Production and Application of Lactic Acid: A Review

Zike Zhou

*

Shanghai Qibaodwight High School, Shanghai, 201101, China

Keywords: Lactic Acid, Fermentation, Bacteria, Preservative, Renewable Plastic.

Abstract: In organic chemistry and food science, lactic acid is one of the most industrially widely used

hydroxycarboxylic acids. This work focuses on the production method, fundamental properties, the reason

for lactic functioning as a preservative, and various applications of lactic acid in different areas. The common

pathways to produce lactic acid are microorganism fermentation and chemical synthesis. Furthermore, the

acidity due to hydrogen bonding and the opposite effect of the hydroxyl group makes lactic acid a good

preservative. In addition, Poly Lactic Acid (PLA) originates from lactic acid and is another promising

application from industrial uses to household usage, such as food takeaway containers.

1 INTRODUCTION

Lactic acid also expressed as 2-hydroxypropanoic

acid or milk acid has molecular formula of

CH

3

CH(OH)COOH and C

3

H

6

O

3

. Its molar mass is

90.078g mol

-1

. It exists in two enantiomeric forms:

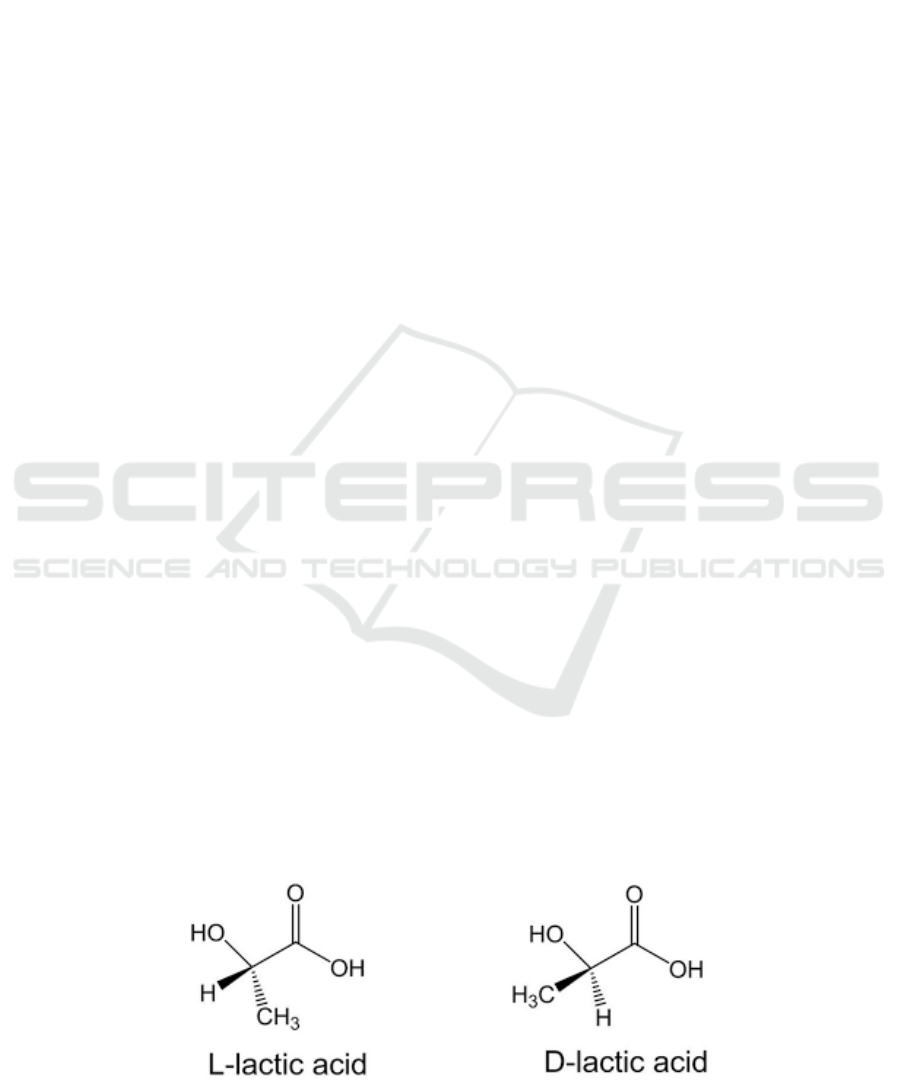

L(+)-lactic acid or D(-)-lactic acid. The structures are

shown in Figure 1.

L-lactic acid can be used for

metabolizing by the human body or animals, so it's

more beneficial for organisms, while the D-lactic acid

cannot be metabolized, and a large proportion of it is

excreted (Dashmeet, 2018).

Lactic acid was first found by C.W.Scheele in sour

milk in 1780, and Fermi successfully extracted lactic

acid by fermentation in 1881, which was then used in

the industrial synthesizing of lactic acid. Lactic acid

exists in different fermented foods like yoghurt and

butter. By 2012, the demand for lactic acid was over

259,000 metric tons per year (Castillo, 2013). The

vast demand is attributed to several functions of lactic

acid.

Lactic acid is widely used as a preservative to

prevent food spoilage by inhibiting the growth of

putrefying bacteria. When it is changed into

potassium or sodium lactate, the shelf life of fish and

meat can be extended by its addition. It also serves as

an acidulant to add savoury flavour to pickled

vegetables, beverages, and baked products. As a pH

regulator, lactic acid produces chocolates and sweets

to achieve the correct pH value.

The textile industry works as a mordant (fixative)

to dye clothes. In addition, lactic acid can be

converted to ethanol, propylene glycol, and acrylic

polymers. In the pharmaceutical industry, lactic acid

works as an electrolyte in implants, pills, and dialysis.

In the cosmetic industry, lactic acid has the functions

of brightening skin and helping remove the brown

spots on the skin. The role of moisturizer due to its

retaining water capacity also makes lactic acid a

popular ingredient in hygiene and aesthetic products

(Krishna, 2019).

Figure 1: The structures of D(-)-lactic acid and L(+)-lactic acid (Dashmeet, 2018).

Zhou, Z.

Production and Application of Lactic Acid: A Review.

DOI: 10.5220/0012003800003625

In Proceedings of the 1st International Conference on Food Science and Biotechnology (FSB 2022), pages 143-148

ISBN: 978-989-758-638-5

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

143

For industrial production, there are several pathways

to obtain lactic acid. The two most popular ones are

fermentation and chemical synthesis (Krishna, 2019).

2 FERMENTATION FOR LACTIC

ACID

Fermentation is a relatively fast and cheap way to

lead one of the enantiomers of lactic acid with high

yields. However, like any other fermentation process,

its yield and efficiency are determined by starting raw

materials, nutrients in the medium and the

microorganisms used, such as bacteria type

(Krishna,

2019).

There are two main patterns of lactic acid bacteria

used in fermentation. The first one is

heterofermentative; these organisms produce several

byproducts and are, therefore, unsuitable for

industrial processes. The second one is

homofermentative. Those organisms only produce

fewer byproducts, but the large yield of lactic acid is

used in commercial production (Dashmeet, 2018).

Table 1 is a summary table of the fermentation

bacteria and their respective isomer result,

fermentation pattern and necessary raw materials.

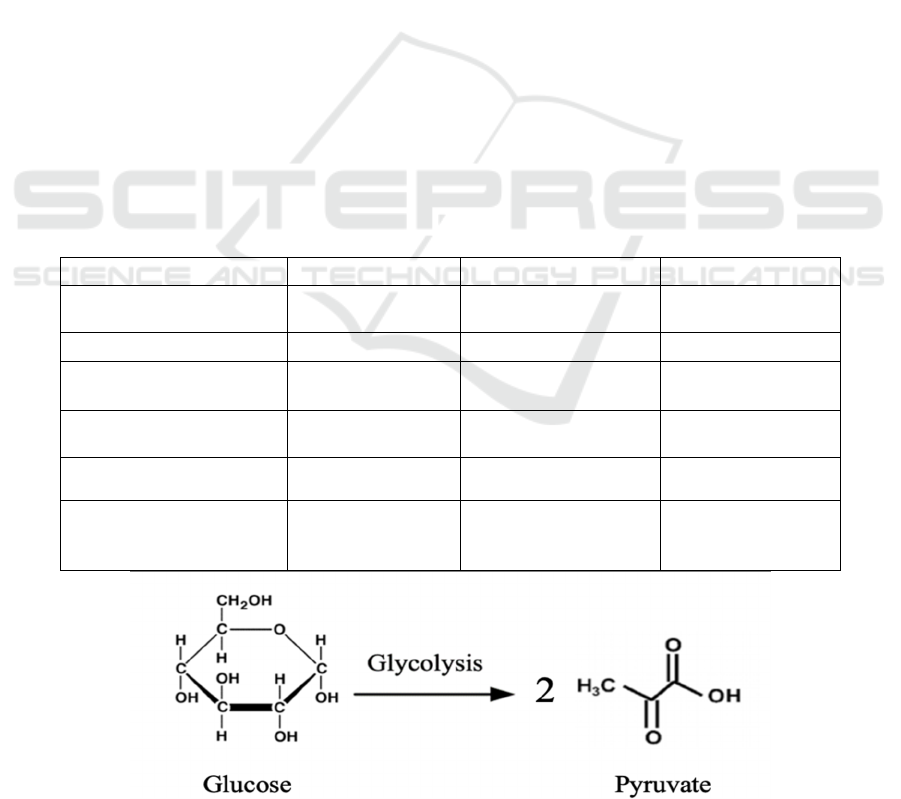

The first kind of fermentation: homofermentative

fermentation produces more than 85% lactic acid

from glucose (Boontawan, 2010). One mole of

glucose can be converted to two moles of lactic acid.

The reaction process is shown by the diagram below.

Step 1.

Figure 2 shows the first step of homofermentative

fermentation. In step 2 shown by Figure 3, pyruvate

is reduced from the aldehyde or ketone oxidation

level to the alcohol oxidation level. The NADH, also

known as dihydropyridine, loses one proton and

becomes positively charged as NAD

+

.

Figure 4 shows the second kind of fermentation:

heterofermentative fermentation produces only 50%

lactic acid and large quantity of ethanol, and carbon

dioxide. With the help of bacteria, 1 mole of glucose

can be converted to 1 mole of lactic acid, 1 mole of

ethanol, and 1 mole of carbon dioxide (Boontawan,

2010).

3 INDUSTRIAL WAY OF

SYNTHESIZING LACTIC ACID

(DRAW DETAILED SCHEME)

The industrial process for commercial production is

Table 1: Characteristics of selected bacteria and molds of interest in lactic acid production (Dashmeet, 2018).

Microorganism Lactic acid isomer Fermentation pattern Raw material

Bacteria:

Lactobacillus amylophilus

L (-) Homofermentative Starch

L. amylovorus DL Homofermentative Starch

L. casei subsp. Rhamnosus

(L. delbueckii NRRL B-445)

L (+) Facultative

heterofermentative

Glucose, sucrose

(molasses)

L. delbueckii subsp.

bulgaricus

D (-) Homofermentative Cheese whey and

permeate (Lactose)

L. helviticus DL Homofermentative Cheese whey and

permeate (Lactose)

Molds:

Rhizopus arrhizus

R. oryzae

L (+)

L (+)

Homofermentative

Homofermentative

Glucose, starch

Glucose, starch

Figure 2: First step of homofermentative fermentation.

FSB 2022 - The International Conference on Food Science and Biotechnology

144

Figure 3: Second step of homofermentative fermentation.

Figure 4: Heterofermentative fermentation.

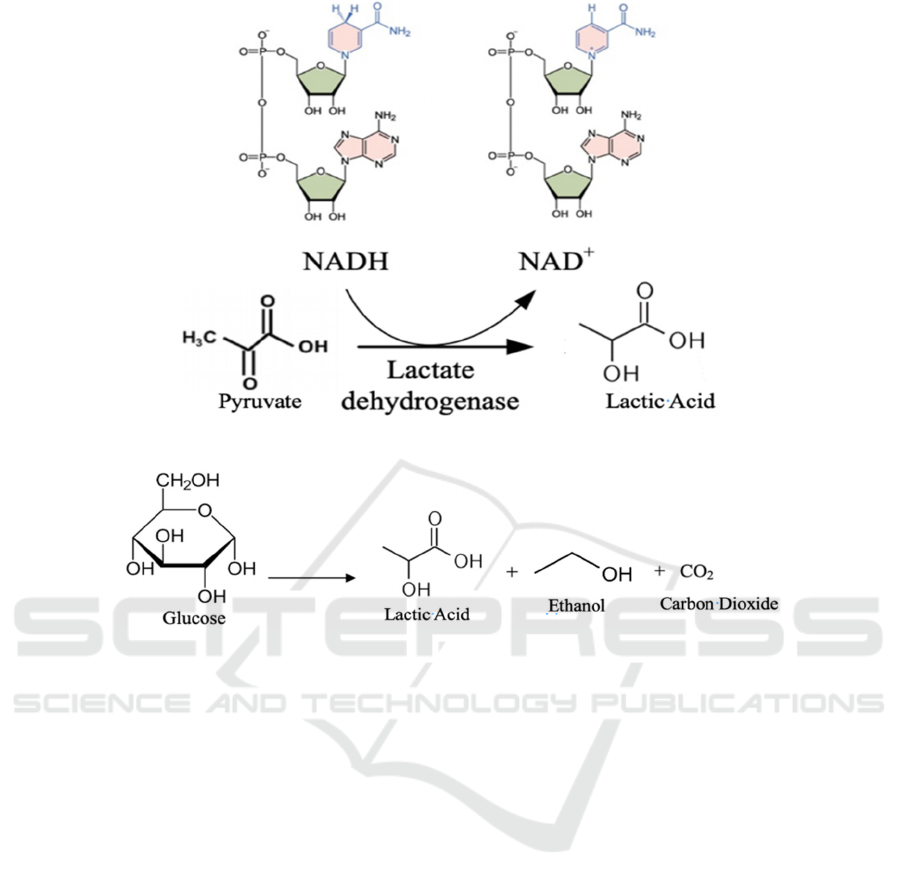

also based on chemical synthesis. The starting

material is lactonitrile produced by acetaldehyde and

hydrogen cyanide. The reaction should be conducted

in liquid phase under high atmospheric pressures. The

crude lactonitrile is then purified by distillation. After

that, concentrated HCl or H

2

SO

4

is used to hydrolyze

the lactic acid to produce ammonium salt and lactic

acid. As methyl lactate is easier to purify through

distillation, the product lactic acid is then esterified

with methanol. After distilling, methyl lactate is

hydrolyzed by water under an acid catalyst to produce

purer lactic acid and methanol. Unlike the

fermentation process, the chemical synthesis method

would produce a mixture of DL-lactic acid. The

process is presented in Figure 6 and Figure 7.

(Boontawan, 2010).

4 LACTIC ACID AS A

PRESERVATIVE

The growth of bacteria and its releasing of mycotoxin

in food are main factors causing food spoilage and

food poisoning. Lactic acid can permeate into the

membrane of the bacteria, reducing the intracellular

pH, to kill the food spoilage bacteria such as

Enterobacteriaceae and Pseudomonadaceae.

(Nasrollahzadeh, 2022)

It is more acidic than another organic acid in

households: acetic acid. Lactic acid has pKa value of

3.86, due to the existence of hydrogen bonding and

the polar effect of hydroxyl group.

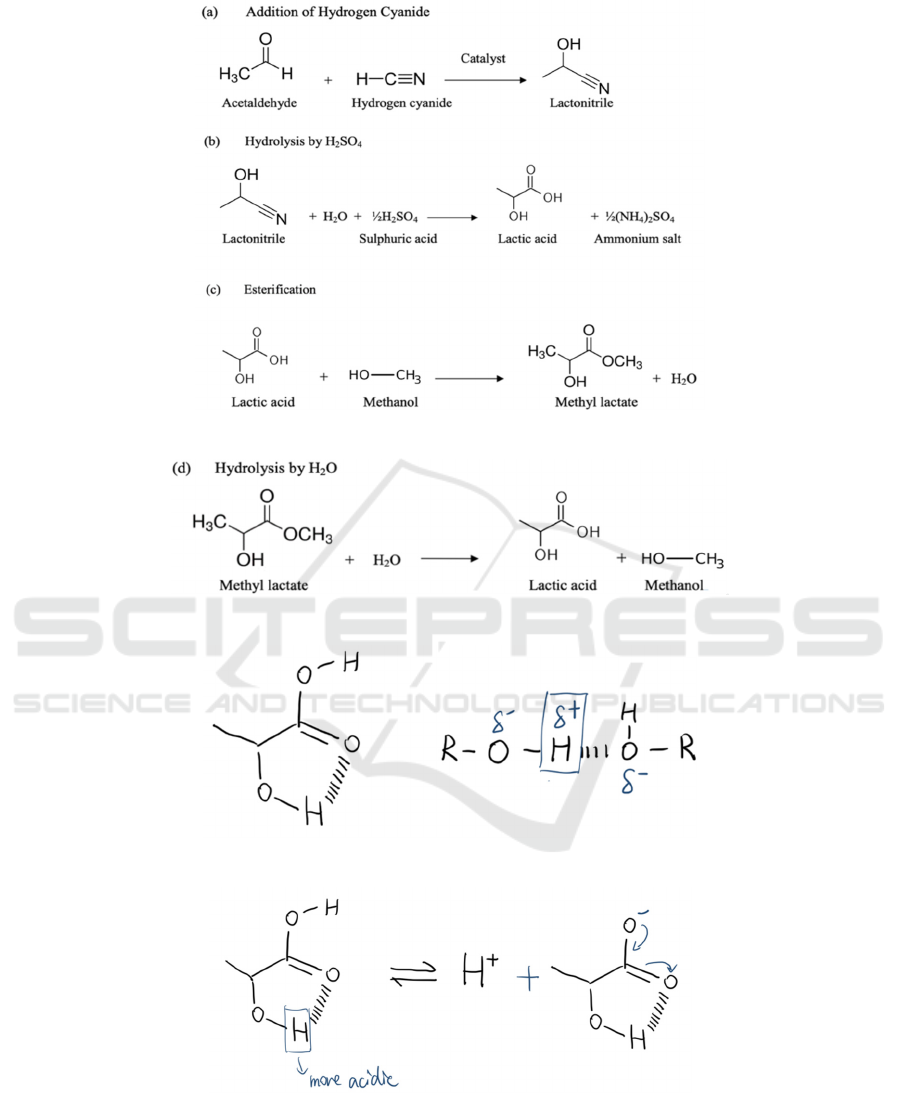

In Figure 7, there are two attraction forces from O

to the H in the bottom right. Shown in the right part

of the diagram, H is relatively more electronegative

than O, so the O atom will make the H atom more

positive. The proton boxed is therefore more acidic.

In addition, hydroxyl OH is an electronegative

functional group, so it will further pull the electrons

far away from the middle H as lactic acid has two

hydroxyl group, which results in the polar effect.

Production and Application of Lactic Acid: A Review

145

Figure 5: Step (a)(b) and(c) of chemical synthesis.

Figure 6: Step(d) of chemical synthesis

Figure 7: Lactic acid with hydrogen bonding.

Figure 8: Formula showing resonance form of lactic acid.

Figure 8 illustrates the resonance form when the

lactic acid loses a proton. The negative charge can

either stay on the top O atom or come down as a

double bond and push the electron to the left O atom.

The two resonance forms also help the negative

charge to spread over the conjugate base of lactic

acid, making it more stable. Therefore, it further

lowers the pKa of lactic acid.

As the growth of bacteria is inhibited by the acidic

environment, lactic acid functions as a good inhibitor.

FSB 2022 - The International Conference on Food Science and Biotechnology

146

Along with its flavouring function and little smell,

lactic acid outstands among a series of organic acids

and becomes a popular food preservative

(Nasrollahzadeh, 2022).

5 OTHER APPLICATIONS OF

LACTIC ACID

Lactic acid can serve as a starting material and

involves in numerous reactions. Table 2 is a summary

table of different kinds of reactions.

The most common reaction involving lactic acid

is to produce lactide, which can be further

transformed into poly lactic acid (PLA). PLA is a

biodegradable plastic and is applied in daily life as

food packages, containers, trash bags, protective

clothing, etc. The full application is shown by Table

3 (Södergård, 2002).

Table 2: Reactions and chemical produced involving lactic

acid (Krishna, 2019).

Reaction Chemical produced

Hydrogenation Propylene oxide

Decarboxylation Acetaldehyde

Deh

y

dration Acr

y

lic aci

d

Reduction Pro

p

anoic aci

d

Condensation 2,3-

p

entanedione

Self-esterification Dilactide

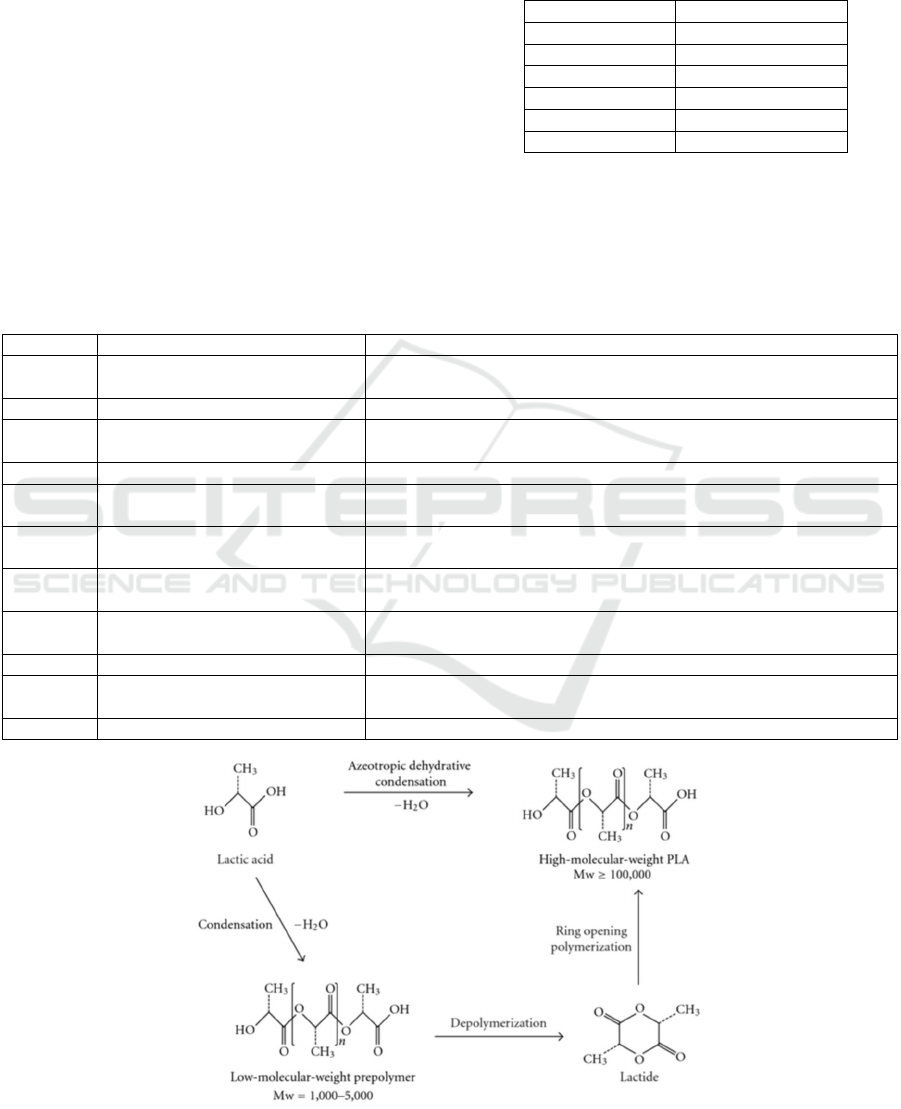

Jem and Tan use a diagram (Figure 9) to illustrate

two pathways from lactic acid to PLA. One is through

condensation, depolymerization, and ring opening

polymerization. The other one involves only

azeotropic dehydrative condensation (Jem, 2020).

Table 3: Polymers types and their applications (Jem and Tan).

Lactide Pol

y

mers A

pp

lications

L-lactide L-lactide for producing PLLA

Membranes and films for medical applications and 3D printing for

p

rosthesis

D-lactide D-lactide for

p

roducin

g

PDLA H

y

dro

g

el and

p

articles for dru

g

deliver

y

L-lactide L-lactide with PEG

Medical applications, drug vehicles, nanoparticles loaded with bioactive

compounds, treatment for cancer and infections

D-lactide D-lactide with PEG Biochemical device and packaging

L-lactide

L-lactide with poly (trimethylene

carbonate)

Biodegradable elastomeric scaffold for vascular engineering

L-lactide L-lactide with PCL

Absorbable suture medical application due to good tensile properties

Packa

g

in

g

a

pp

lication thanks to tunable barrier

p

ro

p

erties

L-lactide/

D-lactide

Lactide with lignin Bio-based composite materials

L-lactide/

DL-lactide

L-lactide with 𝜀-caprolactone and

h

y

drox

y

a

p

atite

Composite materials for bone reconstruction

L-lactide L-lactide with hydroxyapatite Composite scaffolds for bone tissue engineering

L-lactide

L-lactide, glycolide, butyl

succinate/citrate

Bioabsorbable block copolymers for tissue engineering

L-lactide L-lactide with PGA Smart

p

ol

y

mer used as dru

g

deliver

y

device

Figure 9: Reactions of converting lactic acid into PLA.

Production and Application of Lactic Acid: A Review

147

6 CONCLUSION

Lactic acid is widely used in the food, textile,

pharmaceutical, and cosmetic industry as a

preservative, flavouring agent, pH regulator and

moisturizer. It can be obtained through chemical

synthesis or biological fermentation as a functional

organic compound. The selection of a certain

enantiomer of lactic acid is possible in fermentation

by choosing different types of bacteria. Lactic acid

can also be a starting material to produce PLA, a

promising bio-degradable plastic waiting for further

study.

REFERENCES

Boontawan, P 2010, ‘Development of Lactic Acid

Production Process from Cassava By Using Lactic Acid

Bacteria’, Doctor Thesis, Suranaree University of

Technology, pp. 1–204.

Castillo M, FA, Balciunas, EM, Salgado, JM, Domínguez

González, JM, Converti, A & Oliveira, RP de S 2013,

‘Lactic acid properties, applications and production: A

review’, Trends in Food Science & Technology, vol.

30, no. 1, pp. 70–83.

Dashmeet 2018, Lactic Acid: Structure, Biosynthesis,

Fermentation Process and Uses in Food | Industries |

Biotechnology, BioTechnology Notes.

Jem, KJ & Tan, B 2020, ‘The development and challenges

of poly (lactic acid) and poly (glycolic acid)’, Advanced

Industrial and Engineering Polymer Research, vol. 3,

no. 2.

Krishna, BS, K.V, NS, Gantala, S, Tarun, B & Gopinadh,

R 2019, ‘Industrial production of lactic acid and its

applications’, International Journal of Biotech

Research, vol. 1, no. 1, pp. 42–54.

Nasrollahzadeh, A, Mokhtari, S, Khomeiri, M & Saris, PEJ

2022, ‘Antifungal Preservation of Food by Lactic Acid

Bacteria’, Foods, vol. 11, no. 3, p. 395.

Södergård, A & Stolt, M 2002, ‘Properties of lactic acid

based polymers and their correlation with

composition’, Progress in Polymer Science, vol. 27, no.

6, pp. 1123–1163.

FSB 2022 - The International Conference on Food Science and Biotechnology

148