Formulation and Evaluation of Inhalable Porous Tobramycin Powder

Prepared by Spray Drying Technology

Tianxiong Xu

1,a

, Hao Miao

2

, Renjie Li

2

, Daoyin Liu

3

and Zhenbo Tong

1,b*

1

Center for Simulation and Modeling of Particulate Systems, Southeast University-Monash University Joint Research

Institute, Suzhou, Jiangsu, China

2

Department of Chemical Engineering, Monash University, Clayton, Vic, Australia

3

Key Laboratory of Energy Thermal Conversion and Control of Ministry of Education, School of Energy and Environment,

Southeast University, Nanjing, Jiangsu Province, China

Keywords:

Inhaled Tobramycin, Porous Particle, Spray Drying.

Abstract:

Inhaled tobramycin is one of the ideal ways to treat cystic fibrosis. The main purpose of this work is to prepare

inhaled tobramycin dry powder by spray drying through reasonable formula design. The properties of the

engineering particles are then characterized to reveal the particle-forming mechanism and structure-activity

relationship. Tobramycin, which exists in the form of sulphate, has higher stability compared with its

preparation alone. Leucine is enriched and crystallized on the surface of particles, which inhibits the

absorption of environmental water by forming a hydrophobic shell and reduces the cohesion between

particles. Compared with the organic solvent, ammonium bicarbonate (AB) as a porogen is less toxic and

more suitable for scale-up. An optimized formulation was obtained when active pharmaceutical ingredient

(API): Leucine: AB = 20: 7: 19. The sample under this formula has a porosity of 78.93 %. The loose and

porous structure brings good flowability (CI index is 24.63 ± 1.17 %) and 40.78 % fine particles fraction

(FPF). The particle deposition performance has been significantly improved. The drug load reaches 74.1 %,

which adapts to the requirement of high-dose delivery of antibiotics.

1 INTRODUCTION

In the research history of pulmonary delivery of

antibiotics, the treatment of cystic fibrosis (CF) with

inhaled tobramycin powder was a classic case. CF

patients were particularly vulnerable to the lung

infections caused by gram-negative bacteria such as

pseudomonas aeruginosa (PA) (

Alhajj, 2022)

.

Patients infected with PA experienced acute lung

deterioration, reflected by worsening respiratory

symptoms and a sharp decline in lung function.

Tobramycin was a well-known fungicide, which was

mainly active against aerobic gram-negative bacilli

and was considered to be more active against PA than

most other aminoglycoside antibiotics (

Elborn,

2022)

.

The first tobramycin inhaled dry powder (TIP,

TOBI) inhalation product was developed by Novartis

and available in the U.S. market since 2013 (Miller,

2015). TIP should be taken twice a day. Each dose

contained 4 capsules, of which contained 200 mg dry

powder (including 112 mg tobramycin) (

Buttini,

2018)

. The number of capsules limited the

improvement of patient compliance. The excipient

used in TIP was DSPC, a human endogenous

substance, which would bring high pharmaceutical

costs. At the same time, the perfluorooctyl bromide

(PFOB) in the formulation could be replaced with a

suitable porogen, which helped avoid some safety

hazards in the production process (explosion-proof in

workshop and equipment) (

Miller, 2017)

.

The purpose of this paper was to explore the

effects of different formulations and process

parameters on the particle microstructure and final

product properties, and to study the correlations

among parameters, microstructure, properties and

performance. In this work, tobramycin inhaled dry

powder was prepared by spray drying, and the

function and particle microstructure of the above

components were verified by several charac-

terizations, and the particle forming mechanism and

structure-activity relationship of tobramycin inhaled

powder were explored.

42

Xu, T., Miao, H., Li, R., Liu, D. and Tong, Z.

Formulation and Evaluation of Inhalable Porous Tobramycin Powder Prepared by Spray Drying Technology.

DOI: 10.5220/0012001200003625

In Proceedings of the 1st International Conference on Food Science and Biotechnology (FSB 2022), pages 42-46

ISBN: 978-989-758-638-5

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2 MATERIALS AND METHODS

2.1 Materials

United States Pharmacopeia (USP) tobramycin was

purchased from Yuanye Biotechnology Co., Ltd.

(Shanghai, China). 98 % concentrated sulfuric acid

and L-leucine (USP) were purchased from Titan

Technology Co., Ltd. (Shanghai, China). AB (USP)

was purchased from Jizhi Biotechnology Co., Ltd.

(Shanghai, China). Distilled water used in all steps

was produced from a Milli-Q device (~18.2 MΩ cm).

2.2 Preparation of The Feed Solution

and SD Particles

The feed solution composition was shown in Table 1.

So as to avoid the crystallization of naked

tobramycin, a certain amount of tobramycin was

dissolved in the aqueous solution before adding 98 %

concentrated sulfuric acid with a mass ratio of 3 to 1

under ultrasonication to acquire a clear solution. The

ratio was obtained from the commercial formulations

(TIP, TOBI), which had been thoroughly discussed

and reviewed regarding their safety (US Patent,

10744098B2). Leucine was then added to the

precursor formula. The enrichment of leucine on the

particle surface also helped reduce the cohesion

between particles and improved the powder delivery

efficiency. To obtain a particle of low density, e. g. a

porous particle structure similar to Pulmosphere

®

, AB

was eventually added to replace PFOB. In the formula

abbreviation, SD represented for spray drying; the

subscript numbers of TS and L (leucine) represented

the mass ratio between them; the subscript numbers

of AB represented their ratio to API; the last digit

represented the total solid content of the feed solution.

2.3 Methods

2.3.1 Particle Size Distribution

The particle size distribution was determined by laser

diffraction using the Sympatec HELOS system

equipped with the INHALER module (Sympatec

GmbH, Clausthal-Zellerfeld, Germany). The

dispersion pressure of the powders was 4 bars, and the

dispersion agent was compressed air. Before

measurement, each capsule was filled with

approximately 10 mg of sample and subjected to

static elimination. The particle size distribution of the

powder was calculated by applying the Fraunhofer

model preset in the instrument software.

2.3.2 Scanning Electron Microscopy

Scanning electron microscope (SEM, S-4700, Hitachi

High Technologies Corporation, Japan) was used to

characterize the powder morphology. The

accelerating voltage of the SEM was 15 kV and the

magnification of the images was 800–20000 times.

Before observation, the conductive carbon tape was

fixed on the sample preparation table, and an

appropriate amount of sample powder was placed on

the conductive carbon tape, and then loaded into the

ion sputtering coater (MC1000, Hitachi Ltd., Japan).

Finally, the powder was platinized by sputtering to

make the surface sample conductive and avoid charge

build-up during observation in the SEM.

2.3.3 Infrared Spectroscopy

The residual degree of AB was determined by Fourier

transform infrared spectroscopy (FTIR) to evaluate

the decomposition of AB. These spectra were

obtained by a single reflection diamond ATR

(Universal ATR) in a Nicolet IS50 FTIR spectrometer

(Thermo Fisher Scientific Inc.). The FTIR spectra

were obtained at a resolution of 0.09 cm

-1

over a

wavelength range from 400 cm

-1

to 4000 cm

-1

.

2.3.4 Pore Size, Porosity and Density

The porosity and pore size distribution of the sample

were determined with a mercury porosimeter

(AutoPore IV, Micromeritics, US). Under standard

atmospheric pressure conditions, 3ml sample was

placed in a permeameter, which was bonded to a glass

capillary rod. When pressure was applied, the

mercury moved down the capillary rod and filled the

voids in and around the sample. The change in

capacitance due to the loss of mercury in the capillary

rod could be analyzed to determine the porosity and

pore size distribution.

The bulk density (ρ

b

) was measured by measuring

the mass of about 4 mL of particles in a glass cylinder

before being tapped and the tapped density (ρ

t

) was

determined by measuring the volume after tapping the

above-mentioned particles of known mass. The

sample’s flowability was characterized by Carr's

index (CI) calculated by Eq. (1):

𝐶𝐼 =

𝜌

−𝜌

𝜌

∗ 100%

1

2.3.5 Aerodynamic Properties

The aerodynamic characteristics of inhaled

tobramycin particles were studied using the next

generation impactor (NGI) (Copley Science,

Formulation and Evaluation of Inhalable Porous Tobramycin Powder Prepared by Spray Drying Technology

43

Nottingham, UK). The samples were dispersed by the

Twincaps

®

(BrightGene Ltd., Soochow, China) at 60

L/min evaluated by a Critical Flow Controller

(Erweka, Heusenstamm, Germany). A vacuum pump

(Erweka, Heusenstamm, Germany) was used to set

the pressure drop across the whole device at 4 KPa.

Each formulation would be dispersed for 4 s to attain

4 L volume. The specific operation was carried out

according to the weighing method stipulated in the

British Pharmacopoeia. The FPF and mass median

aerodynamic diameter (MMAD) of the sample could

be calculated by the data processing software

CITDAS (Copley Science, Nottingham, UK).

3 RESULTS AND DISCUSSION

3.1 Particle Size, Morphology and

Density

The sample particles were successfully prepared by

spray-drying feed liquids with different formulations

(Table 1). Table 2 summarized the physical properties

of various spray-dried (SD) microparticles.

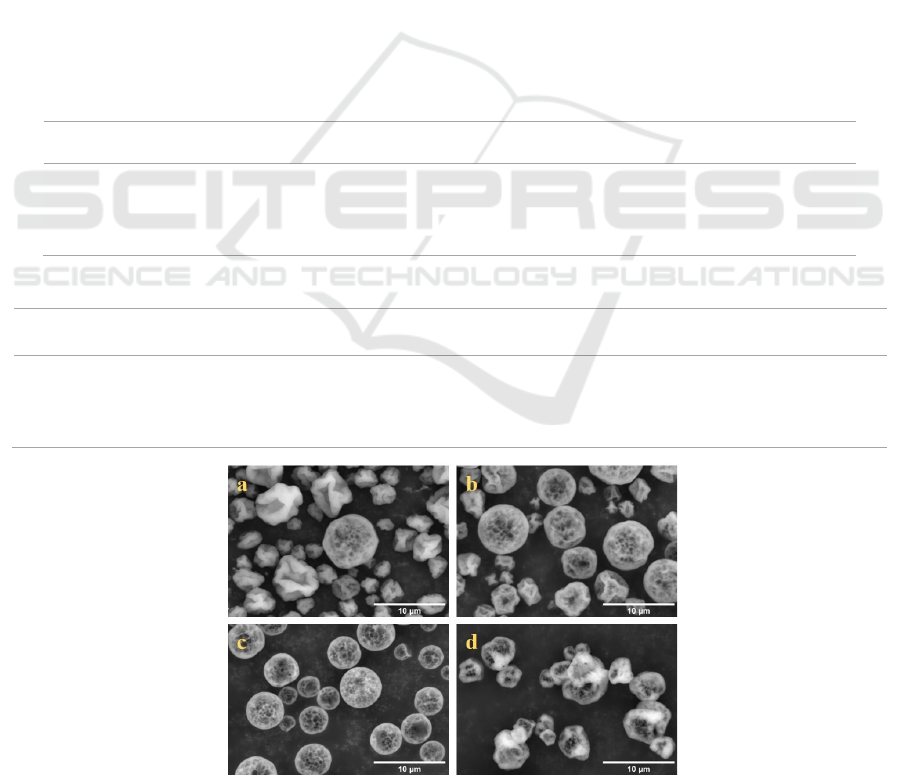

After adding AB to the precursor solution (Fig. 1), the

morphology of the particles showed that the

sphericity of the particles gradually recovered with

the increase of the amount of AB added. Since the

amount of AB was included in the total solid content,

its decomposition and gas escape did not lead to a

significant change in particle size. Under the same

ratio of TS and leucine, the CI decreased from 29.12

± 0.82 % (SD-TS

1

L

0.35

-AB

1

-0.68) to the lowest 24.63

± 1.17 % (SD-TS

1

L

0.35

-AB

3.5

-0.5), indicating that the

appearance of pores brought about a significant

improvement in fluidity. It should be noted that the

addition of excess AB would lead to obvious

agglomeration behavior of the particles, the particle

size rose to 34.10 ± 1.88 μm, and the CI rose to 28.44

± 2.79 %, indicating that the flowability also had a

certain degree of loss. The inference of this

phenomenon would be analyzed in conjunction with

the pore structure below.

Table 1: Precursor formulation and process parameters for spray drying.

Sample Tobramycin

(10

-2

g/ml)

Sulfate

(10

-2

g/ml)

Leu

(10

-2

g/ml)

AB

(10

-2

g/ml)

Total solid content

(%w/w)

SD-TS

1

L

0.35

-AB

1

-0.5

0.228 0.080 0.108 0.083 0.50

SD-TS

1

L

0.35

-AB

2

-0.5

0.196 0.068 0.093 0.143 0.50

SD-TS

1

L

0.35

-AB

3.5

-0.5

0.161 0.056 0.076 0.206 0.50

SD-TS

1

L

0.35

-AB

5

-0.5

0.137 0.048 0.065 0.250 0.50

Table 2: Physical properties of different formulations.

Sample Bulk density

ρ

b

(g/cm

3

)

Tapped density

ρ

t

(g/cm

3

)

CI

(%)

D

50

(μm)

Porosity

(%)

SD-TS

1

L

0.35

-AB

1

-0.5

0.353±0.002 0.498±0.003 29.12±0.82 8.19±0.28 -

SD-TS

1

L

0.35

-AB

2

-0.5

0.164±0.001 0.224±0.002 26.79±1.08 9.95±0.39 56.75

SD-TS

1

L

0.35

-AB

3.5

-0.5

0.061±0.001 0.081±0.001 24.69±1.53 10.92±0.36 78.93

SD-TS

1

L

0.35

-AB

5

-0.5

0.075±0.002 0.105±0.003 28.57±3.83 34.10±1.88 54.07

Figure 1: SEM images of (a) SD-TS

1

L

0.35

-AB

1

-0.5; (b) SD-TS

1

L

0.35

-AB

2

-0.5; (c) SD-TS

1

L

0.35

-AB

3.5

-0.5; (d) SD-TS

1

L

0.35

-AB

5

-

0.5.

FSB 2022 - The International Conference on Food Science and Biotechnology

44

Figure 2: Infrared spectral images of (a) tobramycin sulfate; (b) leucine; (c) ammonium bicarbonate; (d) SD-TS

1

L

0.35

-AB

2

-

0.5; (e) SD-TS

1

L

0.35

-AB

3.5

-0.5; (f) SD-TS

1

L

0.35

-AB

5

-0.5.

3.2

Porous Structure and Residual

Ammonium Bicarbonate

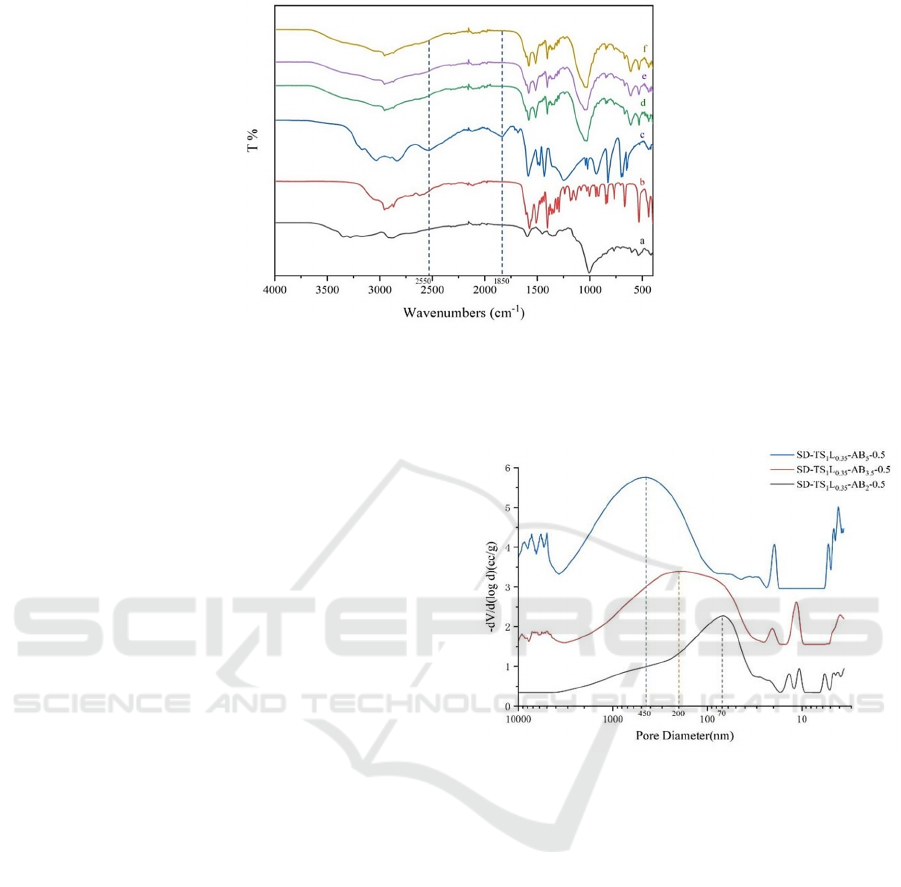

Infrared results for TS, leucine, AB, and samples

were analyzed (Figure 2). Specifically, AB had

unique characteristic peaks near 1850 cm

-1

and 2550

cm

-1

, but these characteristic peaks did not appear in

the infrared image of the sample. This confirmed that

AB has been completely decomposed with negligible

residues.

The mercury intrusion analysis results (Fig. 3)

showed that from sample SD-TS

1

L

0.35

-AB

2

-0.5 to

SD-TS

1

L

0.35

-AB

3.5

-0.5, the porosity increased from

56.75 % to 78.93 %, and the pore size increased from

70 nm to 200 nm. This showed that the decomposition

of AB, gas accumulation and final pore formation

were stable and controllable in the particle formation

process under the current conditions, which was of

great significance for the formation of a feasible

process flow. However, when the addition of AB

continued to increase (SD-TS

1

L

0.35

-AB

5

-0.5), the

pore size expanded to 450 nm, while the porosity was

significantly reduced to 54.07 %. Combining the

results of the SEM images, particle size, and

flowability data for this formulation above, the reason

for this phenomenon was that the relative proportions

of AB and the rest of the solids (TS and leucine) were

too high, while the total solids content of the

precursors was constant. In order to maintain the

particle structure at a substantially constant particle

size, the required solid content in the sample particles

was already insufficient, which led to the collapse of

the basic structure of the particles, and the porosity

that should continue to increase also decreased. The

finally obtained sample particles had serious

agglomeration, increased cohesion, and decreased

dispersibility and fluidity.

Figure 3: Images of the pore size distribution of (a) SD-

TS

1

L

0.35

-AB

2

-0.5; (b) SD-TS

1

L

0.35

-AB

3.5

-0.5; (c) SD-

TS

1

L

0.35

-AB

5

-0.5.

3.3

Aerodynamic Performance

In order to obtain particles suitable for inhalation

therapy, proper aerodynamic behavior was required.

In general, the aerodynamic particle size of particles

for inhalation should be between 0.5 and 5 μm. On

this basis, the aerodynamic particle size distribution

of the samples was characterized by NGI.

Preliminary experiments found that under the

existing conditions, when the ratio of API and leucine

was 20:7, the aerodynamic performance of the

formulation was relatively optimal. Based on this

ratio of leucine and TS, AB was added to the

precursor solution and the aerodynamic performance

of the samples were characterized (Fig. 4). From the

formulation of SD-TS

1

L

0.35

-AB

1

-0.5 to SD-TS

1

L

0.35

-

AB

3.5

-0.5, it could be seen that the particle

Formulation and Evaluation of Inhalable Porous Tobramycin Powder Prepared by Spray Drying Technology

45

Figure 4: NGI results for different formulations.

distribution of each level had a tendency to gradually

aggregate to higher levels. The deposition amount of

the formula SD-TS

1

L

0.35

-AB

3.5

-0.5 at stage 6, stage 7,

and MOC was significantly higher than that of other

formulas, indicating that the pores left by AB in the

sample particles could significantly improve the

aerodynamic performance of samples. The MMAD

of the SD-TS

1

L

0.35

-AB

3.5

-0.5 formula had dropped to

about 2.4 μm, and the FPF had increased to 40.78 %.

However, for the SD-TS

1

L

0.35

-AB

5

-0.5, the FPF did

not increase further but decreased to 34.07 %, and the

MMAD also increased to 2.8 μm, which was

consistent with the characterization results of SEM

images, particle size and particle density. At this time,

the agglomeration between particles was intensified,

the fluidity and dispersion of the powder were also

deteriorated, and the unsatisfactory particle structure

eventually led to the decline of aerodynamic

performance. Eventually, the formulation of SD-

TS

1

L

0.35

-AB

3.5

-0.5 was optimized.

4 CONCLUSION

This work explored the heat-mass coupling process in

the spray drying process by adjusting the formulation

and parameters, and finally achieved a FPF of

40.78 % in the optimal formulation. The low-density,

loose and porous particle structure in the expected

target was verified by multiple characterization

results such as SEM images and porosity. This

structure provided particles with better dispersibility

and flowability and smaller aerodynamic size,

making them suitable for efficient pulmonary

delivery. AB residues in the final product were also

substantially absent as evidenced by infrared

spectroscopy. When the preferred ratio of API to

leucine is 20: 7, leucine was enriched on the outer

surface of the particles to a certain extent. When the

ratio of non-porous components to AB was 10: 7, the

porous particles had higher porosity and lower

density, resulting in lower aerodynamic particle size.

The final optimized spray drying formulation was

SD-TS

1

L

0.35

-AB

3.5

-0.5. The particles prepared under

this formula had large geometric size, loose porosity,

good deposition performance and high stability.

Inhalation of particles was both the core idea of this

article and the starting point for continuous

improvement in formulation design.

ACKNOWLEDGEMENTS

The authors are grateful to the National Key R&D

Project of China (2021YFB1715500) for the financial

support of this work.

REFERENCES

Alhajj, N., O'Reilly, N. J., Cathcart, H. (2022)

Developing Ciprofloxacin Dry Powder for

Inhalation: A Story of Challenges and Rational

Design in the Treatment of Cystic Fibrosis Lung

Infection.

International Journal of Pharmaceutics.

613

: 121388.

Elborn, J. S., Blasi, F., Haworth, C. S., Ballmann, M.,

Tiddens, H. A., Murris-Espin, M., Chalmers, J. D.,

Cantin, A. M. (2022) Bronchiectasis and inhaled

tobramycin: A literature review. Respiratory

medicine. 192: 106728.

Buttini, F., Balducci, A. G., Colombo, G., Sonvico, F.,

Montanari, S., Pisi, G., Rossi, A., Colombo, P. (2018)

Dose administration maneuvers and patient care in

tobramycin dry powder inhalation therapy.

International journal of pharmaceutics.

548: 182-191.

Miller, D. P., Tan, T., Tarara, T. E., Nakamura, J.,

Malcolmson, R. J., Weers, J. G. (2015) Physical

characterization of tobramycin inhalation powder:

I

.

Rational design of a stable engineered-particle

formulation for delivery to the lungs

. Molecular

pharmaceutics

. 12 (8): 2582-2593.

Miller, D. P., Tan, T., Nakamura, J., Malcolmson, R. J.,

Tarara, T. E., Weers, J. G. (2017) Physical

characterization of tobramycin inhalation powder: II.

State diagram of an amorphous engineered particle

formulation.

Molecular pharmaceutics

. 14 (6):

1950-1960.

FSB 2022 - The International Conference on Food Science and Biotechnology

46