Research on Fresh Produce Simultaneous Delivery and Pickup

Vehicle Path Optimization

Jun Wan

a

and Jingru Wang

b

School of Marketing Management, Liaoning Technical University, Huludao 125105, China

Keywords: Simultaneous Delivery and Pickup, Ant Colony System Genetic Algorithm, Fresh Produce, Vehicle Path.

Abstract: To address the two-way circulation problem of pickup and delivery of fresh agricultural products arising

from the perishable characteristics of fresh agricultural products, a fresh agricultural products simultaneous

delivery and pickup vehicle path optimization model is constructed with the goal of total cost optimization

based on the start-up cost, transportation cost, carbon emission cost and time penalty cost of vehicles in the

distribution process. To solve the problem that the ant colony algorithm is robust but easy to fall into local

optimum, it is combined with genetic algorithm to improve the global search ability, and the proposed ant

colony genetic algorithm's move probability selection rule, pheromone transfer strategy and crossover

operator are improved to solve the model. The model and algorithm are simulated through examples, and

the experimental results show that the optimized model and hybrid algorithm can propose a cost-optimal

solution that can improve the vehicle loading rate while ensuring customer satisfaction, and can provide a

reference for logistics companies to make vehicle path decisions for fresh produce delivery and pickup.

1 INTRODUCTION

1

Fresh agricultural products have high moisture

content and are affected by temperature and

humidity in the air, and are prone to spoilage and

deterioration during storage (e.g. Zhou, 2022). The

perishable nature of fresh agricultural products

determines that in real life, customers not only have

the demand for delivery, but also the demand for

picking up unsold agricultural products due to the

decline of freshness, so the two-way flow of picking

up and delivering obviously has stricter

requirements for fresh agricultural products cold

chain logistics distribution.

The vehicle routing problem with simultaneous

delivery and pickup (VRPSDP) describing the

characteristic was first proposed by Min (1989),

considering the pickup demand at each customer

point on the basis of fresh agricultural products cold

chain logistics distribution. Sebastian et al (2018)

considered the delivery and pickup distribution path

optimization problem with simultaneous delivery

and pickup and demand divisible in different cases

such as cluster backhaul, mixed route backhaul and

a

https://orcid.org/0000-0001-9609-9460

b

https://orcid.org/0000-0002-2999-9407

backhaul, and proposed lateral loading and dividing

the loading space into separate compartments for

long-haul and backhaul customer shipments.

Henriette et al (2018) developed a simultaneous

delivery and pickup distribution model with time

windows and 3D loading constraints for the

warehouse-to-customer simultaneous delivery and

pickup problem, and solved it using a hybrid

algorithm of adaptive large domain search and

heuristic algorithms. (Li et al., 2021) solved the

distribution path problem for the combination of

enterprise forward logistics distribution and scrap

recycling by using a hybrid optimization algorithm

combining simulated annealing and adaptive

large-scale domain search (SA-ALDS). (Yao et al.,

2019) constructed a single distribution center

urban-rural two-way logistics distribution model

with distribution cost, time window and vehicle

empty rate as the objective functions based on the

assumption that consumer goods and agricultural

products can be transported in a mixed way, and

solved it by genetic algorithm. Most domestic and

foreign scholars have applied the simultaneous

delivery and pickup path problem to material

distribution and packaging or scrap recycling, and

less research has been conducted in the cold chain

logistics of fresh agricultural products. A rare study

Wan, J. and Wang, J.

Research on Fresh Produce Simultaneous Delivery and Pickup Vehicle Path Optimization.

DOI: 10.5220/0012071500003624

In Proceedings of the 2nd International Conference on Public Management and Big Data Analysis (PMBDA 2022), pages 161-171

ISBN: 978-989-758-658-3

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

161

that considered the pickup and delivery operations

of fresh produce proposed two distribution methods:

the pickup and delivery separation service method of

unified pickup followed by unified delivery and the

simultaneous pickup and delivery mode. The results

of the research show that the vehicle space is not

well utilized and the distance traveled by the vehicle

increases in the pickup and delivery separation mode,

while the simultaneous pickup and delivery service

mode can circumvent these problems well (e.g. Ji

and Zhang, 2019).

In terms of vehicle path distribution optimization

algorithms, some scholars have used heuristic

algorithms to solve VRP and achieved good results

(e.g. Haitam and Najat (2021), Puspitasari and

Kurniawan (2021) and Ma et al. (2021)). Other

scholars proposed the genetic ant colony algorithm

(GAA) (e.g. Ding et al., 2003) and ant colony

system genetic algorithm (ACSGA) (e.g. Mao et al.,

2006) to integrate the advantages of ant colony

algorithm and genetic algorithm. The ACSGA

circumvents the inconvenience caused by the

genetic ant colony algorithm that requires multiple

experiments to determine the alternation time of the

algorithm, and has its unique superiority.

Considering that the freshness of fresh agricultural

products will increase the carbon emission of the

cold chain distribution process, in order to comply

with the policy of energy saving and emission

reduction in China and ensure the freshness of

agricultural products, we construct a fresh

agricultural products cold chain logistics

simultaneous delivery and pickup distribution model

considering carbon emission and time window, and

solve the model by using ant colony system genetic

algorithm. The research is done to enrich the

research on fresh agricultural products cold chain

logistics and to provide reference for logistics

companies to carry out simultaneous delivery and

pickup logistics and distribution services for fresh

agricultural products.

2 PROBLEM DESCRIPTION

Due to the high cost of logistics infrastructure

construction, logistics companies are restricted by

costs and will not build multiple distribution centers

(e.g. Fang et al., 2019). According to the circulation

mode of fresh agricultural products with wholesale

market as the distribution center, this paper studies

the problem of single distribution center fresh

agricultural products cold chain logistics with

simultaneous delivery and pickup distribution paths,

where refrigerated vehicles loaded with fresh

agricultural products depart from the distribution

center to each customer demand point for delivery,

while recovering unsold agricultural products at

each node due to decreasing freshness and returning

to the distribution center.

Under the premise of satisfying the customer's

demand for delivery and pickup, how to develop a

vehicle path decision for the distribution center that

minimizes the comprehensive cost consisting of

vehicle fixed cost, transportation cost, carbon

emission cost and time penalty cost under the

constraints of the customer's specified time and

vehicle load is the problem to be solved in this

paper.

3 MODELING

3.1 Model Assumptions

Assumption 1: The location of the distribution

center and each customer's demand node is known,

and the quantity of each customer's delivery and

pickup demand, service time and time window are

known.

Assumption 2: The distribution center has the

same vehicle type, i.e. all agricultural products are

delivered by the same type of vehicle.

Assumption 3: The demand for fresh produce

from each customer is within the maximum full

capacity of the vehicle.

Assumption 4: Each path starts and ends at the

distribution center, and each customer demand node

can only be served by one vehicle.

Assumption 5: The logistics company will pay a

penalty if the vehicle does not deliver the goods

within the time specified by the customer.

Assumption 6: Each kind of fresh produce can be

mixed, i.e., it can be loaded and delivered by the

same refrigerated vehicle.

3.2 Analysis of Known Parameters and

Decision Variables

(1) The known parameters are shown in Table 1.

PMBDA 2022 - International Conference on Public Management and Big Data Analysis

162

Table 1: Description of VRPSDP problem parameters.

Symbols Description

N

collection of distribution centers and customer demand points

N

i

collection of customer demand points, i

∈

{1,2,…,n}

N

0

d

istribution cente

r

K

collection of serviceable vehicles at distribution centers,

K

={1,2,…,m}

f

k

fixed costs for using a distribution vehicle

c vehicle unit transportation cost

D

i

delivery volume of customer point i

P

i

pickup volume of customer point i

Q

refrigerated truck rated capacity

Q

ij

the weight of the cargo carried by the reefer truck travels from customer point i to customer point j , i,

j

∈

N

i

d

ij

d

istance of reefer truck from customer i to customer

j

unit time penalty cost for vehicles arriving at customer i before the earliest time (ET

i

)

unit time penalty cost for vehicles arriving at customer i before the latest time (LT

i

)

S

i

service hours for customer i

v carbon taxes

ω

carbon emission factor

(2) The decision variables are analyzed as

follows.

1 vehicle drives from customer point to customer point

0or else

ijk

kij

x

=

,

,

When vehicle k transports cargo from customer

point i to customer point j, that is, x

ijk

is 1 when the

vehicle passes through path (i, j) and 0 otherwise.

1 the demand of customer is satisfied by vehicle

0 or else

ik

ik

y

=

,

,

When the demand of customer i is satisfied by

vehicle k, y

ik

is 1, otherwise it is 0.

(3) Derivative variables

St

i

denotes the start time of service at customer

point i; T

ij

denotes the time spent by the reefer truck

from customer point i to customer point j; Q

0k

denotes the loading of vehicle k when it departs

from the distribution center; Q

ik

denotes the loading

of vehicle k when it leaves customer i, i ∈{1,2,...,n}.

3.3 Model Building

(1) Vehicle fixed costs (C

1

)

The fixed costs required for vehicle activation

generally include staff salaries, vehicle depreciation

and maintenance costs, etc. As shown in equation

(1).

1

mn

0jk

k

k=1 j=1

f

Cx

=

(1)

In Eq. (1),

1

0jk

x

=

when vehicle k leaves the

distribution center for delivery to node j, otherwise it

is 0.

(2) Vehicle transportation cost (C

2

)

Vehicle transportation cost mainly refers to the

cost of fuel consumption in transit, which is related

to the distance traveled by the vehicle, and can be

expressed as equation (2) according to the research

content of this paper.

2

10 0

mn n

ij ijk

ki j

c

Cdx

== =

=

(2)

(3) Carbon emission cost (C

3

)

Vehicles consuming fuel in the distribution

process will produce CO

2

gas, and distribution

centers need to pay for the environmental pollution

caused by the emission of CO

2

gas. In a study of the

relationship between carbon emissions and climate,

Ottmar (2014) proposed that carbon emissions = fuel

consumption * CO

2

emission factor.

Fuel consumption is usually calculated using the

load estimation method (e.g. Kang et al., 2019). The

maximum vehicle load is Q. The fuel consumption

per unit distance traveled when the vehicle is empty

is

ρ

0

, and the fuel consumption per unit distance

traveled when it is fully loaded is

ρ

*. There is a

certain linear relationship between fuel consumption

and vehicle load, and the fuel consumption per unit

distance traveled when the vehicle is loaded with A

can be expressed by equation (3).

*

0

0

A A

Q

ρρ

ρ

ρ

−

=+()

(3)

The carbon emissions generated during the

distribution process of the vehicle from the

Research on Fresh Produce Simultaneous Delivery and Pickup Vehicle Path Optimization

163

distribution center to each customer point, if the

goods with a cargo capacity of Q

ij

are delivered from

customer point i to customer point j, can be

expressed as:

1

()

ij

ij

Q

d

E

ωρ

=

(4)

The carbon emission cost under the carbon tax

mechanism is expressed as: carbon emission cost =

carbon tax *carbon emission. Let the carbon tax be v,

and the total carbon emission cost C

3

of the vehicle

in the distribution process is:

3

001

()

nnm

ij ijk

ij

ijk

v

Q

Cdx

ωρ

===

=

(5)

(4) Penalty Cost (C

4

)

The customer agrees with the distribution center

on the delivery time when placing an order. If the

vehicle dispatched by the distribution center does

not deliver the goods within the agreed time of the

customer, the customer will pursue the responsibility

according to the right, that is, the distribution center

needs to deliver the corresponding penalty C

4

.

{

}

{

}

41 2

11

,0 ,0

nn

jjjj

jj

max max

CStSt

ET LT

εε

==

=−+−

(6)

In summary, the fresh produce simultaneous

delivery and pickup vehicle path optimization model

constructed in this paper is:

{}

{}

1234

10 0

001

1

1

2

1

()

,0

,0

mn mnn

0jk ij ijk

k

k=1 j=1 k i j

nnm

ij ijk

ij

ijk

n

j

j

j

n

j

j

j

minZ

CC CC

c

f

x

dx

v

Q

dx

max

St

ET

max

St

LT

ωρ

ε

ε

== =

===

=

=

=+++

=+

+

+−

+−

(7)

s.t.

1,

k

ij

iNkK

jN

x

∈∈

=∀∈

(8)

00

1,

kk

ji

jN iN

kK

xx

∈∈

==∀∈

(9)

10,

0

,

nn

k

i

j

ijji

i

k

kK

Q

x

D

==≠

∈

=

(10)

(1)

,

ii

ik i k

iN

QQ

DP

−

∈=−+

(11)

,,

ik

Qi Nk K

Q

≤∈ ∈

(12)

,,

,,

ii i

ij

ii

j

iii

ij

i

SETStLTiN

tS

T

S

t

ET St ET i N

S

T

++ < < ∀∈

=

++ ≤ ∀∈

(13)

Equation (7) is the objective function; constraint

(8) indicates that each customer point can only be

served by one vehicle; constraint (9) indicates that

all refrigerated vehicles depart from the distribution

center and eventually return; constraint (10)

indicates that the loading of a vehicle when it

departs from the distribution center is the sum of the

delivery volume of all customer points on a certain

path; constraint (11) indicates that the loading of a

vehicle when it leaves a certain customer = loading

when it leaves the previous customer point - its own

delivery volume + its own pickup volume; constraint

(12) ensures that the vehicle is not overloaded at any

moment in the distribution service; constraint (13)

indicates that the vehicle delivers and picks up the

goods within the time window of the customer point.

4 DESIGN OF ANT COLONY

SYSTEM GENETIC

ALGORITHM

The ant colony algorithm is more robust and can be

easily combined with other algorithms, but it also

has the disadvantages of long search time and easy

to fall into local optimum (e.g. Chen et al., 2019).

The cold chain distribution process of fresh

agricultural products studied in this paper is

different from the traditional distribution problem of

decreasing vehicle load, in that there is simultaneous

pickup and delivery, and the vehicle load presents

dynamic irregular changes, which requires a higher

global search capability of the algorithm.

The basic

ant colony algorithm cannot meet the research

conditions. In order to improve the global

optimization-seeking ability of the ant colony

algorithm, the ant colony system genetic algorithm

(ACSGA), combining the ant colony system

algorithm with the genetic algorithm, is proposed to

solve the model. The basic idea of the ant colony

system genetic algorithm is to introduce the genetic

algorithm into the iteration of the ant colony

algorithm system, and the solution obtained by the

ant colony system is used as the initial population of

the genetic algorithm, and the genetic algorithm

evolves for the optimal solution by multiple

iterations.

PMBDA 2022 - International Conference on Public Management and Big Data Analysis

164

4.1 Moving Probability Selection Rules

The ant selects the next client point j for transfer

from client point i by a certain probability selection

rule, which is expressed in equation (14).

[ ( )] [ ( )]

()

[ ( )] [ ( )]

0,

k

ij

ij

k

k

u tabu

iu iu

ij

k

tt

j

tabu

t

tt

p

jtabu

αβ

αβ

η

τ

τη

∈

∈

=

∉

,

(14)

In Eq. (14),

τ

ij

(t) denotes the amount of

information on the path from node i to node j at

moment t;

η

ij

(t)=1/d

ij

is the heuristic function;

α

and

β

denote the information heuristic factor and the

expectation heuristic factor, respectively.

4.2 Pheromone Update Strategy

The residual pheromone of each path will diminish

with time, and when k ants have traveled the full

distance, the pheromone on each pathway needs to

be adjusted as follows.

()(1)()

ij

ij ij

tn t

ρ

τ

ττ

+=− +Δ

(15)

1

m

k

ij

ij

k

τ

τ

=

=Δ

Δ

(16)

ρ

denotes the degree of pheromone

τ

ij

(t)

weakening over time,

ρ

∈ (0,1);

k

ij

τ

Δ

denotes the

pheromone left by ant k between client nodes i and j

in this cycle, which is generally calculated using the

Ant-Cycle model.

()

if the th ant in this cycle passes through

or else

,

Δ=

0

k

M

k

L

ij

kij

t

τ

,

(17)

M denotes the total amount of pheromones

produced by the ant k cycles in one turn, and L

k

denotes the cycle route of the kth ant.

4.3 Adaptation Function

The fitness function is a criterion for evaluating the

merit of the solution in the genetic algorithm and is

set according to the study as shown in equation (18).

Z denotes the objective function cost.

1

=f

Z

(18)

4.4 Crossover Operator Improvement

The crossover operation in the genetic algorithm is

performed by exchanging some genes of two

mutually paired individuals to obtain two new

individuals to improve the algorithm's merit-seeking

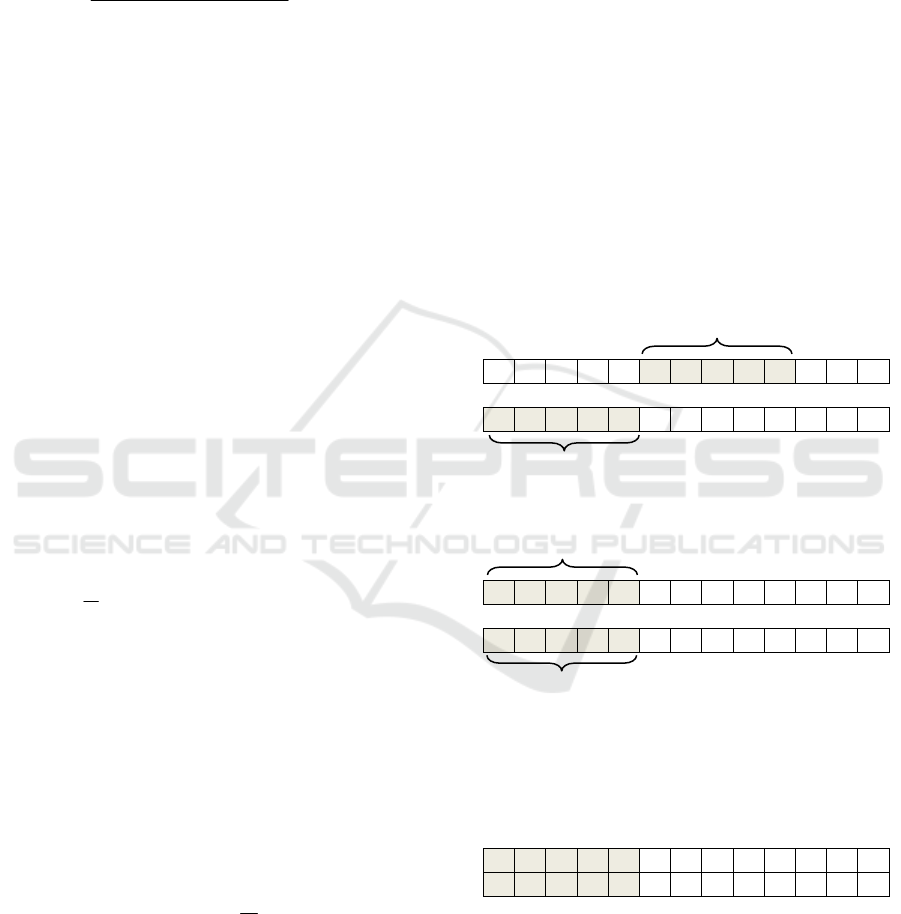

ability. Assuming that there are 9 customer nodes, 0

represents the distribution center. This paper adopts

the partial mapping crossover method to improve the

crossover operation. The execution steps are as

follows.

1) Selecting two parent chromosomes and

choosing a complete path at random for each will

result in path 1 and path 2, as shown in Figure 1(a).

2) Precede path 1 and path 2 and remove

duplicate genes, swap the positions of path 1 and

path 2, and get offspring chromosomes 1 and 2, as

shown in Figure 1(b).

3) Perform conflict detection and establish a

mapping relationship between genes of path 1 and

path 2 using the partial crossover method, and map

all genes with conflicts until there is no conflict,

thus forming new offspring chromosomes, as shown

in Figure 1(c).

Paternal chromosome 1

Paternal chromosome 2

0319

7 0 4 2 8 0 6 5 0

0 9 7 5 0 1 2 6 3 0 8 4 0

(a) Randomly selected paths of parental chromosome parts

Offspring chromosome 1

Offspring chromosome 2

0 9 7 5 0 3 1 9 7 0 6 5 0

0 4 2 8 0 1 2 6 3 0 8 4 0

(b) Successive prepending, deleting and swapping

operations on chromosomes

The mapping relationship between the

chromosomal genes generated by paths 1 and 2 is:

9↔4 7↔2 8↔5

Offspring chromosome 1

Offspring chromosome 2

0 9 7 5 0 3 1 4 2 0 6 8 0

0 4 2 8 0 1 7 6 3 0 5 9 0

(c) Partial chromosomal gene mapping crossover

Figure 1: Schematic diagram of chromosome crossover.

4.5 Ant Colony Genetic Algorithm

Process

The hybrid algorithm relies on the global search

ability of the genetic algorithm to determine the

Path 1

Path 2

Path 2

Path 1

Research on Fresh Produce Simultaneous Delivery and Pickup Vehicle Path Optimization

165

optimal solution range in the early stage of operation,

and mainly relies on the local search ability of the ant

colony algorithm to precisely locate the optimal

solution in the later stage. In order to avoid the

phenomenon of degradation of good individuals

caused by useless iterations of already premature

populations due to the existence of premature

disadvantage of genetic algorithm (e.g. Liang et al.,

2014) the adjustment rule of the number of iterations

is introduced in the hybrid algorithm so that it only

performs mutation operation at the later stage to

improve the convergence speed. The specific

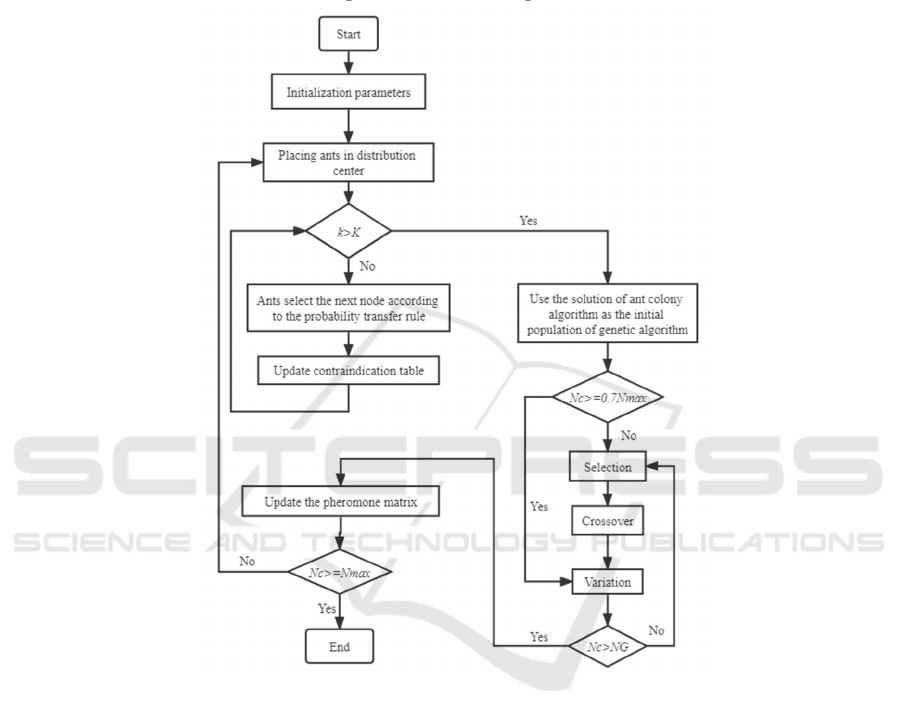

algorithm design flowchart is shown in Figure 2, and

the steps are as follows.

Figure 2: Flow chart of ant colony system genetic algorithm.

Step1: Initialize the parameters, N

c

=0, set the

maximum number of cycles N

max

and the number of

genetic algorithm iterations NG.

Step2: Initialize the ant positions and place K

ants in the distribution center.

Step3: Determine whether a complete path is

formed, if yes, proceed to step 5, if not, proceed to

step 4.

Step4: The ants select the next customer node

according to the movement transfer probability

formula (14) and update the contraindication table.

Step5: The solution obtained from the ant colony

system is used as the initial population of the genetic

algorithm, and then we determine whether

N

c

≥0.7N

max

holds, if it does, proceed to step 7, if it

does not, proceed to step 6.

Step6: The population obtained by the ant colony

algorithm is selected and crossed to generate the

new generation of individuals.

Step7: Perform mutation operation on the

population to generate new generation of

individuals.

Step8: Determine whether the genetic algorithm

reaches the set maximum number of iterations NG,

if yes, proceed to step 9, otherwise return to step 6.

Step9: Update the pheromone matrix according

to the pheromone update strategy formula (15).

Step10: Determine whether the algorithm

reaches the maximum number of cycles N

max

, if yes,

output the optimal solution and end the algorithm, if

not, return to step 2.

PMBDA 2022 - International Conference on Public Management and Big Data Analysis

166

5 SOLVING AND ANALYSIS OF

ALGORITHMS

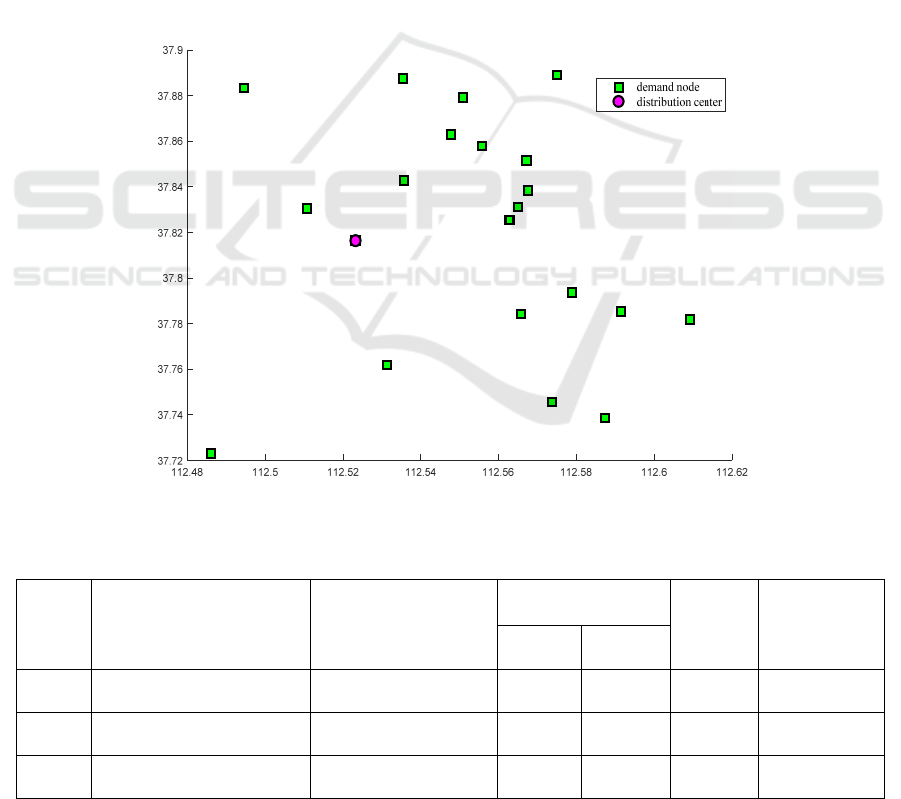

In order to verify the effectiveness of the ant colony

system genetic algorithm, the distribution task of

one day in Taiyuan city R.Q fresh fruit wholesale

distribution center is used as an example for solution

testing. The distribution center is responsible for

supplying the fresh fruit counters of large

supermarkets such as Metropolis, Wal-Mart and

Wang, F.-J Department Store in Taiyuan. 20

supermarkets served by the distribution center are

selected and the coordinate locations are obtained in

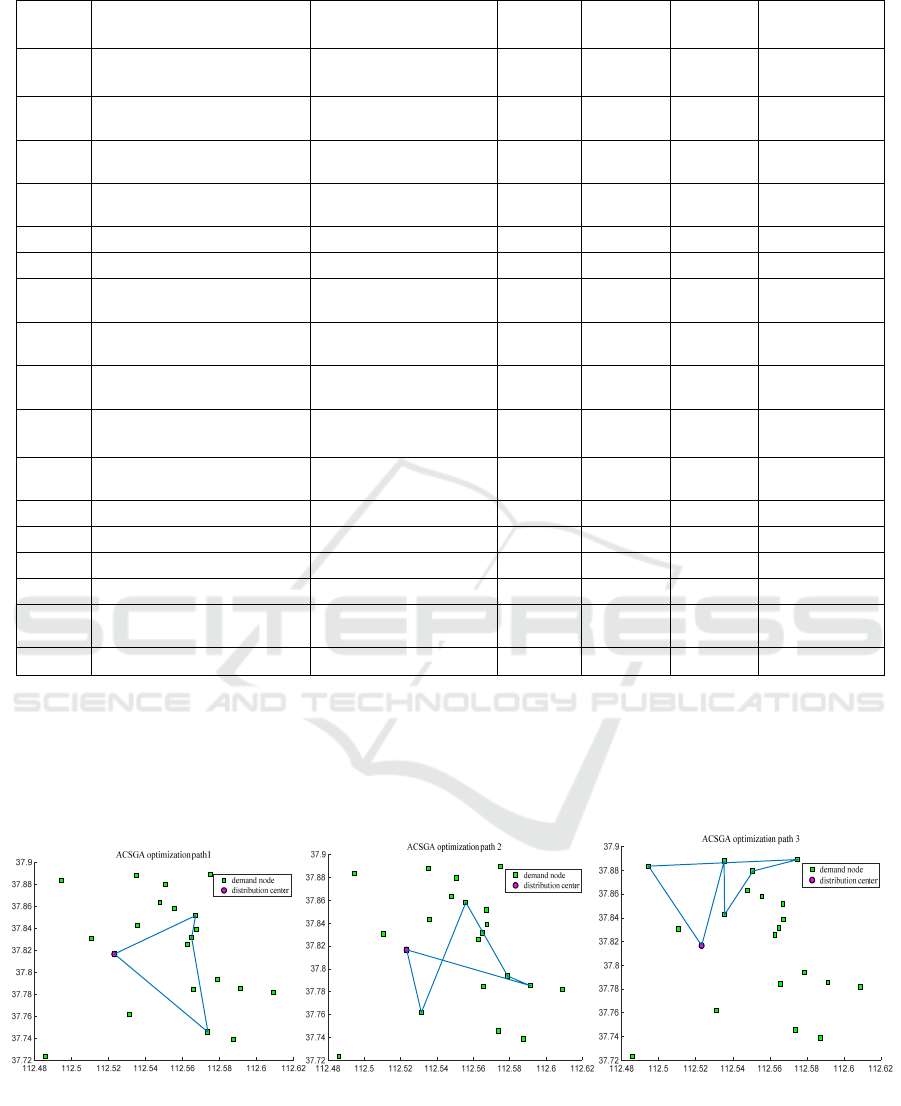

the map, as shown in Figure 3.

The refrigerated truck departs from R.Q fresh

fruit distribution center at 6:00 a.m., and delivers the

fruits and vegetables to the customer within the

specified time, and sends some of the customers'

fruits and vegetables that need to be recycled back to

the distribution center for secondary processing due

to the decline in freshness, and the vehicle will be

fined 50 or 100 RMB per hour if it delivers the goods

earlier or later than the specified time. Reefer start-up

cost is 150 yuan, unit transportation cost is 4 yuan

per kilometer, maximum load capacity is 3.7 tons,

fuel consumption is 0.165 and 0.377 liters per

kilometer when empty and full load respectively;

considering the city 7:00 a.m. to 9:00 a.m. for traffic

congestion, the vehicle speed is calculated at 30 km/h

throughout; CO

2

emission factor is 2.63 kg per liter,

carbon tax is 43 yuan per ton. The location of R.Q

fresh fruit wholesale distribution center and each

customer node is known. The customer specified

time window and delivery-pickup requirements are

shown in Table 2, with the number 0 representing the

distribution center and each customer node numbered

1, 2, ...20 in order, and the Matlab R2015b software

is used to solve the algorithm.

Figure 3: Map location of distribution center and each super node.

Table 2: Information table of R.Q Fresh Fruit Wholesale Distribution Center and the demand for each superstore.

Node

number

Node Name Longitude and Latitude

Delivery and pickup

demand(t)

Service

Time /min

Time Window

Delivery

volume

Pickup

volume

0

R.Q Fresh Fruit Wholesale

Distribution Center

112.523320,37.816424

- - - -

1

Wang, F.-J. Department

Store

112.565022,37.831129 1.20 0.24 20 (6:30-8:30)

2

Wal-Mart (Hutchinson

Fashion Mall)

112.562784,37.825208 0.75 0.00 10 (6:30-8:30)

Research on Fresh Produce Simultaneous Delivery and Pickup Vehicle Path Optimization

167

3 Wal-Mart (Taiyuan S. Road) 112.575213,37.888957 0.75 0.16 15 (7:30-10:00)

4 Metropolis (X.D District) 112.565867,37.784022 0.54 0.00 9 (7:20-10:00)

5

Metropolis (K.Z Ten Mile

City)

112.587438,37.738523 0.80 0.00 12 (7:25-9:40)

6

Metropolis (Crescent Moon

International Store)

112.573819,37.745356

1.42 0.40 20

(7:30-8:30)

7

Metropolis (W.C Mall

Store)

112.567605,37.838313

0.65 0.08 16

(6:20-8:00)

8 Metropolis (Z.E Lane) 112.609162,37.781732 0.40 0.00 8 (6:40-7:40)

9 Metropolis (YZ District) 112.547865,37.863072 0.95 0.20 18 (6:30-8:00)

10

Metropolis (T.Y North Road

Store)

112.550985,37.879256 0.65 0.00 10 (6:30-8:30)

11

Metropolis (Connaught

Street)

112.555893,37.857877

0.80 0.15 15

(7:20-8:20)

12

Metropolis (W.C South

Road)

112.591506,37.785145 1.00 0.35 20 (7:00-9:00)

13 Metropolis (Poly Lily Store) 112.494598,37.883346 0.75 0.00 10 (8:10-10:00)

14

Metropolis (W, B.-L.

District)

112.535420,37.887478

0.60 0.00 10

(6:20-8:30)

15 Metropolis (YJ West Road)

112.510691,37.830578

1.25 0.27 20

(7:00-9:00)

16 Metropolis (JY District)

112.486144,37.722930

1.50 0.32 20

(7:00-9:00)

17 Metropolis (Z.D Branch) 112.531407,37.761645 0.86 0.14 15 (7:30-9:00)

18 Metropolis (YSMZ Store) 112.578954,37.793417 0.70 0.00 10 (6:40-8:00)

19

Metropolis (South Inner

Ring West Street)

112.535699,37.842549 0.55 0.00 8 (6:30-9:00)

20 Metropolis J.F South Store

112.567166,37.851265

0.96 0.24 16

(6:00-8:00)

5.1 Analysis of Results

The proposed optimization model is solved

according to the actual arithmetic example and the

ant colony system genetic algorithm. The number of

ants is set as 6, α=1, β=1, ρ=0.8, the total number of

pheromones is 100, and the number of iterations is

100, resulting in the optimal vehicle distribution

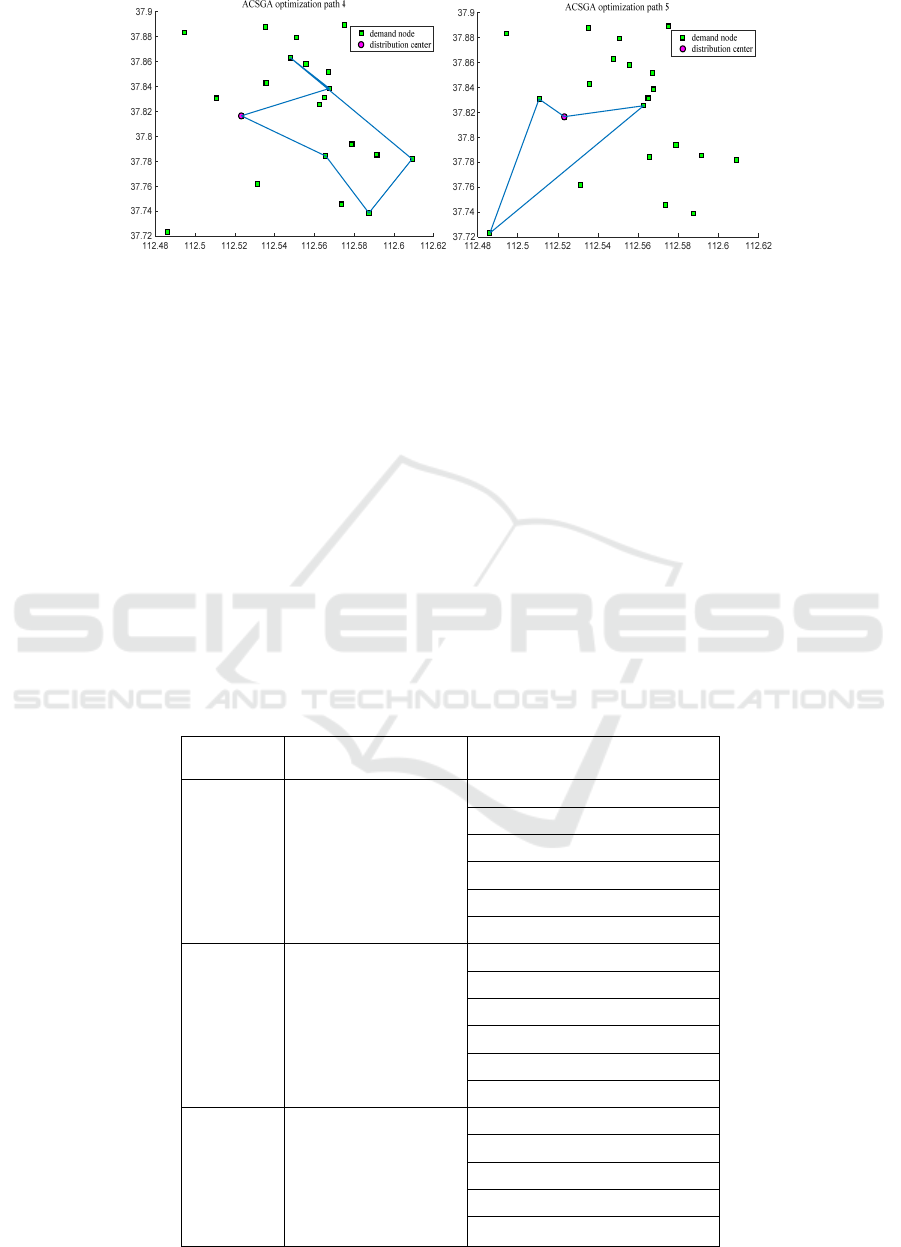

path as shown in Figure 4.

PMBDA 2022 - International Conference on Public Management and Big Data Analysis

168

Figure 4: Ant colony system genetic algorithm vehicle path optimization diagram.

From Figure 4, it can be seen that five

refrigerated trucks are required for distribution using

the ant colony genetic hybrid algorithm to solve the

model. Combined with Table 2 and Figure 3, the

distribution vehicles departed from R.Q fresh fruit

wholesale distribution center, vehicle 1 carried 3.58

tons of fruits and vegetables in order to customers

20, 1, 6 for delivery and pickup service and then

returned to the distribution center; vehicle 2 carried

3.36 tons of fruits and vegetables in order to

customers 12, 18, 11, 17 for delivery and pickup

service and then returned to the distribution center;

vehicle 3 carried 3.3 tons of fruits and vegetables in

order to customers 14, 19, 10, 3, 13 for delivery and

pick-up service and then returned to the distribution

center; vehicle 4 carried 3.34 tons of fruits and

vegetables in order to customers 7, 9, 8, 5, 4 for

delivery and pick-up service and then returned to the

distribution center; vehicle 5 carried 3.5 tons of

fruits and vegetables in order to customers 2, 16, 15

for delivery and pick-up service and then returned to

the distribution center. The total comprehensive cost

was 1422.31 yuan.

5.2 Experimental Comparison

In order to verify the effectiveness of the ant colony

system genetic algorithm, it was solved and

compared with the basic algorithm for the cases

separately, and the total distribution cost and optimal

routes obtained from 10 runs are shown in Table 3.

Table 3: Optimal distribution strategy corresponding to each algorithm.

Algorithm

Optimal distribution

cost (yuan)

Optimal Distribution Path

ACO 1619.76

0➝20➝14➝5➝17➝ 0

0➝2➝1➝0

0➝10➝7➝19➝3➝11➝0

0➝9➝8➝12➝4➝13➝0

0➝16➝15➝0

0➝6➝18➝0

GA 1617.66

0➝20➝1➝6➝0

0➝12➝18➝11➝17➝0

0➝19➝14➝10➝3➝13➝0

0➝7➝9➝8➝5➝4➝0

0➝16➝15➝0

0➝2➝0

ACSGA 1422.31

0➝20➝1➝6➝0

0➝12➝18➝11➝17➝0

0➝14➝19➝10➝3➝13➝0

0➝7➝9➝8➝5➝4➝0

0➝2➝16➝15➝0

Research on Fresh Produce Simultaneous Delivery and Pickup Vehicle Path Optimization

169

As can be seen from Table 3, for the fresh

produce with time window while picking up and

delivering vehicle path optimization problem, both

basic ant colony algorithm and genetic algorithm

need 6 vehicles, and ant colony genetic algorithm

only needs 5 vehicles, from the situation of vehicle

scheduling, ant colony system genetic algorithm can

reasonably allocate vehicles and effectively reduce

the vehicle empty rate; from the comprehensive

optimal cost, the comprehensive cost obtained by

ant colony system genetic algorithm is 1422.31 yuan,

which is nearly 200 yuan less than the basic

algorithm. If based on the same conditions and

number of distribution tasks, using the hybrid

algorithm can save nearly 6000 yuan a month. In

summary, the ant colony system genetic algorithm

designed in this paper is effective in reducing the

vehicle empty rate and the integrated cost.

Specifically, the distribution cost components and

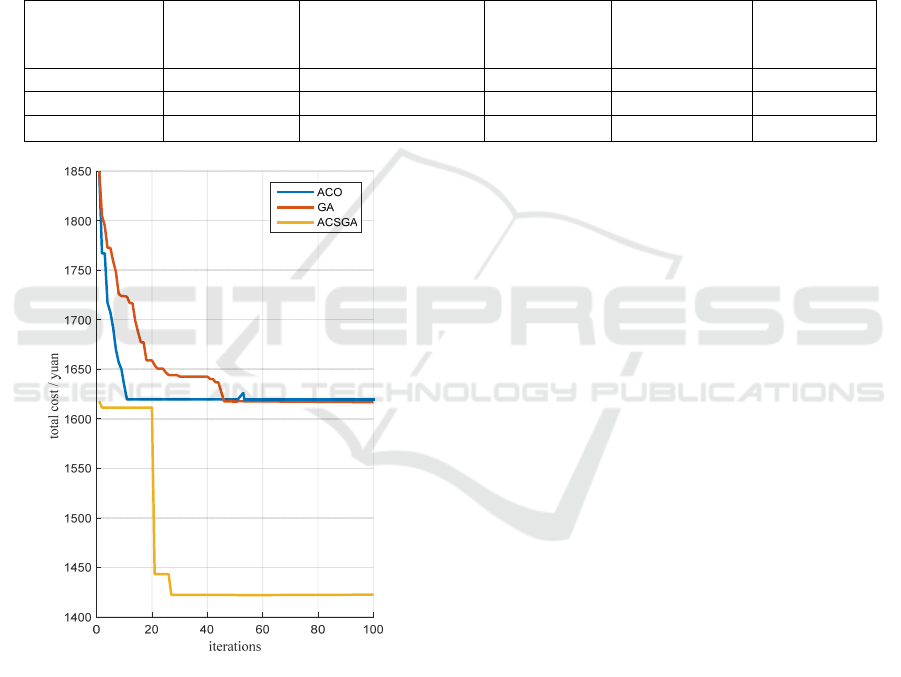

convergence curves of each algorithm are shown in

Table 4 and Figure 5.

Table 4: Cost Analysis of Optimal Distribution Solution.

Algorithm

Total

distribution

cost/yuan

Vehicle fixed

cost/yuan

Transportation

cost/yuan

Carbon

emission

cost/yuan

Time penalty

cost/yuan

ACO 1619.75 900 455.27 3.44 261.04

GA 1617.67 900 421.86 3.16 292.65

ACSGA 1422.31 750 427.92 3.37 241.02

Figure 5: Convergence curve.

According to the analysis of distribution cost

composition in Table 4, all the costs of the ant

colony algorithm are higher, and combined with

Figure 5, we can see that the ant colony algorithm is

trapped in the local optimum and difficult to jump

out in the process of finding the best. The carbon

emission cost and transportation cost obtained by the

genetic algorithm are slightly lower than the ant

colony system genetic algorithm, but the local

search ability is weak and the search process is slow

in the late stage of the solution process, the fixed

cost of the vehicle and the time penalty cost are

higher, and the genetic algorithm cannot make full

use of the vehicle space and cannot guarantee

customer satisfaction. The ant colony system genetic

algorithm integrates the advantages of the basic

algorithms, using the global search ability of the

genetic algorithm to lock the optimal solution range

in the early stage of the solution, and using the local

search ability of the ant colony algorithm to find the

optimal solution precisely in the later stage of the

solution. The hybrid algorithm converges faster,

improves the on-time delivery rate while making full

use of the vehicle space, ensures the customer

satisfaction and reduces the comprehensive cost. In

summary, the ant colony system genetic algorithm

designed in this paper can find the optimal solution

faster and ensure customer satisfaction, which is

effective for solving the fresh produce simultaneous

delivery and pickup vehicle path problem.

6 CONCLUSIONS

As the demand for freshness of fresh agricultural

products improves, the short timeliness of fresh

agricultural products determines that important fresh

agricultural products sales entities such as fresh

supermarkets not only have the demand for delivery

but also the demand for recovery of agricultural

products that are not sold in time due to the decline

of freshness. In this paper, we study the optimization

of fresh agricultural products cold chain logistics

PMBDA 2022 - International Conference on Public Management and Big Data Analysis

170

with time windows for simultaneous delivery and

retrieval vehicle paths under the consideration of

energy saving and emission reduction, and construct

an optimization model with the objective function of

minimizing comprehensive cost. In order to improve

the global search capability of the basic ant colony

algorithm, a hybrid ant colony system genetic

algorithm is proposed and the crossover operator is

improved to solve the model. In order to verify the

validity of the model and the algorithm, simulation

experiments are conducted on the actual cases and

the hybrid algorithm is compared with the basic

algorithm. The results show that the constructed

optimization model and the hybrid ant colony

system genetic algorithm can arrive at the lowest

comprehensive cost and the most optimal path,

which can reduce the vehicle empty rate and

improve customer satisfaction at the same time. It is

suitable for solving the problem of simultaneous

delivery and pickup of fresh agricultural products,

and can provide methodological support for logistics

companies to distribute fresh agricultural products,

which has certain practical significance and

reference value.

REFERENCES

Chen, Z., Jiang, Z.-J., Liu, Y., 2019. Research on low

carbon logistics path optimization based on improved

ant colony algorithm for different road sections.

Ecological Economics 35(12):53-59+66.

Ding, J.-S., Chen Z.-Z., Yuan Z.-Z., 2003. Fusion of

genetic algorithm and ant algorithm. Computer

Research and Development 40(9):1351-1356.

Fang, W.-T., Ai, S.-Z., W, Q., Fan, J.-B., 2019. Research

on cold chain logistics distribution path optimization

based on hybrid ant colony algorithm. China

Management Science 27(11):107-115.

Haitam, E., Najat, R., Jaafar, A., 2021. Metaheuristics

methods for The VRP in Home Health Care by

minimizing fuel consumption for environmental gain.

E3S Web of Conferences 234, 94-101.

Henriette, K., Andreas, B., Gerhard, W., 2018. A hybrid

algorithm for the vehicle routing problem with

backhauls, time windows and three-dimensional

loading constraints. OR Spectrum 40(04): 1029-1075.

JI, J.-H., ZHANG, X., 2019. Optimization model and

algorithm for fresh produce distribution path

considering pickup and delivery operations. Journal of

Systems Science 27(01):130-135.

Kang, K., Han, J., Pu, W. et al., 2019. Research on the

optimization of low-carbon distribution path for fresh

agricultural products cold chain logistics. Computer

Engineering and Applications 55(02):259-265.

Li, J., Duan, Y., Hao, L.-Y.et al., 2021. Hybrid

optimization algorithm for solving simultaneous

delivery and pickup vehicle path problems. Computer

Science and Exploration 1-12.

Liang, X., Huang, M., Ning, T., 2014. Modern intelligent

optimization hybrid algorithms and their applications.

Beijing: Electronic Industry Press.

Ma, Y.-F., Li, B.-Y., Yang Y.-F., Feng C.-Y.,

2021.Research on two-level path problem and

algorithm for fresh food delivery under customer

classification. Computer Engineering and

Applications 57(20):287-298.

Mao, N., Gu, J.-H., Tan, Q. et al., 2006. Ant colony

genetic hybrid algorithm. Computer Applications

(07):1692-1693+1696.

MIN H. 1989. The multiple vehicle routing problem with

simultaneous delivery and pick-up points.

Transportation Research Part A: General 23 (5):

377-386.

Ottmar R.-D., 2014.Wildland fire emissions, carbon, and

climate: Modeling fuel consumption. Forest Ecology

& Management, 317(2) 41-50.

Puspitasari, F.- H., Kurniawan, V.-R.-B., 2021. Designing

Optimal Distribution Routes using a Vehicle Routing

Problem (VRP) Model in a Logistics Service Provider.

IOP Conference Series: Materials Science and

Engineering 1071(01):120-131.

Sebastian, R., Andreas, B., Lars, M., 2018. Heuristics for

vehicle routing problems with backhauls, time

windows, and 3D loading constraints. European

Journal of Operational Research 266 (03): 877-894.

Yao, G.-X., Wu, J., Zhu, C.-J.et al., 2019. Research on

urban-rural logistics distribution based on two-way

circulation under fuzzy environment. Business

Economics Research (20):107-109.

Zhou, L.-L., 2022. Expert Forum-Quality Control of

Perishable Fruits and Vegetables. China Fruit and

Vegetable 42(09), 1.

Research on Fresh Produce Simultaneous Delivery and Pickup Vehicle Path Optimization

171