A Review of Permeable Pavement in Indonesia: Performance and

Application

Yudi Pranoto

1

, Nor Fazilah Hasim

1

and Tumingan

2

1

Faculty of Technology and Informatics Razak, Universiti Teknologi Malaysia, Jalan Sultan Yahya Petra 54100,

Kuala Lumpur, Malaysia

2

Civil Engineering Department, Samarinda State Polytechnic, Jalan Ciptomangunkusumo 75131, Samarinda,

East Kalimantan, Indonesia

Keywords: Permeable Pavement in Indonesia, Performance, Application.

Abstract: This work aims to provide an overview of the development of permeable pavement in Indonesia based on the

latest literatures regarding performance, infiltration, and application. Permeable pavements have become

well-known as effective stormwater management for controlling rainwater runoff. Permeable pavement

provides excellent benefits, especially in largely populated areas with a view catchment area so frequent

flooding. This study was conducted by collecting the latest studies on a permeable pavement in Indonesia in

recent years. From the literature collected, it was found that: first, the permeable pavement has excellent

advantages. It can absorb water into the soil through its pores but has low strength. Second, in Indonesia,

various studies have been carried out to increase the strength of permeable pavement by adding various

additives but have not found optimum conditions. Third, in Indonesia, the permeable pavement has varying

compressive strength but yet, it has a low compressive strength where can be implemented for parking,

pedestrians, garden, and other uses. Several issues have been identified as challenges and needs for future

research on permeable pavement systems: (a) Optimizing structural performances by modifying design; (b)

developing a standard maintenance procedure to restore infiltration capacity, and (c) improving the bearing

capacity of the structure to withstand higher vehicular loads.

1 INTRODUCTION

Indonesia is a developing country, especially in the

socio-economic field in the last few decades. This can

be seen in the infrastructure development plan in

2021. Indonesia plans to build 1,078.48 km roads,

three large bridges, 2,189 flats, and two dams in

2021(Fadli, 2021). Massive infrastructure

development has reduced water catchment areas, so

developing an environmentally friendly sustainable

development concept is necessary.

The concept of sustainable development has wide

applications. In this study, the concept of watertight

surface infrastructure development is used. Several

researchers have reviewed impermeable surfaces and

rainwater waste (Jayakaran et al., 2019; Kováč and

Sičáková, 2018; Kováč and Sičáková, 2017). Larger

amounts of rainwater end up falling on impermeable

surfaces such as roads, buildings, sidewalks, and

parking lots rather than seeping onto the ground. This

creates an imbalance in the natural ecosystem and

causes several problems such as flooding and erosion

(Koohmishi and Azarhoosh, 2021). Typically,

parking lots, driveways, sidewalks and roads etc are

constructed with Portland cement concrete and

asphalt. Concrete and asphalt are impermeable to

water, helping to increase surface runoff which

strains infrastructure and causes flooding in

construction areas.

Permeable pavement is an alternative impervious

pavement, allows stormwater to flow through the

voids in the layer and then infiltrate the underlying

original soil (Razzaghmanesh and Borst, 2018;

Stormwater, 2019). Recent reviews stated that

permeable pavement could provide many

environmental benefits over conventional pavements,

including reduced runoff and increased rainwater

infiltration, improved groundwater quality, increased

surface skid resistance, reduced hydroplaning and

heat islands. This benefit can increase the resilience

and traffic safety of the transportation system for road

users or the community (Xie, Akin, and Shi, 2019;

992

Pranoto, Y., Hasim, N. and Tumingan, .

A Review of Permeable Pavement in Indonesia: Performance and Application.

DOI: 10.5220/0012000100003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 992-1000

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Jusli et al. 2014; Yu et al. 2021; Winston et al. 2016;

Cheng et al. 2019; Kuruppu, Rahman, and Rahman,

2019; Li, Kayhanian, and Harvey, 2013; El-maaty,

2016). It also very useful to overcome urbanization in

densely populated areas, where many buildings and

roads are built where the catchment area are reduced,

and eventually, become main cause of flooding

during heavy rain. The system of permeable

pavement infiltration shows in Figure 1. This type of

pavement can be used for low-traffic roads, parking

lots, gardens, and sidewalks.

The most commonly used permeable pavement

surfaces are pervious concrete (PC), porous asphalt

(PA), and permeable interlocking concrete pavers

(PICP) (Alam et al. 2019; Selbig and Buer, 2018;

Huang et al. 2016). The visual differences between

the three types of permeable pavements can be seen

in Figure 2. Razzaghmanesh and Beecham (2018)

conducted a study by comparing the three types of

permeable pavement and showed that porous

concrete had the highest infiltration rate, followed by

permeable interlocking concrete pavers and porous

asphalt. The average infiltration rate was reduced in

the second year after the installation.

In Indonesia, permeable pavements are used for

parks, gardens, and sidewalks. Several studies have

been conducted to increase the strength and durability

of permeable pavement. (Pradoto et al., 2019), used

Figure 1: Permeable pavement system infiltration (Hein and

Schaus, 2013).

fly ash as a filler in porous asphalt, volcanic ash

(Rifa’i and Yasufuku, 2017), and coconut fiber

(Maharana, Jena, and Panda, 2020).

1.1 Pervious Concrete (PC)

Pervious concrete is an open-graded structure with

interconnected voids through which rain and

stormwater are permitted to percolate into the aquifer

(Maguesvari and Narasimha, 2013). According to [3]

translucent concrete is a product of traditional

materials used for the manufacture of concrete but

without fine aggregate or the amount of fine

aggregate added is very small to get high porosity in

the range of 0.14 - 0.35. Pervious concrete is

produced by adding aggregate into a cementious mix

to maintain interconnected void space. As a result, it

has a coarser appearance than standard concrete.

Additives also can be combined to increase strength

and improve binding, compared to conventional

concrete due to its high porosity. Permeable concrete

has a large cavity size, in contrast to conventional

concrete which has small cavities. Pervious concrete

has a large size of voids, different with conventional

concrete, which has small voids. The porosity of the

pervious concrete varies from 15% to 25% by volume

(Dover, 2020; Paul et al. 2004; Chandrappa and

Biligiri, 2016). The water permeability of pervious

concrete typically ranges from 0.14 cm/s to 1.22 cm/s,

and the compressive strengths generally fall under the

range of 2.8 MPa to 28 MPa (ACI 552R-10 2010),

compared to 1x9

-10

mm/s for normal weight concrete.

According to the American Concrete Institute and

pervious concrete has a lower compressive strength

of 5-10 MPa, the compressive strength is generally

below the range of 2.8 MPa to 28 MPa compared to

normal concrete because of its high porosity and

tensile strength of between 1-3,8 MPa (ACI 552R-10

2010). Stability and durability of translucent concrete

are affected due to lower compressive strength. Due

to its relatively lower strength, the application of axle

(a)

(b) (c)

Figure 2: Porous asphalt (a), pervious concrete (b), permeable interlocking concrete pavers (c) (Schultze-allen, 2018).

A Review of Permeable Pavement in Indonesia: Performance and Application

993

concrete is limited to low traffic. Additives can also

be combined to increase strength and improve

bonding. There have been many studies to improve

the performance of porous concrete. Ramadhansyah

et al., (2020) using Nano black rice husk ash, fly ash

and superplasticizer. The same study was conducted

by (Irlan, Rintawati, and Paikun, 2020; Mulyono and

anisah, 2019; Mulyono and Anisah, 2019a) using fly

ash, superplasticizer, and fiber. From their research

found that additives can increase the strength of

pervious concrete.

1.2 Porous Asphalt (PA)

Porous asphalt typically consists of conventional

warm mix asphalt (WMA) or hot mix asphalt (HMA)

with significantly reduced fines resulting in an open-

graded mixture that allows water to pass through

interconnected void space. The porous asphalt surface

void space typically ranges from 10% to 25%. In

comparison, voids for standard asphalt are typically

2% to 3%, and they are not interconnected (Dover,

2020). The properties of porous asphalt is shown in

Table 1.

Table 1: Physical Properties of Porous Asphalt (Australian

Asphalt Pavement Association 2004).

No Planning criteria Grade

1 Marshall Stability (kg) Min. 500

2 Flow (mm) 2 - 6

3 Void in Mix (VIM) (%) 18 - 25

4 Marshall Quotient (kg/mm) Max 400

1.3 Permeable Interlocking Concrete

Pavers (PICP)

Permeable interlocking concrete pavement (PICP)

comprises manufactured concrete units that reduce

stormwater runoff volume, rate, and pollutants. The

impervious units are designed with small permeable

joints. The openings typically comprise 5% to 15% of

the paver surface area, maintaining high permeability

with small-sized aggregate fill. The joints allow

stormwater to flow into a crushed stone aggregate

bedding layer and base/subbase supporting the pavers

while providing water storage, runoff quantity, and

quality treatment. PICP is visually attractive, durable,

easily repaired, requires low maintenance, and can

withstand heavy vehicle loads (Dover, 2020). The

physical properties of the paving block are shown in

Table 2. Quality A used for road, quality B for

parking, quality C for pedestrians, and quality D for

garden and other uses.

Table 2: Physical Properties of Paving Block (SNI 03-0691

1996).

Quality

Compressive

Strength

(MPa)

Wear

Resistance

(mm/minute)

Maximum

absorption

(%)

Average Min Average Min

A 40 35 0.09 0.10 3

B 20 17 0.13 0.15 6

C 15 12.5 0.16 0.18 8

D 10 8.5 0.22 0.25 10

Although Permeable pavement can provide

environmental benefits, it has problems with the

application which is related to durability and

clogging. Some factors contributing to permeable

pavement damage include sediments in stormwater

from adjacent land or collapsed pores from vehicular

traffic; (Kia, Wong, and Cheeseman, 2018; Kia,

Wong, and Cheeseman, 2021). These problems are

essential factors that affect in design, construction,

and maintenance of Permeable pavements. In this

case, this research aims to provide an overview of the

development of permeable pavement in Indonesia,

focusing on its performance, infiltration, and

application.

2 METHODS

The research method uses a literature review from

previous research studies that have been carried out

in Indonesia. The structured literature review is a

method in which critical research papers and studies

directly related to the research question are collected

and analyzed systematically. This study is designed

to find future research on permeable pavements in

Indonesia.

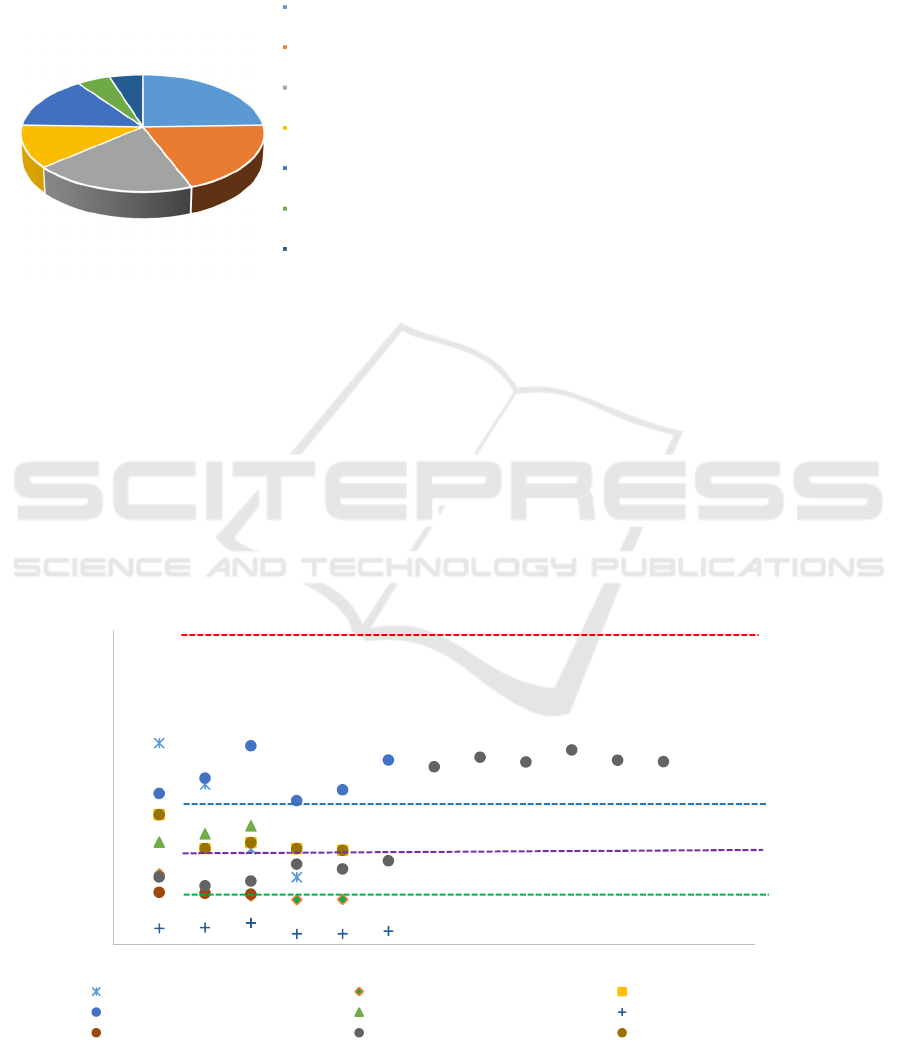

The literature is collected via keywords search on

major databases including Google Scholar, Scopus,

and, Web of Science journals. The keywords used

include permeable pavement, paving porous,

pervious concrete, asphalt porous, infiltration, and

others presented in figure 3. Journals, proceedings,

and books since 2011 were collected for review.

Consideration of the suitability of the journal with the

material used by the following criteria: relevance to

the topic of review, quality, and impact on permeable

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

994

pavement research in Indonesia. The final result of

this work is to identify research gaps and provide

recommendations for future research to enhance the

performance of permeable pavement in Indonesia as

a sustainable stormwater management practice.

Figure 3: Categories studies on the permeable pavement.

3 RESULT AND DISCUSSION

3.1 Performance

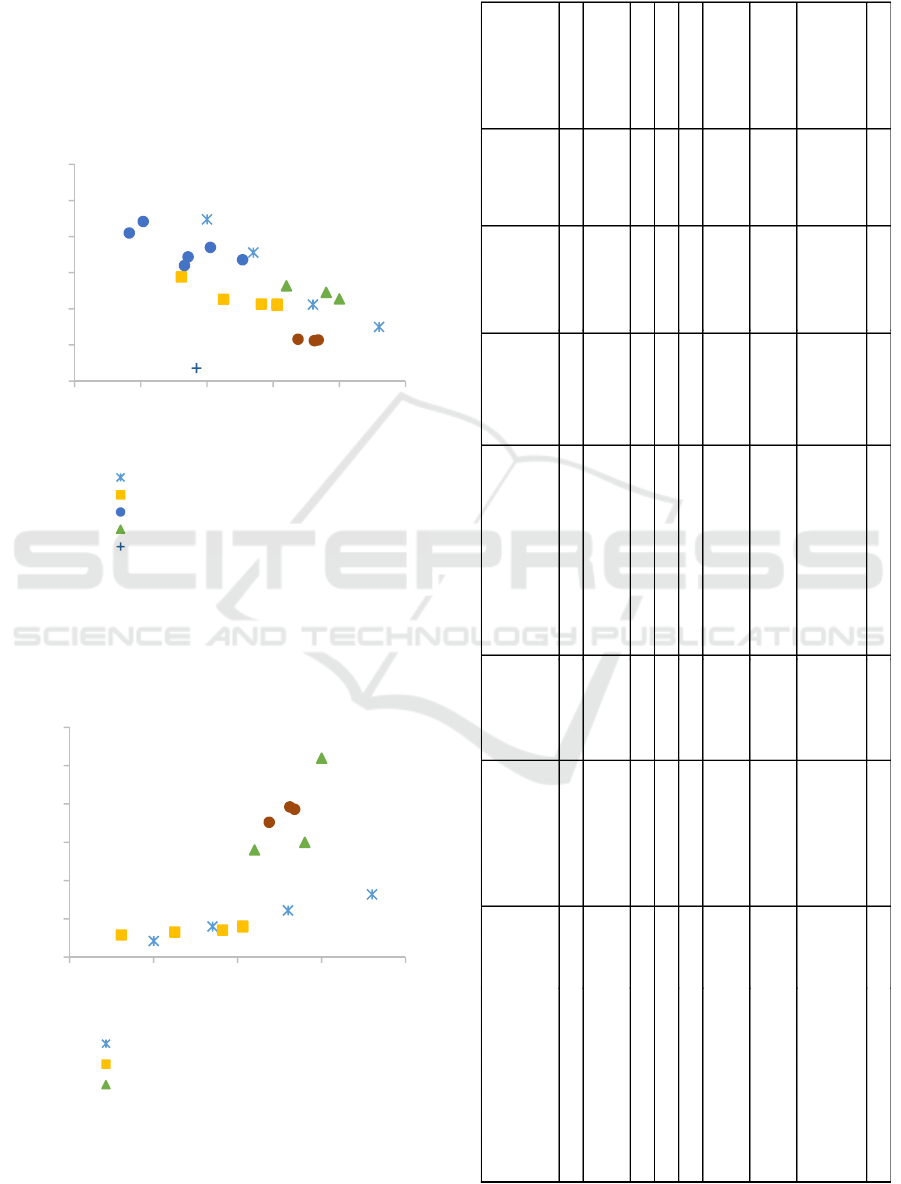

For PC and PIPC, several studies in Indonesia, as

shown in Figure 4, show that the compressive

strength of the PC and PIPC varies, but in general, has

low compressive strength (not more than 30

MPa)(Limantara et al. 2018; Rifqi, Amin, and

Lesmana, 2018; Rifa’i and Yasufuku, 2017; Aman et

al. 2016; Wijaya and Ekaputri, 2014; Saputra and

Arie Wardhono, 2018; Mulyono et al. 2019; Ridwan

et al. 2018; Chairuddin et al. 2016). In this research,

efforts have been made to increase the compressive

strength of permeable pavements by using additives.

Materials such as fly ash, volcanic ash, coconut fiber,

circle aggregate, natural aggregate, superplasticizer,

recycle asphalt, and coal ash as shown in table 3. It is

necessary to develop new permeable pavement in

order to produce high-quality permeable pavement.

Meanwhile, table 4 shows the good performance of

porous asphalt in Indonesia where can be seen from

the perspective of Stability, flow, marshal quotient,

and porosity (Ramadhan and Reza, 2014; Tronge et

al. 2017; Ayun, 2017; Rifqi et al. 2019; Arlia, Saleh,

and Anggraini, 2018; Saleh, Anggraini, and Aquina,

2014). From the previous research, not all of them

have been porosity tested. It is necessary to determine

the percentage of void in mix of porous asphalt.

3.2 Porosity and Permeability

The compressive strength decrease as the porosity

increase refers to Figure 5. It is caused by voids content

in the structure of permeable pavement. When the void

percentage increases, the strength of the hardened

concrete tends to decreases. Permeability is a property

of a porous material that allows the flow of seepage

from a liquid (water or oil) to flow through the pore

cavity. Based on previous

study in Indonesia, the

permeability of the permeable pavement varies

Figure 4: Performance of permeable pavement in Indonesia (Rifa’i and Yasufuku, 2017; Mulyono and Anisah, 2019; Rifqi,

Amin, and Lesmana, 2018; Aman et al. 2016; Wijaya and Ekaputri, 2014; Saputra and Arie Wardhono, 2018; Ridwan et al.

2018; Chairuddin et al. 2016; Limantara et al. 2018).

Porous Paving

Porous Asphalt

Permeable Concrete

Permeable pavement

Infiltration

Stormwater

Application of

Permeable pavement

0

5

10

15

20

25

30

35

02468101214

Compressive strength (MPa)

Limantara et al, 2018 M. G. Rifqi et al, 2018 Saputra and Wardhono, 2018

Mulyono and Anisah, 2019 Care et al, 2018 F. Chairuddin et al, 2016

A. Rifa’i and N. Yasufuku, 2017

Wijaya and ekaputri, 2014 Saputra, F.G, 2016

Quality A

Quality B

Quality C

Quality D

A Review of Permeable Pavement in Indonesia: Performance and Application

995

greatly between 0.21 to 2.6 cm/s (Limantara et al.

2018; Saputra and Arie Wardhono, 2018; Rifa’i and

Yasufuku, 2017; Ridwan et al. 2018). The

permeability and porosity data are plotted in Figure 6.

From Figure 6, it can be seen that the porosity is

recorded between 15% until 35%. This porosity value

is also in line accordance with the ACI standard with

porosity between 15-35%.

Figure 5: Correlation between compressive strength and

porosity of some studies in Indonesia (Limantara et al.

2018; Rifqi, Amin, and Lesmana, 2018: Rifa’i and

Yasufuku, 2017; Saputra and Arie Wardhono, 2018;

Mulyono et al, 2019; Ridwan et al. 2018; Chairuddin et al.

2016).

Figure 6: Correlation between porosity and permeability in

some studies in Indonesia (Rifa’i and Yasufuku, 2017;

Saputra and Arie Wardhono, 2018; Ridwan et al. 2018;

Chairuddin et al. 2016; Limantara et al. 2018).

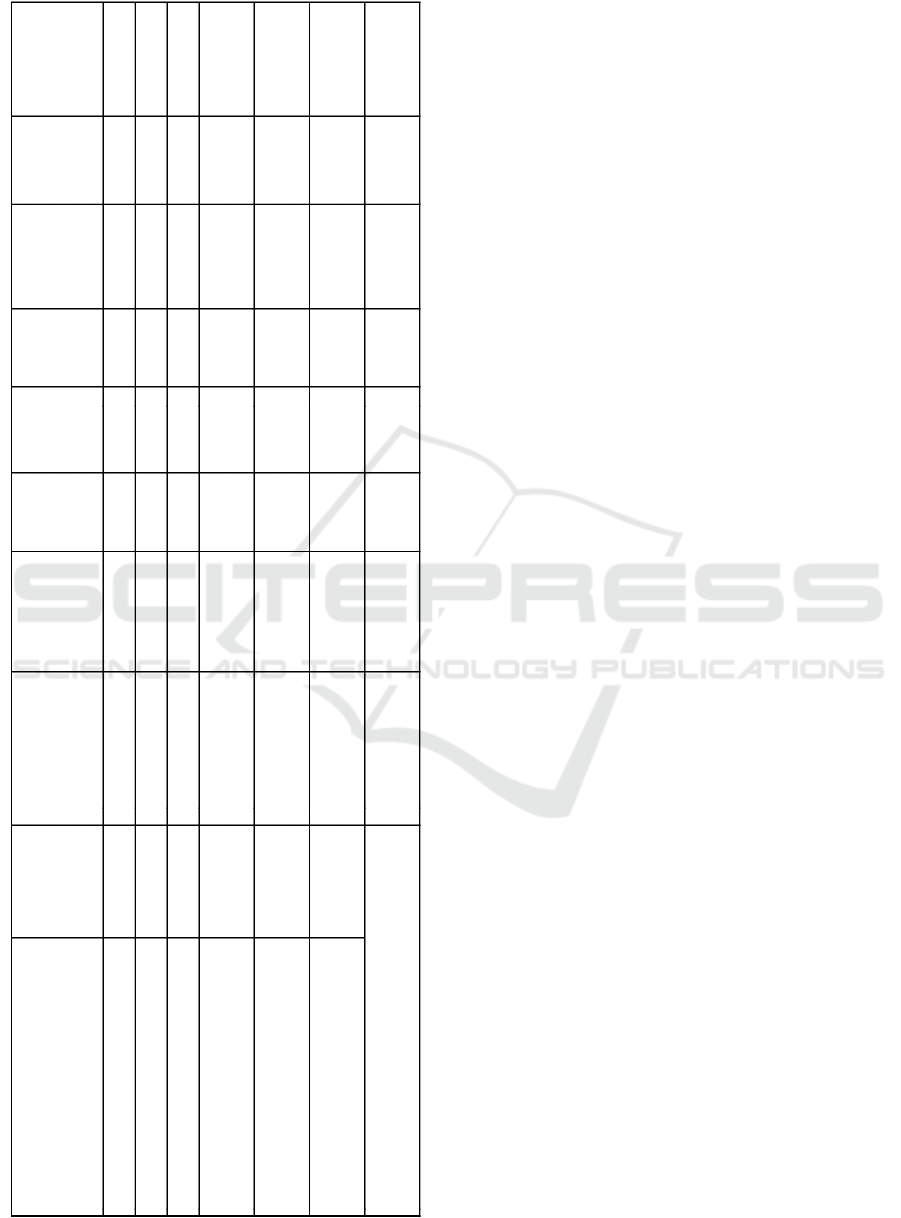

Table 3: Summary of selected studies on PC and PICP in

Indonesia.

0

5

10

15

20

25

30

10 15 20 25 30 35

Compressive strength (Mpa)

Porosity (%)

Limantara et al, 2018

Saputra and Wardhono, 2018

Mulyono and Anisah, 2019

Care et al, 2018

F. Chairuddin et al, 2016

0

0,5

1

1,5

2

2,5

3

15 20 25 30 35

Permeability (cm/sec)

Porosity (%)

Limantara et al, 2018

Saputra and Wardhono, 2018

Care et al, 2017

Ref

Research

Location (year)

Type of

permeable

pavement

Addition materials Content (%)

Compressiv

e strength

(MPa)

Porousity

(%)

Permeability

(cm/sec)

(Limantara et al. 2018) Kediri PC Coconut fiber 17.10 23.00 0.50

(Rifqi, Amin, and Lesmana,

2018)

Banyuwangi PIPC Circle river aggregate 7.84 16.93 0.26

(Rifa’i and Yasufuku, 2017) Prambanan PIPC Bantak and volcanic ash 6.05 28.40 1.93

(Aman et al. 2016) Riau PIPC Fly ash 18.84 - -

(Wijaya and Ekaputri, 2014) Mojokerto PIPC Coal ash 20.80 5.27 -

(Saputra and Arie Wardhono,

2018)

Surabaya PIPC Fly ash 10,00 14.44 25.30 0,41

(Mulyono and Anisah, 2019) Jakarta PC Fly ash,

superplasticizer

15,00

0.20

15 – 22 20 – 22 1.7 - 2.1

(Ridwan et al. 2018) Bandung PC Fly ash

HRWR

VMA

0.60 – 0.70

2-2.4

6.2 – 15.2 25 - 32 1.4 – 2.6

(Chairuddin et al. 2016) Makasar PA Buton natural asphalt 4,00 2.40 19.20 -

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

996

Table 4: Summary of selected studies on PA in Indonesia.

3.3 Application

The applications of permeable pavement can be used

for low-volume pavements; residential roads and

walkways; sidewalks and pathways; parking lots;

tennis courts; slope stabilization; floors for fish

hatcheries, floors for zoos or children parks, etc.

Based on previous research, which is summarized in

Figure 4, it can be seen that permeable pavement in

Indonesia is classified into quality B, C, and D refer

to the (SNI 03-0691, 1996). These pavements can be

used for parking, pedestrians, garden, and other uses.

The current design specifications and several studies

have been carried out to investigate and find solutions

and innovations to improve permeable pavement

performance. These efforts can be seen in table 1, but

they still have not produced a strength of more than

35 MPa (Quality A) so that it can be used for roads.

4 THE POTENCY OF FUTURE

RESEARCH

This paper has identified several pavement permeable

problems in Indonesia. Repairs are required for use

on road pavements, especially repairs in terms of mix

design, manufacture, and maintenance. Several

studies have been carried out to investigate the

properties of the permeable pavement, but no ideal

proportion has been found. Permeable pavement in

Indonesia has a low compressive strength, it is

necessary to develop an appropriate innovation to

optimize the performance of porous pavement.

Innovation can be done from the mix design, shape,

method of manufacture, and maintenance.

In summary, several challenges and needs for

future research on permeable pavement systems were

identified mainly on: (a) optimizing structural

performance by modifying the design; (b) The right

treatment system so that the permeable pavement can

function properly and last a long time.

5 CONCLUSIONS

This review has identified several unresolved

performance, infiltration, and application issues that

require further investigation to optimize permeable

pavement application as sustainable urban drainage

systems in Indonesia. The compressive strength of the

permeable pavement in Indonesia is still minimal

which is, less than 30 MPa and cannot be applied for

road. Porosity and permeability are following the

Ref Location

(year)

Type of

permeable

pavement

Addition

materials

Content

(%)

Stability

(kg)

Flow

(%)

M.Quotient

(kg/mm)

Porousity

(%)

Permeability

(cm/sec)

(Ramadhan and Reza, 2014) Malang PA Gilsonite 8.00 805.196 3.78 219.22 - -

(Tronge et al. 2017) Makasar PA Wetfik 0.33 854.14 3.00 287.90 17.26 0.28

(Ayun, 2017) Surabaya PA Sulfur 10.00 563 2.70 203,70 - 0,517

(Rifqi, Amin, and Lesmana,

2018)

Banyuwangi PA

Local

material

5.00 1123,61 4.68 241.82 - 0.367

(Arlia, Saleh, and Anggraini,

2018)

Aceh PA Gondorukem 8.00

554.81

0.28 143.02 - -

(Saleh, Anggraini, and Aquina,

2014)

Aceh PA

Styrofoam

9.00 495.92 3.07 169.05 0.144

Standard

Min.

500

2 -6 Max. 400 15 - 25 -

A Review of Permeable Pavement in Indonesia: Performance and Application

997

requirements of SNI 03-0691-1996. The permeability

obtained from the existing reference is between 0-25

cm/sec, while the porosity is between 15 - 35%. This

review also highlights the need to develop new

permeable pavement with high compressive strength

that can effectively reduce stormwater runoff.

ACKNOWLEDGEMENTS

The authors of this paper would like to thank

Universiti Teknologi Malaysia (UTM) and

Samarinda State Polytechnic (POLNES) for the

support and sponsor under UTM Encouragement

Research Grants, Vot No. Q.K130000.2656.18J25,

each of which enabled this paper to be written. The

authors also thank the POLNES permeable pavement

research group (Bella Aprilia Puspita Sari, Ririn

Laras Wati, Muhammad Fachrizandy).

REFERENCES

ACI 552R-10. (2010). Report on Pervious Concrete,

American Concrete Institute.

Alam, Taufiqul et al. (2019). “A Comparison of Three

Types of Permeable Pavements for Urban Runoff

Mitigation in the Semi-Arid South Texas, U.S.A.”

Water (Switzerland) 11(10): 1–23.

Aman, Awaluddin Amir, Ahmad Adrianto, and Monita

Olivia. (2016). “Paving Blok Geopolimer Dari Fly Ash

Limbah Pabrik.” In Pelestarian Lingkungan & Mitigasi

Bencana, , 113–18.

Arlia, Leni, Sofyan M Saleh, and Renni Anggraini. (2018).

“Karakteristik Campuran Aspal Porus Dengan

Substitusi Gondorukem Pada Aspal Penetrasi 60/70.”

Jurnal Teknik Sipil Universitas Syiah Kuala 1(2004):

657–66.

Australian Asphalt Pavement Association. (2004). Asphalt

Mix Design a Guide to the Process of Design and

Selection of an Asphalt Job Mix.

Ayun, Qurratul. (2017). “Pengaruh Penambahan Sulfur

Terhadap Karakteristik Marshall Dan Permeabilitas

Pada Aspal Berpori.” Jurnal Ilmiah Teknik Sipil 1(1):

117–22.

Chairuddin, Firdaus, M Wihardi Tjaronge, Muhammad

Ramli, and Johannes Patanduk. (2016). “Compressive

Strength of Permeable Asphalt Pavement Using

Domato Stone ( Quarzite Dolomite ) and Buton Natural

Asphalt ( BNA ) Blend.” International Journal of

Engineering and Technology (September 2017).

Chandrappa, Anush K., and Krishna Prapoorna Biligiri.

(2016). “Comprehensive Investigation of Permeability

Characteristics of Pervious Concrete: A Hydrodynamic

Approach.” Construction and Building Materials 123:

627–37.

http://dx.doi.org/10.1016/j.conbuildmat.2016.07.035.

Cheng, Yung Yun et al. (2019). “Field Testing of Porous

Pavement Performance on Runoff and Temperature

Control in Taipei City.” Water (Switzerland) 11(12).

Dover, John W. 2020. Green Infrastructure Permeable

Pavements.

El-maaty, Ahmed Ebrahim Abu. (2016). “Establishing a

Balance Between Mechanical and Durability Properties

of Pervious Concrete Pavement.” American Journal of

Traffic and Transportation Engineering 1(2): 13–25.

Fadli, Ardiansyah. (2021). “Daftar 25 Proyek Infrastruktur

Tahun 2021. ”Kompas.com. https://www.kompas.com/

properti/read/2020/12/14/180929021/ini-daftar-25-pro

yek-infrastruktur-kpbu-tahun-2021 (September 23,

2021).

Hein, David K., and Lori Schaus. (2013). “Permeable

Pavement Design and Construction: What Have We

Learned Recently?” Proceedings of the 2nd Green

Streets, Highways, and Development Conference

(November 2013): 31–44.

Huang, Jian, Caterina Valeo, Jianxun He, and Angus Chu.

(2016). “Three Types of Permeable Pavements in Cold

Climates: Hydraulic and Environmental Performance.”

Journal of Environmental Engineering 142(6):

04016025.

Irlan, Ade Okvianti, Dewi Rintawati, and Paikun. (2020).

“Studi Literatur Beton Berpori Dengan Penambahan

Fly Ash, Superplasticizer, Dan Serat Terhadap Kuat

Tekan.” KILAT 9(2): 171–80.

Jayakaran, Anand D., Thorsten Knappenberger, John D.

Stark, and Curtis Hinman. (2019). “Remediation of

Stormwater Pollutants by Porous Asphalt Pavement.”

Water (Switzerland) 11(3): 1–22.

Jusli, Euniza et al. (2014). “Effect of Using Waste Tyre

Rubber on the Properties of Double Layer Rubberized

Concrete Paving Blocks.” Jurnal Teknologi 71(3): 1–5.

Kia, Alalea, Hong S. Wong, and Christoper R. Cheeseman.

(2018). “Defining Clogging Potential for Permeable

Concrete.” Journal of Environmental Management

220: 44–53.

Kia, Alalea, Hong S. Wong, and Christopher R.

Cheeseman. (2021). “High-Strength Clogging

Resistant Permeable Pavement.” International Journal

of Pavement Engineering 22(3): 271–82.

https://doi.org/10.1080/10298436.2019.1600693.

Koohmishi, Mehdi, and Alireza Azarhoosh. (2021).

“Assessment of Permeability of Granular Drainage

Layer Considering Particle Size and Air Void

Distribution.” Construction and Building Materials

270: 121373. https://doi.org/10.1016/j.conbuildmat.

2020.121373.

Kováč, Marek, and Alena Sičáková. (2017). “Pervious

Concrete as a Sustainable Solution for Pavements in

Urban Areas.” 10th International Conference on

Environmental Engineering, ICEE 2017 2017-

April(November).

———. (2018). “Pervious Concrete as an Environmental

Solution for Pavements: Focus on Key Properties.”

Environments - MDPI 5(1): 3–9.

Kuruppu, Upeka, Ataur Rahman, and M. Azizur Rahman.

(2019). “Permeable Pavement as a Stormwater Best

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

998

Management Practice: A Review and Discussion.”

Environmental Earth Sciences 78(10): 1–20.

https://doi.org/10.1007/s12665-019-8312-2.

Li, Hui, Masoud Kayhanian, and John T. Harvey. (2013).

“Comparative Field Permeability Measurement of

Permeable Pavements Using ASTM C1701 and NCAT

Permeameter Methods.” Journal of Environmental

Management 118: 144–52. http://dx.doi.org/10.1016/

j.jenvman.2013.01.016.

Limantara, A. D. et al. (2018). “Optimization of Standard

Mix Design of Porous Paving Coconut Fiber and Shell

for the Parking Area.” AIP Conference Proceedings

2020(October 2018).

Maguesvari, M. Uma, and V.L. Narasimha. (2013).

“Studies on Characterization of Pervious Concrete for

Pavement Applications.” Procedia - Social and

Behavioral Sciences 104: 198–207.

Maharana, Gitanjali, Biswajit Jena, and Sagarika Panda.

(2020). “A Study On Mechanical And Durability

Properties Of Interlocking Fly Ash Based Concrete

Paver Block Using Different Types Chopped Fibers.”

Journal of Xi’an University of Architecture &

Technology XII(V): 6–9.

Mulyono, T., and Anisah. (2019). “Laboratory Experiment:

Pervious Concrete for Permeable Pavement, Focus in

Compressive Strength and Permeability.” IOP

Conference Series: Earth and Environmental Science

366(1): 0–14.

———. 2019b. “Laboratory Experiment: Pervious

Concrete for Permeable Pavement, Focus in

Compressive Strength and Permeability.” IOP

Conference Series: Earth and Environmental Science

366(1).

Mulyono, T, and . Anisah. (2019). “Sustainable Material for

Local Road Using Pervious Concrete with Various

Aggregates.” KnE Social Sciences 3(12): 65.

Paul, Tennis D et al. (2004). Portland C Pervious Concrete

Pavements.

Pradoto, Rani et al. (2019). “Improving Strength of Porous

Asphalt : Utilizing Fly Ash Into Nanomaterials in

Experimental Approach.” Jurnal Rekayasa Sipil 15(2):

75–89.

Ramadhan, Nizar, and Rachmad Reza. (2014). Pengaruh

Penambahan Additive Gilsonite HMA Modifier Grade

Terhadap Kinerja Aspal. Malang: Universitas

Brawijaya.

Ramadhansyah, P. J. et al. (2020). “Strength and Porosity

of Porous Concrete Pavement Containing Nano Black

Rice Husk Ash.” IOP Conference Series: Materials

Science and Engineering 712(1).

Razzaghmanesh, Mostafa, and Simon Beecham. (2018). “A

Review of Permeable Pavement Clogging

Investigations and Recommended Maintenance

Regimes.”

Water (Switzerland) 10(3).

Razzaghmanesh, Mostafa, and Michael Borst. (2018).

“Investigation Clogging Dynamic of Permeable

Pavement Systems Using Embedded Sensors.” Journal

of Hydrology 557: 887–96. https://doi.org/10.1016/

j.jhydrol.2018.01.012.

Ridwan, Frisky, Aldila Melania, Bambang Sugeng

Subagio, and Harmein Rahman. (2018). “Porous

Concrete Basic Property Criteria as Rigid Pavement

Base Layer in Indonesia.” 02008: 1–11.

Rifa’i, Ahmad, and Noriyuki Yasufuku. (2017).

“Utilization of Bantak and Merapi Volcanic Ash for

Porous Paving Block as Drainage Control in the

Prambanan Temple Yard.” International Journal of

GEOMATE 12(31): 141–46.

Rifqi, Mirza Ghulam, M. Shofi’ul Amin, and Yuris Indra

Lesmana. (2018). “Karakteristik Paving Berongga

Menggunakan Material Batu Kali Bulat Berbasis

Ramah Lingkungan.” Potensi : Jurnal Sipil Politeknik

20(1): 28–32.

Rifqi, Mirza Ghulam, Wahyu Nariswari, Enes Ariyanto,

and Tri Gunawan. (2019). “Nilai Stabilitas Porous

Asphalt Menggunakan Material Lokal.” POTENSI

(June): 33–40.

Saleh, Sofyan M., Renni Anggraini, and Hesty Aquina.

(2014). “Karakteristik Campuran Aspal Porus Dengan

Substitusi Styrofoam Pada Aspal Penetrasi 60/70.”

Jurnal Teknik Sipil 21(3): 241.

Saputra, Firman Ganda, and Arie Wardhono. (2018).

“Pemanfaatan Abu Terbang Limbah Batu Bara

Terhadap Kuat Tekan Dan Tingkat Porositas Paving

Stone Berpori.” Jurnal Rekayasa Teknik Sipil 1(1):

186–94.

Schultze-allen, Peter. (2018). GSI Handbook Details

Workshop GSI Handbook Details Pervious Pavement.

Selbig, William R., and Nicolas Buer. (2018). U.S.

Geological Survey Scientific Investigations Report

2018–5037 Hydraulic, Water-Quality, and

Temperature Performance of Three Types of

Permeable Pavement under High Sediment Loading

Conditions. https://pubs.er.usgs.gov/publication/sir20

185037.

SNI 03-0691. 1996. Badan Standar Nasional Indonesia

Bata Beton (Paving Block).

Stormwater. (2019). “Permeable Paver Diagram.” Storm

water report: 1. https://dev-stormwater.wef.org/2019/

06/permeable-pavement-guide-helps-practitioners-avoi

d-pitfalls/swr-permeable-paver-diagram-july19/.

Tronge, M Wihardi, Jurusan Sipil, Fakultas Teknik, and

Universitas Hasanuddin. (2017). “Effect of The Use of

Hydrocarbon Based Additive Material on Porous

Asphalt Characteristics.” Jurnal Teknik Sipil dan

Rekayasa 1(1): 12–20.

Wijaya, Yulia Putri, and Januarti Jaya Ekaputri. (2014).

“Paving Geopolimer Dari Coal Ash Limbah Pabrik.”

Jurusan Teknik Sipil FTSP ITS, Surabaya (June): 33–

42.

Winston, Ryan J, Ahmed M Al-Rubaei, Godecke T

Blecken, and William F Hunt. (2016). “Maintenance

for Preservation and Recovery of Permeable Pavement

Hydraulics: Effects of Vacuum Cleaning, High

Pressure Washing, Street Sweeping, and Milling

Entretien Pour La Préservation et Le Rétablissement

Des Caractéristiques Hydrauliques de Chaussées.”

NOVATECH: 1–6.

A Review of Permeable Pavement in Indonesia: Performance and Application

999

Xie, Ning, Michelle Akin, and Xianming Shi. (2019).

“Permeable Concrete Pavements: A Review of

Environmental Benefits and Durability.” Journal of

Cleaner Production 210: 1605–21. https://doi.org/

10.1016/j.jclepro.2018.11.134.

Yu, Zhiji et al. (2021). “Performance of Permeable

Pavement Systems on Stormwater Permeability and

Pollutant Removal.” Environmental Science and

Pollution Research (2006).

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

1000