines requires four quantities of

each item which can be collected in a batch. The shelf

trucks are used for smaller items, while pallet trucks

are used for larger items. For heavier items, the pick-

ing time can be increased as a picker needs to lift it

and the truck gets heavier.

To understand the different aspects affecting the

order picking time, we use an ML technique to pro-

cess raw data for analyzing and predicting picking

time for future orders.

4 EXPLICIT PREDICTION OF

ORDER PICKING TIME

In this work, we use supervised, interpretable-by-

nature AI methods. Supervised algorithms use fea-

tures (input) and target (output) data to model the pro-

cess. An ML model is a linear or non-linear mathe-

matical representation of the process dynamics. Fea-

tures are information contributing to the outcome that

we want to predict, i.e., target. The target variable ex-

tracted from the historic data is referred to as ground

truth. The goal of supervised ML modeling is to reli-

ably predict the target variable when new unseen data

is given to the model.

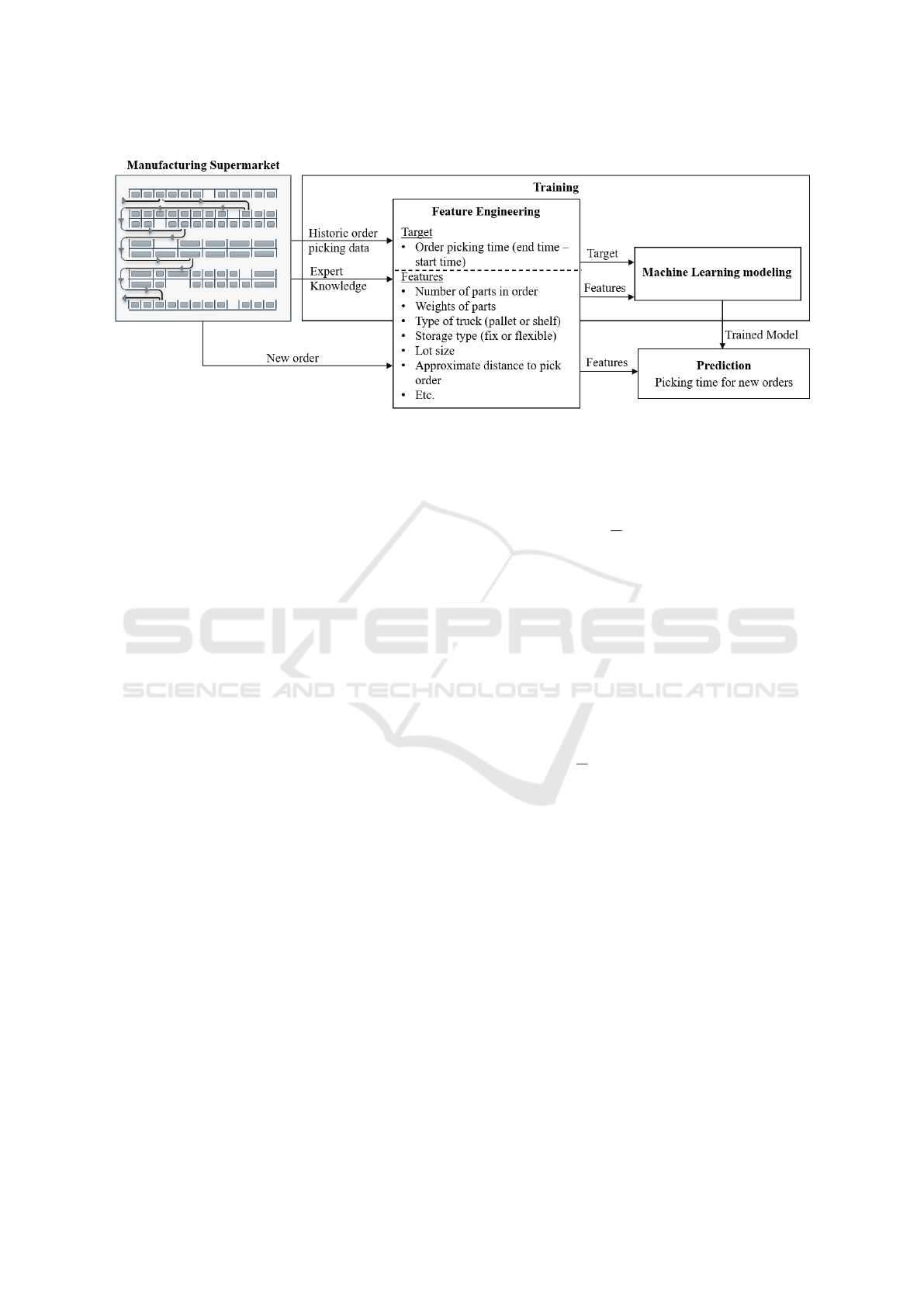

Fig. 1 represents our approach in general. Our

goal is to predict the time required to pick an order.

For this purpose, first, we extract the relevant infor-

mation from the historic raw data of this process. Fac-

tors such as the layout of the manufacturing super-

market, weights of products, the means to carry them

around, and others contribute to the time it takes to

pick an order.

Our approach comprises two steps: first, features

are extracted from the raw data (Section 4.1). Then, a

regression is fitted, learning the dependency between

the features and the order picking time (Section 4.2).

4.1 Feature Engineering

Identifying useful features from the raw data is a cru-

cial part of ML modeling. An example of the features

calculated in our use case is given in the Feature En-

gineering block of Fig. 1.

The target order picking time is calculated by tak-

ing a difference of timestamps (end time and start

time) of the whole process of picking one order.

To predict this target, various features, which sup-

posedly influence the order picking time, are created.

The number of items is the number of different items

required for production of a product. The weight of

items is the sum of individual items’ weight. Types

of truck refers to the vehicle being used to carry the

product depending on where it is located on a shelf.

The storage types is added as a feature to understand

its impact on time. In many manufacturing supermar-

kets, storage spaces are separated into fixed and flex-

ible spaces, i.e., a fixed space stores always the same

item whereas the items stored in a flexible space may

vary with different days. The lot size refers to a num-

ber of the same items to be picked.

We have also incorporated expert knowledge in

calculating certain features. For an instance, the raw

data contains information about the specific location

where an item is placed in the supermarket. Com-

bined with an encoded layout of the supermarket, this

data is used to calculate an approximated distance a

picker has to cover to collect all the items. This dis-

tance calculation is carried out such that the short-

est distance will be considered — to resemble human

behavior. Further expert knowledge such as the im-

pact of different types of truck usage on picking time

enabled us to utilize them as features. This expert

knowledge enables (i) to include all features which

presumably have an impact on the order picking time

and (ii) to calculate features which are directly inter-

pretable. Automatically generated features, in con-

trast, require no expert knowledge for the generation

but also comprise features with no or a hard practical

Potentials of Explainable Predictions of Order Picking Times in Industrial Production

407

Figure 1: Prediction process using feature engineering and machine learning modeling.

interpretation.

4.2 Training of Regression Model

Our target variable, order picking time, is a contin-

uous value. Hence, a prediction can be achieved by

regression.

Here, we utilize LASSO Regression (Section

4.2.1) and Decision Tree Regression (Section 4.2.2).

Both algorithms, in a first step, given a historic

database, learn a dependency between the input fea-

tures and the target time. This step is also called train-

ing phase. In a second step, also called operational

phase, the learned model is used to calculate a pre-

diction for a new order, which is not in the historic

database.

The model performance is evaluated using various

metrics such as Root Mean Squared Error (RMSE),

Mean Absolute Error (MAE), R

2

score. Especially

the RMSE and the MAE are directly interpretable, as

their unit is the same as the target variable. R

2

(R-

squared), a commonly used metric for linear regres-

sion, represents how much of the variation in the tar-

get variable can be explained by taking features into

the account.

4.2.1 Linear Regression

LR generates the best fitting line which calculates

the output variable by summing up the weighted fea-

tures. The feature weight, also known as coefficient,

is parameterized by w

i

∈ R for feature x

i

∈ R, i ∈

{1, 2, ...n}. n ∈ N represents the number of features

and w

0

is the intercept of the fitting line. So, a predic-

tion of target variable y can be calculated as

y =

n

∑

i=1

w

i

· x

i

+ w

0

. (1)

LR models a dependency between independent

and dependent variables by minimizing the residual

sum of squares, so

min

1

N

N

∑

j=1

(y

j

− ˆy

j

)

2

(2)

where N ∈ N is the number of observations, y is the

prediction of the linear regression and ˆy is the ground

truth value. Hence, it is also called least squares Lin-

ear Regression. However, when the number of fea-

tures is high, LR tends to overfit, i.e., the coefficients

values are fitted too strong to the training data and the

transferability to the test data is reduced. Hence, we

add a least absolute shrinkage and selection operator

(LASSO). LASSO linear regression adds the squared

sum of coefficients to the minimization function, i.e.,

min

1

N

N

∑

j=1

(y

j

− ˆy

j

)

2

+ α

n

∑

i=0

w

2

i

, (3)

where α ∈ R

≥0

is a regularization factor. Thus, co-

efficients intentionally are held as small as possible.

Coefficients of features having a negligible impact on

the target are set to zero.

4.2.2 Decision Tree Regression

A Decision Tree partitions the feature space using

bound constraints, e.g., x

i

1

≤ t

i

1

with t

i

1

∈ R (Hastie

et al., 2009) (see Figure 2 for an example). Starting

at a root node, constraints on the feature space create

two new branches - one if the constraint is satisfied

and one if not. Thus, a tree of decisions is created. At

the end of each decision path, a leaf node assigns the

examined order a prediction value.

There are various algorithms for learning a tree.

The most popular one is presumably CART (Breiman

et al., 2017) which aims at maximizing the informa-

tion gain. However, many efficient algorithms, e.g.,

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

408

Figure 2: Example of a Decision Tree. The root node is

patterned, leaf nodes are filled gray.

ID4.5 (Utgoff, 1989), have been published in the last

years.

4.3 Operational Phase

In the operational phase, the learned model is used

to predict the order picking time of new orders. For

this purpose, for the new order, also the features are

extracted using the same feature generation procedure

used for training. These features then are given as an

input to the learned model.

5 RESULTS

5.1 Application Case

The examined supermarket contains around 300

places for different parts, from which 200 are fixed

places and 100 are flexible places. A typical order

comprises between ten and 20 different parts, typical

lot sizes are between 8 and 30.

The typical time for one process is between four

and twelve minutes.

5.2 Performance

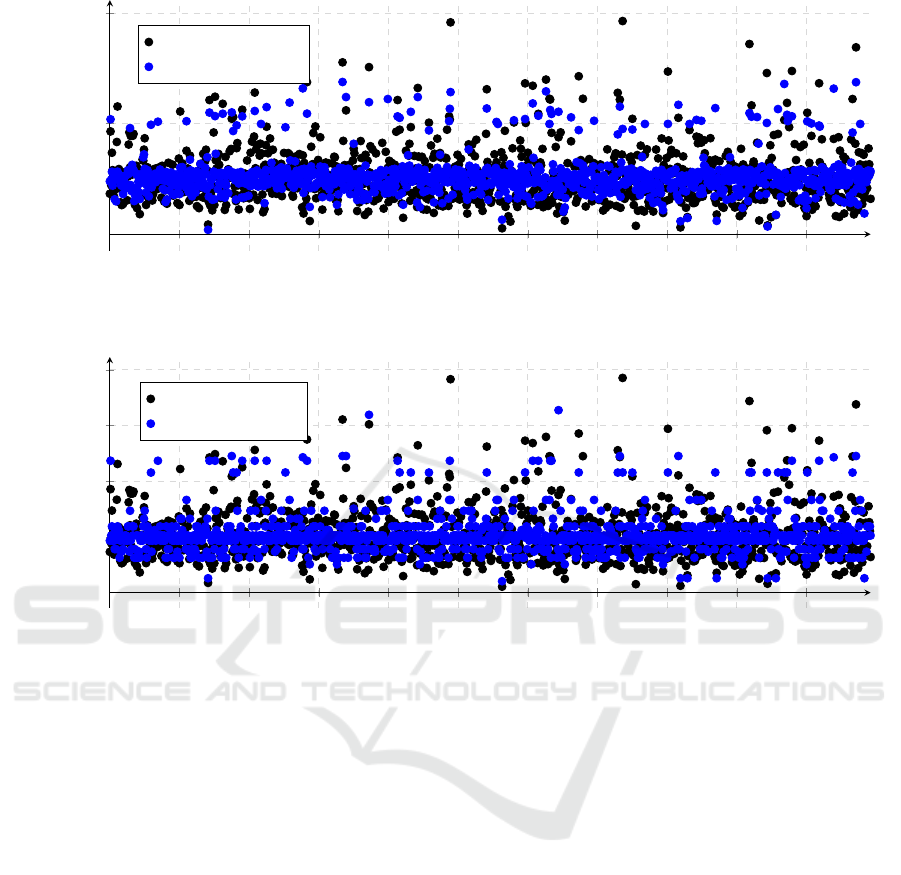

We performed two different types of regression:

Lasso regression and Decision Tree Regression. The

results of the linear regression are illustrated in Figure

3; the results of the decision tree regression are illus-

trated in Figure 4. Black points represent the ground

truth, i.e., the actually measured time for commission-

ing stored in the test data. Blue points represent the

prediction of the corresponding regression method.

The mean absolute error for the linear regression

is approximately 2.4 minutes; the mean absolute error

for the decision tree regression is approximately 2.5

minutes.

From the regression, it can be drawn that the fea-

tures lot size and number of different products in an

order are very relevant for the prediction of the time

required for commissioning.

5.3 Comparison of Decision Tree

Regression and LASSO Regression

for Explainability

Table 1 discusses LASSO and Decision Tree Regres-

sion in terms of interpretability and applicability. In

general, both approaches are interpretable in training

and prediction. LASSO regression minimizes squared

residuals, whereas DTR creates a tree consisting of

constraints on features.

DTR allows for the direct extraction of decision

rules, which, according to our estimation, are more

easily to understand for operators who have few prior

knowledge about AI. LASSO regression creates an

equation allowing for estimating the quantitative in-

fluence of features on the target variable. This equa-

tion, however, requires some knowledge about mathe-

matics or AI, respectively, to allow for an appropriate

interpretation. Furthermore, as regression requires a

normalization of features a-priori, further transforma-

tions are required to allow for an interpretation of co-

efficients in accordance with the un-normalized order

of magnitude of the feature.

However, LASSO creates a continuously differen-

tiable equation representing the dependency between

the features and the target variable. This equation can

directly be used in a subsequent optimization step.

As modern optimization algorithms mainly operate

on gradient descent methods, the property of contin-

uous differentiability enables the application of many

optimization algorithms. DTR, on the other hand, cre-

ates a sequence of decision rules, that, however, is

not continuously differentiable. Hence, further man-

ual efforts are required to integrate such a prediction

into an optimization method.

The number of features may also pose a challenge

for AI algorithms. As LASSO contains a term that

reduces the magnitude of coefficients, also many fea-

tures can be handled well. Features which a small im-

portance actively are assigned a zero coefficient. De-

cision Trees, however, are well known to tend to over-

fitting. Here, a careful parametrization of the learning

algorithm is necessary to enable a proper handling in

case of many feature available.

6 DISCUSSION

Predicting order picking times harbors diverse poten-

tials for further AI applications. In this section, var-

Potentials of Explainable Predictions of Order Picking Times in Industrial Production

409

100 200 300 400 500 600 700 800 900 1,000

20

40

index of examined picking order

prediction

Ground truth

Lasso prediction

Figure 3: Prediction results for LASSO.

100

200 300 400 500 600 700 800 900 1,000

10

20

30

40

index of examined picking order

prediction

Ground truth

DTR prediction

Figure 4: Prediction results for decision tree regression.

ious potentials are discussed. For reducing the or-

der picking times, knowledge about features having a

large influence on the order picking time is crucial. In

Section 6.1, how to extract these features is presented.

The sequence of picking orders has potential for op-

timization, as it may ensures deadlines to be met and

buffer times to be reduced. A discussion of this AI

application is given in Section 6.2. The optimization

of other processes which depend on the order picking

process is presented in Section 6.3.

6.1 Identification of Features with Low

and High Influence

From LASSO Linear Regression, the influence of

each feature can be directly drawn from the learned

model (3). So, previously unknown dependencies,

e.g. that the total weight of a picking order has a

severe impact on the picking time, can be extracted.

This information about the influence of different fea-

tures on the picking time allows for identifying adap-

tations to the picking process that reduce the picking

time. For example, if the total weight of a picking or-

der has a sever impact on the picking time, the pick-

ing orders can be adapted such that the total weight

is reduced, e.g. by splitting large orders into multiple

single orders. In addition, features that have a very

small or negligible impact can be identified as their

coefficients are either close to zero or zero.

From the decision tree, decision rules directly can

be extracted: each path from the root node to a leaf

node creates a set of intuitively interpretable decision

rules. These rules consist of constraints on the feature.

After application of all decision rules extracted from

a path, a decision tree assigns a value to the examined

picking order. Furthermore, decision trees allow for

drawing conclusion about the importance of individ-

ual features. Features in nodes close to the root cause

usually have a higher influence on the decision than

features closer to leave nodes. However, the absolute

frequency of a feature also gives information about

the importance of a feature (Tierney et al., 2022).

Thus, practitioners are enabled to evaluate differ-

ent adaptations that aim at reducing the time of the

picking process. Using the knowledge about the im-

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

410

Table 1: Comparison of LASSO Regression and Decision Tree Regression in terms of explainability and applicability for

industrial manufacturing.

Criterion LASSO DTR

General interpretability of learned model yes yes

Extraction of decision rules no yes

Direct integration in optimization algorithm possible yes no

Appropriate handling of many features yes no

portance of the features, new rules aiming at reducing

the specific features can be created. For example, in

case the weight has a crucial impact on the picking

time, reducing the total weight of orders could lead to

a reduction of time of the picking process.

6.2 Optimization of Order Picking

Process

The main goal of modeling the picking process is

its optimization, by using this data-driven approach.

Typically, companies have a stock of orders that have

to be processed, until a certain point in time. There-

fore, pickers get the next order on the list and start

the picking process. Since we can predict the time

of picking orders, we can use the model to optimize

that. Sequence planning is well known in produc-

tion (SAP, ) and can now be transferred to the or-

der picking process. The optimization criteria can

be manifold, e.g., increasing the efficiency, shifting

workloads from night-shift to day-shift, increasing the

buffer for the production, or avoiding workload picks.

In the following, we will describe two criteria in more

detail, shifting workloads and increasing efficiency.

During the order picking process, the highest pri-

ority is to provide always enough material for the pro-

duction. To optimize the shifts, the predicted number

of workers in every shift should be close to a whole

number, to avoid underemployed workers. Further-

more, orders with a high degree of picking effort and

low production effort can be planned during the day

shift, whereas orders with low picking effort and high

production effort can be completed during the night

shift. This enables to reduce the number of required

pickers at night.

To increase the efficiency of the picking process,

the sequence of orders can be adjusted or orders can

be combined. Changing the sequence is relatively

easy to implement, but depending on the lot sizes the

effect might be small. Combining orders with small

lot sizes has more potential, since picking larger lot

sizes is generally more efficient. However, many con-

straints have to be considered, e.g. the capacity of

the trucks, the delivery time for each product, and the

load factor of each line, if multiple production lines

are provided. Anyway, if all constraints are known,

they can be considered by planning. We suppose that

we can achieve good results with heuristics, which

can process large order sets in short times.

6.3 Integrating the Order Picking

Process into Production

As described above, it is possible to optimize the

order picking process by using the model presented

in this work. However, the information about how

long a picking process takes can be used for opti-

mization of the overall production planning. So, the

picking orders can be triggered by the production,

which will lead to an optimal production or the pro-

duction is triggered by available orders, which leads

to an optimal picking process. Both will lead to a

local optimum of one process. To reach a global op-

timum, both processes have to be combined in one

plan. Besides increased efficiency, it also enables a

more customized or reduced buffer, since the pro-

cesses are more connected and better synchronized.

However, the combined optimization increases the so-

lution space, which makes it more challenging to find

an optimal solution. This makes it hard or impossible

to solve these issues with classical approaches. But

since we have a model, new approaches such as rein-

forcement learning can be used and help to tackle this

challenge (Panzer et al., 2021). However, only such

a holistic view can enable a more efficient process.

From a practical point of view, the creation of an ap-

propriate problem model and the implementation of

a suitable solution algorithm are the key challenges

here.

7 CONCLUSION

The order picking process in a manufacturing super-

market is the process of a picker collecting items re-

quired for production of a specific product. Nowa-

days, this process often is a black box, so the time

needed for collecting all items for a specific order is

unknown in advance. Also, the dependencies in the

process, e.g., how the number of items that need to

be collected affects the order picking time, usually

are not known. However, much data about the or-

Potentials of Explainable Predictions of Order Picking Times in Industrial Production

411

der picking process is collected, allowing for thor-

ough analyses. In this work, an approach for analyz-

ing this data to generate a prediction of order picking

times is presented. The approach is based on explain-

able AI methods that learn the dependencies between

the features of historic picking orders and the time re-

quired. A comparison of LASSO and Decision Tree

Regression discusses the benefits and drawbacks of

the individual approaches. We highlight the poten-

tials this prediction harbors for industrial production:

it enables the identification of features affecting the

order picking time significantly or just marginally, it

allows for optimization of the order picking process

itself, and it enables the optimization of overall pro-

duction as the prediction of order picking time can be

integrated into global optimization approaches.

ACKNOWLEDGEMENTS

This work was funded by research grant “005-2001-

0031” of the MWIDE NRW in form of the Spitzen-

cluster it’s OWL intitiative in the research project

IMAGINE. We thank the Wilo SE for providng the

application case.

REFERENCES

Ahmed, I., Jeon, G., and Piccialli, F. (2022). From artificial

intelligence to explainable artificial intelligence in in-

dustry 4.0: a survey on what, how, and where. IEEE

Transactions on Industrial Informatics, 18(8):5031–

5042.

Balzereit, K., Diedrich, A., Kubus, D., Ginster, J., and

Bunte, A. (2022). Generating causal hypotheses

for explaining black-box industrial processes. 5th

IEEE International Conference on Industrial Cyber-

Physical Systems (ICPS).

Balzereit, K., Maier, A., Barig, B., Hutschenreuther, T., and

Niggemann, O. (2019). Data-driven identification of

causal dependencies in cyber-physical production sys-

tems. In 11th International Conference on Agents and

Artificial Intelligence.

Breiman, L., Friedman, J. H., Olshen, R. A., and Stone,

C. J. (2017). Classification and regression trees. Rout-

ledge.

Burinskiene, A. (2010). Order picking process at ware-

houses. International Journal of Logistics Systems

and Management - Int J Logist Syst Manag, 6.

Burkart, N. and Huber, M. F. (2021). A survey on the ex-

plainability of supervised machine learning. Journal

of Artificial Intelligence Research, 70:245–317.

Do

ˇ

silovi

´

c, F. K., Br

ˇ

ci

´

c, M., and Hlupi

´

c, N. (2018). Ex-

plainable artificial intelligence: A survey. In 2018 41st

International convention on information and commu-

nication technology, electronics and microelectronics

(MIPRO), pages 0210–0215. IEEE.

Ene, S. and

¨

Ozt

¨

urk, N. (2012). Storage location assignment

and order picking optimization in the automotive in-

dustry. The international journal of advanced manu-

facturing technology, 60(5):787–797.

European Factories of the Future Research Association

(2019). EFFRA Vision for a manufacturing partner-

ship in Horizon Europe. 2021-2027.

Grzeszick, R., Lenk, J. M., Rueda, F. M., Fink, G. A., Feld-

horst, S., and Ten Hompel, M. (2017). Deep neural

network based human activity recognition for the or-

der picking process. In Proceedings of the 4th inter-

national Workshop on Sensor-based Activity Recogni-

tion and Interaction, pages 1–6.

Hastie, T., Tibshirani, R., Friedman, J. H., and Friedman,

J. H. (2009). The elements of statistical learning: data

mining, inference, and prediction, volume 2. Springer.

Holzinger, A., Langs, G., Denk, H., Zatloukal, K., and

M

¨

uller, H. (2019). Causability and explainability of

artificial intelligence in medicine. Wiley Interdisci-

plinary Reviews: Data Mining and Knowledge Dis-

covery, 9(4):e1312.

Lu, Y. (2019). Artificial intelligence: a survey on evolu-

tion, models, applications and future trends. Journal

of Management Analytics, 6(1):1–29.

Moeller, K. (2011). Increasing warehouse order picking

performance by sequence optimization. Procedia-

Social and Behavioral Sciences, 20:177–185.

Monostori, L. (2014). Cyber-physical production systems:

Roots, expectations and r&d challenges. Procedia

Cirp, 17:9–13.

Nor, A. K. M., Pedapati, S. R., Muhammad, M., and

Leiva, V. (2021). Overview of explainable artificial

intelligence for prognostic and health management of

industrial assets based on preferred reporting items

for systematic reviews and meta-analyses. Sensors,

21(23):8020.

Panzer, M., Bender, B., and Gronau, N. (2021). Deep re-

inforcement learning in production planning and con-

trol: A systematic literature review. In Conference on

Production Systems and Logistics (CPSL).

SAP. Sequence planning - documentation of sap manufac-

turing exection.

Tierney, K., Balzereit, K., Bunte, A., and Nieh

¨

orster, O.

(2022). Explaining solutions to multi-stage stochas-

tic optimization problems to decision makers. In

2022 IEEE 27th International Conference on Emerg-

ing Technologies and Factory Automation (ETFA),

pages 1–4.

Towill, D. R. (2010). Industrial engineering the toyota pro-

duction system. Journal of Management History.

Utgoff, P. E. (1989). Incremental induction of decision

trees. Machine learning, 4(2):161–186.

World Intellectual Property Organization (2019). WIPO

technology trends. Artificial Intelligence.

Yang, T., Kuo, Y., Su, C.-T., and Hou, C.-L. (2015). Lean

production system design for fishing net manufactur-

ing using lean principles and simulation optimization.

Journal of Manufacturing Systems, 34:66–73.

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

412