Design of Multi Device Infusion Control and Monitoring System

Based on Internet of Things

Ruminto Subekti, Nur Jamiludin Ramadhan

a

and Riyan Septiana

Jurusan Teknik Otomasi Manufaktur dan Mekatronika, Politeknik Manufaktur Bandung, Jalan Kanayakan No. 21,

Dago, Coblong, Bandung, 40135, Indonesia

Keywords: Infusion, IoT, PID, Medical Device.

Abstract: The COVID-19 pandemic is spreading in almost all parts of the world. This situation requires the community

to comply with the efforts that have been made in various activities, including activities in hospitals. One of

these activities is the provision of nutrition to patients. Problems that are often found in the infusion process

include air bubbles in the hose, delays in changing the infusion flask, clogged liquid, excessive volume, and

the flowrate entering the body is not appropriate. The method used to build this tool is waterfall. Testing this

tool uses hardware consisting of ESP32 and Arduino nano as controllers, optocoupler sensors as droplet

detectors, bubble sensors as air bubble detectors, nextion and nodered as interfaces with users, servo motors

as hose presses, and buzzers as alarm indications. The findings show that droplet detection has an accuracy

rate of 100%, flowrate calculation has an accuracy of 94.52%, volume calculation has an accuracy of 95.53%,

hazard detection such as bubbles, exhausted liquid, clogged liquid, excess volume, and incorrect flowrate has

an accuracy of 100%, PID controller has parameters Kp = 0,057499, Ki = 0,099194, Kd = 0,0047985, the

control and monitoring process using nextion and nodered runs well.

1 INTRODUCTION

The COVID-19 pandemic is spreading in almost all

parts of the world. Recorded on December 27, 2021,

COVID-19 cases have reached 279,114,972 cases

with the number of deaths reaching 5,397,580.

(WHO, 2021). This has resulted in various efforts

made by the government to suppress the spread of

COVID-19 cases. These efforts include lockdowns,

maintaining distance, washing hands with soap and

using masks. This situation requires the community

to comply with the efforts that have been made in

various activities, including activities in hospitals.

One of these activities is providing nutrition to

patients which serves to maximize the healing process

for patients (Pitri et al., 2019). The provision of

nutrition is carried out through infusion therapy.

Hospital conditions that are full during a pandemic

result in the need for infusion therapy being very

important to do. To perform infusion therapy, the

nurse will count the droplets along with looking at the

clock to set the flowrate. This arrangement is carried

out because the impact of infusion dosing that is not

a

https://orcid.org/0000-0002-0909-0503

in accordance with patient needs can result in

endema, shortness of breath, high blood pressure, and

decreased urine quality (Mordhoko and Satria, 2013);

(Iskandar et al., 2018).

From these problems, it is found that several

previous studies have been conducted, including by

Primahayu (Primahayu et al., 2017) to create an

infusion fluid monitoring system. Red infusion fluid

in the flask is detected by image processing using a

camera. However, this system still has shortcomings,

namely infusion fluids are generally colorless, this

makes reading infusion fluids difficult to do. Another

research was conducted by D. Natalia (Natalia et al.,

2016) which resulted in an infusion monitoring tool

to determine the volume of infusion fluid by detecting

droplets in the chamber. However, in its application,

this tool still has shortcomings, namely that it cannot

be monitored remotely by nurses because it uses

cables.

The analysis results from previous studies did not

find any air bubble sensor in the system. Air bubbles

should not contaminate the patient's body because it

will poison the blood and will also cause embolism or

Subekti, R., Ramadhan, N. and Septiana, R.

Design of Multi Device Infusion Control and Monitoring System Based on Internet of Things.

DOI: 10.5220/0012056500003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 1035-1042

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1035

the entry of foreign objects into the lungs (Kurrahman

, 2017). In addition, the results of the analysis of

previous research can be examined and improved in

terms of system deficiencies and combined into a new

system design that is better and more developed.

Therefore, this study was proposed which is expected

to help ease the burden on nurses, especially during

the COVID-19 pandemic and provide better handling

to patients who need infusion therapy.

2 PROBLEM FORMULATION

AND PROBLEM SOLVING

The lack of effective infusion facilities in middle-

class hospitals during the COVID-19 pandemic has

made it difficult for nurses to identify errors that

occur in patient infusions such as flowrate deviations,

excess volume values, fluid blockage, fluid depletion,

and air bubbles in patient infusion tubes. In addition

to the flowrate instability in the infusion, there is a

risk of worsening the patient's condition. Nurses must

also monitor the condition of multiple infusions

without having to be in physical contact with the

patient for a long time.

To overcome these problems, a study was made in

the form of 2 infusion devices that can perform the

function of controlling the flowrate value by pressing

on the hose and monitoring hazardous conditions in

patient infusion, including: deviation of flowrate

value, deviation of volume value, infusion fluid runs

out, clogged infusion fluid, and detection of air

bubbles in the infusion hose which will be displayed

in the Human Machine Interface (HMI). The HMI

will display the sensor data sent by the

microcontroller. In addition, the microcontroller also

sends data to the cloud database in real time through

the application server which will be displayed on the

monitor screen in the nurse's room.

2.1 System Design

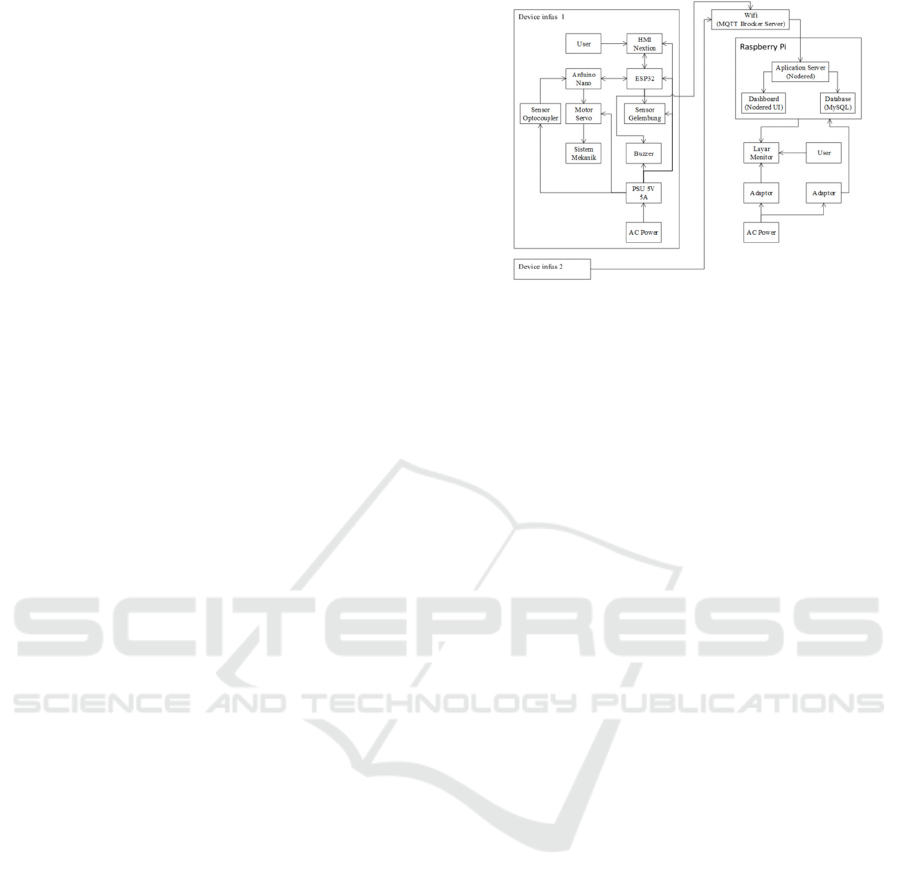

From the system architecture diagram in Figure 1, it

can be seen that the data transmission protocol used

in the Internet Of Things (IoT) system is MQTT

Brocker to perform a monitoring system for 2 infuse

devices on the monitor screen. The monitor screen

will display the Nodered UI IP installed on the

raspberry pi. The Nodered UI gets data from the

Nodered application server which will process all

data, receive data from the ESP32 microcontroller

and send data to MySQL. The infusion device itself

uses a bubble sensor to detect air bubbles in the

Figure 1: System Architecture Diagram.

infusion hose, an optocoupler sensor to detect

droplets and volume of infusion fluid, a servo motor

to clamp the infusion hose, a buzzer as an indication

in case of danger, and Nextion as an HMI. Arduino

nano and ESP32 have different roles, Arduino nano

will receive a signal from the optocoupler sensor then

will calculate the flowrate and volume values. From

the calculation of the flowrate value obtained,

Arduino nano will calculate the Proportional

Differential Integral (PID) algorithm to determine the

position of the servo motor. After that, the system will

send the data to ESP32 for further processing. ESP 32

itself will receive data from Arduino nano, then create

an alarm algorithm for infusion fluid administration.

ESP32 will receive a signal from the bubble sensor

then send a signal to the buzzer as an indication of

failure when the alarm algorithm works. In addition,

ESP32 will also send data to the HMI, server and

Arduino nano. All devices on the infuse device get a

power supply from an alternating current (AC) to

direct current (DC) adapter.

2.1.1 Flow Diagram

From the system flow diagram in Figure 2, it is known

that the system starts when the raspberry pi is turned

on and connected to Wi-Fi so that it can configure it

to nodered. After that the switch on the infuse device

is turned on and the ESP32 microcontroller will be

connected to Wi-Fi. The process continues by

entering parameters and pressing the start button on

the Nextion HMI. After that, the process of reading

the infusion liquid droplets by the optocoupler sensor

begins. When there are bubbles in the infusion hose,

it will cause a danger condition so that it sends a

signal to the buzzer to activate. When the buzzer is

active, the user can press the 'mute' button to turn off

the buzzer. When there are no drops within a certain

period of time, it will also cause a danger condition

and activate the buzzer again. When there is no

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1036

danger condition, the Arduino nano microcontroller

will calculate the flowrate and volume calculation

algorithm. Furthermore, the microcontroller will

calculate the control system from the flowrate

variable obtained to regulate the flow of liquid

through the speed of the servo motor. The final

process of the ESP32 microcontroller will send data

to the Nextion HMI and nodered server.

Figure 2: System Flowchart.

2.1.2 Electrical Design

Figure 3: Electrical Design.

As seen in Figure 3, this research uses 2

microcontrollers, namely Arduino nano and ESP32.

Both microcontrollers have their respective roles.

ESP32 is used to perform centralized data

communication between all elements. ESP32 will

communicate with HMI Nextion through Universal

Asynchronous Receiver Transmitter (UART) serial

data to display data and control parameters on the

infuse device. Then the parameter data will be sent to

Arduino nano to be processed. In addition, ESP32

will also send data to the server using MQTT broker.

While the Arduino microcontroller plays a role to

perform the control function using the control system.

Where the control system input is obtained from the

flowrate algorithm from the droplet reading results by

the optocoupler sensor while the control system

output will be used to move the servo position. Data

transmission between ESP32 and Nextion is done

through UART serial data. There are 3 data sent by

ESP 32, namely alarm, flowrate value, and volume

value. While Nextion will send 4 data, namely the

flowrate set, volume set, ON button and reset button.

In addition, data transmission is also carried out

between ESP32 and Arduino nano via UART serial

data. There are 4 data sent by ESP32, namely ON

condition, set flowrate, set volume, and reset

condition. While Arduino nano will send 3 data,

namely the flowrate value, volume value, and clogged

alarm condition.

2.1.3 PID Control System Design

The PID control system in this research is used to

control the infusion flowrate so that it can be aligned

with the manual input given by the Nextion HMI. PID

input is given from the calculation of the flowrate

calculation. In this study, the flowrate calculation was

obtained by determining how many drops of liquid in

one minute. Illustration of taking flowrate

Design of Multi Device Infusion Control and Monitoring System Based on Internet of Things

1037

calculations can be seen in Figure 4 below.

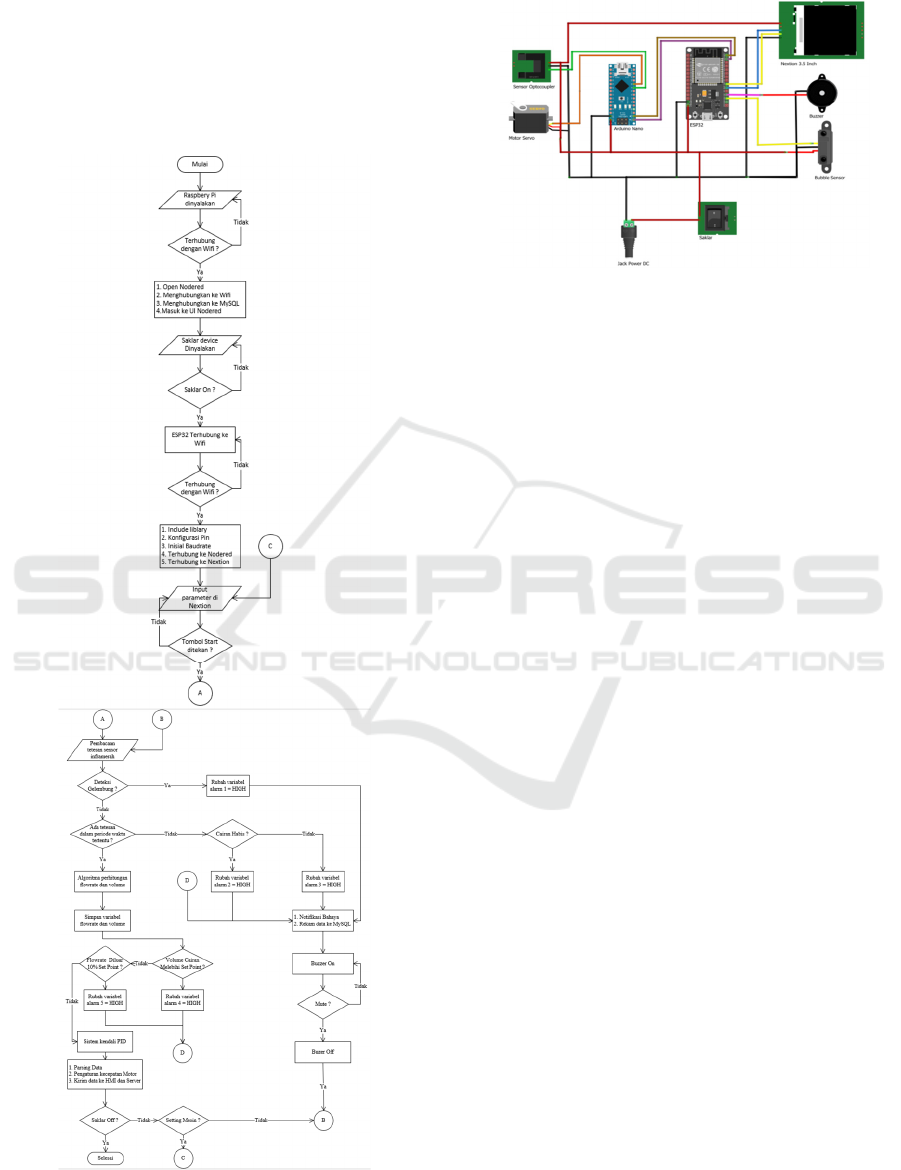

Figure 4: Flowrate Data Retrieval.

Where ∆T is the cycletime or time required to

complete one droplet. To determine the resulting

flowrate can be seen in the following equation (1).

𝑓

𝑙𝑜𝑤𝑟𝑎𝑡𝑒

𝑑𝑟𝑜𝑝𝑠

𝑚𝑖𝑛𝑢𝑡𝑒

60000

𝐶𝑦𝑐𝑙𝑒𝑡𝑖𝑚𝑒

(1)

Figure 5 is a block diagram design where the PID

setpoint is drops/minute. The setpoint will be

compared with the flowrate obtained from the plant

through the optocoupler sensor reading and will be

stored in the error variable. The variable will be sent

to the PID to be calculated based on the

predetermined formula.

Figure 5: Block Diagram of Control System.

Figure 6: Infusion Hose Pressing System Design.

The output of the PID will be used as pulse width

modulation (PWM) to drive the servo motor. The

servo motor will clamp the hose based on the angle of

emphasis, the smaller the angle given, the greater the

emphasis on the infusion hose so that the droplets will

be inhibited. Conversely, the greater the angle given,

the smaller the emphasis will be on the infusion hose

so that the droplets will flow quickly. This principle

will be controlled by PID. A picture of the mechanical

system on the hose emphasis can be seen in Figure 6.

3 RESULTS

3.1 HMI Display Testing

Figure 7: Implementation of HMI Nextion.

Figure 7 below shows the machine settings window.

Testing is done by doing a setpoint flowrate of 200

and a volume of 100. After pressing the 'OK' button,

the parameters under the machine settings change

according to the inputted set point. Testing is done by

pressing the start button to start the system. After that,

the flowrate and volume will be updated according to

actual conditions. In addition, there is a green

indicator to indicate the system is running.

3.2 Dashboard Display Testing

In Figure 8 below can be seen the super admin

window. Testing is done by activating the infuse

device and entering the set point on the HMI nextion.

The result is that the set point value and realtime value

of the flowrate and volume variables enter the super

admin dashboard.

Figure 8: Nodered Dashboard Implementation.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1038

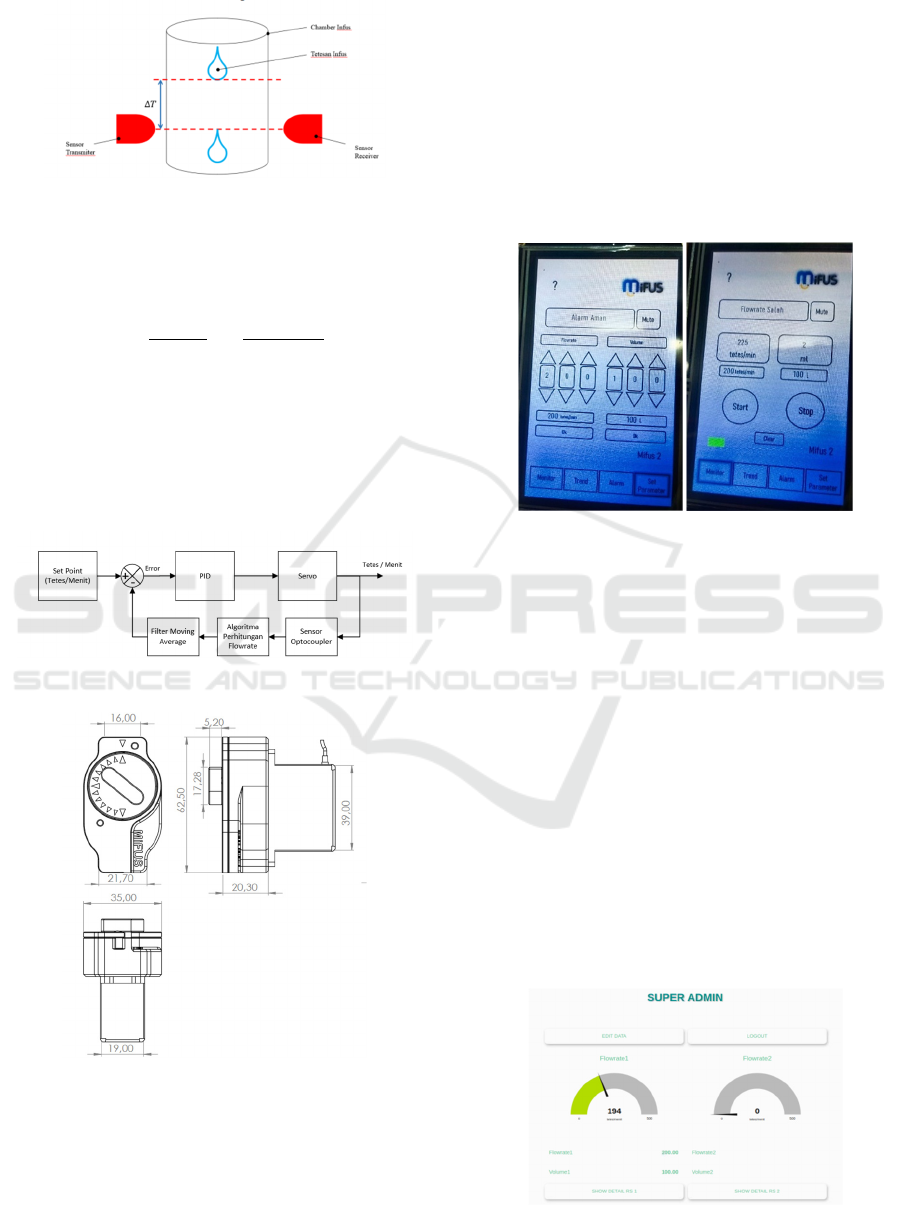

3.3 Testing Droplet Sensor Readings

Optocoupler sensor testing is carried out with the aim

of knowing the accuracy of sensor readings. Testing

is done using an Arduino Uno, optocoupler sensor

and voltage sensor. The following is a comparison

table.

Figure 9: Comparison Chart of Voltage Against Number of

Drops.

From the 100 sample data obtained based on Figure

9, it is known that when the optocoupler sensor is

active, the voltage will range from 2.96V to 3.45 V,

and when the sensor is not active, the sensor will have

a voltage ranging from 0V to 0.86V. In addition,

sensor testing is also carried out by comparing the

calculations in the algorithm with manual

calculations. The following is a comparison graph.

Figure 10: Comparison Chart of Number of Drops Sensor

Calculation and Manual Calculation.

Figure 10 is a comparison of the number of drops

detected by the optocoupler sensor and manual

calculation at a relatively medium speed and can be

seen with the human eye. Testing was carried out 5

times by taking sample data of 100 drops. The results

of each experiment show linear data between the

amount of liquid detected by the sensor and the

amount of liquid calculated manually. The difference

is obtained when the speed of the drops cannot be

seen by the human eye where the algorithm will

produce noise data. This can occur because there is a

delay of 50 ms in the sensor reading. So that with a

drop speed that is too fast, some drops of liquid are

not detected by the sensor. This is the case when the

sensor reading delay is reduced to 5 ms. This makes

the sensor not very accurate when detecting a

relatively medium or even slow drip speed. Because

the sensor will detect 2 to 3 times for one drop. With

a relatively moderate speed, it can be concluded that

the sensor reading has an accuracy of 100%.

3.4 Flowrate Accuracy Testing

Flowrate accuracy testing is done by comparing the

flowrate algorithm with the reading of the drip value

for 1 minute. the following is a table of flowrate

accuracy testing data.

Figure 11: Comparison Chart of Flowrate to Number of

Drops.

Figure 12: Comparison Chart of Filter Result Flowrate

against Number of Drops.

Figure 11 and Figure 12 are the comparison of

flowrate to the number of drops. The experiment was

conducted 5 times with different speeds. There are 2

data taken, namely flowrate data and filtered flowrate

data using the moving average method. The purpose

of using the moving average filter is to eliminate error

data that often appears. The algorithm will calculate

10 data samples and then average them. After

obtaining the 11th data, the 1st data will be discarded

so that there are still 10 data samples. The following

is the difference in errors generated with and without

using a moving average filter.

Design of Multi Device Infusion Control and Monitoring System Based on Internet of Things

1039

Table 1: Error Table of Filter and Non-Filter Flowrate.

Descript

ion

1st

data

2nd

data

3rd

data

4th

Data

5th

Data

avera

ge

Non

Filte

r

6,98% 5,71% 6,06% 16,00% 9,30% 8,81%

Filter 4,65% 5,71% 6,06% 4,00% 6,98% 5,48%

From Table 1 above, it can be seen that the error

obtained from the moving average filter results is

lower if without using the filter at all. The difference

occurs because there are some error data captured by

the system. In addition, sensor readings greatly affect

the delay time between droplets. From the

experiments that have been carried out, it can be

concluded that the reading of the flowrate value using

the moving average filter produces an accuracy of

94.52%.

3.5 Volume Accuracy Testing

Volume accuracy testing is done by comparing the

volume algorithm with the volume value reading

using the sensor. The following is a graph of the

experiment results.

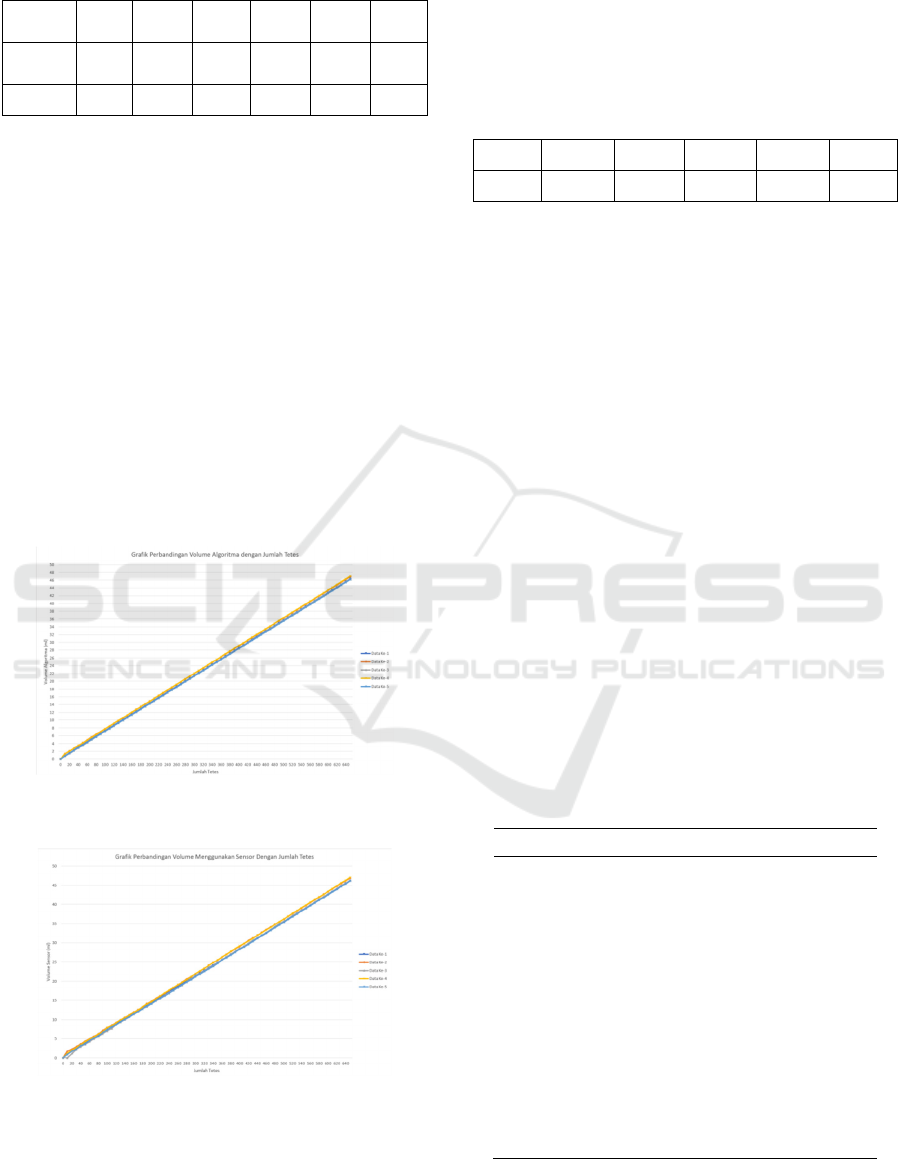

Figure 13: Comparison Chart of Algorima Volume against

Number of Drops.

Figure 14: Comparison Chart of Volume Using Sensor

Against Number of Drops.

Figure 13 and Figure 14 are the comparison of

volume to the number of drops. Testing was done 5

times by comparing the volume obtained from the

algorithm with the loadcell sensor. The volume of the

algorithm is obtained using the linear regression

method and produces 14.6 drops for 1 ml. based on

the data that has been obtained, the error table is as

follows.

Table 2: Volume Accuracy Error Table.

1st data 2nd data 3rd data 4th Data 5th Data average

2,5% 2,17% 0,66% 16,1% 0,90% 4,4%

Error data in Table 2 is influenced by the different

volume of droplets flowing in the infusion hose. Each

droplet does not run linearly as shown by the volume

in the algorithm. This happens because of the

difference in pressure in the infusion flask when the

initial condition and the condition afterwards. The

decrease in volume in the infusion flask results in a

decrease in the pressure contained in the flask. This

causes the drip speed and volume of each drop to

change along with the decreasing pressure in the

infusion flask. From the experiments that have been

carried out, it can be concluded that reading the

volume value using the linear regression method

produces an accuracy of 95.53%.

3.6 Alarm Testing

3.6.1 Bubble Alarm Testing

Bubble alarm testing is done by placing the bubble

sensor on the infusion hose. To get bubbles, the

infusion hose is removed from the flask for a while

and then put back in the flask. The following is a table

of tests carried out.

Table 3: Bubble Alarm Testing Table.

Trial Bubble Sensor Alarm

1 0 OFF

2 0 OFF

3 0 OFF

4 0 OFF

5 1 ON

6 1 ON

7 1 ON

8 0 OFF

9 0 OFF

10 1 ON

Based on table 3, namely the bubble alarm test above,

it can be concluded that the accuracy of detecting a

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1040

bubble alarm is 100%.

3.6.2 Testing the Liquid out Alarm

Testing the liquid running out alarm is done by testing

the volume read on the algorithm. Furthermore, the

alarm will activate when the volume is close to 10%

of the set volume. The set volume in the test is 50

milli liters. The following are the results of the test.

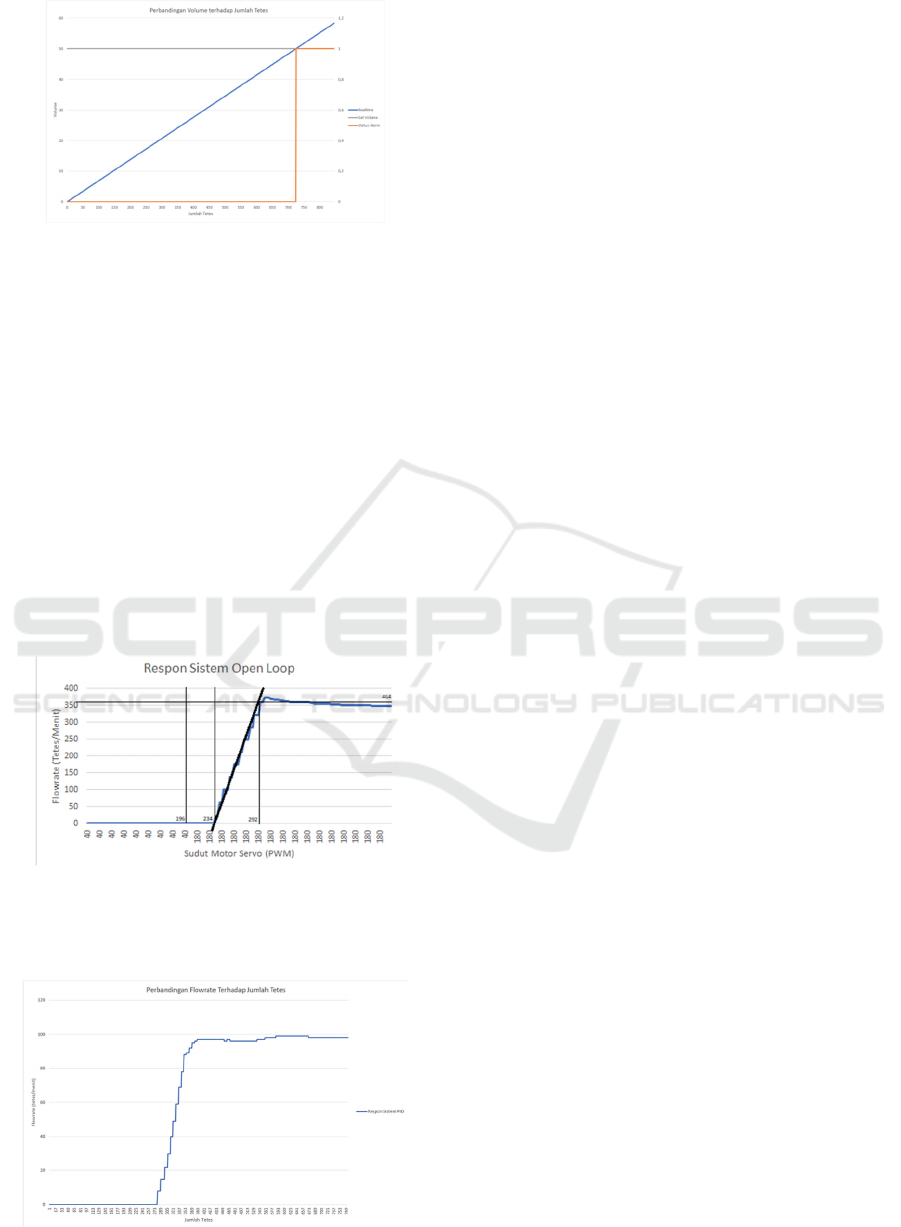

Figure 15: Liquid Out Alarm Response Chart.

Based on Figure 15, which is testing the liquid alarm,

it can be seen that the set volume is 50 milliliters.

While the alarm will be active when the volume is

close to 10% of the set point, which is more than 45

milliliters. From the test results it can be seen that the

alarm is active when the volume reaches 45.54

milliliters. The conclusion of this test is that the alarm

is functioning properly.

3.6.3 Clogged Liquid Alarm Testing

Testing the clogged liquid alarm is done by testing the

time difference between droplets. The alarm will

activate when there is no dripping for more than 10

seconds. To cause a blockage effect, the hose will be

clamped for more than 10 seconds. The following is

a table of test results.

Table 4: Clogged Liquid Alarm Testing Table.

Trial Drip time difference Alarm

1 2,2 OFF

2 1,8 OFF

3 1,4 OFF

4 2,2 OFF

5 0,8 OFF

6 1,8 OFF

7 7,2 OFF

8 10,1 ON

9 22,3 ON

10 0,1 OFF

Based on Table 4, namely testing the clogged liquid

alarm, it can be seen that the alarm will function when

the difference in drip time has exceeded 10000

milliseconds or 10 seconds. The 7th and 8th drops

have a drip time difference of 100062 milliseconds.

The 8th and 9th drops have a drip time difference of

22256 milliseconds. So the alarm is active on the 7th

drop and the 8th drop. The conclusion of this test is

that the alarm is functioning properly.

3.6.4 False Flowrate Alarm Testing

Testing the wrong flowrate alarm is done by testing

the difference between the set flowrate and the

flowrate generated by the algorithm. This alarm will

be activated when the resulting difference exceeds

10%. The following is a table of test results.

Table 5: False Flowrate Testing Table.

Trial- Set Flowrate Flowrate Alarm

1 60 54 OFF

2 60 54 OFF

3 60 53 ON

4 60 53 ON

5 60 53 ON

6 60 53 ON

7 60 54 OFF

8 60 54 OFF

9 60 119 ON

10 60 425 ON

Testing the wrong flowrate alarm is done by

testing the difference between the set flowrate and the

flowrate generated by the algorithm. This alarm will

be activated when the resulting difference exceeds

10%. The following is a table of test results.

3.6.5 Excess Volume Alarm Testing

Testing the excess volume alarm is done by testing

the volume read on the algorithm. Furthermore, the

alarm will be active when the volume has exceeded

the set volume. The following is a table of test results.

Design of Multi Device Infusion Control and Monitoring System Based on Internet of Things

1041

Figure 16: Excess Volume Alarm Response Chart.

Based on Figure 16, the excessive volume alarm test,

it can be seen that the set volume is 50 milliliters.

Furthermore, the alarm is active when the volume is

more than 50 milliliters. This happens when the

droplets have reached 740 with a volume of 50.37

milliliters. The conclusion of this test is that the alarm

is functioning properly.

3.7 PID Control System Testing

Testing the control system is done by giving step

input to the system. To apply to the plan, first the

servo motor is closed tightly so that no liquid drips,

then open the servo fully so that the liquid can flow

and record the resulting flowrate. The following are

the results of open loop system testing.

Figure 17: System Open Loop Response.

By using Kp =0.037499, Ti =0.029194, Td = 0.0047

985. Then the resulting system response is as follows.

Figure 18: System Close Loop Response Graph.

4 CONCLUSIONS

Based on the results of data analysis and discussion

that has been carried out, there are several

conclusions that can be drawn including the

following.

1. Droplet detection using an optocoupler sensor

has an accuracy of 100%.

2. The calculation of the flowrate value on the

infuse device with the moving average filter

method has an accuracy of 94.52%.

3. The calculation of the volume value on the

infusion device has an accuracy of 95.53%.

4. Detection of infusion errors such as bubbles,

fluid depletion, fluid blockage, incorrect flowrate

and excessive volume can be done well.

5. Flowrate control using PID control system can

run as expected and has parameters Kp =

0,057499, Ki = 0,099194, Kd = 0,0047985.

6. The process of controlling and monitoring each

infuse device using the nextion HMI runs well

for all windows.

7. The centralized monitoring process using

nodered dashboard can run well for all windows.

REFERENCES

(2021), “WHO Coronavirus (COVID-19) Dashboard _

WHO Coronavirus (COVID-19) Dashboard with

Vaccination Data.” https://covid19.who.int/

A. D. Pitri, S. Ismail, M. E. Magister, K. Departemen,

K. Fakultas, and K. Universitasdiponegoro,

“EKSPLORASI Peran Perawat Dan Ahli Gizi

Dalam Pemberian NUTRISI PADA PASIEN

KRITIS,” 2019.

K. Mordhoko and F. Chandra Satria Arisgraha,

“Rancang Bangun Sistem Optimasi INFUS

DROP RATE,” 2013.

D. Iskandar, A. Kholiq, J. Teknik, E. Politeknik, K.

Kementerian, and K. Surabaya, “Analisis Infus

Set Terhadap Keakurasian Infus Pump Di Ruang

ICU RSUD KARANGANYAR,” 2018. [Online].

Available: https://halosehat.com/review/tindakan

R. A. Primahayu, F. Utaminingrum, and D. Syauqy,

“Sistem Monitoring Cairan Infus Terpusat

Menggunakan Pengolahan Citra Digital,” 2017.

[Online]. Available: http://j-ptiik.ub.ac.id

D. Nataliana, N. Taryana, and E. Riandita, “Alat

Monitoring Infus Set pada Pasien Rawat Inap

Berbasis Mikrokontroler ATmega 8535,”

Bandung, Jan. 2016.

T. Kurrahman, “Pendeteksi Gelembung Udara Pada

Pemberian Cairan infuse,” Universitas

Muhammadiyah Yogyakarta, Yogyakarta, 2017.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1042