Application of Metal–Organic Frameworks-Based Functional

Materials for Gas Separation

Haoming Li

1,†

, Yuehan Lyu

2,†

, Yanqi Shao

3,†

and Tianye Sheng

4*,†

1

Changwai Bilingual School, Changzhou 213100, China

2

The Affiliated International School of Shenzhen University, Shenzhen 518066, China

3

Malvern College Qingdao, Qingdao 266109, China

4

WLSA Shanghai Academy, Shanghai 200433, China

Keywords: MOFs, Functional Materials, Gas Separation, Application.

Abstract: Energy scarcity is becoming the biggest problem of scientific research and industrial production in this

century. And gas separation, as an essential part of production activities, naturally needs to be considered a

more sustainable and environmentally friendly change. As an emerging porous material, metal–organic

frameworks (MOFs) are one of the candidates to replace the traditional distillation process due to their special

structural characteristics, such unique porous structure and adjustable surface properties. Therefore, MOFs-

based functional materials have been widely used for a diverse of various fields, such as fuel cell construction,

antibacterial agent development and gas separation. Due to each type of gas’s chemical/physical properties, a

variety of promising and practical separation functional materials based on MOFs are prepared by using the

advanced laboratory techniques, like UTSA-68 for C

2

H

2

/CO

2

separation, r-FUM 67-MES 33-FCu-MOF for

CH

4

/N

2

and IRMOF-1 for Xe and Ar separation. Herein, this research will not only summarize the current

importance and status of the application of functional materials in the field of gas separation, which include

CH

4

/N

2

, C

2

H

2

/CO

2

, Ar/Kr, Ar/Xe and Xe/Kr.

1 INTRODUCTION

A diverse of different functional materials have been

used for gas separation over the past century, such as

zeolite, which are now being utilized extensively in

industrial development. In any event, developing new

functional materials, such as metal-organic

frameworks (MOFs), is currently making significant

strides forward. Scientists began to realize the

commercial potential of MOFs around the year 1990,

which coincided with several significant

technological advances. For instance, the high

ductility, flexibility and efficient gas separation

offered by MOFs contribute to the material’s high

industrial value. The chemical properties of various

MOFs are different, and some changes typically

influence these differences in temperature and

pressure. As a result, this opens a wide variety of

opportunities for gas separation. Recently, MOFs-

based functional materials have been the subject of

extensive exploration and research (Wang, 2022), and

now their industrial potential is being realized. As

more time passes, MOFs will be used in more official

capacities in industrial applications.

Traditional thermal drive technology is based on

distillation which is relatively energy-intensive by a

continuous cycle of evaporation and condensation.

The separation of similar volatile gas mixtures (e.g.,

hydrocarbons) are processed industrially to obtain the

desired purity. To solve energy shortage and

environmental pollution, more and more attention is

paid to the energy consumption and sustainable

development of the process. The traditional

distillation separation process is bound to be replaced

by a more environmentally friendly and efficient non-

thermal process. Among these, porous materials are

one of the focuses of future development.

MOFs are one of typical porous materials that

involve single metal ions and coordination bonds

connected by organic ligands. In gas separation

applications, MOFs have plenty of benefits based on

their special and unique structures and properties

(Cui, 2021). The crucial characteristic of MOFs that

enables the absorption of several guest gas species is

high surface area, and an efficient procedure will be

viable since less stuff is required. Moreover, MOFs

can accept variable functional sites and highly adjust

the interaction between host and guest species. These

Li, H., Lyu, Y., Shao, Y. and Sheng, T.

Application of Metalâ

˘

A ¸SOrganic Frameworks-Based Functional Materials for Gas Separation.

DOI: 10.5220/0012003400003625

In Proceedings of the 1st International Conference on Food Science and Biotechnology (FSB 2022), pages 121-127

ISBN: 978-989-758-638-5

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

121

open metal sites can bind with guest species, forming

interactions with ligands. MOFs are controlled easily

due to their adjustable pore size and tunable porosity.

In other words, scientists can regulate the

functionalization of MOFs for specific applications

such as capturing particular species. The controllable

chemical properties of pores make various mixtures

of this material, which means lots of different and

advanced designs so that higher selectivity and

efficiency of gas species can be achieved. Overall,

MOFs will play a significant role in industrial

progress in reducing energy consumption and

improving industrial production efficiency.

This research will describe the research and

development of MOFs-based functional materials for

gas separation in recent years. MOFs and their

composites have excellent application prospects in

gas separation. MOFs and membrane separation

technology are used in gas separation. These

applications are easy to operate and reduce energy

consumption by more than 30% compared with other

methods, which meets the requirements of energy-

saving society development. In the research process,

it is also found that methane and nitrogen showed

different pair interaction intensities in MOFs,

resulting in a more significant pair surface diffusion

rate. The combination of MOFs and membrane makes

membrane have excellent separation performance,

providing a new way for methane concentration and

purification in natural gas and coalbed methane. The

existing MOFs-based membrane materials are

studied, and the selection of MOFs separation

membranes and their synthesis process are discussed

from the perspective of the surface diffusion rate of

gas, as well as the application of MOFs-based

functional materials in gas separation.

2 APPLICATION OF

MOFs-BASED FUNCTIONAL

MATERIALS FOR GAS

SEPARATION

2.1 C

2

H

2

/CO

2

Separation

Acetylene (C

2

H

2

) and carbon dioxide (CO

2

)

separation is an essential process in the industry since

C

2

H

2

acts as a crucial raw material and has a broader

application. C

2

H

2

can be produced from the cracking

process of hydrocarbon under high temperatures or

the incomplete combustion of methane (Wang, 2022).

According to public statistics, the global market value

of acetylene is approximately 11.42 billion dollars,

and it is expected to increase by 6% each year which

displays the importance of this stock (Cui, 2021). As

for the application of C

2

H

2

, it can be widely used in

producing chemical substances such as acetic acid

and benzene. It is also used for welding and cutting

metals (Guo, 2017). These reactions need high purity

of acetylene to be achieved, instead, carbon dioxide

always exists as an impurity to affect

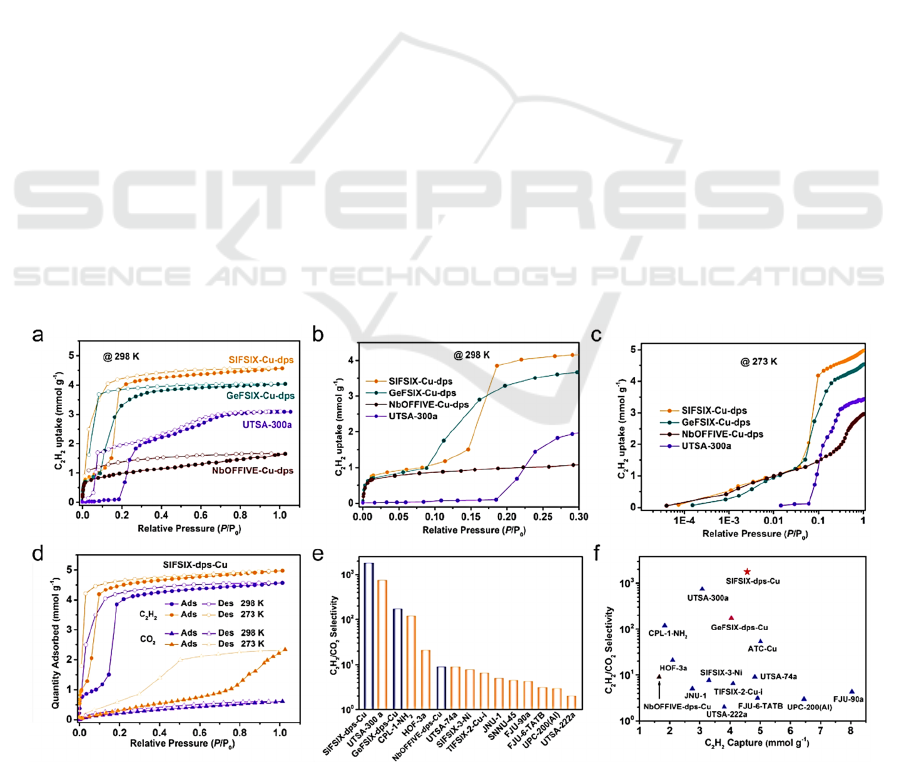

Figure 1: Application of MOFs for C

2

H

2

/CO

2

separation (Wang, 2022).

FSB 2022 - The International Conference on Food Science and Biotechnology

122

industrial manufacture, so it is necessary to separate

CO

2

from C

2

H

2

. However, C

2

H

2

/CO

2

separation is

difficult as they have similar molecular sizes and

physical properties like the critical temperature.

Overall, the appearance of MOFs-based functional

materials will play a significant role on C

2

H

2

/CO

2

separation, which will benefit the industries, as shown

in Fig. 1.

A previous study used molecular simulations to

identify the adsorption power of magnesium format

(Fischer, 2010). This light metal-organic framework

is called magnesium formate, which combines with

the most uncomplicated carboxylate formate. In

comparing the single-component isotherms in the

experiment, high absorption of 65.7 cm

3

/g at 298 K

and 1 bar of the pressure for acetylene is measured so

that high selectivity of acetylene over carbon dioxide

could be observed. Even though the theoretical

acetylene absorption is smaller than the single-

component isotherms, almost no carbon dioxide can

be adsorbed. This result shows that magnesium

formate’s capacity to separate C

2

H

2

and CO

2

molecules should be nearly constant at a suitable

pressure range. To explore the ability of adsorption

for magnesium formate, the calculated Henry

constants ratio was used, which is shown in a line

graph, and acetylene is highly adsorptive from carbon

dioxide at room or even lower temperatures.

Another method is to discuss the potential field of

these two species. As for the C

2

H

2

, the interaction

power ranges from -25 to over -40 KJ/Mol, whereas

less than -30 KJ/Mol interaction is measured for CO

2

.

Due to the greater power of interacting with the

framework for C

2

H

2

, the energetic areas will be taken

up absolutely by acetylene molecules rather than

carbon dioxide. These avoid the adsorption of carbon

dioxide molecules effectively. In summary,

magnesium formate should be efficient in C

2

H

2

/CO

2

separation. The UTSA-68 is an instance of an

unpenetrated framework and can adsorb 70.1 cm

3

/g

amount of C

2

H

2

due to the porosity at 296 K and 1

atm pressure (Chang, 2016). The C

2

H

2

molecules can

occupy inside the framework more frequently as the

increasing porosity, and high selectivity is also

possible for UTSA-68. The calculated range of

selectivity, which is 5-3.4 based on the Ideal

Adsorbed Solution Theory (IAST), is a comparatively

high result. Above all this evidence, it is believed that

UTSA-68 has beneficial properties such as a high

ability of adsorption to be applied for C

2

H

2

/CO

2

separation.

In terms of MOFs with ultra-micropores,

[Cu(hfipbb)(Hhfipbb0.5)] was studied by scientists

(Cui, 2021). The pore size of this framework is

suitable for acetylene and carbon dioxide molecules

contributing to the sieving effect. First, the

thermogravimetry analysis demonstrates that this

MOFs can be maintained at about 350°. Compare the

adsorption of guest molecules at 273 K and 298 K.

Their powers are similar, while there is a significant

difference (sevenfold) in the amount of acetylene and

carbon dioxide adsorbed by MOFs. In other words,

this microporous MOFs does have the potential to be

applied. In addition, the IAST calculation investigates

the adsorption capacity when the mixture contains the

same mole of two gas species. Moreover, 696

selectivity is concluded, which is higher than most of

the MOFs. The simulations suggest that CO

2

molecules can interact with the framework while the

hydrogen repulsion prevents the interaction of C

2

H

2

.

That is why the reverse separation of C

2

H

2

and CO

2

is observed. After that, column breakthrough

experiments are utilized to confirm the adsorption

power. Since no CO

2

is indicated at the exit, it is

possible to prove that a great ability of separation can

be achieved to obtain pure C

2

H

2

when using this type

of MOFs under the kinetic circumstance.

2.2 CH4/N2 Separation

Methane (CH

4

) is necessary for the world to reach

zero emissions, yet it cannot separate from nitrogen

(N

2

). Due to the identical polarizability and kinetic

dimensions of CH

4

and N

2

, it is difficult to achieve

CH

4

/N

2

separation. Most common kinds of porous

materials, including zeolite, do not sufficiently

separate CH

4

/N

2

in industrial applications. Also, it is

crucial to separate CH

4

from N

2

, which can reduce

greenhouse gas emissions. The only technique

employed directly to separate the gaseous mixture on

a significant scale is cryogenic distillation. Although

this method produces high purity products, it is

expensive and energy-intensive.

According to the separation mechanism, there are

two categories of adsorbents. Since CH

4

has stronger

adsorption contacts and a greater capacity for

adsorption than N

2

, CH

4

-selective adsorbents are

primarily based on the equilibrium process. N

2

-

selective adsorbents based on kinetic or steric effects

as N

2

can be adsorbed over CH

4

. Because of their

strong chemical stability and unique surface areas,

porous organic frameworks contribute significantly

in the separation of CH

4

and N

2

. For example, when

light metal ions are used to prepare functional

materials, the affinity for the prepared functional

materials can be greatly enhanced for adsorbing CH

4

as compared to the materials without added light

metal ions, resulting in a high selectivity for CH

4

/N

2

Application of Metalâ

˘

A¸SOrganic Frameworks-Based Functional Materials for Gas Separation

123

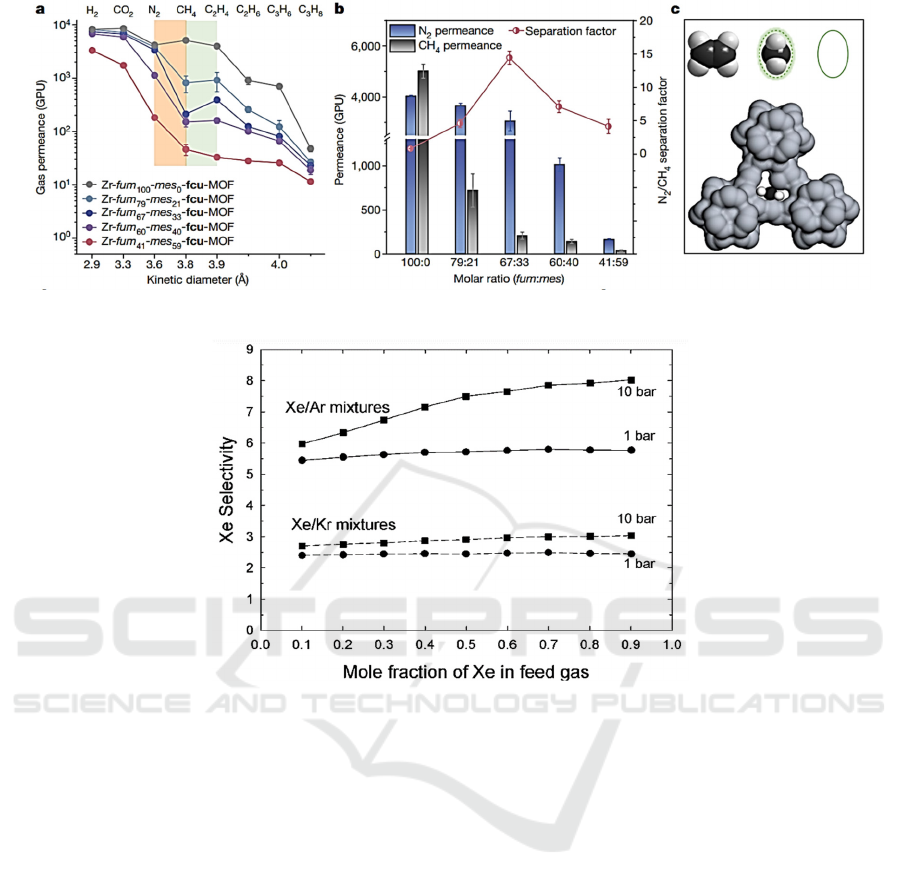

Figure 2: Performance of CH

4

/N

2

separation by using the prepared MOFs-based functional materials (Zhou, 2022).

Figure 3: Influence of mole fraction of Xe in feed gas on Xe selectivity (Greathouse, 2009).

separation. Gas separation may be able to filter

natural gas effectively using membranes (Wu, 2021).

One component of the gas mixture can enter these

membranes’ holes only when desired. However, even

the most sophisticated membranes offer poor

selectivity because CH

4

and N

2

share many physical

and chemical characteristics. Zhou et al. designed a

new MOFs-based membrane material for CH

4

/N

2

separation (Zhou, 2022), as shown in Fig. 2. In this

work, they have fine-tuned the pore structure

characteristics of the prepared membrane materials,

making them exhibit good selectivity for CH

4

/N

2

separation. In addition, the prepared membrane

material still exhibits high CH

4

/N

2

selectivity and N

2

permeability at practical pressures up to 50 bar.

Scientists employ water as a solvent for the

electrochemical synthesis of MOFs membranes for

membrane manufacturing, in which an external

current is used to apply deprotonation. All the films

had an excellent symbiotic layer, a similar crystal

shape, and an ultra-thin thickness of roughly 30 nm

when the conditions were optimized, and the ratios of

the various components were changed (Zhou, 2022).

Additionally, as a demonstration of concept for

reducing the price of membranes, the authors

demonstrate that the same synthetic MOFs film

displays comparable layer thickness and intactness on

low-cost support made of stainless-steel nets

modified with carbon nanotubes. Of course, the

literature has also reported other efficient MOFs-

based functional materials for CH

4

/N

2

separation,

such as zeolites-based MOFs (Wu, 2019).

2.3 Noble Gas Separation

Noble gases have very low conductivity and

reactivity and are therefore favoured in human

industry. Among other things, inert gases can be used

in light bulbs and protective gases. For example,

Krypton can be used in lasers and Xenon can be used

in cosmic rays. A new type of material, MOFs, is

currently valued by scientists because of its high

efficiency, tunable void size, and industrial potential.

Greathouse et al. prepared IRMOF-1 that can

FSB 2022 - The International Conference on Food Science and Biotechnology

124

selectively absorb Xe atoms in Xe/Kr and Xe/Ar

mixtures (Greathouse, 2009), as shown in Fig. 3. In

both their models and their tests, they discovered a

correlation between an increase in the polarizability

of the linker and an improvement in adsorbate

interaction, as well as an improvement in adsorption

selectivity for the Xe/Kr separation. With a specific

cavity width, the IRMOF-1 has a pore capacity that is

equivalent to 74% of its overall volume. Because the

system has a significant amount of empty space, the

adsorbates act as if there were just a single component

present. For instance, slow Xe atoms do not

considerably diffusion of Kr atoms that have

relatively short, which suggests the correlation

relationship influence among the various adsorbates

are relatively minimal, which ultimately results in KP

accuracy that is very high. This comparison

demonstrates that the KP correlation adequately

predicts Xe/Kr mixes’ self-diffusivities under various

situations. The preceding reasoning also applies to

combinations of Xe and Ar in IRMOF-1 (Greathouse,

2009). And the performance of the MOFs in

adsorbing noble gases is also optimized. (Meek,

2012; Gurdal, 2012; Gurdal, 2013).

2.4 Oxygen Separation

Oxygen accounts for approximately 20.9% of the

total composition of air and is one of the main

components for maintaining human metabolism.

Moreover, it is an indispensable substance in various

industries and processes. In the petroleum

purification industry, oxygen has already been

employed for air-in-furnace enrichment, which

provides the convenience of reduced fuel

consumption, increased capacity and better

temperature control. It is used in water treatment for

water purification, as an oxidizer, and in oxyfuel

technology using acetylene for oxyfuel welding and

cutting. However, those low-efficiency methods such

as cryogenic distillation, membrane or zeolite

separation dominate the modern O

2

supply. While

most of these technologies yield high purity and

large-scale finished products, the complexity, high

cost and energy intensity behind them cannot be

ignored. To balance the economics and efficiency of

separation processes, metal-organic frameworks are

naturally one of the promising processes for the future

owing to their porosity and adjustable host/guest

interactions.

The MOFs-based functional materials are

reported to have different selectivity for mixtures of

oxygen and nitrogen at characteristic temperatures

and pressures, as shown in Fig. 4. At low

Figure 4: The selectively for O

2

/N

2

with the used functional

materials (Wang, 2017).

temperatures, oxygen can be adsorbed more

selectively compared to nitrogen. This

thermodynamic and kinetic selectivity was confirmed

in experiments and structural probes. At typical

temperature regions, the internal energy of oxygen

adsorption amount is one half more than that of

nitrogen, an unprecedented increment in materials

with oxygen selectivity. The opening door process

can be used to explain the positive proportional

change in the coverage and the internal energy of

adsorption of the two gases. One of them is due to the

increasing number of gas molecules during the

opening of the door, or it is because the energy in the

subsequent steps reduces the amount of escape in the

expansion of the process (Wang, 2017).

UIO-66 containing fluorine was found to have

superior oxygen adsorption capacity. In the

experimentally obtained adsorption isotherm results,

highest flourine concentration UiO-66-F100 showed

the remarkable absorptional ability to adsorb more

and more oxygen with increasing pressure. At 40 bar,

each gram of MOFs can even store an astonishing

amount of oxygen-72mg. However, the steric

hindrance of the functional group causes the decrease

of the average available volume of material which

does not affect the superiority of the total adsorption

capacity of this MOFs (compared to the conventional

UIO-66). It is the oxygen/fluorine interaction makes

its exceptional ability, which is different from the

usual functional group/guest adsorption (Piscopo,

2016).

The newly-discovered MOFs “Fe-BTTri” is

decorated with an iron (II) center bound in a

hemoglobin-like environment. Its unique framework

could adjust to iron centers of different spin-height

which made it suitable for studying the various

electronic transitions. The experiment demonstrates

that Fe-BTTri can undergo electronic changes like

those occurring when hemoglobin and oxygen bind,

Application of Metalâ

˘

A¸SOrganic Frameworks-Based Functional Materials for Gas Separation

125

thereby allowing for a much higher O

2

/N

2

selectivity

than other iron-based adsorbents. The oxygen

adsorption result of the MOFs is characterized by a

progressive decrease in its relative adsorption

capacity for oxygen as the pressure increases.

However, the performance is average at high

pressures, in the region of 210 mbar. The adsorption

capacity of the used functional materials can be up to

3.3 mM/g, or about 10 wt% of O

2

, suggesting that the

prepared MOFs-based functional material can be

used as a promising material for O

2

separation (Reed,

2020).

3 CONCLUSION

In conclusion, MOFs-based functional materials have

the potential to be applied in gas separation due to

their unique properties and structure. Through the

research in the previous study, the application of a

diverse of different MOFs-based functional materials

to four different types of gas separations is analyzed.

As for the C

2

H

2

/CO

2

separation, three categories of

MOFs, including light, unpenetrated and

ultramicroporous MOFs, are studied through

experiments such as molecular simulation. Owing to

the data, they can all separate C

2

H

2

and CO

2

molecules effectively. MOFs-based membrane with

fumarate and mesaconate linkers can be utilized in

CH

4

/N

2

separation, which shows an excellent

selectivity on specific gases and is also so energy-

efficient that it can substitute cryogenic distillation.

Another MOFs called IRMOF-1 plays a role in

adsorbing Xe atoms from Kr or Ar mixtures based on

the data of experiments and simulation. Regarding O

2

separation, MOFs-based functional materials like

UIO-66 containing fluorine, Fe-BTTri, and RPM3-

Zn are all practical for oxygen adsorption according

to their unique structural characteristics. Only several

kinds of gas separation are focused on in this report,

but it would be better if more research on MOFs

application could be done so that utility of MOFs can

be achieved to the maximum extent in the industry

and benefit humans.

REFERENCES

Cui, H., Xie, Y., Ye, Y., Shi, Y., Liang, B., & Chen, B.

(2021). An ultramicroporous metal-organic framework

with record high selectivity for inverse CO

2

/C

2

H

2

separation. Bulletin of the Chemical Society of Japan,

94(11), 2698-2701.

Chang, G., Li, B., Wang, H., Hu, T., Bao, Z., & Chen, B.

(2016). Control of interpenetration in a microporous

metal–organic framework for significantly enhanced

C

2

H

2

/CO

2

separation at room temperature. Chemical

Communications, 52(17), 3494-3496.

Fischer, M., Hoffmann, F., & Fröba, M. (2010). New

microporous materials for acetylene storage and

C

2

H

2

/CO

2

separation: insights from molecular

simulations. ChemPhysChem, 11(10), 2220-2229.

Greathouse, J. A., Kinnibrugh, T. L., & Allendorf, M. D.

(2009). Adsorption and separation of noble gases by

IRMOF-1: grand canonical Monte Carlo simulations.

Industrial & Engineering Chemistry Research, 48(7),

3425-3431.

Guo, Z. J., Yu, J., Zhang, Y. Z., Zhang, J., Chen, Y., Wu, Y.,

et al. (2017). Water-Stable In (III)-Based Metal–

Organic Frameworks with Rod-Shaped Secondary

Building Units: Single-Crystal to Single-Crystal

Transformation and Selective Sorption of C

2

H

2

over

CO

2

and CH

4

. Inorganic chemistry, 56(4), 2188-2197.

Gurdal, Y., & Keskin, S. (2012). Atomically detailed

modeling of metal organic frameworks for adsorption,

diffusion, and separation of noble gas mixtures.

Industrial & engineering chemistry research, 51(21),

7373-7382.

Gurdal, Y., & Keskin, S. (2013). Predicting noble gas

separation performance of metal organic frameworks

using theoretical correlations. The Journal of Physical

Chemistry C, 117(10), 5229-5241.

Meek, S. T., Teich-McGoldrick, S. L., Perry, J. J.,

Greathouse, J. A., & Allendorf, M. D. (2012). Effects of

polarizability on the adsorption of noble gases at low

pressures in monohalogenated isoreticular metal–

organic frameworks. The Journal of Physical Chemistry

C, 116(37), 19765-19772.

Piscopo, C. G., Trapani, F., Polyzoidis, A., Schwarzer, M.,

Pace, A., & Loebbecke, S. (2016). Positive effect of the

fluorine moiety on the oxygen storage capacity of UiO-

66 metal–organic frameworks. New Journal of

Chemistry, 40(10), 8220-8224.

Reed, D. A., Xiao, D. J., Jiang, H. Z., Chakarawet, K.,

Oktawiec, J., & Long, J. R. (2020). Biomimetic O 2

adsorption in an iron metal–organic framework for air

separation. Chemical science, 11(6), 1698-1702.

Wang, J., Zhang, Y., Su, Y., Liu, X., Zhang, P., Lin, R.

B., et al. (2022). Fine pore engineering in a series of

isoreticular metal-organic frameworks for efficient

C

2

H

2

/CO

2

separation. Nature communications,

13(1), 1-8.

Wu, Y., & Weckhuysen, B. M. (2021). Separation and

purification of hydrocarbons with porous materials.

Angewandte Chemie International Edition, 60(35),

18930-18949.

Wu, Y., Yuan, D., He, D., Xing, J., Zeng, S., Xu, S., et al.

(2019). Decorated traditional zeolites with subunits of

metal–organic frameworks for CH

4

/N

2

separation.

Angewandte Chemie International Edition, 58(30),

10241-10244.

Wang, C. Y., Wang, L., Belnick, A., Wang, H., Li, J., &

Lueking, A. D. (2017). Oxygen-selective adsorption in

FSB 2022 - The International Conference on Food Science and Biotechnology

126

RPM3-Zn metal organic framework. Chemical

Engineering Science, 165, 122-130.

Zhou, S., Shekhah, O., Ramírez, A., Lyu, P., Abou-Hamad,

E., Jia, J., et al. (2022). Asymmetric pore windows in

MOF membranes for natural gas valorization. Nature,

606(7915), 706-712.

Application of Metalâ

˘

A¸SOrganic Frameworks-Based Functional Materials for Gas Separation

127