Hydroponic Nutrition Water Quality Identification System on

Cayenne Pepper Using Fuzzy Method Based on IoT

Mohammad Ainun Ardiansyah

1

, I Gede Wiryawan

1 a

, Khafidurrohman Agustianto

1 b

,

Prawidya Destarianto

1 c

, Shabrina Choirunnisa

1 d

and Fitri Krismiratsih

2

1

Department of Informatics Technology, Politeknik Negeri Jember, Jember, Indonesia

2

Department of Agribusiness Management, Politeknik Negeri Jember, Jember, Indonesia

Keywords: Internet of Things, Hydroponic, Fuzzy, Cayenne Pepper.

Abstract: This study aims for an Internet of Things system for determining the nutritional water quality of hydroponic

cayenne pepper plants based on fuzzy logic. Variable values were obtained from the readings of three sensors,

water temperature, TDS, and pH. Hydroponic cayenne pepper plants can grow optimally at a water

temperature from 18 to 28 °C, with a pH of 5 - 7. Nutrient levels in cayenne pepper will increase according

to the age of the chili. The IoT system can provide corrections to any variables outside the specified range by

giving commands from Arduino to the actuator. The actuators that run the water pump turn on and off, the

addition of nutrients and water levels, and the process of neutralizing the pH with KOH and HCl compounds.

The results of testing the IoT system send data to the website successfully, and then it is processed using fuzzy

logic. This study found that the average accuracy of the three sensors was 93.61%.

1 INTRODUCTION

Hydroponics is a plant cultivation technique that

utilizes water-containing nutrients as a growing

medium and no longer needs to use soil media. Water

is mixed with fertilizer to meet the nutrients required

by plants (Swastika et al., 2017). The level of

nutrients dissolved in water or the concentration of

the mixture is expressed by TDS (Total Dissolved

Solid). The TDS value is an essential indicator in

hydroponic cultivation systems. Plants have normal

levels to absorb nutrients for plant growth

(Rahmadhani et al., 2020). If the TDS value is too

high or too low, it will interfere with the absorption

of nutrients in plants. The effect of a TDS value that

is too high is that the plant leaves will turn yellow or

burn due to excess nutrients. The degree of acidity

(pH) and water temperature also affect the growth

rate of hydroponic plants. Temperatures that are too

high can cause plants to wither. So it needs good

regulation of nutrient levels, pH, and temperature in

hydroponic water.

a

https://orcid.org/0000-0002-8528-5011

b

https://orcid.org/0000-0002-0494-3124

c

https://orcid.org/0000-0001-6228-4967

d

https://orcid.org/0000-0001-8581-2136

Cayenne pepper is a leading commodity in

Indonesia. Cayenne pepper is commonly used to add

a spicy taste and natural red coloring to food. Based

on data from the Central Statistics Agency and the

Directorate General of Horticulture, the productivity

of cayenne pepper increased by 13.07% from 2017 to

2018, with a productivity of 7.78 tons/ha. Farmers are

increasingly carrying out the cultivation of cayenne

pepper with a hydroponic system. The advantage of

growing cayenne pepper using hydroponics is that it

does not require a large area of land and can be done

on a household scale.

Problems that arise and are still experienced by

many farmers are regulating and monitoring levels of

TDS values, pH, and hydroponic water temperatures

continuously. If nutrient water is not monitored

regularly and carefully, it can disrupt plant growth

(Aprillia & Myori, 2020). Improper nutrient water

regulation will affect the growth rate of cayenne

pepper plants. When monitoring nutrient water

conditions, Hydroponic farmers mostly do it

manually using a TDS meter to measure TDS value

Ardiansyah, M., Wiryawan, I., Agustianto, K., Destarianto, P., Choirunnisa, S. and Krismiratsih, F.

Hydroponic Nutrition Water Quality Identification System on Cayenne Pepper Using Fuzzy Method Based on IoT.

DOI: 10.5220/0012056600003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 1043-1051

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1043

and temperature; and a pH meter to measure the pH

value of nutrient water.

This study was preceded by using the linear

regression method to design a nutrient monitoring

information system for hydroponic plants (Wibowo et

al., 2022). In applying hydroponics, nutrition is a

need that must always be met for plant development,

where each plant requires different nutrients. The

Nutrient Film Technique (NFT) is a technique that is

often used in hydroponic cultivation. Because in this

method, the circulation of nutrients in the water will

constantly flow through the plant at any time. So plant

growth is faster because plants get oxygen and

nutrients all the time. The NFT technique is said to be

an energy-intensive technique because the water

pump will run continuously and still use human

power. Previously some studies designed the design

of the same system (Setyo Wibowo et al., 2022). This

study aims to design a nutrient monitoring

information system for hydroponic water spinach

plants with an NFT system to increase the

productivity of hydroponic farmers by automatically

regulating nutrition and monitoring nutrients in

hydroponic plants using the Linear Regression

method. This Linear Regression method can

determine the nutritional valve opening the next day

so that the system can monitor nutrition.

Previously, the internet of things had also been

carried out on oyster mushroom cultivation

(Agustianto et al., 2021). In this study, the fuzzy logic

method was applied to monitor oyster mushroom

cultivation. The research then proceeds to the

adaptive application of temperature and humidity

using a fuzzy neural network algorithm (Hartadi et

al., 2022). The use of modern technology can be a

solution to the above problems. One solution is to use

an Arduino microcontroller and several sensors such

as TDS, pH, and temperature sensors as readings for

hydroponic nutrient water conditions. Real-time

monitoring through the website can also help farmers

to know firsthand the necessity of nutrient water.

Then Farmers can access the website via a

smartphone or laptop. The microcontroller that can be

integrated by Arduino and used to send nutrient water

condition data to the website is the MCU node. The

MCU node sends data using the internet network.

Then the decision determination from the input is

processed using the Sugeno fuzzy logic method—this

study's purpose using it because of the suitability of

the problems described above. Sugeno's fuzzy logic

has a rule in the form of IF-THEN to determine the

desired result in using nutrient water conditions for

hydroponic cayenne pepper. This research aims to

monitor the quality of hydroponic water in real-time

and to produce a tool in the form of an IoT-based

hydroponic system. The decision results from fuzzy

logic calculations of water temperature are used for:

Automating on/off the water pump; Automating the

administration of nutrient concentrations; And

automating the administration of compounds to

neutralize the pH of the water.

2 LITERATURE REVIEW

2.1 Hydroponics

According to Sardare in (Dudwadkar et al., 2020)

hydroponics is the process of cultivating plants that

do not use soil media but water. Hydroponic plants

can be grown on a household scale as a hobby or a

large scale for commercial purposes. Cultivating this

plant does not require a large area of land. It can also

be done in the yard, on the house's terrace, or in a

greenhouse. Some hydroponic experts suggest

several advantages of the hydroponic system

compared to conventional farming, including more

efficient land use, plants growing without using soil,

no risk for continuous planting throughout the year,

higher and cleaner production quantity and quality,

and fewer human resource requirements. , the use of

fertilizers and water is more efficient, pest and disease

control is more manageable, and the selling price of

crop products is higher than non-hydroponic

products.

2.2 Hydroponic Nutrient Water

Hydroponic nutrient water is a mixture of water with

soluble inorganic minerals used as a nutrient provider

by plants. Plants need 16 nutrients/nutrients for

growth from air, water, and fertilizer. These elements

are carbon (C), hydrogen (H), oxygen (O), nitrogen

(N), phosphorus (P), potassium (K), sulfur (S),

calcium (Ca), iron (Fe), magnesium (Mg), boron (B),

manganese (Mn), copper (Cu), zinc (Zn),

molybdenum (Mo) and chlorine (Cl) (Agricultural

Research and Development Agency, 2019). Two

crucial factors in a nutrient solution formula are the

composition of the solution and the concentration of

the solution. These two factors greatly determine crop

production. Each type of plant requires a balance of

the amount and composition of the nutrient solution

and different concentration levels (Swastika et al.,

2017).

Every liquid has TDS (Total Dissolved Solid),

acidity (pH), and temperature. Total Dissolved Solid

(TDS) shows the number of solids dissolved in

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1044

nutrients as measured from the TDS meter. Liquid

objects also have a degree of acidity written pH

(power of hydrogen). pH is used to express a

solution's acidity or alkalinity level. The pH of the

nutrient water is kept in the range of 5 to 7 to get good

results and tends to be acidic (Swastika et al., 2017).

Indicators of good nutrient water can also be seen in

the temperature of the water. The ideal temperature

for good nutrient water for plants is 18 – 28°C.

Temperatures too high will make the plants wither

quickly (Firdausyah et al., 2022).

2.3 Cayenne Pepper

Chili is a plant classified as a member of the genus

Capsicum. Chili is a food ingredient that is needed by

the community. Chili is commonly used as a cooking

ingredient and as a healthy plant. Chili also contains

nutrients that are indispensable for human health

(Afrilia, 2017). The cultivation of chili plants in

Indonesia is very diverse. Not only planted on

extensive land but also a narrow land, such as in the

yard of the house planted in pots and polybags or

planted in a hydroponic system. Cayenne pepper can

be grown hydroponically using the Dutch bucket

system. Here are the parameters/average temperature,

nutrient levels, and pH in the growth of hydroponic

chili plants.

Table 1: Parameters of Hydroponic Chili Plant Cultivation

Needs.

Parameters

Normal level

Temperature

18 – 28oC

Nutrition

500 – 2500 ppm

pH

5 - 7

2.4 Fuzzy Logic

Fuzzy logic was first introduced by a researcher at the

University of California, Barkley, in the field of

computer science named Prof. Lutfi A. Zadeh in 1965

(Adiguna, 2017). The difference between digital logic

and fuzzy logic is the degree of membership which

has a value of zero to one, while digital logic only has

a value of 0 or 1 which means "yes" or "no". Fuzzy

logic can explain an uncertainty phenomenon in a

mathematical model (Hariyadi, n.d.). Fuzzy divides

the degree of membership and truth on the interval

[0,1], which is something that can be partially true

and partially false at the same time. Fuzzy logic

translates a quantity described using language

(linguistics). For example, the magnitude of the TDS

value in ppm is expressed as very low, low, normal,

high, and very high. The advantages of fuzzy logic

are its ability to model very complex nonlinear

functions, easy-to-understand logic concepts, and

flexible use.

2.5 Internet of Things

Internet of Things is a modern and latest technology

that allows every electronic device to be controlled,

communicate, and exchange information between

other devices through the internet network (Ciptadi &

Hardyanto, 2018). Every device connected to the

internet can exchange data and information. IoT can

also virtualize anything tangible onto the internet.

Another advantage of IoT is that it can monitor a

device that works remotely by connecting it to the

internet and then using other devices such as

smartphones. Not only can it be used to watch, but

IoT also acts as a medium for remote control of

working devices. The function of IoT is to facilitate

human work, increase work efficiency, and increase

work productivity.

2.6 Website

A website is an application stored on a server

computer that is accessed via the internet. According

to Yeni Susilowati, a website has several pages with

interrelated topics between one page and another.

Websites are generally built using HTML and CSS

programming languages to beautify the appearance of

a page (Reizandi, 2019). The contents of the website

pages vary and can contain text or text, images,

videos, animations, or a combination of one another.

Data from the website is stored in a structured

database. Someone who wants to access a web page

must type the URL in a browser.

3 DESIGN METHODOLOGY

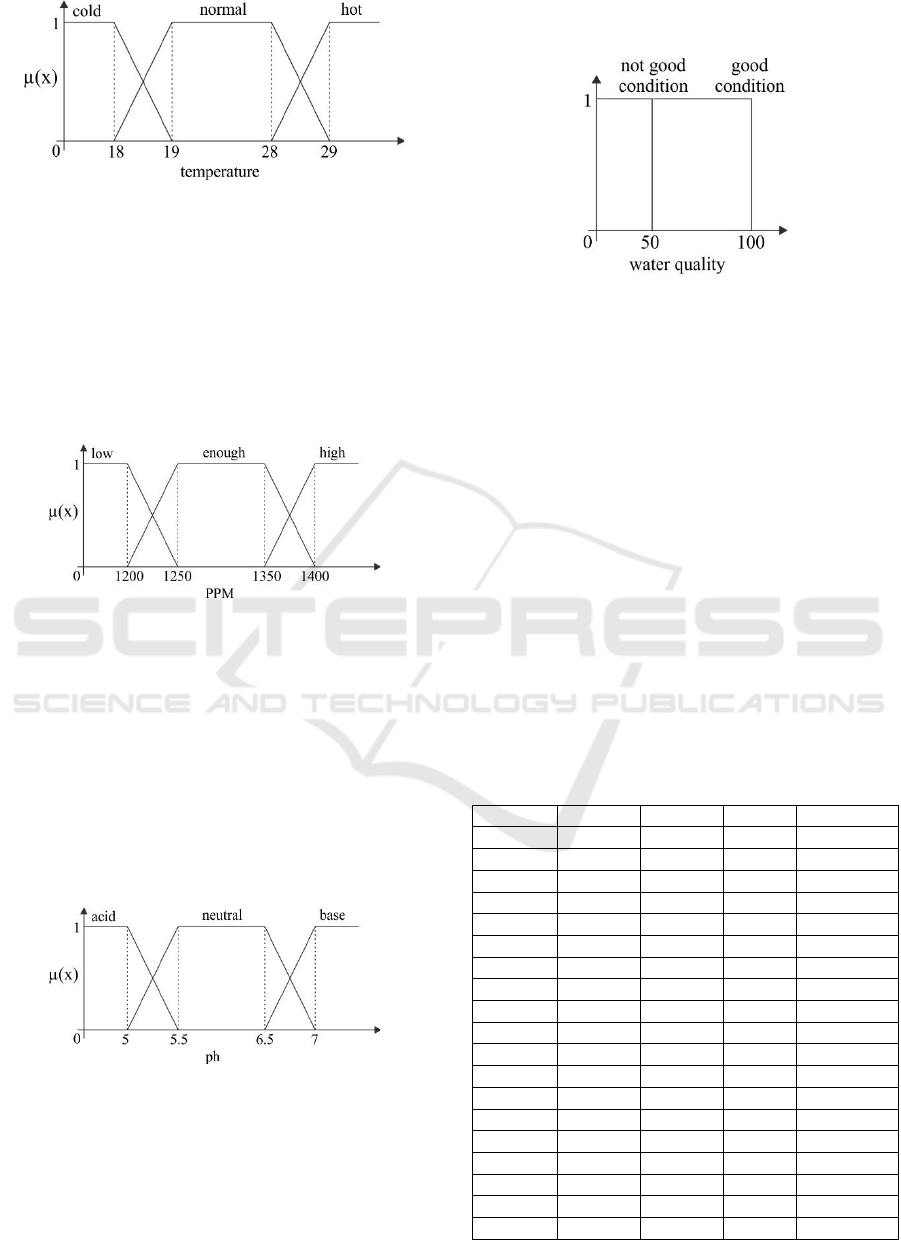

3.1 Fuzzy Membership Function

This study uses a fuzzy logic method to determine the

nutritional water quality of hydroponic chili plants,

whose value is obtained from the readings of three

sensors. The variables of this study were water

temperature, nutrient content (ppm), and acidity (pH).

Water temperature has a fuzzy set: cold, average, and

hot. Nutrient levels have a group: low, sufficient, and

high. The degree of acidity or pH has a fuzzy set:

acidic, neutral, and essential. The collection of each

variable described above is presented as a graphic

diagram of the group of fuzzy membership functions.

Hydroponic Nutrition Water Quality Identification System on Cayenne Pepper Using Fuzzy Method Based on IoT

1045

Figure 1: Water Temperature Chart.

If the temperature is too hot or more than 29 °C,

the nutrient water pump from the reservoir will work

to cool the water in the pot. The best average water

temperature as nutrient water is in the range of 18 –

29 °C. However, if the temperature is too cold or

below 18 °C, the system does not perform a

command, and the nutrient water heating process

does not occur in the reservoir.

Figure 2: Water Ppm Chart.

The water ppm graph is obtained from the data

regarding the relationship between water ppm and the

addition of ab mix nutrient water or the addition of

water. The picture above shows that the ppm level

was entirely from 1200 to 1400. The ppm is adjusted

according to the age of the chili plant. If the ppm is

too high or more than specified, the water pump will

work to lower the nutrient levels. However, if the ppm

is too low or below the set, the system will add a mix

of nutrients to the nutrient water bath.

Figure 3: Water pH Chart.

The pH graph of the water is obtained from the

data on the relationship between the pH of the water

and the neutralization of the acidity of the nutrient

water. The neutral pH of the nutrient water is in the

range of 5 – 7. The system will add alkaline

compounds to neutralize the nutrient water if the pH

is too acidic. However, the system will add a sour

mixture if the pH is too alkaline or above 7.

Figure 4: Water Quality Output Chart.

Water quality is declared less good if it is in values

0-50. From this value, various actions are taken

according to predetermined rules. Nutrient water

conditions are announced well if the fuzzy calculation

results show a value range of more than 50 to 100.

Based on interviews with experts, the author's

observations showed that there are two kinds of

nutritional water quality for hydroponic chili plants,

namely water quality with good conditions and water

quality with poor conditions. Good water conditions

are temperatures in the normal range and ppm in an

acceptable range. While an acid or alkaline state can

tolerate it, the IoT system still gives orders to the

actuator to neutralize it.

3.2 Determination of Nutritional Water

Quality

Table 2: Determination of Nutritional Water Quality

Conditions.

Rule

Temp

Ppm

Ph

Quality

[R1]

Cold

Low

Acid

Not Good

[R2]

Cold

Low

Netral

Not Good

[R3]

Cold

Low

Alkali

Not Good

[R4]

Cold

Fair

Acid

Not Good

[R5]

Cold

Fair

Netral

Not Good

[R6]

Cold

Fair

Alkali

Not Good

[R7]

Cold

High

Acid

Not Good

[R8]

Cold

High

Netral

Not Good

[R9]

Cold

High

Alkali

Not Good

[R10]

Normal

Low

Acid

Not Good

[R11]

Normal

Low

Netral

Not Good

[R12]

Normal

Low

Alkali

Not Good

[R13]

Normal

Fair

Acid

Good

[R14]

Normal

Fair

Netral

Good

[R15]

Normal

Fair

Alkali

Good

[R16]

Normal

High

Acid

Not Good

[R17]

Normal

High

Netral

Not Good

[R18]

Normal

High

Alkali

Not Good

[R19]

Hot

Low

Acid

Not Good

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1046

Table 2: Determination of Nutritional Water Quality

Conditions.(cont.)

Rule

Temp

Ppm

Ph

Quality

[R20]

Hot

Low

Netral

Not Good

[R21]

Hot

Low

Alkali

Not Good

[R22]

Hot

Fair

Acid

Not Good

[R23]

Hot

Fair

Netral

Not Good

[R24]

Hot

Fair

Alkali

Not Good

[R25]

Hot

High

Acid

Not Good

[R26]

Hot

High

Netral

Not Good

[R27]

Hot

High

Alkali

Not Good

3.3 Actuator Motion Determination

On Arduino, each variable's fuzzy logic calculation

process is carried out without relating to other

variables. The calculation is done to determine the

motion of the actuator so that the quality of nutrient

water is always in good condition. The following is a

table for deciding actuator motion in an IoT system.

Table 3: Actuator Motion Determination.

Temperature

Cold

Normal

Hot

PPM

&

PH

Low

& Acid

Add

nutrition,

add KOH

Add

nutrition,

add KOH

Add

nutrition,

add KOH,

turn on the

nutrition

water pump

Low &

Netral

Add nutrition

Add nutrition

Add nutrition,

turn on the

nutrition

water pump

Low

& Alkali

Add nutrition,

Add HCl

Add nutrition,

Add HCl

Add nutrition,

Add HCl, turn

on the

nutrition

water pump

Fair

& Acid

Add KOH

Add KOH

Add KOH,

turn on the

nutrition

water pump

Fair

& Netral

No action

No action

Turn on the

nutrition

water pump

Fair

& Alkali

Add HCl

Add HCl

Add HCl, turn

on the

nutrition

water pump

High

& Acid

Add water,

add KOH

Add water,

add KOH

Add water,

add KOH,

turn on the

nutrition

water pump

High

& Netral

Add water

Add water

Add air, turn

on the

nutrition

water pump

High

& Alkali

Add water,

Add HCl

Add water,

Add HCl

Add water,

add HCl, turn

on the

nutrition

water pump

3.4 Plant Nutrient Needs

The nutritional needs of hydroponic plants are

directly proportional to the age of the plant. The older

the chili plant, the more dietary needs are. The

following is a table of the nutritional needs of

hydroponic cayenne pepper plants. The following is a

table of the dietary needs of hydroponic cayenne

pepper plants, along with the age of the plant.

Table 4: Hydroponic Chili Nutrition Needs.

Plant Age (HST)

Nutritional needs

(ppm)

8 – 14 HST

500 – 700

15 – 21 HST

700 – 1000

22 – 28 HST

1000 – 1200

29 – 35 HST

1200 – 1400

36 – 42 HST

1200 – 1400

43 – 49 HST

1400 – 1600

50 – 56 HST

1600 – 1800

57 – 63 HST

1800 – 2000

64 – and so on

2000 – 2200

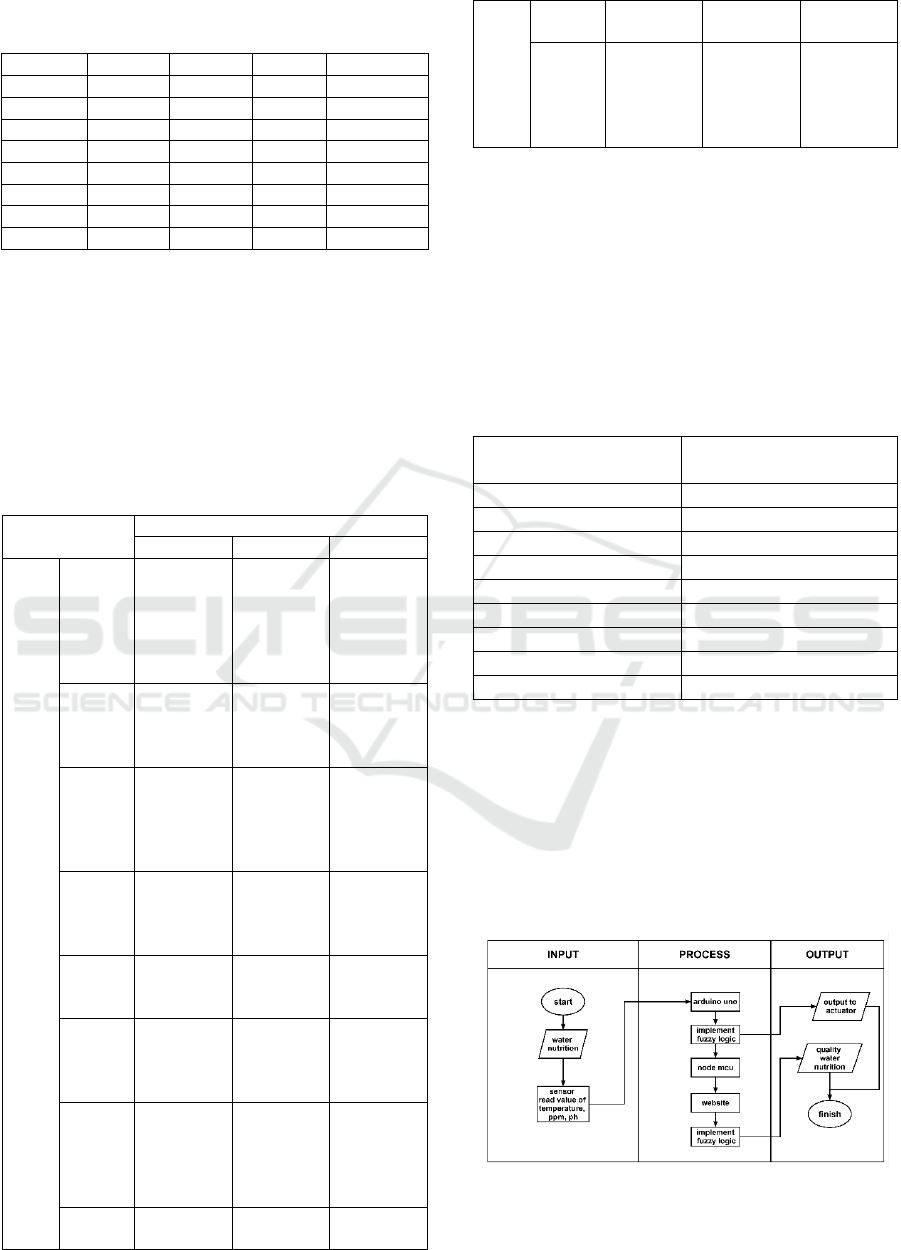

3.5 Research Stages

The following is a flow chart of the system's work,

illustrated in the image below. The diagram explains

the input flow in the form of sensor readings, part of

the process, namely calculations with fuzzy logic, and

output commands to the actuator and sending sensor

reading values to the website.

Figure 5: How the System Works.

Hydroponic Nutrition Water Quality Identification System on Cayenne Pepper Using Fuzzy Method Based on IoT

1047

The system's first part is the reading of

temperature sensor values, TDS, and pH on

hydroponic nutrients. The units for each data are:

TDS has units of ppm (parts per million); PH has

units of pH (Power of Hydrogen); The author takes

units of degrees Celsius (°C) for temperature data.

The three sensors are immersed in the nutrient

water in the sensor reading container. The sensor

placement should be protected from direct sunlight so

that the sensor usage time becomes longer. The sensor

readings are received by Arduino and then processed

using fuzzy logic.

The calculation process is carried out starting

from the fuzzification process. Fuzzification is

converting actual values into a fuzzy form using a

membership function. The three sensor values are

searched for the membership function value or its

Miu(). Then the inference process is carried out;

namely, the application of the IF THEN ELSE rule

based on the knowledge base of the expert. After that,

defuzzification changes back from the fuzzy value to

a firm value that will be used as a determinant of the

actuator's work. Temperature data is also sent to the

MCU Node, which is then sent to the website.

The output of the Fuzzy calculation is in the form

of nutritional water quality conditions on the website.

On this website, farmers can monitor whether the

quality of nutrient water is in good condition or not.

Arduino also processes sensor data into fuzzy logic in

response to actuators. The calculation results

determine if, for example, the temperature is included

in the too high category. Arduino will give an order

to pump nutrient water to drain water with a lower

temperature in the reservoir. Or if the TDS sensor

readings find that the nutrient level is too low, the

system will drain the nutrients to the pool.

3.6 IoT Devices Flowchart

The first IoT system workflow is the reading of

temperature, TDS, and pH sensors in nutrient water.

The results of the sensor readings are sent to Arduino,

and then the calculation process is carried out with

fuzzy logic. Each sensor value is calculated fuzzy to

determine the actuator output to be run. Arduino will

make corrections to stabilize the condition of the

nutrient water so that it is always in good condition.

Figure 6: IoT Devices Flowchart.

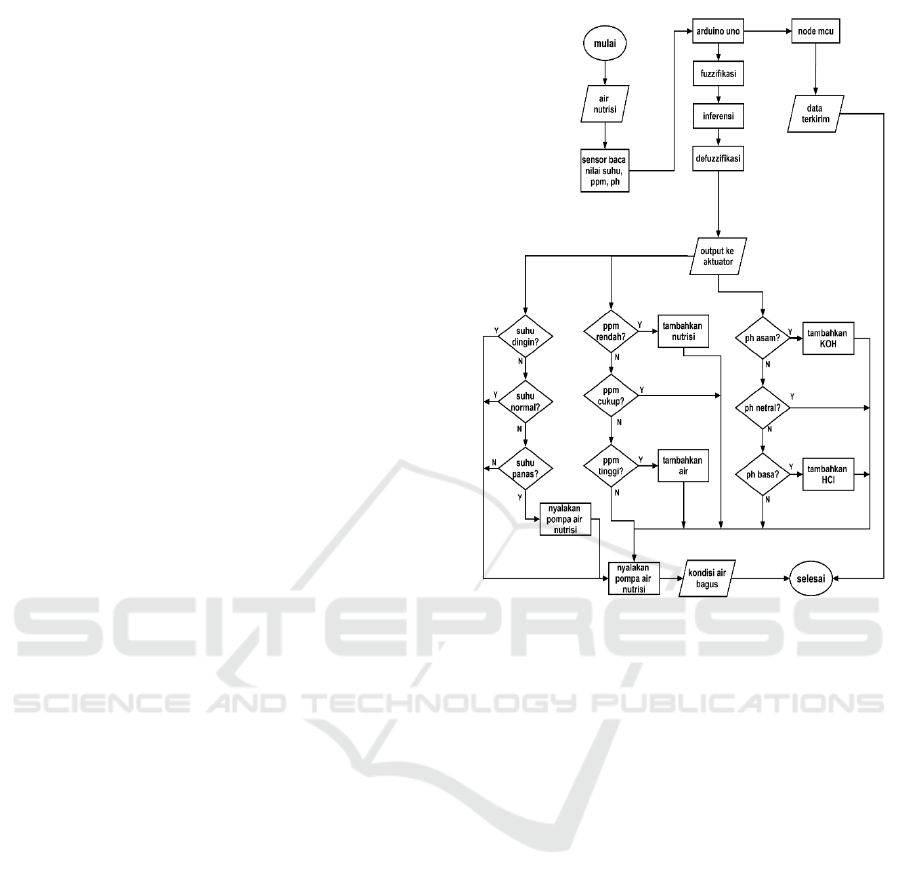

3.7 Website System Flowchart

The system's workflow on the first website is admin

or farmer logging in on the login page by filling in the

username and password. If appropriate, it will enter

the dashboard page. Admins or farmers can see the

current condition of nutrient water quality and graph

each sensor reading sent to the website. The admin

can process (add, change, delete) the ppm data on the

ppm processing data page. The fuzzy calculation page

displays the results of calculations with fuzzy logic

for determining nutrient water quality.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1048

Figure 7: Website System Flowchart.

3.8 Design of Iot Devices

The design of IoT tools will be described in this

section. Electronic components consist of Arduino as

a microcontroller for sensor readings and a command

center for the actuator.

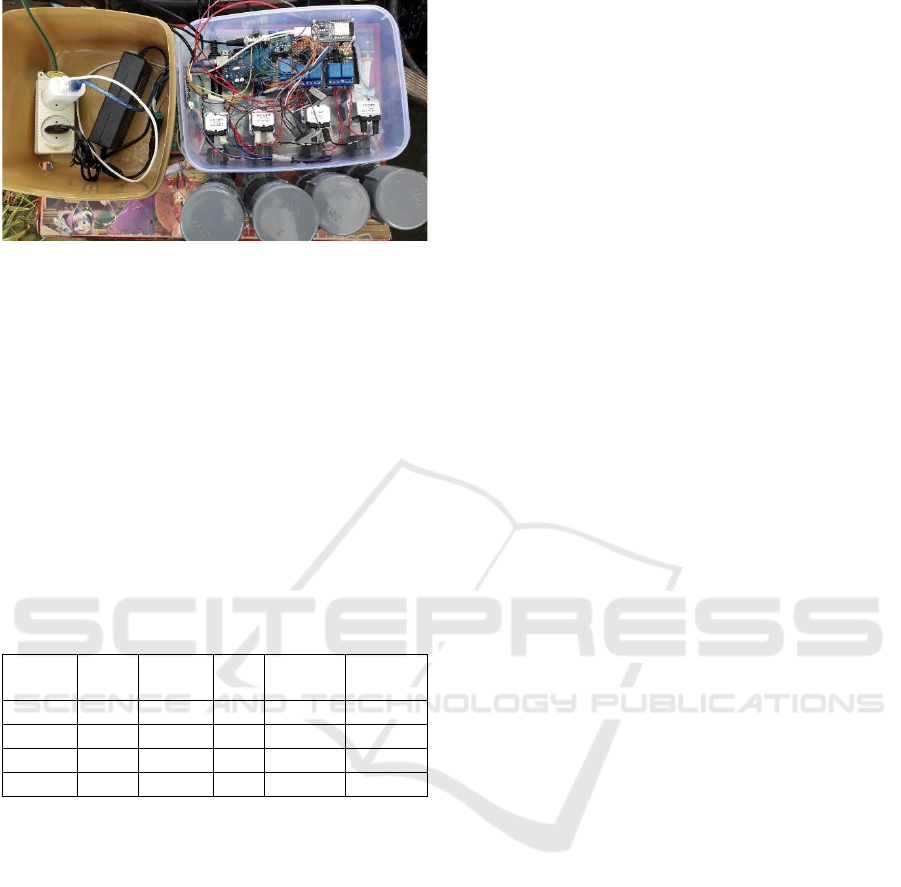

Figure 8: Desain Alat IoT.

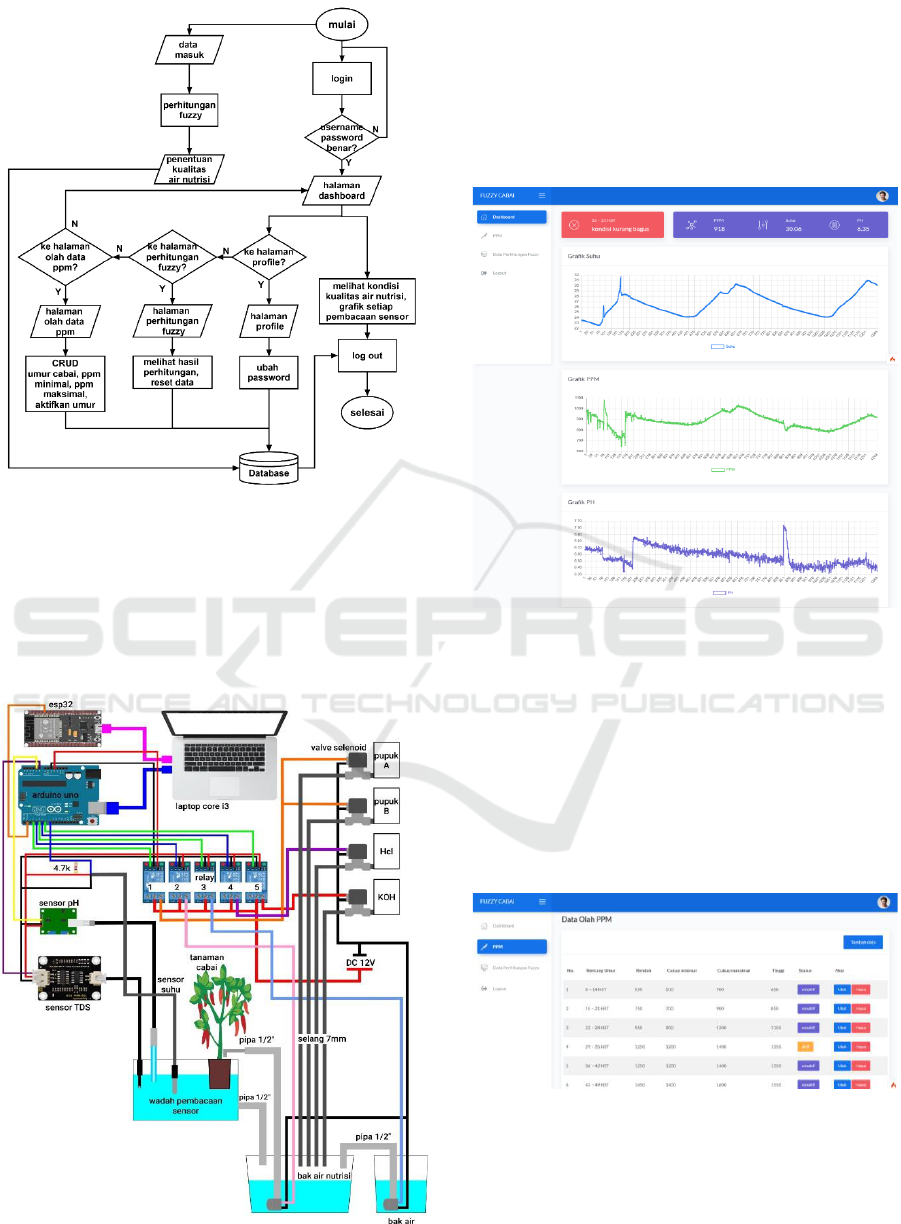

4 RESULTS AND DISCUSSIONS

The following is a website page to monitor the quality

of hydroponic nutrient water for cayenne pepper

plants. There are three graphs of each sensor reading,

and the results of the last sensor readings and the

nutritional water quality are also displayed.

Figure 9: Dashboard Page.

This ppm data processing page is helpful for

processing ppm data that is adjusted to the planting

age of chili. Admins or farmers can process the data,

such as adding, changing, and deleting data. This

page contains the age range of chili peppers and the

minimum – maximum levels of nutrients that plants

need. Farmers can activate it via a button, and the

fuzzy logic calculation process will automatically

follow the selection of the active ppm range.

Figure 10: Ppm Processed Data Page.

Hydroponic Nutrition Water Quality Identification System on Cayenne Pepper Using Fuzzy Method Based on IoT

1049

Figure 11: IoT Device System.

Figure 11 is a ready-made IoT tool. Electronic

components such as Arduino, ESP32 MCU nodes,

and how many relays are in the white case. Between

electronic components are connected with jumper

cables. The solenoid valve connected to the relay is

also located in a white container, whose water flows

from a line of pipes. The brown case has a 12V DC

ADAPTER and a 5V DC ADAPTER 2 USB ports.

The 12V DC adapter is used to supply power to two

pumps and four solenoid valves. ADAPTER DC 5 V

2 USB ports control the Arduino and the ESP32 MCU

node. All ADAPTERS are connected to 220V AC

home power.

Table 5: Pengujian Akurasi Alat.

Var.

Man.

Sensors

Dev.

Dev. (%)

Accu.

(%)

Temp

29,9

28,06

1,84

6,55

93,45

Ppm

506

497

9

1,81

98,19

PH

6

6.65

0,65

10,83

89,17

Av.

3,83

6,39

93,61

The table above results from testing the accuracy

of IoT tools compared to manual measuring tools.

The most significant difference between reading the

sensor and reading from a manual measuring

instrument is in ppm, which is 9. However, in this

case, it is in the range of 500, much higher than the

other variables. The temperature and pH variables are

in the field of tens and units values (temperature in

the range of 28 - 29, pH in the range of 6 - 7). So if it

is calculated based on proportions, reading the ppm

value has the smallest value of 1.81% and has the

highest accuracy of 98.19%. The accuracy of reading

the pH sensor on the measurement of the measuring

instrument showed the lowest result, 89.17%, with a

difference of 10.83%. It happens because the sensor

has been used for a long time and may be damaged,

or it could be from reading a manual measuring

instrument that uses litmus paper, not a pH meter, to

make it more accurate. At the IoT accuracy testing

stage, the accuracy value is 93.61%, so the IoT tool

runs quite accurately.

5 CONCLUSIONS

This research has succeeded in developing a

Hydroponic Nutrition Water Quality Identification

System. Determination of nutritional water quality of

hydroponic using fuzzy logic method. The nutrition

content was increased successfully by giving

commands via Arduino to the actuator. The actuator

activates and deactivates the water pump that already

contains the required nutrients. The results of testing

the IoT system send data to the website successfully,

and then it is processed using fuzzy logic. This study

found that the average accuracy of the three sensors

was 93.61%. This research can be extended to the

other plant case for further work. So the variable can

be variated.

ACKNOWLEDGEMENTS

We did all stages of this research with the funding

support of the research and community service center

of Politeknik Negeri Jember. This research take place

at KSI Laboratory, so thanks to the Information

Technology Department of Politeknik Negeri Jember

for providing all the facilities.

REFERENCES

Afrilia. (2017). Beragam Jenis Cabai di Dunia.

http://kaltim.litbang.pertanian.go.id/ind/index.php?opti

on=com_content&view=article&id=880&Itemid=59

Agustianto, K., Wardana, R., Destarianto, P., Mulyadi, E.,

& Wiryawan, I. G. (2021). Development of automatic

temperature and humidity control system in kumbung

(oyster mushroom) using fuzzy logic controller. IOP

Conference Series: Earth and Environmental Science,

672(1). https://doi.org/10.1088/1755-

1315/672/1/012090

Aprillia, S., & Myori, D. E. (2020). Pengontrolan Electro

Conductivity pada Larutan Nutrisi Hidroponik Berbasis

Arduino. JTEIN: Jurnal Teknik Elektro Indonesia, 1(2),

261–265. https://doi.org/10.24036/jtein.v1i2.89

Ciptadi, P. W., & Hardyanto, R. H. (2018). Penerapan

Teknologi IoT pada Tanaman Hidroponik

menggunakan Arduino dan Blynk Android. Jurnal

Dinamika Informatika, 7(2), 29–40.

Dudwadkar, D. A., Das, T., Suryawanshi, S., Dolas, R., &

Kothawade, T. (2020). Automated Hydroponics with

Remote Monitoring and Control using IoT.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1050

International Journal of Engineering Research And,

V9(06). https://doi.org/10.17577/ijertv9is060677

Firdausyah, M. J. D., Rusimamto, P. W., & Suprianto, B. E.

(2022). Sistem Pengendali Suhu Air Nutrisi Pada

Hidroponik NFT Berbasis PID Controller. Jurnal

Teknik Elektro, 11(1), 117–125.

Hariyadi, M. F. (n.d.). Implementasi Model Fuzzy untuk

Pengaturan Irigasi Tetes berbasis Mikrokontroler.

FAKULTAS ILMU KOMPUTER.

Hartadi, D. R., Agustianto, K., Destarianto, P., Wardana,

R., Kustiari, T., Wiryawan, I. G., & Mulyadi, E. (2022).

Adaptive Temperature And Humidity Control System

on Kumbung Mushroom using Fuzzy Neural Network

Algorithm. IOP Conference Series: Earth and

Environmental Science, 980(1), 012063.

https://doi.org/10.1088/1755-1315/980/1/012063

Rahmadhani, L. E., Widuri, L. I., & Dewanti, P. (2020).

Kualitas Mutu Sayur Kasepak (Kangkung, Selada, Dan

Pakcoy) Dengan Sistem Budidaya Akuaponik Dan

Hidroponik. Jurnal Agroteknologi, 14(01), 33.

https://doi.org/10.19184/j-agt.v14i01.15481

Reizandi, F. (2019). Aplikasi Berbasis Website.

https://bbpombandung.app/kms/artikel/2/aplikasi-

berbasis-website

Setyo Wibowo, N., Muknizah Aziziah, I Gede Wiryawan,

& Eva Rosdiana. (2022). Desain Sistem Informasi

Monitoring Nutrisi Tanaman Hidroponik Kangkung

Dengan Menggunakan Metode Regresi Linear. Jurnal

Ilmiah Inovasi, 22(1), 51–58.

https://doi.org/10.25047/jii.v22i1.3115

Swastika, S., Yulfida, A., & Sumitro, Y. (2017). Budidaya

Sayuran Hidroponik Bertanam Tanpa Media Tanah.

Balai Pengkajian Teknologi Pertanian (BPTP)

Balitbangtan Riau, Badan Penelitian Dan

Pengembangan Pertanian, Kementerian Pertanian, 31.

Wibowo, N. S., Aziziah, M., Wiryawan, I. G., & Rosdiana,

E. (2022). Implementasi Metode Regresi Linier Pada

Rancang Bangun Sistem Informasi Monitoring Nutrisi

Tanaman Hidroponik Kangkung. JTIM : Jurnal

Teknologi Informasi Dan Multimedia, 4(1), 13–24.

https://doi.org/10.35746/jtim.v4i1.186

Hydroponic Nutrition Water Quality Identification System on Cayenne Pepper Using Fuzzy Method Based on IoT

1051