Analysis of a Simple Method to Change the Wettability of the PDMS

Surface for Biomicrofluidic Applications

Inês M. Gonçalves

1,2

, Diana Pinho

3

, Andrea Zille

4

, Hirokazu Kaji

5

, Graça Minas

6

, Rui Lima

1,7,8

,

Patrícia C. Sousa

3

and Ana Moita

2,9

1

METRICS, University of Minho, Guimarães, Portugal

2

IN+, Instituto Superior Técnico, Universidade de Lisboa, Lisboa, Portugal

3

Integrated Micro and Nanotechnologies, INL International Iberian Nanotechnology Laboratory, Braga, Portugal

4

2C2T - Centre for Textile Science and Technology, University of Minho, Guimarães, Portugal

5

Tokyo Medical and Dental University, Tokyo, Japan

6

Center for MicroElectromechanical Systems (CMEMS-UMinho), University of Minho, Guimarães, Portugal

7

CEFT, Faculty of Engineering of the University of Porto, Porto, Portugal

8

ALiCE, Faculty of Engineering, University of Porto, Porto, Portugal

9

Centro de Investigação Desenvolvimento e Inovação da Academia Militar, Academia Militar,

Instituto Universitário Militar, Rua Gomes Freire, 1169-203, Lisboa, Portugal

Keywords: Wettability, PDMS, Biomicrofluidic Applications, Microscopy, Optical Tensiometer, Spectroscopy.

Abstract: One of the most often utilized materials for making microfluidic devices is polydimethylsiloxane (PDMS).

Organs-on-a-chip (OoC) is a novel class of devices that blends cell culture with microfluidic technology.

These devices replicate the microphysiological characteristics of the human body to make it easier to research

both healthy and unhealthy conditions. Due to its mechanical and chemical characteristics, as well as the fact

that it is a biocompatible and inert substance, PDMS is one of the materials of choice to manufacture OoC.

However, PDMS has the tendency to promote the adsorption of non-specific molecules due to its hydrophobic

properties, which may impede cell culture adhesion and growth and reduce the specificity of several

biochemical tests. It is also necessary to use external sources for flow control, such as syringe pumps, due to

the hydrophobicity of the materials' potential effects on fluid flow within the microchannels of microfluidic

devices. Oxygen plasma treatment is one of the frequently used methods for enhancing the wettability of the

PDMS surface. This strategy is, however, only effective for a limited time. Another tactic is to add ingredients

like surfactants during manufacturing to change the bulk of PDMS. In this study, PDMS was mixed with a

variety of surfactants at a concentration of 1% wt. The wettability changes were examined on the day the

samples were collected and one week later. A week after manufacture, two surfactants continued to improve

the wettability of the PDMS surface to a hydrophilic behavior.

1 INTRODUCTION

The organic polymer polydimethylsiloxane (PDMS),

which has physicochemical and mechanical qualities

like optical transparency, gas permeability,

nontoxicity, and biocompatibility, is frequently used

in the biomedical sector. Additionally, its fabrication

is a quick and inexpensive procedure (Gokaltun et al.,

2017). The evaluation and research of blood

phenomena, such as the behavior of red blood cells or

the emergence of aneurysms, is one of its applications

(Miranda et al., 2021; Pinho et al., 2020).

Lab-on-a-chip (LoC) and organ-on-a-chip (OoC)

technology has also utilized PDMS for the

manufacture of the respective devices (Carvalho et

al., 2021; Gonçalves, Carvalho, et al., 2022;

Gonçalves, Rodrigues, et al., 2022; Miranda et al.,

2021; Vlassov et al., 2018). Although the

hydrophobicity of the polymer, due to a contact angle

with water of around 108⁰ ± 7⁰ (Gokaltun et al., 2017;

Klasner et al., 2009), helps the substance be removed

from molds, it can be detrimental for its use in

medicine because it promotes undesired, non-specific

protein and small molecule adsorption. This might

impact analyte mobility and lessen the sensitivity of

116

Gonçalves, I., Pinho, D., Zille, A., Kaji, H., Minas, G., Lima, R., Sousa, P. and Moita, A.

Analysis of a Simple Method to Change the Wettability of the PDMS Surface for Biomicrofluidic Applications.

DOI: 10.5220/0011651900003414

In Proceedings of the 16th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2023) - Volume 1: BIODEVICES, pages 116-120

ISBN: 978-989-758-631-6; ISSN: 2184-4305

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

the detection (Gokaltun et al., 2017; Han & Lee,

2018). Since it is challenging to move a fluid across

the surface of the polymer due to its hydrophobicity,

external pumping sources are necessary for

microfluidic research (Kim et al., 2010; Litwinowicz

et al., 2021).

Numerous techniques have been used to increase

the wettability of PDMS. These tactics could

comprise modifications to the surface and to the bulk

of the material. (Hu et al., 2020) The oxygen plasma

treatment is one method of surface modification that

is frequently employed (Han & Lee, 2018; Seo & Lee,

2006). The hydrophilicity produced by this method is

just momentary, whereas the PDMS quickly regains

its hydrophobicity (Hu et al., 2020; Kim et al., 2010).

The optical and mechanical properties of the polymer

may be better maintained with surface changes.

However, their processes are frequently challenging.

Adding hydrophilic moieties or surfactants to the

polymer surface is another option since surfactants

lower the substance's surface tension, promoting

aqueous solutions to scatter more broadly. (Hu et al.,

2020; Litwinowicz et al., 2021; Seo & Lee, 2006)

The composition of the material used in this study

was changed by combining PDMS with various

surfactants. The wettability of the surfaces was then

evaluated and compared over a week. The

transparency of the most promising samples was also

evaluated. Lastly, preliminary microfluidic studies

were performed using altered PDMS.

2 MATERIALS AND METHODS

Six distinct samples were prepared for this work. All

samples were produced starting from a 1:10 mixture

of the pre-polymer and PDMS curing agent. On five

of the samples, polyethylene glycol (PEG), PDMS-b-

ethylene oxide (PDMS-b-PEO), Triton X-100

(TX100), Leophen ML, or Leophen BN were added

at a concentration of 1% wt. The surfactants PEG,

PDMS-b-PEO and TX-100 were selected since

previous works showed that non-ionic surfactants can

present antimicrobial properties and have improved

PDMS wettability (Litwinowicz et al., 2021; Madadi

& Casals-Terré, 2013). Leophen ML and BN are non-

ionic emulsifiers used as wetting agents in the textile

field. Each sample was placed into a rectangular mold

and cured in an oven set to 80 °C for three hours.

After curing, the samples were taken out of the mold,

and the static contact angle between a 5 μL drop of

distilled water and the surface was measured to

evaluate the wettability of the surfaces.

Contact angles were determined on the optical

tensiometer THETA (Attention) by processing the

captured images of the profile of the droplet deposited

on the samples’ surface. 640 × 480 pixels were

evaluated during the image capture (corresponding to

240 images per test). The spatial resolution for the

system's optical configuration that was used is 15.6

μm/pixel. The images were post-processed using a

drop detection method based on the Young-Laplace

equation (One Attension software). According to

(Cheng et al., 1990), the algorithm's precision is in the

range of ±0.1°. After one week, the same approach

was used to evaluate the samples' contact angles once

more.

After the samples dried from the contact angle

readings, the transmittance spectrum was determined.

The UV-2600 spectrophotometer (Shimadzu, Japan)

and associated software were employed. A

wavelength between 200 and 800 nm was used for the

measurements.

In summary, the sample was introduced into the

apparatus after being placed in a holder. Using a

grating, the monochromator divides the light from the

emitting source into various wavelengths, allowing

only one beam at a single wavelength to pass through

the sample. The amount of light detected by the

detector on the other side then determines the

sample's transmittance. Depending on the user-

selected range, the beam's wavelength varies.

Preliminary microfluidic assays were performed

using unaltered PDMS and PDMS altered with

PDMS-b-PEO. Two types of microchannels were

used, as presented in Figure 3. One of the channels

presented a constriction in width while the other was

a linear channel, without any change in the geometry.

For the microfluidic assays, a blood analog fluid

was prepared as described in (Carneiro et al., 2021).

In brief, a PDMS pre-polymer mixed with a curing

agent in a ratio of 6:4 (Corning Sylgards 184 kit) and

added to an aqueous solution of sodium dodecyl

sulfate (SDS) 4% w/w. After vortex stirring the

solution was filtered using a filter with a hydrophilic

membrane, with 10 μm pore size (Versapors

Acrodiscs Syringe Filter, PALL). The filtered

solution was then left to cure in an oven at 80 ⁰C for

three hours. Lastly, a solution with 1% particle

concentration was prepared to be used for the

microfluidic assays.

Analysis of a Simple Method to Change the Wettability of the PDMS Surface for Biomicrofluidic Applications

117

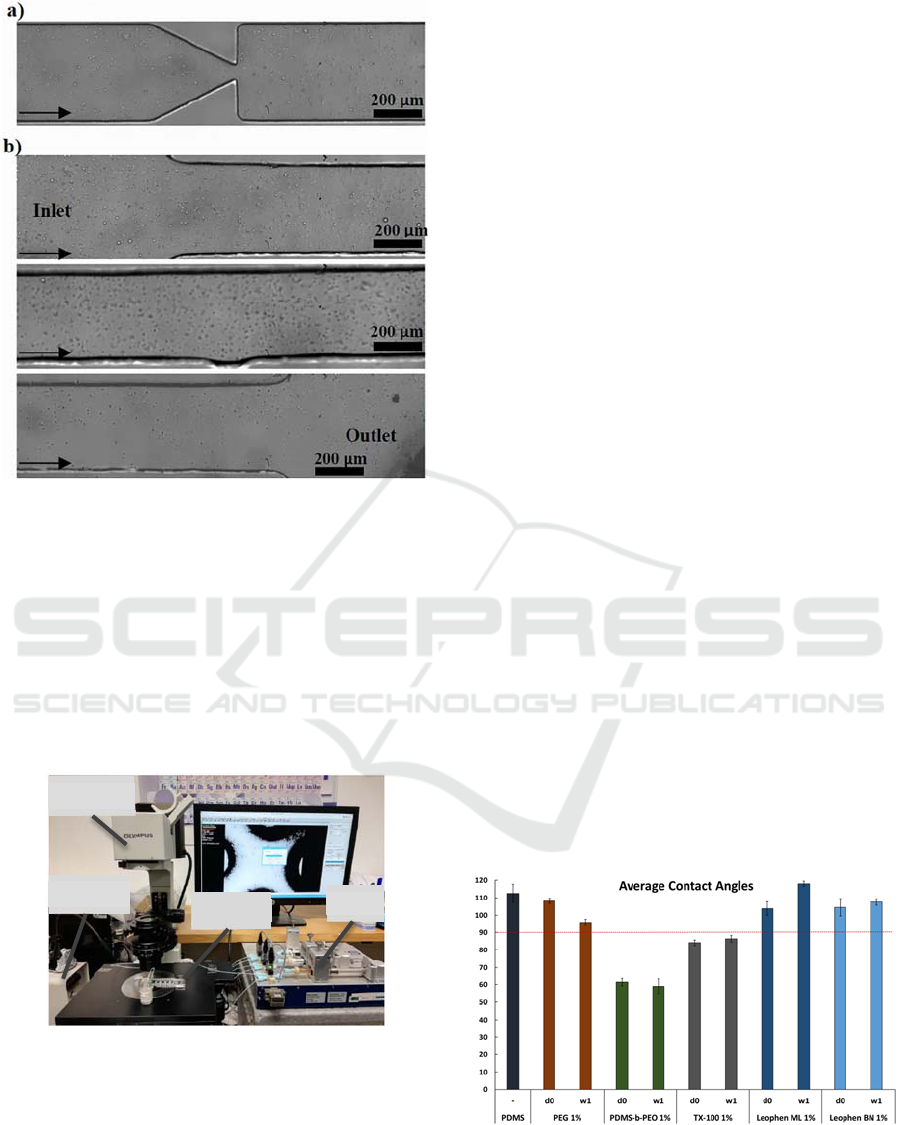

Figure 1: Microscopy images of the microchannels used for

preliminary microfluidic assays: a) constriction channel and

b) linear channel.

The microfluidic devices used for the assays were

placed on an inverted microscope (IX71, Olympus,

Tokyo, Japan) connected to a high-speed camera

(Fastcam SA3, Photron, San Diego, CA, USA) for the

visualization and record of the particle flow. To

control the fluid flow in the devices a syringe pump

(CetoniNEMESYS Syringe Pump) was used. The set-

up for the microfluidic assays is shown in Figure 4.

Figure 2: Experimental apparatus used to perform the

preliminary microfluidic assays. In: Inverted microscope;

H: High-speed camera; M: Microfluidic device; S: syringe

pump.

The fluid flow values used for the constriction

channel were 10, 20, 30 and 50 μl/min while for the

linear channel the fluid flow was kept constant at 30

μl/min. The recording of the flow was performed at

3000 frames per second and using an objective with a

magnification of 10x and an aperture of 0.25. The

acquired videos were a

nalysed with an ImageJ plugin,

the MTrackJ.

3 RESULTS AND DISCUSSION

3.1 Contact Angle Measurements

Unaltered PDMS had an average contact angle of

112⁰ ± 5⁰, which is consistent with values reported in

the literature. Figure 5 illustrates how the samples

with a surfactant showed a reduction in the average

contact angle compared to PDMS alone. The

Leophen ML, Leophen BN and PEG modified

samples had average contact angles that were 108.23⁰

± 1.48⁰, 103.86⁰ ± 3.92⁰, and 104.55⁰ ± 5.00⁰,

respectively, immediately after manufacture. These

values were higher than 90⁰, even though they were

lower than the value found for unaltered PDMS,

demonstrating that the samples still exhibit

hydrophobic behavior. After manufacture, the

samples treated with PDMS-b-PEO and TX-100 had

average contact angles that were 61.35⁰ ± 2.17⁰ and

84.12⁰ ± 1.56⁰, respectively. These values are under

90⁰, demonstrating the hydrophilicity of the samples.

The samples continued to show a hydrophilic

behavior a week later, with an average contact angle

value that was similar to the value recorded on the day

of manufacturing. When PDMS-b-PEO was used, the

contact angle value reduction was more noticeable.

The presence of PDMS in the PDMS-b-PEO structure

enhanced the surfactant's compatibility with the

polymer. For the desired hydrophilic behavior using

the other substances, higher concentrations might be

needed.

Figure 3: Contact angle measurements of PDMS and

modified PDMS using distilled water. Bellow 90⁰ the

behavior is hydrophilic and above is hydrophobic.

In

H

S

M

BIODEVICES 2023 - 16th International Conference on Biomedical Electronics and Devices

118

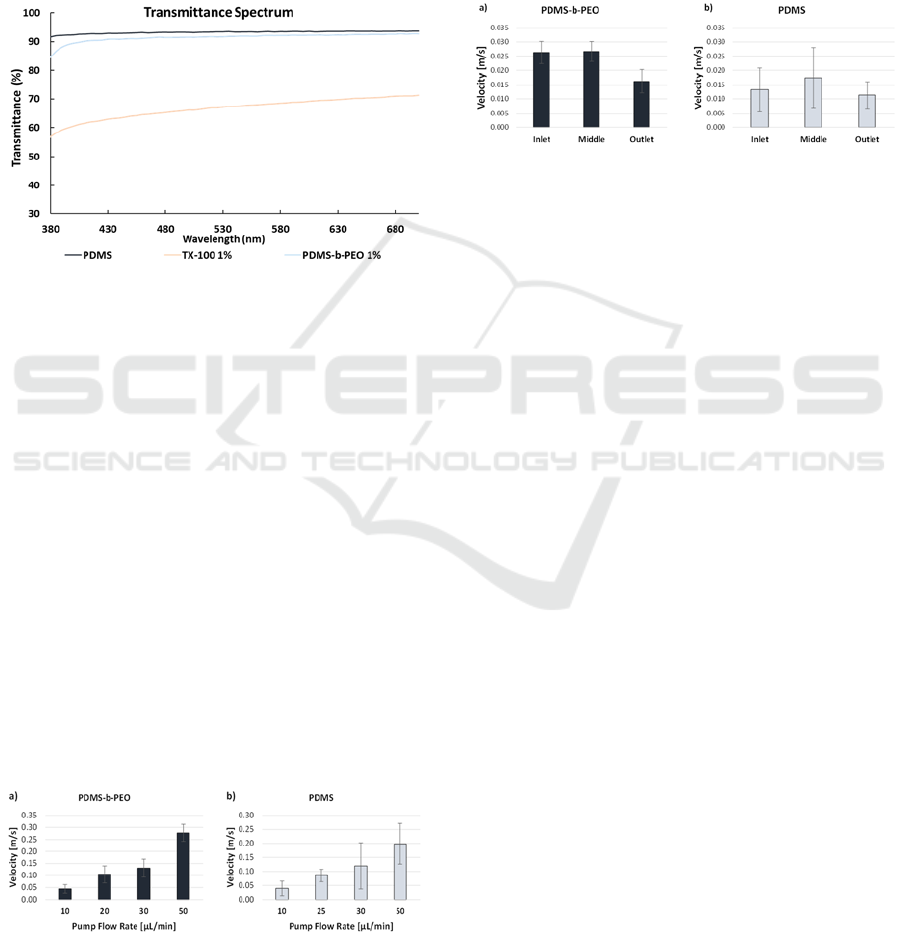

3.2 Transmittance Spectrum

Since the modified PDMS has potential to be used on

microfluidic assays that require optical analysis, the

transparency of the samples is a relevant parameter to

consider. The impact of the bulk PDMS alteration on

the material's transparency was one challenge that

was confirmed. As shown in Figure 6, the unaltered

PDMS sample exhibits a transmittance of

approximately 93% in the visible light spectrum.

Figure 4: Transmittance spectrum of unaltered and

modified PDMS.

While the sample containing 1% wt. of PDMS-b-

PEO kept the value at 91%, the addition of TX-100

caused the transparency to drop to about 67%. The

addition of TX-100 can drastically change the optical

characteristics of PDMS despite the improvement in

wettability. As PDMS-b-PEO only slightly reduced

the material's optical characteristics, it demonstrated

superior compatibility with the PDMS pre-polymer.

3.3 Microfluidic Assays

The maximum velocity of different particles passing

through the constriction channel was measured and

the average for each flow rate is presented in Figure

7. The velocity values increase with the increase of

the flow rate, as expected, and are slightly higher on

the microchannels with the altered PDMS. Also, the

variation between the values is smaller on the altered

PDMS channels.

Figure 5: Maximum particle velocity for different flow rates

on microchannels made using a) altered PDMS and b)

unaltered PDMS.

On the linear channels, the average velocity of

several particles was measured on three different

regions of the microchannel: near the inlet, on the

middle and near the outlet. The average of all the

velocities on each region is presented in Figure 8.

Higher velocities were registered on the

microchannel with altered PDMS, and the variation

between the values was also smaller than the ones

presented on the microchannels with unaltered

PDMS.

Figure 6: Average particle velocity in three different

regions of the microchannel using a) altered PDMS and b)

unaltered PDMS.

The results on both channels indicate an

improvement regarding the flow on microchannels

when using altered PDMS. However, the results are

still insufficient to draw major conclusions regarding

the benefits of changing the PDMS wettability

through the proposed technique.

4 CONCLUSIONS

To improve the PDMS wettability, our current focus

is on undertaking quantitative study with various

surfactants and hydrophilic solutions. Using PDMS-

b-PEO was the more effective technique to boost

hydrophilicity while keeping transparency. By

applying a small percentage of the surfactant, a

hydrophilic behavior could be kept for over a week.

Preliminary microfluidic studies showed a potential

improvement of the fluid flow when using

microchannels with altered PDMS. The modified

PDMS will be optimized in the future to promote the

manufacture of self-driven microfluidic devices. LoC

and OoC devices could also be improved by such

technology. Future studies will examine the

wettability behavior of the modified PDMS in

prolonged fluid contact, as well as the release of the

surfactant into the fluid and its effects on cell culture.

Biocompatibility and protein adsorption will also be

analysed in future works to determine which type of

PDMS will be better for each part of an OoC device.

Analysis of a Simple Method to Change the Wettability of the PDMS Surface for Biomicrofluidic Applications

119

ACKNOWLEDGEMENTS

I. M. Gonçalves acknowledges FCT for the grant

SFRH/BD/08646/2020, supported by national funds

from Ministérios da Ciência, Tecnologia e Ensino

Superior. This work has been also supported by the

projects, EXPL/EMD-EMD/0650/2021 and

PTDC/EEI-EEE/2846/2021 through the

COMPETE2020, under the PORTUGAL 2020

Partnership Agreement through the European

Regional Development Fund (FEDER) and by

Fundação para a Ciência e Tecnologia (FCT). The

authors acknowledge the partial financial support

within the R&D Units Project Scope:

UIDB/00690/2020, UIDB/04077/2020, UIDB/

04436/2020, UIDB/00532/2020. The authors also

acknowledge the financial support (4004) from the

Research Center for Biomedical Engineering from

Tokyo Medical and Dental University, Japan.

REFERENCES

Carneiro, J., Lima, R., Campos, J. B. L. M., & Miranda, J.

M. (2021). A microparticle blood analogue suspension

matching blood rheology. Soft Matter. https://doi.org/

10.1039/D1SM00106J

Carvalho, V., Gonçalves, I., Lage, T., Rodrigues, R. O.,

Minas, G., Teixeira, S. F. C. F., Moita, A. S., Hori, T.,

Kaji, H., & Lima, R. A. (2021). 3D Printing Techniques

and Their Applications to Organ-on-a-Chip Platforms:

A Systematic Review. Sensors, 21(9), 3304.

https://doi.org/10.3390/s21093304

Cheng, P., Li, D., Boruvka, L., Rotenberg, Y., & Neumann,

A. W. (1990). Automation of axisymmetric drop shape

analysis for measurements of interfacial tensions and

contact angles. Colloids and Surfaces, 43(2), 151–167.

https://doi.org/https://doi.org/10.1016/0166-6622(90)8

0286-D

Gokaltun, A., Yarmush, M. L., Asatekin, A., & Usta, O. B.

(2017). Recent advances in nonbiofouling PDMS

surface modification strategies applicable to

microfluidic technology. Technology, 05(01), 1–12.

https://doi.org/10.1142/s2339547817300013

Gonçalves, I. M., Carvalho, V., Rodrigues, R. O., Pinho, D.,

Teixeira, S. F. C. F., Moita, A., Hori, T., Kaji, H., Lima,

R., & Minas, G. (2022). Organ-on-a-Chip Platforms for

Drug Screening and Delivery in Tumor Cells: A

Systematic Review. Cancers, 14(4), 935. https://doi.

org/10.3390/cancers14040935

Gonçalves, I. M., Rodrigues, R. O., Moita, A. S., Hori, T.,

Kaji, H., Lima, R. A., & Minas, G. (2022). Recent

trends of biomaterials and biosensors for organ-on-chip

platforms. Bioprinting, 26, e00202. https://doi.org/

10.1016/j.bprint.2022.e00202

Han, C. M., & Lee, B. K. (2018). Effect of hydrophilicity

of polydimethylsiloxane stamp in capillary force

lithography process of thermoplastic polyurethane.

Microelectronic Engineering, 190, 38–43. https://

doi.org/10.1016/j.mee.2018.01.001

Hu, H., Li, S., Ying, C., Zhang, R., Li, Y., Qian, W., Zheng,

L., Fu, X., Liu, Q., Hu, S., & Wong, C. P. (2020).

Hydrophilic PDMS with a sandwich-like structure and

no loss of mechanical properties and optical

transparency. Applied Surface Science, 503(September

2019), 144126. https://doi.org/10.1016/j.apsusc.

2019.144126

Kim, Y. C., Kim, S. H., Kim, D., Park, S. J., & Park, J. K.

(2010). Plasma extraction in a capillary-driven

microfluidic device using surfactant-added

poly(dimethylsiloxane). Sensors and Actuators, B:

Chemical, 145(2), 861–868. https://doi.org/

10.1016/j.snb.2010.01.017

Klasner, S. A., Metto, E. C., Roman, G. T., & Culbertson,

C. T. (2009). Synthesis and characterization of a

poly(dimethylsiloxane)-poly (ethylene oxide) block

copolymer for fabrication of amphiphilic surfaces on

microfluidic devices. Langmuir, 25(17), 10390–10396.

https://doi.org/10.1021/la900920q

Litwinowicz, M., Rogers, S., Caruana, A., Kinane, C.,

Tellam, J., & Thompson, R. (2021). Tuning the Bulk

and Surface Properties of PDMS Networks through

Cross-Linker and Surfactant Concentration.

Macromolecules, 54(20), 9636–9648. https://doi.org/

10.1021/acs.macromol.1c01600

Madadi, H., & Casals-Terré, J. (2013). Long-term behavior

of nonionic surfactant-added PDMS for self-driven

microchips. Microsystem Technologies, 19(1), 143–

150. https://doi.org/10.1007/s00542-012-1641-7

Miranda, I., Souza, A., Sousa, P., Ribeiro, J., Castanheira,

E. M. S., Lima, R., & Minas, G. (2021). Properties and

Applications of PDMS for Biomedical Engineering: A

Review. Journal of Functional Biomaterials, 13(1), 2.

https://doi.org/10.3390/jfb13010002

Pinho, D., Carvalho, V., Gonçalves, I. M., Teixeira, S., &

Lima, R. (2020). Visualization and Measurements of

Blood Cells Flowing in Microfluidic Systems and

Blood Rheology: A Personalized Medicine Perspective.

Journal of Personalized Medicine, 10(4), 249.

https://doi.org/10.3390/jpm10040249

Seo, J., & Lee, L. P. (2006). Effects on wettability

by surfactant accumulation/depletion in bulk

polydimethylsiloxane (PDMS). Sensors and Actuators,

B: Chemical, 119(1), 192–198. https://doi.org/

10.1016/j.snb.2005.12.019

Vlassov, S., Oras, S., Antsov, M., Sosnin, I., Polyakov, B.,

Shutka, A., Krauchanka, M. Y., & Dorogin, L. M.

(2018). Adhesion and Mechanical Properties of PDMS-

Based Materials Probed with AFM: A Review.

REVIEWS ON ADVANCED MATERIALS SCIENCE,

56(1), 62–78. https://doi.org/10.1515/rams-2018-0038.

BIODEVICES 2023 - 16th International Conference on Biomedical Electronics and Devices

120