Multi-Objective Optimization of the Dynamic and Flexible Job Shop

Scheduling Problem Under Workers Fatigue Constraints

Dorsaf Aribi

2 a

, Olfa Belkahla Driss

1,2 b

and Hind Bril El Haouzi

3 c

1

Univ. Manouba, ESCT, Campus Universitaire Manouba, 2010, Tunisia

2

Univ. Manouba, ENSI, LARIA UR22ES01, Campus Universitaire Manouba, 2010, Tunisia

3

Universit

´

e de Lorraine, CNRS, CRAN, F-88000 Epinal, France

Keywords:

Dynamic Scheduling, Workers’ Fatigue, Flexible Job-Shop Rescheduling, New Job Insertion, Machine

Breakdown, Job Cancellation , Multi-Objective Optimization, NSGA-II.

Abstract:

A massive number of studies has tackled the scheduling problem, but they mainly seek to solve the classic

problem by reducing the real constraints of the environment like workers’ fatigue, which may lead to defective

production, and the occurrence of unexpected events that makes the initial scheduling obsolete. In this paper,

we study the multi-objective dynamic flexible job shop-scheduling problem under workers’ fatigue constraints

(DFJSP-WF) through three unexpected events: job insertion, machine breakdown and job cancellation. First,

a multi-objective model is established with objectives to minimize makespan and total weighted tardiness,

earliness and rejected parts due to workers’ errors, which depend on workers’ fatigue. Second, to deal with

this model, a non-dominated sorting genetic algorithm II (NSGA-II) is adapted. Computational results are

presented using three sets of well-known benchmark literature instances.

1 INTRODUCTION

Production scheduling plays an essential role in the

modern manufacturing system thanks to its great po-

tential to promote efficiency and productivity. Differ-

ent complexities often arise during production such

as machine breakdown and rush orders. The occur-

rence of these unexpected events may disrupt the orig-

inal production scheduling and hinder the realization

of scheduling objectives. The consideration of such

events makes the scheduling process dynamic and re-

quires a rescheduling (Liang and Yu, 2001). The main

aim of scheduling/rescheduling is to allow available

resources to perform a number of tasks, over a given

period of time, in the best possible way to optimize

one or more objectives with respecting the existing

constraints of the manufacturing environment (Jain

and Elmaraghy, 1997).

In such an agile environment, workers and ma-

chines complement each other to accomplish the pro-

duction. At each stage, operators play an important

role in leading and participating in the whole process

a

https://orcid.org/0000-0002-0872-413X

b

https://orcid.org/0000-0003-3077-6240

c

https://orcid.org/0000-0003-4746-5342

of production, controlling and supervising all kinds of

equipment, completing all kinds of work, and com-

municating with the environment.The human factor

plays an important role in ensuring production safety

and the success of the operation.

In this research, we tackle the Dynamic Flexible

Job Shop Scheduling Problem under Worker Fatigue

Constraint (DFJSP-WF), which is a generalization

of the classical Job shop scheduling problem (JSP).

To solve this problem, we apply a bi-objective op-

timization based on Non-dominated sorting genetic

algorithm II (NSGA-II). The two objectives studied

are the completion time (makespan) and the total

weighted tardiness, earliness and rejected pieces. The

unexpected events considered are new job arrival, job

cancellation and machine breakdown. Experimental

results are presented in order to prove the effective-

ness of the proposed algorithm.

The rest of the paper is organized as follows. Sec-

tion 2 gives a critical survey of the current literature.

In Section 3, the description and formulation of the

proposed DFJSP-WF are depicted in detail. The pro-

posed NSGA-II is introduced in Section 4. In Section

5, an example is presented to clarify the subject. To

evaluate the performance of the proposed algorithm,

comprehensive experiments are conducted and the re-

Aribi, D., Belkahla Driss, O. and El Haouzi, H.

Multi-Objective Optimization of the Dynamic and Flexible Job Shop Scheduling Problem Under Workers Fatigue Constraints.

DOI: 10.5220/0011663800003393

In Proceedings of the 15th International Conference on Agents and Artificial Intelligence (ICAART 2023) - Volume 3, pages 301-308

ISBN: 978-989-758-623-1; ISSN: 2184-433X

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

301

sults are illustrated in Section 6. Finally, concluding

remarks and future works are described in Section 7.

2 RELATED WORK

2.1 Dynamic Flexible Job Shop

Scheduling

Most scheduling problems are proved NP hard prob-

lems (Blazewicz et al., 1983). Clearly, dynamic

scheduling is more complex and challenging to solve.

Ze Tao and Xiaoxia Liu, (Tao and Liu, 2019) stud-

ied the dynamic scheduling problem of blocking job

shop constrained by machines and workers based on

genetic algorithm and simulated annealing algorithm

(GASA). The performance of the method was exam-

ined based on two cases, to be rescheduled or minor

adjusted according to their influence on the comple-

tion time, and the results show that the method pro-

posed is effective and feasible. The study of Frutos

and al. (Frutos et al., 2010) proposed a memetic al-

gorithm based on NSGA-II to solve a Bi-objective

FJSP. Authors integrated a simulated annealing stage

as a local search procedure to minimize the makespan

and the total operating cost. . (Chen et al., 2018)

also used NSGA-II to study a multi-objective dy-

namic flexible job shop scheduling problem with ma-

chine breakdown to minimize makespan and total ma-

chine workload. The performance of two reschedul-

ing strategies including transfer strategy and complete

strategy is analyzed in terms of the scheduling effi-

ciency and its stability. Earlier in 2015, (Shen and

Yao, 2015) developed a multi-objective evolutionary

algorithm (MOEA)-based proactive-reactive method

in order to capture the dynamic and multi-objective

nature of flexible job shop scheduling. Besides, Shen

constructed a new mathematical model for the multi-

objective dynamic flexible job shop scheduling prob-

lem (MODFJSP).

2.2 Fatigue in the Manufacturing

Systems

Two resources such as workers and machines are

constrained in the manufacturing process and this

problem is called Dual-resource constrained job shop

scheduling problem.

Dual-resource constrained scheduling has been

given more and more attention in recent years (Dhi-

flaoui et al., 2018) (Gong et al., 2019) (Mraihi et al.,

2022) (Farjallah et al., 2022). However, most of the

objectives studied are profit/cost oriented. Only re-

cently new models have been proposed in order to op-

timize the working conditions such as to reduce phys-

ical workload (Mossa et al., 2016). This shows an

important gap in scheduling literature where the im-

pact of scheduling decisions on human performance

and health is usually ignored (Lodree et al., 2009). To

fill this gap, a significant effort on modeling of hu-

man factors has to be made. We would focus on the

integration of one of such factors like the human ac-

cumulated fatigue in scheduling decision-making pro-

cesses.

In (Jaber et al., 2013), the authors evaluated fa-

tigue F using the model defined by the equation 1,

where R is the residual fatigue carried, λ is a fatigue

exponent specifying fatigue rate, t

n

is the production

time of the cycle i and t

i

is determined by projecting

the value of R(τ

i

) on the fatigue curve.

F

i+1

(t) = R(τ

i

) + (1 − R(τ

i

))(1 − e

−λ(t

n

−t

i

)

) (1)

In (Ferjani et al., 2017), the authors associated a

penalty coefficient d

j

to each machine j to model the

difficulty of work on that machine, such as 0 ≤ d j ≤ 1.

This coefficient d

j

expresses the speed of fatigue ac-

cumulation. The increase of fatigue ∆

i, j

generated

during a new task on machine j, between its begin-

ning t

i

and the current time t, is expressed as follows:

∆

i, j

(t

i

,t) = (1 − F

i

(t

i

))(1 − e

−d

j

(t−t

i

)

) (2)

As a consequence, from time t to t

i

, the level of fatigue

is updated as follows:

F

i

(t) = F

i

(t

i

) + ∆

i, j

(t

i

,t) (3)

(Zhang and Luo, 2020) had another vision. They pre-

sented a mathematical model of job fatigue time vary-

ing with time in the equation 4.

FT

i

= αFS[(1 + F

j

) ∗

n

∑

j=1

m

i j

∗ mod

j

], ∀i ∈ I;∀ j ∈ J

(4)

where I represents task set, I = {1,2,3,...}; J repre-

sents the set of sequence numbers, J = {1, 2, 3, ...};

m

j

represents each action element; F

j

represents the

fatigue index of each action; mod

i j

represents the

time required to complete each pose under the MOD

method in seconds; n represents the number of oc-

currences of a single action to complete a task, n =

{1,2,3...}; FS represents the fatigue state values of

workers in different time periods; FT

i

represents fa-

tigue time in seconds and α represents confidence,

(0.95 < α < 1).

3 DFJSP-WF

The DFJSP-WF considers only the flexibility of the

machine. To optimize the worker’s fatigue impact

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

302

and system productivity, the Total Weighted Tardi-

ness, Earliness and Rejected Parts (TWET RP) and

makespan (C

max

) are employed as objectives. In this

section, the description and formulation of the pro-

posed DFJSP-WF are depicted in detail.

3.1 Problem Description

The DFJSP-WF is described as follows. There is a

set of n independent jobs J = {J

1

,J

2

,. . . , J

n

}, a set of

m machines M = {M

1

,M

2

,. . . , M

m

}, and a set of m

workers W = {W

1

,W

2

,. . . ,W

m

}. A job J

i

has a se-

quence of r

i

operations {O

i1

,O

i2

,. . . , O

ir

i

} to be pro-

cessed one after another according to the precedence

constraint. Each operation O

i j

, namely, the jth oper-

ation of J

i

, must be executed on a given machine M

k

chosen from the given machine set M

i j

with a specific

processing time t

i jk

. Each machine M

k

must be oper-

ated by the given worker W

k

. Workers will experience

fatigue and recovery during production. Worker fa-

tigue accumulates during a continuous period of work

while alleviates during a continuous period of rest.

For the dynamic impact, we considered three

events: a new job arrival, a job cancellation and a ma-

chine breakdown. Each event is characterized with an

occurrence time. At each event, we are supposed to

provide a rescheduling.

For the first case, a new job arrival, rescheduling is

a necessary procedure for a flexible job shop when

newly arrived priority jobs must be inserted into

an existing schedule. In the second case, job can-

cellation, it is rescheduled if the remainder task is

heavy, otherwise, the remainder jobs will be pro-

cessed corresponding to initial scheduling. And for

the last event, machine breakdown, according to (Tao

and Liu, 2019), there are two different situations of

machine breakdown according to the fault repairing

time:

• Major fault : the fault repairing time is long ⇒ a

rescheduling is recommended

• Minor fault : the fault repairing time is short ⇒

a rescheduling becomes not necessary because it

has little effect on the completion time.

To clarify the proposed problem, the following as-

sumptions are considered:

1. Preemption of jobs is not allowed.

2. All raw material and production resources (ma-

chine and worker) are available at time 0.

3. Processing time is deterministic and predefined.

4. The worker cannot be interrupted during process-

ing.

5. Worker has no fatigue at time 0.

Table 1: Model parameters and decision variables.

Notation Description

n The number of jobs

m The number of machines/ The number

of workers

r

i

Total number of operations for job J

i

O

i j

The jth operation of job J

i

M

i j

The set of compatible machines for O

i j

t

i jk

The processing time of operation O

i j

on the machine M

k

L A big positive number

X

i jk

If the operation O

i j

is processed on

M

k

, X

i jk

= 1; otherwise, X

i jk

= 0 , i ∈

{1,2,..,n}, j ∈ {1,2,..,r

i

}, M

p

⊆ M

i j

Y

k

i j,i

′

j

′

If the operation O

i j

is processed adja-

cently before O

i

′

j

′

on M

k

, Y

k

i j,i

′

j

′

= 1;

otherwise, Y

k

i j,i

′

j

′

= 0 , i,i

′

∈ {1, 2, .., n},

j ∈ {1,2,..,r

i

}, j

′

∈ {1, 2, .., r

′

i

}, M

p

⊆

M

i j

∩ Mi

′

j

′

6. The processing routing of each job and the pro-

cessing time of each operation are known when

the job is inserted.

7. Each machine can only process one operation at a

time.

The used parameters and decision variables are listed

in Table 1.

3.2 Mathematical Model of DFJSP-WF

The first objective is to process jobs in Just-In-

Time, which means minimizing late deliveries but

also avoiding early ones. We also want to consider

the effect of such strategy on the worker and particu-

larly on his reliability. This can be formulated by eq.

(5):

TW T ERP =

n

∑

i=1

(α

1i

∗ u

i

+ α

2i

∗ e

i

+

m

∑

j=1

α

3 j

∗ r

j

) (5)

where α

1i

is the job i penalty cost per unit of time

of an early delivery, α

2i

is its penalty cost per unit

of time of a late delivery, and α

3 j

is the penalty cost

of rejected deliveries due to quality issues related to

reference j. u

i

is the tardiness period of job i, e

i

is its

earliness period, and r

j

is the number of rejected parts

due to human error after processing a job j which is

modeled using eq. (6). The parameter C is for error

Multi-Objective Optimization of the Dynamic and Flexible Job Shop Scheduling Problem Under Workers Fatigue Constraints

303

Figure 1: Fatigue evolution during jobs processing.

calibration. θ

j

designates the tasks difficulty. Both C

and θ

j

are estimated using a mapping with data pro-

vided by the Human Error Assessment and Reduction

Technique (HEART) (El Mouayni et al., 2019).

r

j

(t) = CF

θ

j

t

(6)

Following the recommendations of the literature,

it is assumed that general fatigue is governed by an

exponential distribution. Thus, the fatigue index be-

tween two successive period t and t + 1 is modeled

using eq. (7) :

F

t+1

= w

t

(1 − (1 − F

t

)e

−λ

k

) + (1 − w

t

)F

t

e

−µ

k

(7)

where F

t

is a float designating the fatigue index (0 ≤

F ≤ 1) at the end of the period t ∈ [0,T − 1], T is an

integer designating the scheduling horizon. λ

k

is the

fatigue rate when processing a job k. The parameter

µ

k

is the recovery rate after processing a job k. The pa-

rameter w

t

designates the worker’s state. It is equal to

1 if worker is busy, 0 if idle. Depending on the sched-

ule, the worker may have some rest windows to re-

cover from fatigue. Similarly, periods with intensive

work may occur leading to excessive fatigue and error

probability raise as shown in Figure 1. On the other

hand, job put-off due to fatigue recovery may lead to

delivery tardiness. Therefore, a trade-off should be

found.

The second objective of makespan (C

max

) is modeled

as the matter of routine and the formulation is shown

as eq. (8).

C

max

= max

i, j

{C

i j

} , i ∈ {1,2,. . . ,n}, j ∈ {1,2,. . . ,m}

(8)

In order to solve the problem in hand, a bi-objective

model is formulated as follows:

minimize

f

1

= TW T ERP

f

2

= C

max

(9)

Subject to:

C

i( j+1)

≥ C

i j

+

m

∑

k=1

t

i( j+1)k

X

i( j+1)k

,

i ∈ {1, 2, .., n}, j ∈ {1, 2, .., r

i

}

(10)

C

i( j+1)

+ (1 −Y

p

i j,i

′

j

′

)L ≥ C

i j

+

m

∑

k=1

t

i

′

j

′

k

X

i

′

j

′

k

,

i,i

′

∈ {1, 2, .., n}, j ∈ {1, 2, .., r

i

},

j

′

∈ {1, 2, .., r

′

i

}, p ∈ 1,2,..m

(11)

m

∑

k=1

X

i jk

= 1 , i ∈ {1, 2, .., n}, j ∈ {1, 2, .., r

i

}

(12)

Y

p

i j,i

′

j

′

Y

p

i

′

j

′

,i j

= 0 ,

i,i

′

∈ {1, 2, .., n}, j ∈ {1, 2, .., r

i

},

j

′

∈ {1, 2, .., r

′

i

},M

p

⊆ M

i j

∩ M

i

′

j

′

(13)

(1 − X

i jp

X

i

′

j

′

p

)Y

p

i j,i

′

j

′

= 0 ,

i,i

′

∈ {1, 2, .., n}, j ∈ {1, 2, .., r

i

},

j

′

∈ {1, 2, .., r

′

i

},M

p

⊆ M

i j

∩ M

i

′

j

′

(14)

The constraint (10) guarantees the precedence re-

lation of job operations. Constraint (11) indicates that

a machine can process only one operation at a time.

Constraint (12) ensures that each operation should

only be processed once. Constraint (13) avoids the

conflicted sequence of operations assigned to a ma-

chine. Constraint (14) is network constraint of the de-

cision variables X and Y , which avoid the conflicted

values between them.

4 NSGA-II FOR DFJSP-WF

The NSGA-II procedure is one of the popularly

used EMO procedures which attempt to find multi-

ple Pareto-optimal solutions for a multi-objective op-

timization problem and has the following three fea-

tures: an elitist principle, an explicit diversity pre-

serving mechanism and non-dominated solutions to

be emphasized.

4.1 Coding and Decoding

Let’s consider that we have to schedule 4 jobs com-

posed respectively by {3,3,2,3} operations. The op-

eration sequence should be encoded in the chromo-

some. The individual is constituted of a random per-

mutation of 1 to the number of operations (11 in our

case). With a simple mathematical equation, each

chromosome is transformed to the job number as il-

lustrated in figure 2.

10 6 5 11 1 3 2 7 8 4 9

⇓ Decoding

4 2 2 4 1 1 1 4 3 2 3

O

41

O

21

O

22

O

42

O

11

O

12

O

13

O

43

O

31

O

23

O

32

Figure 2: Coding and decoding procedure.

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

304

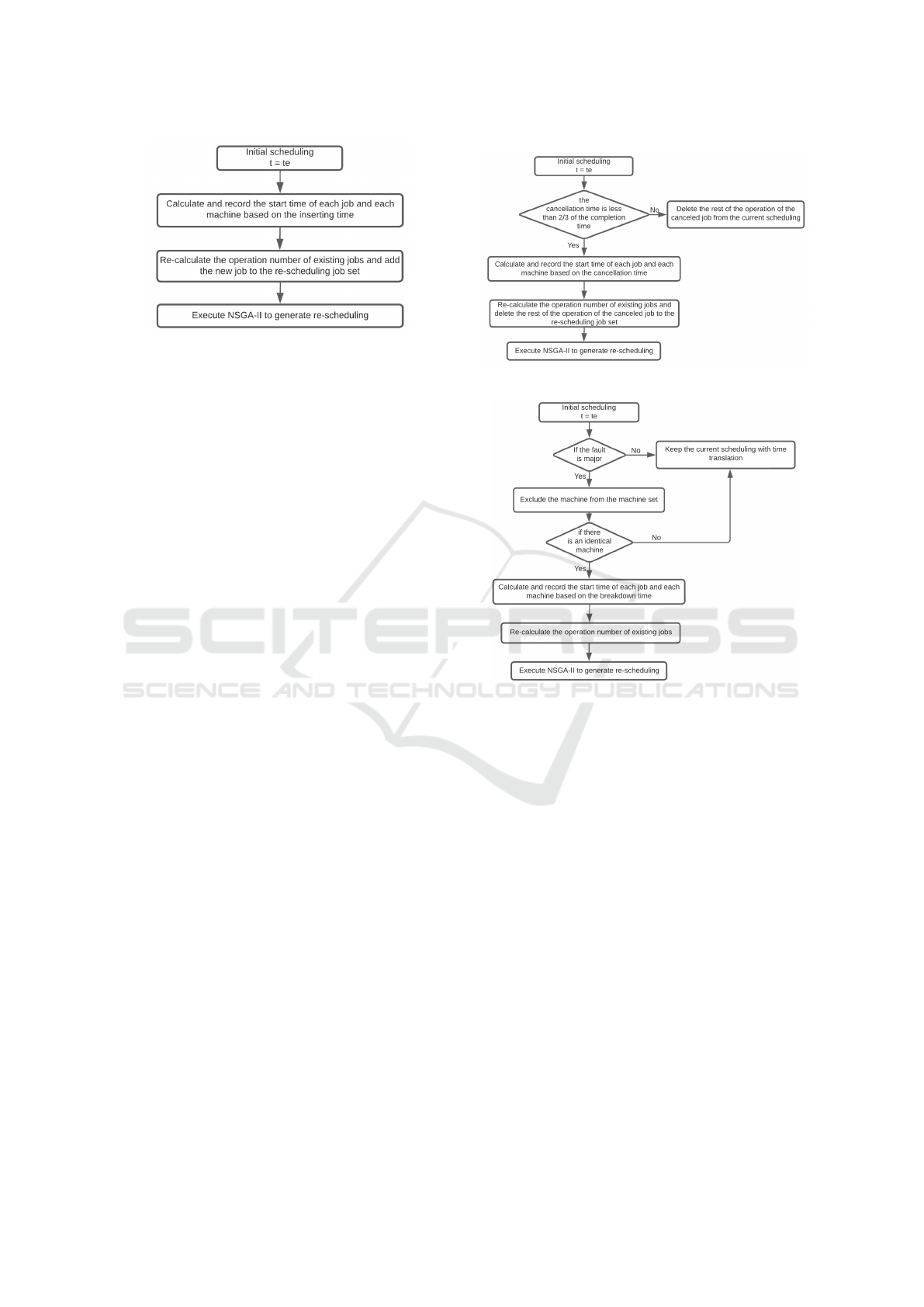

Figure 3: Re-scheduling process after new job arrival.

4.2 Evolutionary Operators of NSGA-II

Two-point crossover operator is used where two

crossover points are picked randomly from the par-

ent chromosomes. The bits in between the two points

are swapped between the parent organisms. The re-

pairment phase is to adjust the appearance time of the

jobs after crossover to guarantee the feasibility of the

solution.

For the mutation, partial transfer mutation operator is

applied. Mutation is a genetic operator used to main-

tain diversity from one generation to the next. The

partial transfer operator is about choosing two posi-

tions in the solution. The gene in the first position

will be in the last and the genes in between are shifted

with one position.

4.3 Re-Scheduling Process

In the scenario of dynamic scheduling, it is impor-

tant to check which operations have been finished and

which operations have not been processed or are be-

ing processed but are incomplete at time t when the

dynamic events occur. The re-scheduling process for

these events is described in the next three sections.

4.3.1 New Job Insertion

At an instant t

e

, a new job arrive so, a re-scheduling

is needed. We start by listing the unprocessed oper-

ations then we add the operations of the new job and

re-execute the NSGA-II to obtain a new PF. The pro-

cess is depicted in figure 3.

4.3.2 Job cancellation

When an order is canceled, we need to verify if the

cancellation time is less than 2/3 of the completion

time. If it’s the case then, a rescheduling is necessary.

The process is shown in figure 4.

Figure 4: Re-scheduling process after a job cancellation.

Figure 5: Re-scheduling process after a machine break-

down.

4.3.3 Machine Breakdown

When a machine breakdown occur, we first need to

verify if it is rather a minor or a major fault. Second,

we should verify if there is an identical machine to

replace the defaulted one. If the two conditions are

verified, then NSGA-II is executed and a new PF is

generated. The steps details are shown in figure 5.

5 ILLUSTRATIVE EXAMPLE

In this section, an illustrative example is provided to

show the efficiency of the algorithm on static and dy-

namic FJSP under worker fatigue constraint.

5.1 Static FJSP

To better understand the different steps of the al-

gorithm, we would introduce an instance IP of the

Multi-Objective Optimization of the Dynamic and Flexible Job Shop Scheduling Problem Under Workers Fatigue Constraints

305

Table 2: Job–machine information of the instance IP.

Job Operations Corresponding

machine

Processing

time

Due

date

Penalty

J1 O11 M1,M2 3,5 20 0.24

O12 M5 4

O13 M3,M4 4,6

J2 O21 M5 10 35 0.2

O22 M1,M2 5,7

O23 M3,M4 6,8

J3 O31 M3,M4 7,9 55 0.3

O32 M5 6

J4 O41 M1,M2 6,10 60 0.15

O42 M5 5

O43 M3,M4 7,8

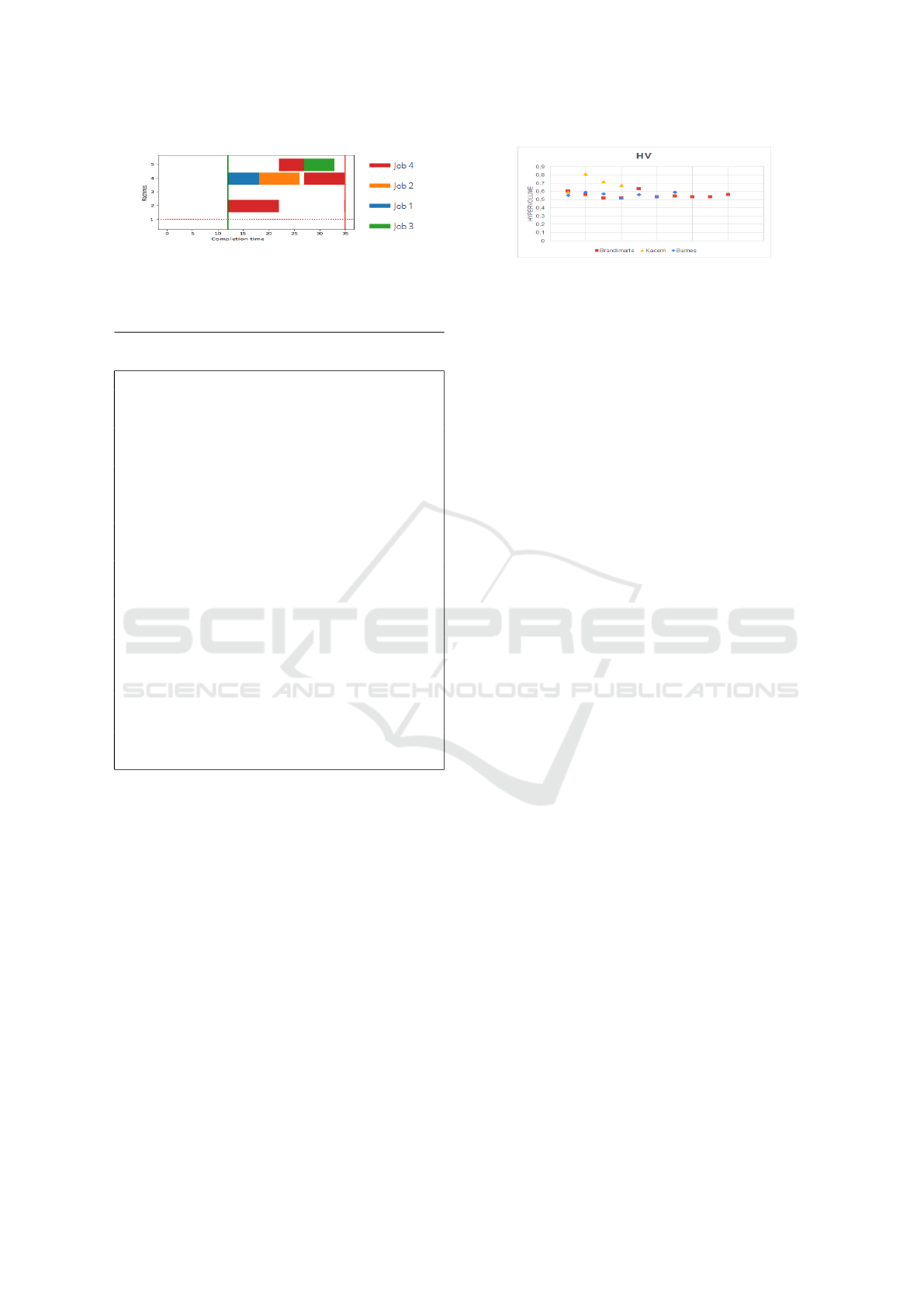

Figure 6: GANTT chart of the optimal makespan value

equal to 25 for IP.

DFJSP-WF, presented in table 2 , that we will con-

sider for the rest of this section. The proposed in-

stance IP consists of 4 jobs, 11 operations and 5 ma-

chines. The optimal solution based on Makespan

value is presented in figure 6.

5.2 Dynamic FJSP

We considered the selected solution presented in fig-

ure 7 as the initial scheduling. Three scenarios of un-

expected events are studied in the following.

(1) New Job Arrival

At t = 15, a new order arrive. The new job data is pre-

sented in table 3. In figure 8, two solutions are repre-

sented. The first solution is selected from the Pareto

front delivered by our approach based on CR (Com-

plete Rescheduling) strategy with C

max

= 38 and the

second one is based on RS (Right-Shift) strategy with

C

max

= 46. We can obviously see that the first strategy

deliver a better result.

(2) Job Cancellation

Figure 7: GANTT chart of the selected solution for

rescheduling.

Table 3: New job arrival data.

Job Operations Corresponding

machine

Processing

time

Penalty Due

date

J5 O51 M3,M4 3,4

O52 M5 5 0.2 70

O53 M1,M2 5,4

Figure 8: GANTT charts of the rescheduling after J

5

inser-

tion with 2 strategies.

The second scenario is the cancellation of job 2 at

t = 10 and we obtain the solution with a makespan

equal to 28 that is presented in figure 9. We observe

that the makespan value is lower that the obtained in

the initial scheduling.

(3) Machine Breakdown

The last considered scenario is machine 1 breakdown

at t = 12. Machine 1 and machine 2 are identical so,

we can generate a rescheduling. One of the obtained

solutions by our approach is presented in figure 10.

6 SIMULATION AND ANALYSIS

In the proposed algorithm, there are several input pa-

rameters that we set as follow: 1) population size

N = 40; 2) crossover probability ρ

c

= 0.8; and 3) mu-

tation probability ρ

m

= 0.05. For the calculation of

fatigue rate of each worker, we consider the following

parameters: machine m difficulty rate θ

m

∈ [0.01,0.5];

error calibration C = 1; fatigue rate λ

i

∈ [0.01, 0.1]

and recovery rate µ

i

∈ [0.1,0.5] after processing job i.

The effectiveness of the NSGA-II for DFJSP under

fatigue constraint is analyzed by performing experi-

ments with static FJSP benchmarks. These instances

Figure 9: GANTT chart of rescheduling after job 2 cancel-

lation.

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

306

Figure 10: GANTT chart of rescheduling after machine 1

breakdown.

Table 4: Results of applying NSGA-II to benchmark in-

stances.

f1 = Cmax f2 = TWTERP

Instance n x m

min max min max

Mk01 10 x 6 68 141 210,64 329,38

Mk02 10 x 6 58 120 378,13 525,37

Mk03 15 x 8 333 550 4106,78 5025,73

Mk04 15 x 8 111 199 858,34 1161,8

Mk05 15 x 4 247 356 1055,36 1465,68

Mk06 10 x 15 183 326 904,17 1169,54

Mk07 20 x 5 265 454 2916,51 3805,47

Mk08 20 x 10 677 932 7926,86 9220,55

Mk09 20 x 10 600 857 8405,23 9648,48

Mk10 20 x 15 518 771 8988,36 10263,5

mt10c1 10 x 11 1195 2156 5317.42 7322.71

mt10cc 10 x 12 1110 2245 5849,1 8419,51

mt10x 10 x 11 1130 2118 4592,01 7116,53

mt10xx 10 x 12 1159 2052 4643.93 6781.03

mt10xxx 10 x 13 1179 2083 4676.2 6559.03

mt10xy 10 x 12 1137 2314 5034.14 7886.35

mt10xyz 10 x 13 1185 2171 3699.67 5332.56

Case1 4 x 5 16 94 1 26

Case2 10 x 7 28 197 7 62

Case3 10 x 10 22 110 16 59

Case4 10 x 15 44 188 16 94

are constructed by (Brandimarte, 1993), (Chambers

and Barnes, 1996) and (Kacem et al., 2002).

Since these instances were formulated in order to

minimize the makespan, we have to add a weight

(penalty) and a due date for each job. We make

α

1i

= α

2i

∈ U[0.01,0.25]. According to (Singer and

Pinedro, 1998), the due date of job j is set as in eq.

(15) a factor f = 1.3.

d

i

= r

i

+ ⌊ f

∑

j

max

m

(p

i jm

)⌋ (15)

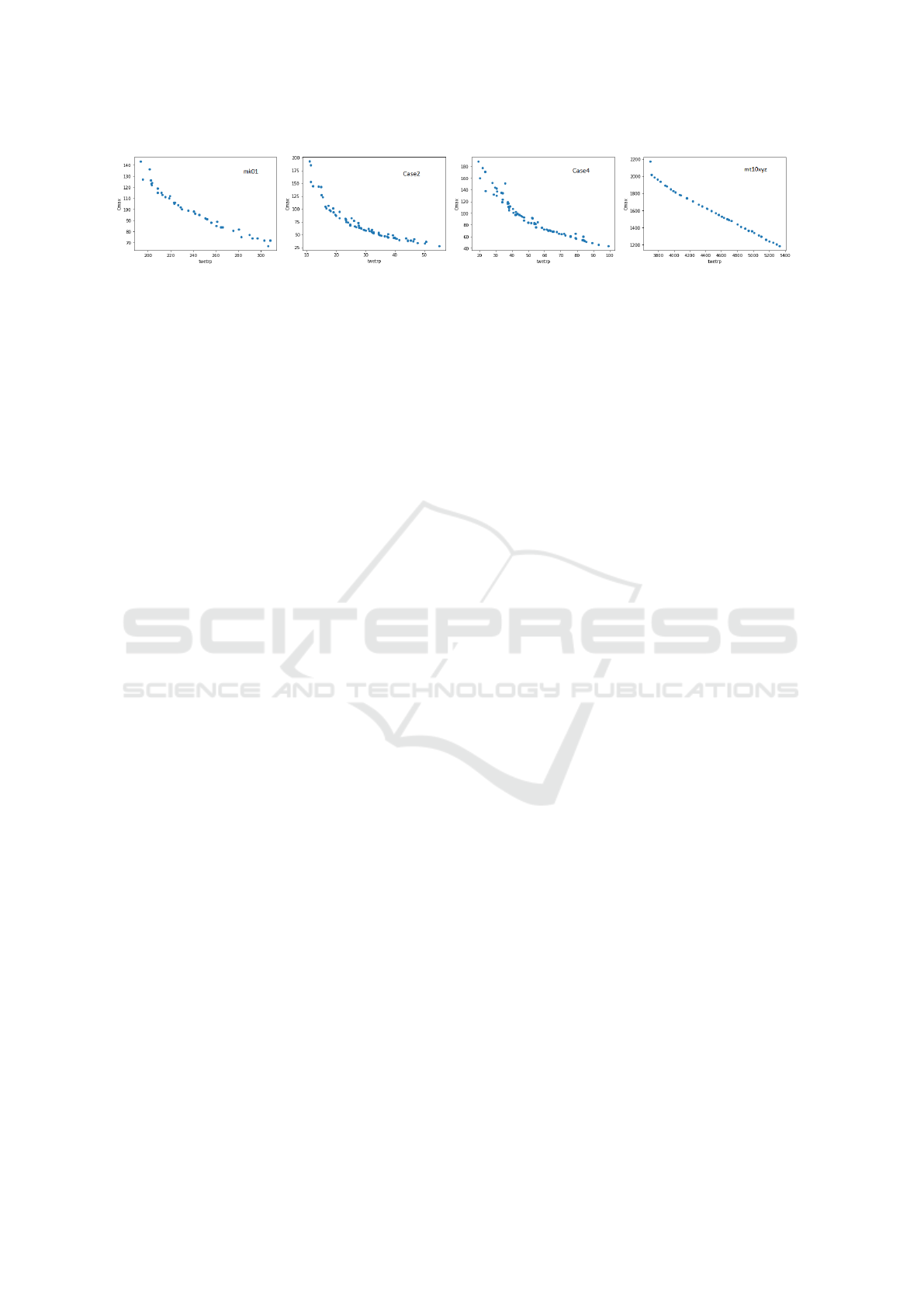

The extreme objective values are listed in Table

4. To demonstrate the effectiveness of the designed

NSGA-II, we start by visualizing the PF obtained. As

shown in figure 12, the PFs shape illustrates a good

convergence and diversity. This is mainly due to the

convergence mechanisms used (ranking and elitism).

In figure 11, the Hypervolume metric evolution is

presented. We observe that HV is grater than 0.5 for

Figure 11: Hypervolume evolution relative to parameters

changing.

all instances and it reach out to 0.85 which demon-

strate the convergence and diversity of the solution

set.

7 CONCLUSION

The purpose of this study is to improve production

effectiveness by planning the appropriate production

schedule. The main objectives are to define the Dy-

namic Flexible Job Shop Scheduling Problem un-

der fatigue constraint and develop an optimization

method to minimize the amount of time required to

manufacture a set of clients’ orders with the least pos-

sible default. Job fatigue, as an integral part of human

factors engineering, has an important impact on work.

The excessive work pressure will not only result in the

workers’ resentment but will also lead to low work ef-

ficiency. For this reason, we are devoted to minimiz-

ing workers’ fatigue in order to reduce its impact on

production. The optimization methods must be prac-

tical in the sense that it can effectively deal with a

large number of operations to be scheduled on several

flexible machines. We also focused on the reschedul-

ing after the interruption of unexpected events. The

occurrence of these unexpected events may disrupt

the original production scheduling and affect the re-

alization of scheduling objectives. In this study, we

considered three types of events new job arrival, job

cancellation and machine breakdown. For each type,

we introduced a rescheduling strategy. The goal of

this study has been successfully achieved by adapting

the effective multi-objective evolutionary algorithm,

NSGA-II with different strategies for rescheduling.

The effectiveness of this algorithm has been proved

by experiments on well-known benchmarks from the

literature.

The research presented in this paper paves the way

for further exploration of exciting areas of research in

the future. We would like to extend the problem be-

yond flexibility only on machines to double-flexibility

on human and material resources. However, further

improvements to the algorithm are needed. Since

reinforcement learning (RL) has made remarkable

achievements in recent years, some RL-based ap-

Multi-Objective Optimization of the Dynamic and Flexible Job Shop Scheduling Problem Under Workers Fatigue Constraints

307

Figure 12: PF of Mk01, Case2, Case4 and mt10xyz.

proaches will be employed to enhance the perfor-

mance of existing heuristic algorithms to effectively

solve the DFJSP-WF.

REFERENCES

Blazewicz, J., Lenstra, J. K., and Kan, A. R. (1983).

Scheduling subject to resource constraints: classifica-

tion and complexity. Discrete applied mathematics,

5(1):11–24.

Brandimarte, P. (1993). Routing and scheduling in a flex-

ible job shop by tabu search. Annals of Operations

research, 41(3):157–183.

Chambers, J. B. and Barnes, J. W. (1996). Tabu search for

the flexible-routing job shop problem.

Chen, C., Ji, Z., and Wang, Y. (2018). Nsga-ii applied

to dynamic flexible job shop scheduling problems

with machine breakdown. Modern Physics Letters B,

32:1840111.

Dhiflaoui, M., Nouri, H. E., and Driss, O. B. (2018). Dual-

resource constraints in classical and flexible job shop

problems: A state-of-the-art review. volume 126,

pages 1507–1515. Knowledge-Based and Intelligent

Information & Engineering Systems: Proceedings of

the 22nd International Conference.

El Mouayni, I., Demesure, G., EL Haouzi, H., Charpentier,

P., and Siadat, A. (2019). Jobs scheduling within in-

dustry 4.0 with consideration of worker’s fatigue and

reliability using greedy randomized adaptive search

procedure. IFAC-PapersOnLine, 52:85–90.

Farjallah, F., Nouri, H. E., and Belkahla Driss, O. (2022).

Multi-start Tabu Agents-Based Model for the Dual-

Resource Constrained Flexible Job Shop Scheduling

Problem, pages 674–686. Springer International Pub-

lishing, Cham.

Ferjani, A., Ammar, A., Pierreval, H., and Elkosantini, S.

(2017). A simulation-optimization based heuristic for

the online assignment of multi-skilled workers sub-

jected to fatigue in manufacturing systems. Comput-

ers & Industrial Engineering, 112:663–674.

Frutos, M., Olivera, A., and Tohm

´

e, F. (2010). A memetic

algorithm based on a nsgaii scheme for the flexible

job-shop scheduling problem. Annals of Operations

Research, 181:745–765.

Gong, G., Chiong, R., Deng, Q., Han, W., Like, Z., Lin,

W., and Li, K. (2019). Energy-efficient flexible flow

shop scheduling with worker flexibility. Expert Sys-

tems with Applications, 141:112902.

Jaber, M., Givi, Z., and Neumann, W. (2013). Incor-

porating human fatigue and recovery into the learn-

ing–forgetting process. Applied Mathematical Mod-

elling, 37(12):7287–7299.

Jain, A. K. and Elmaraghy, H. (1997). Production schedul-

ing/rescheduling in flexible manufacturing. Interna-

tional Journal of Production Research, 35(1):281–

309.

Kacem, I., Hammadi, S., and Borne, P. (2002). Approach by

localization and multiobjective evolutionary optimiza-

tion for flexible job-shop scheduling problems. IEEE

Transactions on Systems, Man, and Cybernetics, Part

C (Applications and Reviews), 32(1):1–13.

Liang, W. and Yu, H. (2001). Learning based dynamic ap-

proach to job-shop scheduling. In 2001 International

Conferences on Info-Tech and Info-Net. Proceedings,

volume 3, pages 274–279.

Lodree, E. J., Geiger, C. D., and Jiang, X. (2009). Tax-

onomy for integrating scheduling theory and human

factors: Review and research opportunities. Interna-

tional Journal of Industrial Ergonomics, 39(1):39–51.

Mossa, G., Boenzi, F., Digiesi, S., Mummolo, G., and Ro-

mano, V. (2016). Productivity and ergonomic risk

in human based production systems: A job-rotation

scheduling model. International Journal of Produc-

tion Economics, 171:471–477.

Mraihi, T., Driss, O. B., and EL-Haouzi, H. B. (2022).

A New Variant of the Distributed Permutation Flow

Shop Scheduling Problem with Worker Flexibility,

pages 587–597. Springer International Publishing,

Cham.

Shen, X.-N. and Yao, X. (2015). Mathematical modeling

and multi-objective evolutionary algorithms applied to

dynamic flexible job shop scheduling problems. Infor-

mation Sciences, 298:198–224.

Singer, M. and Pinedro, M. (1998). A computational study

of branch and bound techniques for minimizing the to-

tal weighted tardiness in job shops. IIE Transactions,

30(2):109–118.

Tao, Z. and Liu, X. (2019). Dynamic scheduling of dual-

resource constrained blocking job shop. In Yu, H.,

Liu, J., Liu, L., Ju, Z., Liu, Y., and Zhou, D., editors,

Intelligent Robotics and Applications, pages 447–456,

Cham. Springer International Publishing.

Zhang, K. and Luo, Y. (2020). Effects of worker fatigue

on assembly line balancing. In 2020 IEEE 11th In-

ternational Conference on Software Engineering and

Service Science (ICSESS), pages 254–257.

ICAART 2023 - 15th International Conference on Agents and Artificial Intelligence

308