Studying the Topography of Laser Cut Aluminium Using Latent

Space Produced by Deep Learning

Alexander F. Courtier

1

, Matthew Praeger

1

, James A. Grant-Jacob

1

, Christophe Codemard

2

,

Paul Harrison

2

, Ben Mills

1

and Michalis N. Zervas

1

1

Optoelectronics Research Centre, University of Southampton, University Road, Southampton, SO17 1BJ, U.K.

2

TRUMPF Lasers UK, 6 Wellington Park, Toolbar Way, Hedge End, Southampton, SO30 2QU, U.K.

bm602@orc.soton.ac.uk, mnz@soton.ac.uk

Keywords: Deep Learning, Laser Cutting, Topography, Convolutional Variational Autoencoders, Neural Networks,

Convolutional Neural Networks.

Abstract: Modelling topography resulting from laser cutting is challenging due to the highly non-linear light-matter

interactions that occur during cutting. We show that unsupervised deep learning offers a data-driven capability

for modelling the changes in the topography of 3mm thick, laser cut, aluminium, under different cutting

conditions. This was achieved by analysing the parameter space encoded by the neural network, to interpolate

between output topographies for different laser cutting parameter settings. This method enabled the use of

neural network parameters to determine relationships between input laser cutting parameters, such as cutting

speed or focus position, and output laser cutting parameters, such as verticality or dross formation. These

relationships can then be used to optimise the laser cutting process.

1 INTRODUCTION

Fibre laser cutting is a materials processing technique

with many applications in industry. It offers many

advantages over competing techniques in terms of

precision, speed, and mechanical stability. Defects

can however be formed during cutting that limit the

final quality of the cut. These defects include

striations, seen as systematic ridges along the cutting

edge, as well as welts, seen as random depressions

along the sample.

The interactions causing these defects are poorly

understood due to their non-linearity (Arai, 2014), so

determining their relationship to input parameters is

challenging. Deep learning enables a data driven

approach to studying laser machining processes, with

much interest shown in recent years (Courtier et al,

2021; McDonnel et al, 2021; Stadter et al, 2020; Mills

and Grant-Jacob, 2021). Unsupervised learning

enables the use of unlabelled laser cut topographies

from which neural networks can extract their own

mathematical models. This enables the use of a latent

parameter space to model the relationships between

laser cutting input parameters, such as the cutting

speed or the focus position, and laser cutting output

parameters, such as verticality or dross formation.

2 EXPERIMENTAL METHODS

Sixty-five 3 mm thick grade 1000 aluminium samples

were cut with a 4 kW continuous wave disk laser. The

workstation was a TRUMPF TruLaser 1030 flatbed

cutting machine with a Precitec ProCutter cutting

head, with a 2.0x magnification focusing objective

and using nitrogen as the co-axial assist gas. The focal

spot size was 210 µm. Edges were measured using

interferometric profiling on a SmartWLI Compact

topographic profiler (GBS) using a Nikon 5x

Michelson interferometric objective lens (CF IC EPI

Plan TI) giving 1.34 µm spatial resolution, 0.57 µm

depth resolution and 3.4 x 2.8 mm field of view.

The focus position is defined as the distance

between the focus of the laser and the sample surface,

and the standoff distance is defined as the separation

between the laser cutting head and the work piece.

Each of these parameters have a dependence on each

other, for example standoff distance will impact the

effect of gas pressure.

Courtier, A., Praeger, M., Grant-Jacob, J., Codemard, C., Harrison, P., Mills, B. and Zervas, M.

Studying the Topography of Laser Cut Aluminium Using Latent Space Produced by Deep Learning.

DOI: 10.5220/0011631400003408

In Proceedings of the 11th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2023), pages 49-51

ISBN: 978-989-758-632-3; ISSN: 2184-4364

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

49

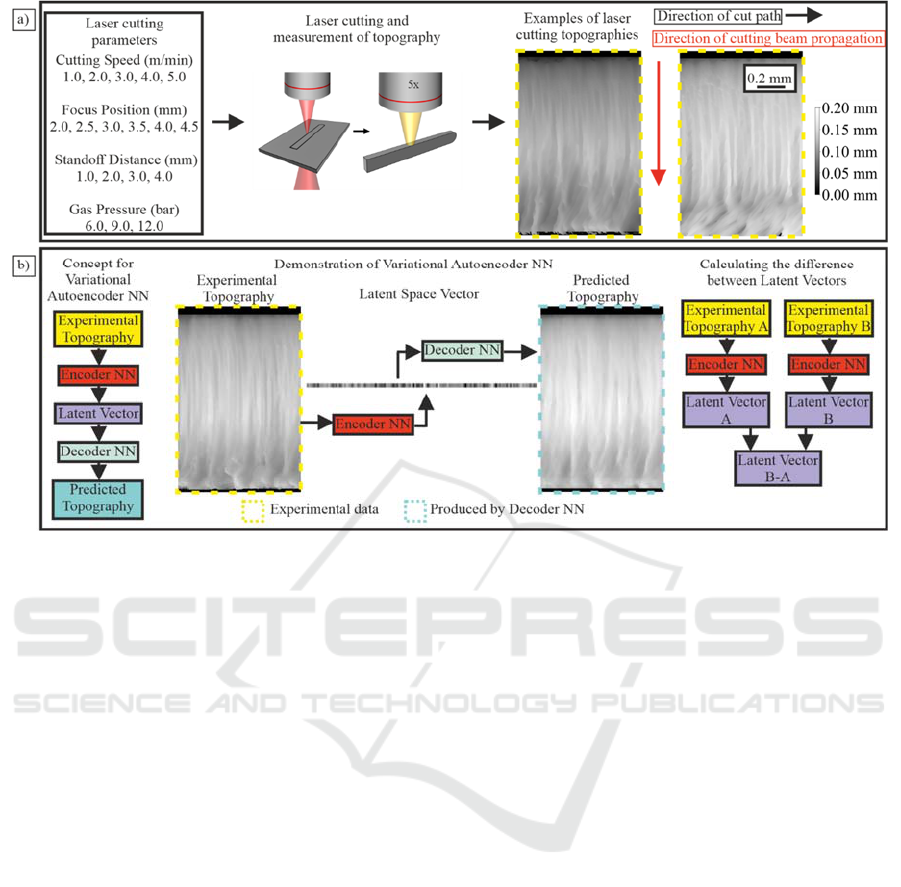

Figure 1: Application of a neural network for measuring the latent space of laser cut topography showing a) a schematic of

the experimental measurement process for collecting training data, and b) the concept of the prediction neural network with

a demonstration using topographic data, which also shows a concept of calculating the difference between latent vectors for

different parameters.

3 RESULTS AND DISCUSSION

Fig. 1 a) illustrates the laser cutting process with an

example of an experimental topography. Fig 1 b)

shows the concept of a Convolutional Variational

Autoencoder (CVAE) both conceptually and using

topographies. I.e. The encoder neural network (NN)

learns to compress the information contained within

the topographic data into alower number of

dimensions, more compact, representation (the latent

space vector). The decoder NN learns to perform the

reverse operation, rebuilding the original topographic

data as accurately as possible from the latent space

vector. The figure also shows a method for calculating

the difference between two latent vectors which can

be used to identify the effects of and interpolate

between different laser cutting parameters.

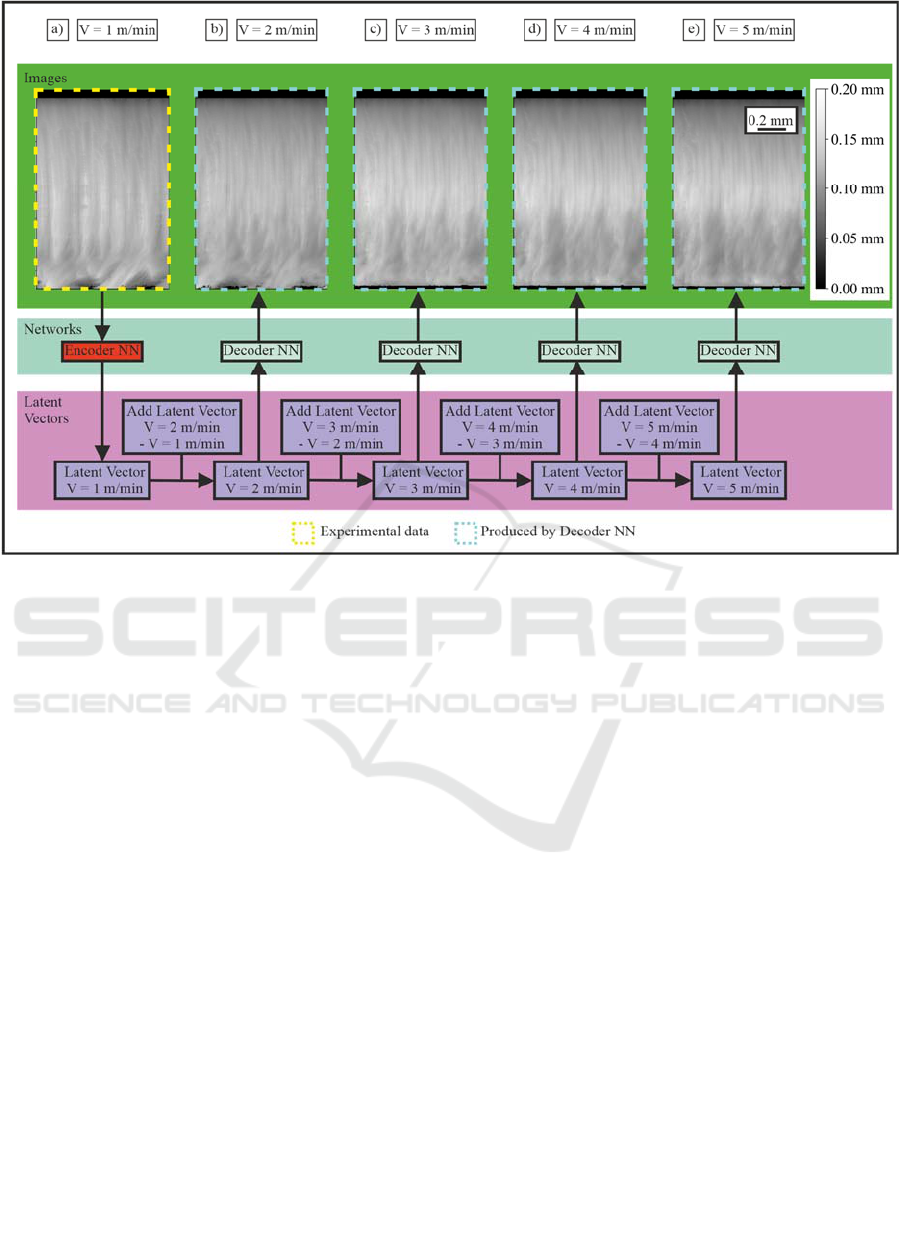

Our key result is shown in Fig. 2 which

demonstrates that latent vector arithmetic can be used

to predict laser machining topographies. When an

experimental topography is fed into our encoder

network, the output is a 1D vector whose parameters

represent the latent space governing the appearance

of the topography. By averaging the latent vectors of

many topographies that were laser machined under

the same conditions, we can produce a latent vector

that is representative of defects that occur under those

conditions. Vector arithmetic can then be used to

combine these representative latent vectors in order to

predict topographies that would result from

intermediate conditions. As the latent vector

parameters are correlated to the input topography, the

latent space can be mapped to determine the linearity

of the relationship between laser cutting parameters

and laser cutting defects. By comparing vector

properties such as the equivalent angle between latent

vectors (in multi-dimensional space) or the difference

in resultant magnitude of latent vectors, it is expected

that relationships between laser cutting input and

output parameters can be determined. Results of this

analysis will be discussed in more detail at the

conference.

4 CONCLUSIONS

In conclusion, a CVAE was trained using

unsupervised learning to model the appearance of

laser cut grade 1000 aluminium. The resultant

latent vectors were then used to model the changes in

PHOTOPTICS 2023 - 11th International Conference on Photonics, Optics and Laser Technology

50

Figure 2: Diagram showing the use of latent vector arithmetic to model the changes of defects from cutting speeds of 1 m/min

to 5 m/min. In these simulated topographies (i.e. produced by the Decoder NN), the focus position was 2.0 mm, the standoff

distance was 4.0 mm and the gas pressure was 9 bar.

appearance using the average difference between

vectors for different cutting conditions. The novelty

in this approach is the use of unsupervised learning to

model the relationships between laser cutting input

parameters, such as the cutting speed or the focus

position, and laser cutting output parameters, such as

verticality or dross formation. These relationships

could then be used to optimise the laser cutting

process by predicting output topographies for given

cutting parameters and for predicting parameter limits

such as maximum or minimum cutting speeds.

REFERENCES

Arai, T. (2014). Generation of Striations During Laser

Cutting of Mild Steel. SOP Transactions On Applied

Physics, 2014(2), 81-95. https://doi.org/10.15764/

aphy.2014.02010

Courtier, A., McDonnell, M., Praeger, M., Grant-Jacob, J.,

Codemard, C., & Harrison, P. et al. (2021). Modelling

of fibre laser cutting via deep learning.

Optics Express, 29(22), 36487. https://doi.org/10.1364/

oe.432741

McDonnell, M., Arnaldo, D., Pelletier, E., Grant-Jacob, J.,

Praeger, M., & Karnakis, D. et al. (2021). Machine

learning for multi-dimensional optimisation and

predictive visualisation of laser machining. Journal Of

Intelligent Manufacturing, 32(5), 1471-1483. https://

doi.org/10.1007/s10845-020-01717-4

Mills, B., Heath, D., Grant-Jacob, J., & Eason, R. (2018).

Predictive capabilities for laser machining via a neural

network. Optics Express, 26(13), 17245. https://doi.

org/10.1364/oe.26.017245

Stadter, C., Schmoeller, M., von Rhein, L., & Zaeh, M.

(2020). Real-time prediction of quality characteristics

in laser beam welding using optical coherence

tomography and machine learning. Journal Of Laser

Applications, 32(2), 022046. https://doi.org/10.2351/

7.0000077.

Studying the Topography of Laser Cut Aluminium Using Latent Space Produced by Deep Learning

51