Low Profiled Angiographic Catheter with Enhanced Pushability and

Flexibility: A Novel Design, Fabrication, and in-Vitro Analysis

Hafsa Inam, Murtaza Najabat Ali and Aimen Arshad

Biomedical Engineering and Sciences Department, School of Mechanical and Manufacturing Engineering (SMME),

National University of Sciences and Technology (NUST), Islamabad, Pakistan

Keywords: Laser-Cut Reinforced Shaft, Laser-Cut Torque Transfer Layer, Angiographic Catheter, Corrosion-Resistant,

Burst Test, Leak Test, Tensile Strength, Flow Rate, Performance Testing.

Abstract: The diagnostic angiographic catheter (DAC) available in the market have improved the survival rate and are

the result of extensive R&D, but there’s still room for improvement in terms of catheter profile, enhanced

pushability, and trackability therefore, the current research focuses on the development of laser-cut reinforced

shaft catheters in an attempt to design a low-profile DAC with enhanced pushability and trackability. A new

‘I’ hollow geometry has been used to fabricate reinforced shafts. Stainless Steel 304 was selected as a material

to fabricate a laser-cut reinforced shaft and PTFE and PEBAX

®

for inner lumen and catheter jacketing. This

study analyzes and reports the design, performance, and behavior of laser-cut reinforced shaft catheters. The

‘I’ geometry of laser-cut reinforced shaft catheter differed from braided catheters based on ovality retention,

enhanced flexural rigidity, and pushability; the pushability force analysis results prove that laser-cut

reinforced shaft catheter exerts a minimal resistive force which is approximately 1/3

rd

times less than the

braided catheter. This study also endeavored to manufacture a significantly lower wall thickness for reinforced

angiographic catheters. Based on this extensive in-vitro assessment, it has been concluded that laser-cut

reinforced shaft catheter performed better in advancement force and flexibility than the braided catheter. In

performance evaluation, the laser-cut reinforced shaft catheter has outperformed 16 and 32 wires braided

catheters, exhibiting an exceptionally minimal pushability force of 6.25 N.

1

INTRODUCTION

Atherosclerosis is the buildup of plaque inside

coronary arteries; as plaque continues to accumulate

in artery walls, arteries tend to stiffen, causing

narrowing and blockage of arteries, and not getting

enough blood supply to the heart muscle can lead to

chest pain (Mozaffarian D, 2016) (Roth, 2017)

(Prabhakaran D, 2018) (Moran AE, 2014) (Sampasa-

Kanyinga H, 2015) (Heart, 2022), (Lappegård,

Kjellmo, & Hovland, 2021), (Lorkowski & Smith,

2022), (Kostromina, et al., 2022).

The major advantage of coronary angiography is

precisely identifying the narrowed artery leading to

the instantaneous decision of requirement of coronary

angioplasty or stent implantation. Angiography has

evolved into a safe and frequently used component of

cardiac catheterization due to advancements in

catheter design, radiographic imaging, contrast

media, and the introduction of therapeutic choices for

the treatment of coronary artery disease. (Baim,

1986), (Ghelfi et al., 2022).

Immediate complications during coronary

angiography include problems with an angiographic

catheter such as catheter advancement, pushability,

kinking trackability, torqueability, vascular damage,

perforation site pain, and discomfort; later

complication includes vascular spasm, tissue damage

caused by X-ray radiation if the procedure is

prolonged, damage to the kidneys caused by the

contrast dye, and heart attack. (NHS, 2021), (Liao, et

al., 2022). Laser-cut tubing (LCT) uses a focused

laser to ablate through a metal or polymer tube wall

before removing the deteriorated material using a

high-pressure coaxial gas nozzle. For more than 30

years, the method has been employed in medical

device manufacture, with substantial breakthroughs

following the push for miniaturization for minimally

invasive treatments (Kevin Hartke, 2020). A

mechanism to achieve a laser-cut catheter-reinforced

shaft was theoretically introduced by Liam (Liam

Inam, H., Ali, M. and Arshad, A.

Low Profiled Angiographic Catheter with Enhanced Pushability and Flexibility: A Novel Design, Fabrication, and in-Vitro Analysis.

DOI: 10.5220/0011633700003414

In Proceedings of the 16th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2023) - Volume 1: BIODEVICES, pages 29-36

ISBN: 978-989-758-631-6; ISSN: 2184-4305

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

29

Farrissey, 2004) previously, based on the variable

pitch of the proximal and distal end of the catheter’s

shaft as the proximal end requires more stiffness and

enhanced pushability, whereas distal end requires

flexibility.

This research work, laser-cut angiographic

catheter, was inspired by the laser-cut hypotubes,

which are being used in angioplasty catheters, as first

mentioned by Liam Farrissey in 2004, who explained

the requirement of variable flexibility and stiffness

throughout the length of the catheter. Therefore, this

research work aims to develop a novel manufacturing

approach comprising disruptive manufacturing and

additive manufacturing techniques to produce a laser-

cut reinforced layer, also known as torque transfer

layer and laser-cut reinforced angiographic catheter.

This study also endeavored to manufacture a

significantly thin-walled angiographic catheter.

The structural parameters of the catheter of this

research are critical in achieving kink-free,

pushability, and flexibility. Higher values for the ‘I’

slotted pattern and higher pitch between rows of

slotted ‘I’ can provide more flexibility and, therefore,

better torque response to rotating the distal end of the

catheter as per the cardiologist’s need. The use of

lumen and jacket polymer coatings (which may

extend into and interface with each other through the

laser-cut lines) allows the ‘I’ slotted pattern to flex

without plastic deformation. Thus, a closer pitch in

the distal end will enhance flexibility which is

desirable while moving through tortuous anatomy.

2

MATERIAL AND METHODS

2.1 Design Considerations of the

Catheter shaft

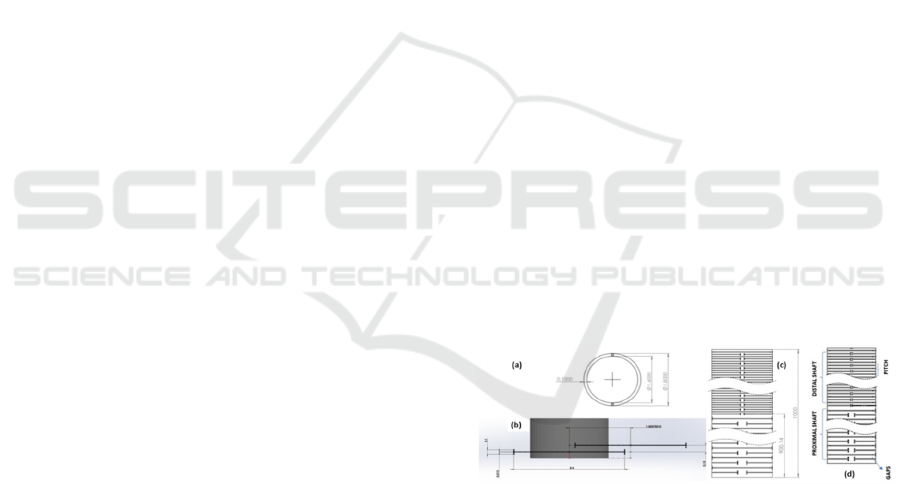

The design of catheter geometry of the present laser-

cut catheter reinforced shaft is built with a plurality of

unit cells shown in Figure 1(b), interconnected with

the help of horizontal and vertical edges to form an

‘I’ pattern and gaps. The design width (DW) and

design length (DL) of the ‘I’ pattern remain the same;

however, the pitch varies from proximal to the distal

end. The proximal and distal shaft dimensions are 900

mm and 100mm, respectively. The tube has a 1.8mm

outer diameter having a wall thickness of 0.1mm

(Hafsa Inam, 2022).

To develop a hollow ‘I’ patterned geometry and

configure it into a tubular reinforced layer form,

Stainless Steel 304 was selected as a material.

PEBAX

®

and PTFE hollow tubes were acquired to

construct ‘I’ patterned reinforced shaft geometry into

a laser-cut reinforced catheter configuration. The

inner lumen of the catheter was lined with thin-walled

polytetrafluoroethylene (PTFE), as it has a lower

coefficient of friction to reduce the advancement

resistance when going through the mock vascular

system. Flouropeels heat shrink extruded tube was

acquired to fuse all polymeric layers to the laser-cut

reinforced shaft for the development of the catheter.

2.1.1 Development of Laser Cut Shaft for

Angiographic Catheter

Laser Cutting of the Catheter’s Reinforced Shaft

The thermo-mechanical cutting method by

computerized numerical control (CNC) guided laser

was adopted to fabricate a laser-cut reinforced

catheter shaft (Silvio Genna, 2020). The laser cutting

method employed in this study was further optimized,

and the fabrication of the catheter reinforced shaft

was conducted on a realistic size of 6 French

angiographic catheters. Medical grade stainless steel

304 tube, commercially known as “18-8 stainless

steel,” was procured from Hechuang Hitech China

based on its highly anti-corrosive and durable

properties (Medical Grade & Surgical Stainless Steel,

2022); these hollow ‘I’ patterned geometry was

manufactured specifically for medical applications.

The stainless steel 304 tube was 0.1mm thick, as

illustrated in Figure 1 (c), and the overall length of the

reinforced tube was 1000mm, as illustrated in Figure

1 (d).

Figure 1: (a) Outer Diameter, Inner Diameter and Wall

Thickness of Metallic tubing (b) The unit cell is hollow ‘I’

pattern (b) ‘I’ hollow pattern measurements (c) The

geometry for the proximal and distal end of the

angiographic catheter’s reinforced shaft (d) Illustration of

'I' pattern drawing from proximal to the distal end of

catheter reinforced tubing. To fabricate an ‘I,’ pattern laser-

cut catheter reinforced shaft, a Star Cut CNC guided laser

system was used; the in-process image is shown in fig.2 (a).

The 2D hollow ‘I’ geometry DXF design was fed into

high precision fiber laser cutting machine’s software,

Preco RT1000, and the laser system emitted optical

energy in an invisible infrared beam. The laser system

BIODEVICES 2023 - 16th International Conference on Biomedical Electronics and Devices

30

used a laser power of around 150W to cut the

workpiece material.

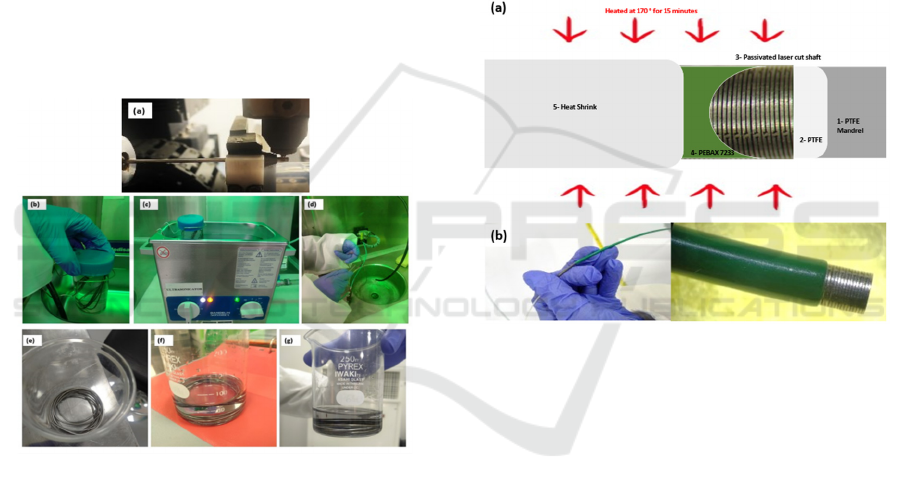

Process of Acid Pickling

Acid pickling solution (150 mL) for the laser-cut

reinforced tube was prepared using pickling solutions

consisting of hydrofluoric acid and nitric acid. The

catheter tubing was immersed in 150 mL of pickling

solution and ultrasonicated for 15 mins.

Subsequently, the laser-cut catheter tubing was rinsed

with warm water and air-dried. The whole process is

shown in Figure 2(b, c, d).

Passivation Process

The passivation solution consisted of nitric acid as it

is an oxidizing acid and is always used. Acid-pickled

laser-cut tubing was dipped in the nitric acid solution

for 5 minutes to create a passivated layer; catheter

tubing was removed, washed with DI water, and dried

with air, as shown in Figure 2(e, f, g).

Figure 2: (a) Laser-cutting of catheter reinforced shaft (b, c,

d) Acid Pickling processes & (c, d, and f) passivation

processes of the laser-cut reinforced shaft.

2.1.2 Development of Laser Cut

Angiographic Catheter

PEBAX

®

7233 extruded jacket tubing and the PTFE

inner lumen were sourced from Zeus (USA). PTFE

monofilament mandrel having an outer diameter of

1.57mm was used as the inner lumen. A peelable

heat-shrink tubing was used as an external layer to

facilitate polymer fusion to laser-cut catheter-

reinforced shaft.

Thermal Fusion of Polymeric Jacket and PTFE

Extruded Tubing

In this process, PTFE, as the inner lining of the

catheter-reinforced shaft, mounted on a PTFE

mandrel, was inserted in passivated laser-cut catheter-

reinforced shaft. An extruded PEBAX

®

jacketing,

7233 (72D durometer), was used to cover the

reinforced shaft. A heat shrink, having an inner

diameter of 2.10mm, was used as an external layer to

combine the whole material. The arrangement is

illustrated in Figure 3(a). The whole shaft was then

exposed to 170°C for 15 minutes in a pre-heated

forming oven. After completing the process, the

catheter tubing was cooled down, and heat shrink was

removed. The polymer-fused catheter-reinforced

shaft is shown in Figure 3(b).

Figure 3: Illustration of the polymeric and metallic layer

layering, depicting heat fusion process (b) Polymeric jacket

fusion on the laser-cut reinforced shaft after removal of

heat-shrink tubing.

Soft Tip and Distal Tube Shaping of Novel

Angiographic Catheter Shaft Using a

Thermoforming Process

The preparation of a novel angiographic catheter was

conducted by welding a soft tip, PEBAX® 35D

durometer (CUUMED Taiwan), and tapering. A

female luer lock, polycarbonate, was attached at the

proximal end using Loctite, a medical-grade glue. To

shape the distal end of the catheter, the catheter shaft

is assembled in Judkins right die Figure 4 (a); the

whole shaft was then placed in a pre-heated

longitudinal oven at 150°C for 15 minutes using

assembling mandrels, Figure 4 (b, c). After

completing the distal shaping process, the catheter

was removed from the thermoforming machine and

eventually from forming die.

Low Profiled Angiographic Catheter with Enhanced Pushability and Flexibility: A Novel Design, Fabrication, and in-Vitro Analysis

31

Figure 4: (a); the whole shaft was then placed in a pre-

heated longitudinal oven at 150°C for 15 minutes using

assembling mandrels, (b, c). After completing the distal

shaping process, the catheter was removed from the

thermoforming machine and eventually from die.

3

RESULTS

3.1 Characterization, in Vitro

Mechanical and Performance

Testing

The novel reinforced DAC was characterized, and its

performance was evaluated in comparison with a

commercially available catheter. In vitro mechanical

testing was carried out to analyze and evaluate the

mechanical performance of the laser-cut reinforced

shaft and laser-cut reinforced angiographic catheter.

A hemolysis test was carried out as per ASTM F756,

physical tests were carried out as per ISO 10555-

1:2013+A1:2017, and pushability testing was carried

out on a mock arterial system developed on ASTM

F2394.

3.2 Statistical Analysis

All experimental approaches were executed in

triplicates. Results are represented as mean ± standard

deviation, n ≥ 3. Statistical analysis was done to

analyze the differences between the experimental

results, and a value of p < 0.05 was considered

significant.

3.3 Analysis of Laser-Cut Metallic

Shaft Fabrication

Formation of ‘I’ Geometry Pattern

The laser-cut reinforced shaft design pattern

comprising a hollow ‘I’ pattern was cut by

interpolating 304 stainless steel tubing movements in

both linear and rotational directions. A thin stainless-

steel tubing of 0.1mm thickness with hollow ‘I’

geometry is shown in

Figure

Figure 5(a). The

reinforced shaft has wider gaps in the proximal end

whereas tighter gaps in distal end making distal end

of reinforced metallic shaft more flexible.

Effect of Pickling on the Laser-Cut Reinforced

Shaft Design

Acid pickling is the smoothest method to remove slag

and impurities from metallic surfaces. Slag was

removed from the laser-cut metallic reinforced shaft

during the acid pickling process as the smoother

surface of the acid pickled shaft is shown in Figure 5

(b). After acid pickling, the unit cells (hollow I

pattern) and laser-cut metallic reinforced shaft

geometry were visible.

Achievement of Passivation

The surface peaks and valleys (i.e., surface

roughness) were removed, and material reduction and

surface smoothness were obtained by dipping the

laser-cut metallic shaft in passivation solution

consisting of nitric acid. As depicted below in Figure

5 (c), the surface definition and characteristics were

significantly improved after passivation.

Figure 5: (a) 'I' patterned geometry of Laser Cut Metal Shaft

(Proximal and Distal End of Angiographic Catheter) (b and

c) Effect of pickling on the laser-cut reinforced shaft design

(slags were removed) (d and e) Effect of passivation on the

laser-cut reinforced shaft design (the shaft surface was

passivated).

Quantitative analysis was conducted by Ultraviolet

(UV) Spectrophotometry at 550nm wavelength of the

supernatant as the absorbance range of hemoglobin is

520-550nm. As shown in Figure 6, the quantitative

analysis results revealed that the laser-cut reinforced

shaft showed 1.27%. The laser-cut reinforced catheter

showed 1.48% hemolysis while negative control with

0% hemolysis. The laser-cut reinforced shaft and

laser-cut reinforced catheter cause <2% hemolysis

BIODEVICES 2023 - 16th International Conference on Biomedical Electronics and Devices

32

when directly encountering blood, as presented in

Figure , categorizing them as non-hemolytic (ASTM

F756, 2017).

Figure 6: Hemolysis Testing of Laser Cut Reinforced Shaft

& Catheter. The laser-cut reinforced shaft and laser-cut

reinforced catheter cause <2% hemolysis when directly

encountering blood, categorizing them as non-hemolytic.

Initially, a laser-cut metallic reinforced shaft was

used to prepare the tubing from the proximal and

distal end to measure the baseline tensile data of the

laser-cut metallic reinforced shaft material as per ISO

10555-1. Therefore, two catheter specimens,

proximal and distal end, were prepared by carefully

cutting the catheter tubing, 10.0mm long, having an

outer diameter of 2.00mm. A SHIMADZU AG-X

plus series tensile tester was used in this study. The

equipment was initially calibrated, and the laser-cut

metallic reinforced shafts specimen from the

proximal and distal ends were then evaluated. The

same test was repeated twice, and the mean of the

baseline stress-strain data for the proximal and distal

end of laser-cut metallic tubing was taken. After

getting the baseline data, the proximal and distal end

of the catheter specimen was tested. The proximal end

of catheter tubing exhibits a higher stress/strain ratio

than the distal end, as shown in Figure 7.

Figure 7: Stress/Strain Curve of Laser Cut Reinforced shaft,

laser-cut reinforced catheter, and hollow PEBAX tubing.

Tensile strength of laser-cut reinforced catheter along

with laser-cut metallic reinforced shaft was carried

out, and optimal results were received, compared with

Dxterity

™

Medtronic (Medtronic, 2016), a fully

braided catheter, having round-wire braid

configuration of 2x1 (32 wires). Infiniti Cordis

®

and

Angiodyn

®

BBraun consist of the non-braided distal

end. Upon comparison with the fully reinforced laser-

cut angiographic catheter, Infiniti

®

Cordis and

Angiodyn

®

BBraun, Dxterity

™

(Figure 8) exhibited a

tensile strength of 16.24g, Angiodyn

®

experienced

33.8g, and Infiniti

®

experienced 22.7g. The laser-cut

reinforced catheter exhibits 37.4g stress which is

most significant compared to commercial catheters.

Figure 8: Stress/Strain of Commercial Catheters (Infiniti

Cordis, Angiodyn BBraun, Dxterity Medtronic).

The laser-cut reinforced catheter yielded an average

flow rate of 63.17mL/minute, as shown in Figure 9 as

per ISO 10555-1 standard requirement.

Figure 9: Laser cut Catheter - Flowrate (ml/min).

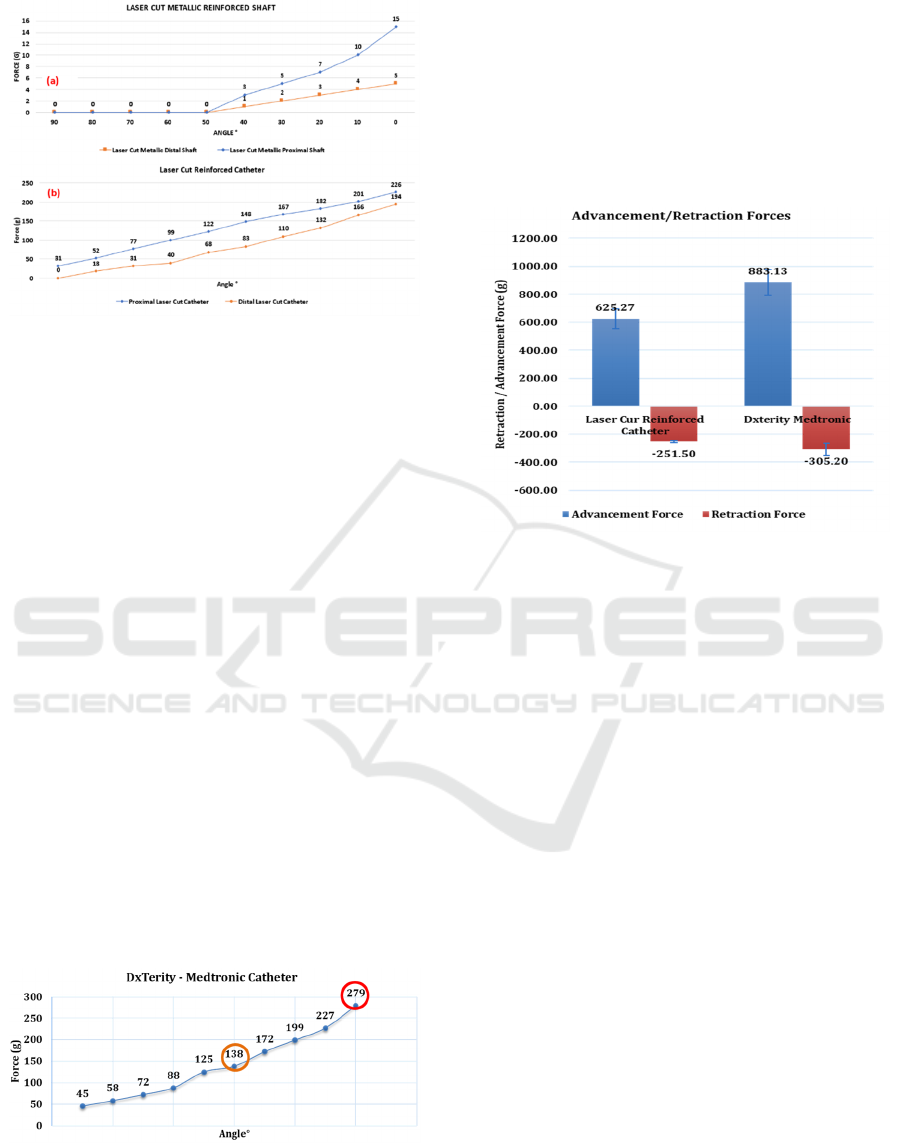

Figure 10 (a) exhibits the flexural rigidity of the

proximal and distal end of the laser-cut metallic shaft,

where the distal end experienced a maximum force of

5.0g when moved to 90-0°. In contrast, the proximal

end experienced a maximum force of 15.0g.

63,17

60,5

58

59

60

61

62

63

64

Laser Cut Reinforced

Catheter

DxTerity, Medtronic

Flowrate (mL/min)

Samples

Flowrate (mL/min)

Low Profiled Angiographic Catheter with Enhanced Pushability and Flexibility: A Novel Design, Fabrication, and in-Vitro Analysis

33

Figure 10: (a) Flexural Rigidity of Proximal and Distal end

of Laser-Cut Metallic Shaft, The proximal end of the laser-

cut reinforced catheter experienced a maximum force of

15.0g when moved from 90-0°, whereas the distal end of

the laser-cut reinforced catheter experienced a maximum

force of 5.0 g (b) Flexural Rigidity of Proximal and Distal

end of Laser-Cut Reinforced Catheter, The proximal end of

the laser-cut reinforced catheter experienced a maximum

force of 226.0g when moved from 90-0° whereas the distal

end of the laser-cut reinforced catheter experienced a

maximum force of 194.0g.

Figure 10(b) illustrates the flexural rigidity of the

distal and proximal end of the laser-cut reinforced

catheter. The proximal end of the laser-cut reinforced

catheter experienced a maximum force of 226.0g

when moved from 90-0°. In contrast, the distal end of

the laser-cut reinforced catheter experienced a

maximum force of 194.0g, which is less than the

proximal shaft. These results depict the distal end as

more responsive to external forces than the proximal

end of the catheter, whose characteristic is to maintain

its patency when subjected to external stresses.

Kinks usually occur with counterclockwise

rotation when trying to engage the left coronary artery

and with clockwise rotation when engaging the right

coronary artery. The best prevention is to refrain from

rotating the catheter more than 180° to prevent the

Figure 11: Dxterity™ Medtronic double braid (2x1, 32

wire) began to kink, and loss of ovality initiated at 40°

(shown in green circle), and kinking, loss of braid ovality

and integrity were noted at 0° (shown in red circle).

build-up of torque proximally that is not transmitted

to the catheter tip (Itsik Ben-Dor, 2018).

Laser-cut reinforced catheter exhibited an average

advancement force of 624.97g. Dxterity exhibited an

average advancement force of 882.9g. 29.2% lesser

advancement force was used to push the catheter to

the required point. 17.6% reduced retraction force

was recorded during retraction.

Figure 12: Laser-cut reinforced catheter exhibited an

average advancement force of 624.97g. Dxterity exhibited

an average advancement force of 882.9g. 29.2% lesser

advancement force was used to push the catheter to the

required point. 17.6% reduced retraction.

Along with a laser-cut reinforced catheter, Dxterity

Medtronic was also evaluated; the distal shaft is

hydrophilic coated to evaluate a fully braided catheter

performance where it experienced a maximum

resistive force of 922.1g and a retractive force of -

402.3g. However, laser-cut reinforced catheters and

Dxterity catheters lost their distal shapes after

continuous usage.

4

DISCUSSION

The objective of this study was twofold: (I) designing

and manufacturing a laser-cut metallic reinforced

shaft in a novel way and (II) configuring this laser-cut

metallic shaft as a laser-cut reinforced catheter for

radiopaque media delivery.

The stiffness and flexural rigidity of various shafts

may be assessed using two and three-point bend tests

or other deflection-based techniques. With this

knowledge, the stiffness of the adjacent shafts may be

adjusted to provide a virtually perfect transition. The

laser-cut metallic catheter shaft and laser-cut

reinforced catheter, as shown in Figure 10, exhibit the

flexural rigidity of the proximal and distal end of a

BIODEVICES 2023 - 16th International Conference on Biomedical Electronics and Devices

34

laser-cut metallic shaft, where the distal end

experienced the maximum force of 5.0g when moved

to 90-0°, whereas proximal end experienced a

maximum force of 15.0g. Figure 10 illustrates that the

proximal end of the laser-cut reinforced catheter

experienced a maximum force of 226.0g when moved

from 90-0°, whereas the distal end of the laser-cut

reinforced catheter experienced a maximum force of

194.0g, which is less than the proximal shaft. To

deliver radiopaque media to coronary arteries, high

pressures are required. The laser-cut reinforced

catheter must maintain lumen patency and endure

high pressure to avoid any vessel injuries. Laser-cut

reinforced catheter can endure 1000psi static burst

pressure and power injection pressure of 1200psi

when evaluated on a liquid pressure tester; however,

the simulation study of the design exhibited

endurance till 700psi (Inam, 2022). Injecting

radiopaque media multiple times during an

angiographic intervention might become necessary.

Therefore, not only flexible behaviours but also

pressure endurance is important.

In this study, due to the limited availability of

medical extruders, the direct extrusion method can be

adopted to develop angiographic catheters so that cost

and time can be saved.

5

CONCLUSIONS

As the medical device industry is evolving at a higher

pace, there is a great need to improve the

angiographic treatment of coronary heart disease

patients suffering from narrowed coronary arteries.

All available angiographic catheters are braided in

nature; the flat and round wire braids are used as a

sandwich layer between two polymeric layers. There

are mainly three costs involved in the placement of an

angiographic catheter to the targeted site (i)

fluoroscopic guidance, (ii) angiographic catheter, and

(iii) patient-specific radiopaque dye. Furthermore,

due to the compromised radial strength and

flexibility/ pushability tradeoff within a low-profile

angiographic catheter, catheters may require a few

episodes of retraction to reach the targeted site. This

research was conducted with the aim of using the

unique hollow ‘I’ pattern geometry for the

development of a novel laser-cut metallic reinforced

shaft and laser-cut reinforced angiographic catheter,

which demonstrates to provide better pushability of

625 0g, keeping catheter profile to lower end. One of

the critical questions addressed in this research is the

deployment of the significantly lower profile,

2.00mm outer diameter of the catheter without

compromising pushability and flexibility. The

fabrication route also determines the enhancement of

hydrophilicity.

The outcome of the comparative analysis, which

was conducted based on the results obtained from the

manufacturing and surface characterization study,

clearly showed that the laser cutting method is an

effective and rapid way of producing flexible, lower-

profile reinforced shaft. It was also established that

laser cutting of stainless-steel tubes to produce

flexible lower profile reinforced shaft would avoid

the problem of continuous ovality throughout. The

distal tube shaping of the laser-cut angiographic

catheter by complete thermal exposure was found to

be more efficient and enhanced the hydrophilic

properties of the catheter (71.3° angle depicts

hydrophilicity of the catheter). It is envisaged that the

laser-cut reinforced angiographic catheter comprising

of variable geometry patterns from proximal to the

distal end provides betters flexibility and flexural

rigidity of an average of 210g without compromising

on the advancement force; this feature of the laser-cut

reinforced catheter has an advantage over the

commercially available braided catheter. Building on

the current findings, clinical studies on the robust use

of this catheter as part of a radiopaque media delivery

functionality in medical devices may be conducted.

REFERENCES

ASTM F756. (2017, april 19). Standard Practice for

Assessment of Hemolytic Properties of Materials.

ASTM F756-17. ASTM.

Baim, D. &. (1986). Coronary angiography. In M. Mauro

Moscucci MD, Cardiac Catheterization, Angiography,

and Intervention. Philadelphia, USA.

Ghelfi, J., Bacle, M., Stephanov, O., de Forges, H.,

Soulairol, I., Roger, P., Frandon, J. (2022).

Collagenase-Induced Patellar Tendinopathy with

Neovascularization: First Results towards a Piglet

Model of Musculoskeletal Embolization. Biomedicines.

Hafsa Inam, M. N. (2022). Design Development and

Modeling of the Laser-Cut Reinforced Shaft for

Radiopaque Media Delivery to Coronary Artery Using

Finite Element Method: Laser cut catheter reinforced

shaft." . 12th International Conference on Bioscience,

Biochemistry and Bioinformatics (pp. 101-107). Tokyo

Japan: ACM.

Heart, A. (2022, 13 02). American Heart Association

Coronary Artery Disease – Coronary Heart Disease.

Retrieved from heart.org: https://www.heart.org/en/

health-topics/consumer-healthcare/what-is-

cardiovascular-disease/coronary-artery-disease

Low Profiled Angiographic Catheter with Enhanced Pushability and Flexibility: A Novel Design, Fabrication, and in-Vitro Analysis

35

Inam, H. N. (2022). Design Development and Modeling of

the Laser-Cut Reinforced Shaft for Radiopaque Media

Delivery to Coronary Artery Using Finite Element

Method: Laser cut catheter reinforced shaft. . 12th

International Conference on Bioscience, Biochemistry

and Bioinformatics. Tokyo, Japan: ACM.

Itsik Ben-Dor, T. R. (2018). Reduction of catheter kinks

and knots via radial approach. Catheter

CardiovascInterv., 1141–1146.

Kevin Hartke. (2020, January). Enhanced catheter

performance made possible with laser cut tubing.

Retrieved from https://resonetics.com/wp-content/

uploads/2020/03/Laser-Cut-Tubing-White-Paper-.pdf

Kostromina, M., Tukhovskaya, E., Shaykhutdinova, E.,

Slashcheva, G., Ismailova, A., Palikov, V., . . .

Lykoshin. (2022). Screening of the Promising Direct

Thrombin Inhibitors from Haematophagous

Organisms. Part I: Recombinant Analogues and Their

Antithrombotic Activity In Vitro. . Biomedicines .

Lappegård, K., Kjellmo, C., & Hovland, A. (2021). High-

Density Lipoprotein Subfractions: Much Ado about

Nothing or Clinically Important? . Biomedicines.

Liam Farrissey. (2004, December). Metal Shafts: Designs

To Meet The Required Performance. Retrieved from

Creganna: https://www.creganna.com/wp-content/up

loads/metalshaft.pdf

Liao, M.-T., Lai, C.-L., Wang, T.-C., Lin, J.-W., Ho, Y.-L.,

& Chan, K. (2022). Red Cell Distribution Width and

Mortality in Patients Undergoing Percutaneous

Coronary Intervention. . Biomedicines .

Lorkowski, S., & Smith, J. (2022). HDL Is Not Dead Yet. .

Biomedicines .

Medical Grade & Surgical Stainless Steel. (2022).

Retrieved from Bergsen Medical: https://berg

sen.com/medical-surgical-stainless-steel

Medtronic. (2016). DxTerity™ diagnostic catheters.

Retrieved from https://www.medtronic.com/us-en/

healthcare-professionals/products/cardiovascular/cathe

ters/dxterity.html

Moran AE, F. M. (2014). Temporal trends in ischemic heart

disease mortality in 21 world regions, 1980 to 2010: the

Global Burden of Disease 2010 study. . Circulation.,

1483–1492.

Mozaffarian D, B. E. (2016). Heart disease and stroke

statistics-2016 update. A report from the American

Heart Association. Circulation. .

NHS. (2021, 12 03). Risks, Cardiac catheterisation and

coronary angiography. Retrieved from NHS: https://

www.nhs.uk/conditions/coronary-angiography/risks/

Prabhakaran D, J. P. (2018). The changing patterns of

cardiovascular diseases and their risk factors in the

states of India: the Global Burden of Disease Study

1990-2016. Lancet Glob Health., 1339–1351.

Roth, G. A.-A. (2017). Global, regional, and national

burden of cardiovascular diseases for 10 causes, 1990

to 2015. Journal of the American college of cardiology.

Sampasa-Kanyinga H, L. R. (2015). Frequent use of social

networking sites is associated with poor psychological

functioning among children and adolescents. .

Cyberpsychology Behav Soc Netw. , 380–385.

Silvio Genna, E. M. (2020). Experimental Investigation of

Industrial Laser Cutting: The Effect of the Material

Selection and the Process Parameters on the Kerf

Quality. Applied Sciences , MPDI.

BIODEVICES 2023 - 16th International Conference on Biomedical Electronics and Devices

36