Study on Methods of Protoplast Preparation of Aspergillus Niger

Xiangzhen Cui

Department of health caring industry, Shandong Institute of Commerce and Technology, Jinan 250103, China

Keywords:

Aspergillus Niger, Protoplast, Regeneration.

Abstract:

Filamentous fungi are important industrial strains. Aspergillus niger is a safe organism for the production of

proteins, organic acids, and chemicals. In order to improve the efficiency of genetic manipulation of A. niger,

we studied the method of preparing protoplasts and improving the regeneration rate, and established a method

of efficient transformation of protoplasts by exogenous DNA. Studies have shown that the preparation and

regeneration of A. niger protoplasts are affected by many factors, such as mycelial growth state, osmotic

pressure stabilizer, cell wall lyase system, enzymatic hydrolysis time, regeneration medium composition and

so on. The highest efficiency of protoplast release and regeneration was obtained by using the mycelium of

A. niger fresh spores cultured for 13-14 hours, using a mixture of snailase and lyticase, 0.6 M sorbitol as an

osmotic pressure stabilizer, and enzymatic hydrolysis at 32 °C for 2 hours.

1 INTRODUCTION

Filamentous fungi are important industrial strains.

The typical filamentous fungi such as Aspergillus

niger, Aspergillus oryzae, Penicillium chrysogenum,

Trichoderma reesei are widely used in the production

of organic acids, antibiotics, enzymes and proteins.

The filamentous fungi A. niger, A. oryzae and T.

reesei are recognized as safe production strains with

mature fermentation and post-processing technology

(Frisvad JC, 2018). As the host of genetic

engineering, filamentous fungi have unique

advantages different from that of bacteria and yeast.

They can correctly perform various post-translational

processing similar to higher eukaryotes. They have

high protein secretion capacity. They can degrade and

utilize a variety of biopolymers, such as starch,

cellulose, hemicellulose, pectin, xylan and protein, so

that they can use renewable resources such as plant

biomass for culture (Knuf C, 2012).

The commonly used transformation methods of

filamentous fungi are protoplast olyethylene glycol

(PEG) transformation, electrotransformation, and

Agrobacterium-mediated transformation. To obtain

higher transformation efficiency, we must obtain

more and higher quality protoplasts, and more

efficient transformation method.

In this study, we first established a method for the

preparation and regeneration of a large number of

niger protoplasts.

2 MATERIALS AND METHODS

2.1 Strains and Media

A. niger N593 ( ATCC Number : 64973 ) is a uridine-

deficient strain. A. niger were inoculated in yeast

extract peptone dextrose (YPED) plus uridine agar

(peptone 2%, glucose 2%, yeast extract 1%, uridine

0.25%, agar 1.5%, natural pH) and cultured at 30ºC

for 5 days to obtain mature spores. Collect the spores

from the agar with sterile water, fully disperse spores

with oscillator to obtain spore concentration 10

6

/mL.

2 ~ 3 mL of spore suspension was inoculated in a 500

mL flask containing 80 mL of modified Czapek 's

medium (glucose 1 %, citric acid 0.3 %, potassium

dihydrogen phosphate 0.5 %, ammonia nitrate 0.2 %,

magnesium sulfate 0.02 %, yeast extract 0.05 %,

Tween 80 0.1 %, uridine 0.25 %, pH6.5), and cultured

for 13-15 hours on a shaker at 30 ºC and 180 rpm.

2.2 Preparation of Protoplasts

The mycelium liquid of A. niger cultured for 13 ~ 14

h was put into two 50 mL centrifuge tubes,

centrifuged at 6000 rpm for 10 min. The supernatant

was removed, and the mycelium precipitate was

retained. Add 20 mL 0.6 M KCl solution to the

centrifuge tube, fully suspend the precipitate,

centrifuge at 6000 rpm for 10 minutes, and discard

the supernatant. Wash repeatedly 2 times. Then 30

Cui, X.

Study on Methods of Protoplast Preparation of Aspergillus Niger.

DOI: 10.5220/0012001500003625

In Proceedings of the 1st International Conference on Food Science and Biotechnology (FSB 2022), pages 59-62

ISBN: 978-989-758-638-5

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

59

mL 0.6 M KCl solution was used to re-suspend the

precipitate, and different proportions of snailase

(S10083, Yuanye biotech, Shanghai, China) and

lyticase (from Arthrobacter luteus, L2524, Sigma-

Aldrich) (totoal 0.01g) were added. The centrifuge

tube was placed at 32ºC water bath for 1~3 hours,

intermittently shaken slightly and sampled regularly

to monitor protoplasts formed. After enzymatic

hydrolysis, the protoplast fluid was filtered with four

layers of sterile wipe mirror paper. The filtrate was

centrifuged at 4000 rpm for 10 min, and the

supernatant was discarded. The precipitate was gently

washed twice with 0.6 M KCl solution and

centrifuged. The protoplast precipitation was

resuspended in 0.5~2 mL of 0.6 M KCl solution and

placed in an ice bath for later use.

2.3 Regeneration of Protoplasts and

Determination of Regeneration

Rate

Preparation of protoplast regeneration medium

(PRM) (glucose 1%, citric acid 0.3%, potassium

dihydrogen phosphate 0.5%, ammonia nitrate 0.2%,

magnesium sulfate 0.02%, yeast extract 0.025%,

uridine 0.25%, potassium chloride 0.6 mol / L, agar

(upper 0.5 %, lower 2%), pH 6.5). Double-layer plate

coating regeneration: After preparing the regenerated

solid medium (lower layer), the freshly prepared

protoplasts were gently mixed with the cooled

regenerated solid medium (upper layer) and poured

onto the lower regenerated solid medium. cultured at

30 ºC for 3~5 days, the formed colonies were counted

(A); in order to eliminate the error caused by the

mycelial fragments remaining in the prepared

protoplast solution and the colonies formed by the

regrowth of hyphal fragment, the prepared protoplast

solution was spread on the regeneration medium

without osmotic stabilizer, and the number of

regenerated colonies was used as control (B). The

number of protoplasts observed under microscope

was C. Regeneration rate was calculated as follows:

Protoplast regeneration rate = [ (A-B) / C] × 100 %

3 RESULTS AND DISCUSSION

3.1 Effect of Lyase on Protoplast

Formation

In order to obtain a higher protoplast yield, it is

necessary to select the appropriate lyase. Fungal cell

wall composition is complex. It is mainly composed

of four layers, from outside to inside is the amorphous

glucan layer, glycoprotein layer, protein layer, chitin

layer (Free SJ, 2013). Therefore, using mixture of

different lyase is better than using one kind of enzyme

alone. Snailase contains chitinase, cellulase,

pectinase, amylase, protease, etc., often used for yeast

cell wall disruption (Cheng, 2018). lyticase, also

known as N-acetylmural glycan hydrolase, can

destroy the β-1,4 glycosidic bond between N-

acetylmural acid and N-acetylglucosamine in the cell

wall (Tang, 2015).

The mycelia cultured in modified Czapek 's

medium for 14 h were collected. 0.6 M KCl was used

as osmotic pressure stabilizer. Firstly, the effects of

snailase and lyticase on protoplast formation were

determined. The results showed that the yield of

protoplasts was 5.41 × 106 / mL and 2.32 × 106 / mL

respectively when snailase (0.01 g / 30 mL hyphal

suspend) or lyticase (0.01 g / 30 mL hyphal suspend)

was used alone after 2 hours of enzymolysis (Fig.

1A). When snailase: lyticase was 2:1, 3:1, 1:1, 1:2,

1:3 (total 0.01 g / 30 mL hyphal suspend), the

production of protoplasts was 9.09 × 10

6

/ mL, 8.17 ×

10

6

/ mL, 1.19 × 10

7

/ mL, 1.21 × 10

7

/ mL, 1.35 × 10

7

/ mL, respectively. When snailase: lyticase = 3:1,

protoplasts reached the highest (Fig. 1B).

Figure 1: Effect of cell wall lyase on protoplast formation. (A) The number of protoplast formation when snailase or lyticase

was used alone. (B) Effects of different proportions of snailase and lyticase on protoplast formation. For ease of comparison,

the vertical coordinates of (A) and (B) are consistent.

FSB 2022 - The International Conference on Food Science and Biotechnology

60

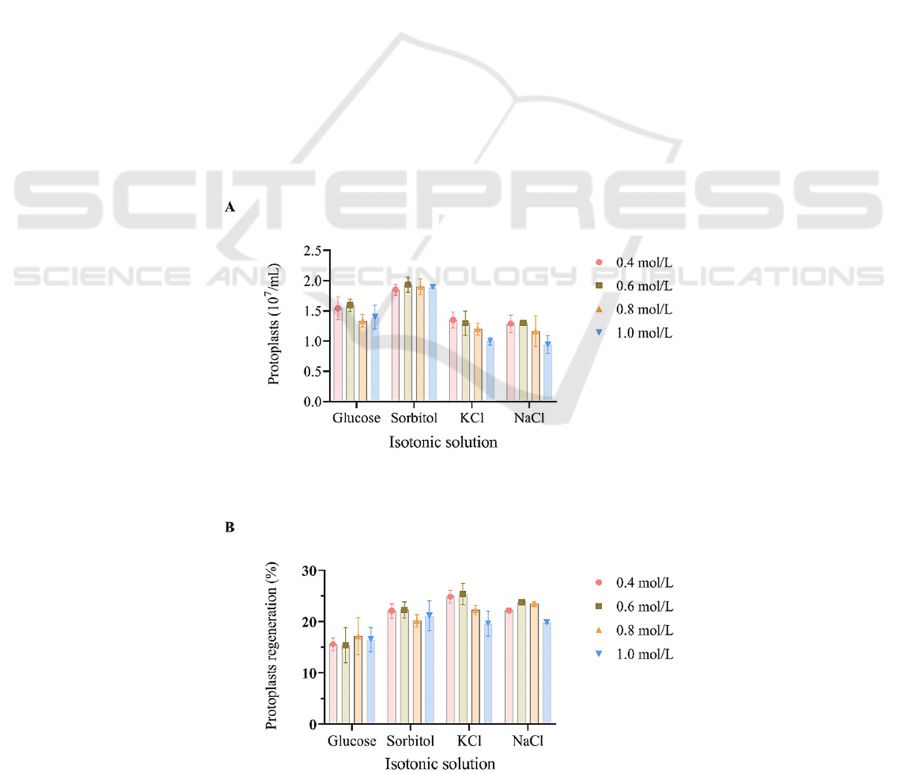

3.2

Effect of Osmotic Pressure

Stabilizer on Protoplast Formation

and Regeneration

The type and concentration of osmotic stabilizer is

the key factor to maintain and control the number of

protoplasts. It can not only maintain the osmotic

balance, but also promote the active reaction of lyase.

On the other side, osmotic stabilizer may aggravate

the damage of protoplasts or inhibit the synthesis of

cell wall during regeneration process. The mycelium

was cultured for 14 h in modified Czapek's medium,

0.6 mol / L KCl was used as osmotic stabilizer, and

the ratio of snailase: lyticase = 1:3 was used as mixed

enzyme to prepare protoplasts. The effects of two

sugars (glucose, sorbitol) and two salts (KCl, NaCl)

as osmotic pressure stabilizer on the production and

regeneration of protoplasts were studied.

The results showed that the formation of

protoplasts was the highest when sorbitol was used as

a stabilizer. When 0.6 mol / L sorbitol was used, the

production of protoplasts was the highest, reaching

1.93 × 10

7

/ mL. When the concentration of each

osmotic pressure stabilizer was between 0.4~0.8 mol

/ L, it had little effect on the formation of protoplasts.

However, when the concentrations of KCl and NaCl

reached 1.0 mol/L, the protoplast formation was

inhibited (Fig. 2A). The osmotic pressure stabilizers

also had a certain effect on the regeneration of

protoplasts. When 0.6 mol / L KCl was used as the

osmotic pressure stabilizer, the regeneration rate of

protoplasts was the highest, reaching 25.40 % (Fig.

2B). Combining the production and regeneration rate

of protoplasts, the number of regenerated protoplasts

was the highest when 0.6 mol / L sorbitol was used.

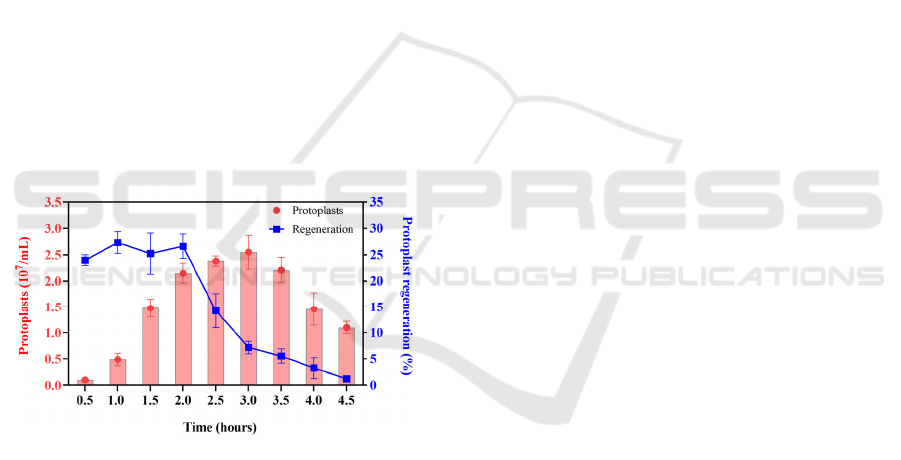

3.3 Effect of Lyase Action Time on

Protoplast Formation and

Regeneration

The mycelium was cultured in modified Czapek 's

medium for 14 h. The ratio of snailase: lyticase = 1:3

was used as mixed enzyme to prepare protoplasts. 0.6

mol / L sorbitol was used as osmotic pressure

stabilizer, and protoplasts were prepared at 32 °C.

The process of protoplast release was observed by

regular sampling. The number of protoplast

formation was monitored (Fig. 3). The mycelium

began to release protoplasts after 30 min of enzymatic

hydrolysis.With the extension of enzymolysis time,

the number of protoplasts gradually increased, and

reached the highest after 3 h, reaching 2.55× 10

7

/mL.

Figure 2: Effects of osmotic stabilizers on protoplast formation and regeneration. (A) Protoplast formation. (B) Protoplast

regeneration.

Study on Methods of Protoplast Preparation of Aspergillus Niger

61

Continue to extend the enzymolysis time, the number

of protoplasts did not continue to increase, but

decreased slightly (Fig. 3). Protoplast is not stable

due to the lack of cell wall. In addition, lysing enzyme

will damage the plasma membrane system of

protoplast to some extent, so the length of

enzymolysis time will seriously affect the

regeneration of protoplast. The enzymolysis time is

short, and the protoplast has not been fully released;

with the extension of enzymolysis time, the number

of protoplasts increased greatly, and the regeneration

rate increased continuously. Continue to extend the

enzymolysis time, the regeneration rate will decline

although the total number of protoplasts will increase.

When the enzymolysis time was 3 h, although the

protoplast production reached the highest, the

regeneration rate decreased significantly, only 27.1 %

of the regeneration rate when the enzymolysis time

was 2 h (Fig. 3). When the enzymolysis time was 4 h,

the regeneration rate decreased to nearly 0. This may

be due to the lack of cell wall in the formed

protoplasts. Therefore, considering the results of

protoplast production and regeneration, the

enzymolysis time should not exceed 2 h. After

enzymolysis, the lysate should be removed as soon as

possible.

Figure 3: Effect of lysing time on protoplast formation and

regeneration.

4 CONCLUSIONS

In this study, the method of preparation and

regeneration of protoplasts and the method of

efficient transformation of A. niger protoplasts by

exogenous DNA were established. The study

provides technical support for improving the

efficiency of gene targeting in A. niger and helps

realizing the genetic engineering with A. niger as cell

factory in future.

REFERENCES

Cheng T, Xu X, Zhang W, Chen L, Liu T. (2018) Protoplast

preparation from enriched flagellates and resting cells

of Haematococcus pluvialis. J Appl Microbiol.

124(2):469-479.

Frisvad JC, Møller LLH, Larsen TO, Kumar R, Arnau J.

(2018) Safety of the fungal workhorses of industrial

biotechnology: update on the mycotoxin and secondary

metabolite potential of Aspergillus niger, Aspergillus

oryzae, and Trichoderma reesei. Appl Microbiol

Biotechnol. 102(22):9481-9515.

Free SJ. (2013) Fungal cell wall organization and

biosynthesis. Adv Genet. 81:33-82.

Knuf C, Nielsen J. (2012) Aspergilli: systems biology and

industrial applications. Biotechnol J. 7(9):1147-1155.

Tang SY, Yi P, Soffe R, Nahavandi S, Shukla R,

Khoshmanesh K. (2015) Using dielectrophoresis to

study the dynamic response of single budding yeast

cells to Lyticase. Anal Bioanal Chem. 407(12):3437-

3448.

FSB 2022 - The International Conference on Food Science and Biotechnology

62