Performance Evaluation of a Parabolic Trough Collector Applying

SolTrace and TRNSYS

B. E. Tarazona-Romero

1,2 a

, A. R. Arenas-Gracia

1

and J. C. Jaimes-Orostegui

1

1

Automation and Control Energy Systems Research Group (GISEAC), Faculty of Natural Sciences and Engineering,

Electromechanical Engineering, Unidades Tecnológicas de Santander (UTS), Student Street No 9-82, 680005,

Bucaramanga, Colombia

2

Energy in Building Research Group (ENEDI), Doctoral Program in Energy Efficiency and Sustainability in Engineering

and Architecture, Department of Machines and Thermal Engines, University of the Basque Country (UPV / EHU),

Engineer Torres Quevedo Square, 1, 48013, Bilbao, BI, Spain

Keywords: Parabolic Trough Collector, Performance, Renewable Energy Soltrace, TRNSYS.

Abstract: This work performs an optical and thermal analysis of an artisanal parabolic trough collector, developed by

the Research Group on energy, automation and control systems of the Technological Units of Santander. For

this, the Monte Carlo ray tracing method is applied through the SolTrace Software and the TRNSYS dynamic

simulator. Three configurations with higher proportions in the geometry of the real system are proposed in

order to identify the incidence of this parameter in the performance of the device. The results showed that the

performance of the device in a hydro-dynamic way is relatively inferior to the hydro-static system, that is, the

simulations in SolTrace present higher values than those carried out in TRNSYS. Additionally, the

performance of the system is directly affected by the increase in the reflection area. Finally, the geometry that

would generate an increase in the performance of the parabolic trough collector is identified.

1 INTRODUCTION

Solar concentrating technology (CSP) is made up of

reflector systems that concentrate direct normal

radiation (DNI), in a focal point that can be linear or

punctual(Lovegrove & Stein, 2021) (Lovegrove &

Pye, 2021). They are classified into 4 technologies

(Pitz-Paal, 2014): Fresnel linear collectors (LFC)

(Tarazona-Romero et al., 2020) (Tarazona-Romero et

al., 2021a), parabolic trough collector (PTC) (Moya,

2021), Parabolic Disc (PD)(Schiel & Keck, 2021) and

Central Tower (CT) (Vant-Hull, 2021). Linear LFC

and PTC systems are known as 2D systems and

operate in a temperature range between 100 ° C and

500 ° C (Häberle & Krüger, 2021), while PD and CT

point systems are known as 3D systems and have

reached a working temperature up to 1000 °

C(Ballestrín et al., 2021) (Meyer et al., 2021).

PTC technology currently presents greater

maturity and application at a centralized level than the

others. This is due to the fact that it presents higher

yields, as well as lower manufacturing, operation and

a

https://orcid.org/0000-0003-3508-3160

maintenance costs (Barone et al., 2019). On the other

hand, its application at a decentralized level is an

option aimed at the production of hot water and or

steam, for small residential systems in urban or

isolated areas, with favorable DNI conditions

(González Martínez & Villabona Niño, 2021).

Its design is simple, it is composed of an area of

solar reflection, generally made up of highly

reflective mirrors that direct the DNI to a linear focal

point through which a heat transfer fluid is circulated

(Ahlgren et al., 2018). Decentralized systems use

pumping systems and simple thermodynamic cycles

for their operation (Gowda et al., 2020). Meanwhile,

small-scale systems use thermosyphons or small solar

pumping units for their operation(Dutta et al., 2021)

(Fernández-García et al., 2018).

The development of CSP systems and specifically

PTC, is accompanied by design processes and

analysis of optical and thermal performance of the

units through different methodologies such

as(Malekan et al., 2021) (Yang et al., 2020): Monte

Carlo ray tracing method (MTCR) (González

Tarazona-Romero, B., Arenas-Gracia, A. and Jaimes-Orostegui, J.

Performance Evaluation of a Parabolic Trough Collector Applying SolTrace and TRNSYS.

DOI: 10.5220/0011959700003612

In Proceedings of the 3rd International Symposium on Automation, Information and Computing (ISAIC 2022), pages 545-551

ISBN: 978-989-758-622-4; ISSN: 2975-9463

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

545

Martínez & Villabona Niño, 2021), numerical

simulation (Wu et al., 2021), dynamic simulations

(Crespo et al., 2021) and CFD modeling (Kouche &

Gallego, 2021). Highlighting the MTCR

methodology for its precession and simplicity to

analyze renewable systems in a stationary way

(Mohammadi et al., 2021) and dynamic simulations,

for its analysis under time intervals and desired

operating meteorological conditions (Ziyaei et al.,

2021).

Eventually, the Research Group on energy,

automation and control systems (GISEAC) of the

Unidades Tecnológicas de Santander (UTS),

developed an artisan prototype of a parabolic trough

collector (PTC) under the concept of appropriate

technology(González Martínez & Villabona Niño,

2021) (Forero Monsalve & Jaimes Grimaldos, 2021).

The device was experimentally evaluated with a

steady flow and presented low efficiencies, due to the

fact that it was manufactured with local materials and

labor, generating a low-cost unit.

Finally, the present work seeks to analyze the

performance of a PTC applying the Monte Carlo ray

tracing method (MTCR) through SolTrace Software

and a dynamic simulation through TRNSYS,

evaluating three geometrically different systems to

the real PTC, but with the same construction

materials, varying the area of reflection.

Consequently, section 2 presents the methods and

materials used for the development of the

simulations, including characteristics of the real

prototype and the geometric variations to be

simulated. Section 3 presents the results obtained

from the simulation process and, finally, section 4

describes the main conclusions of the development of

the work.

2 METHODS AND MATERIALS

2.1 PTC System Features

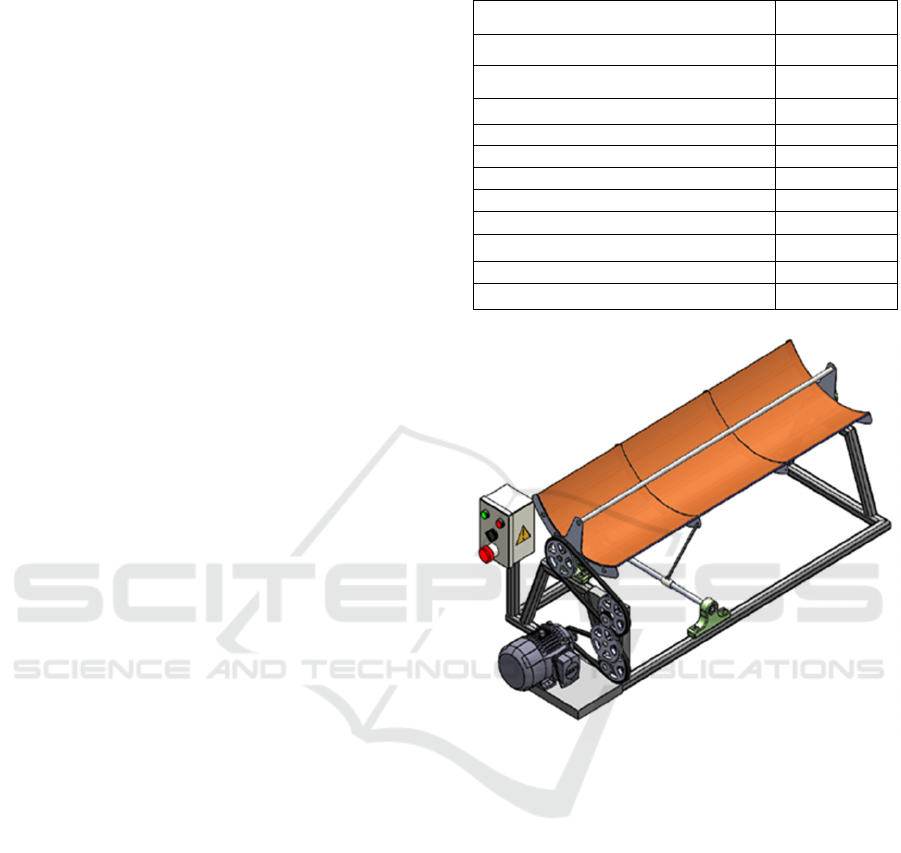

Table 1 presents the geometric and optical

characteristics of the real PTC prototype that was

previously subjected to an experimental process and

presented a performance of 36.9% for a steady state

of flow. Additionally, the Information in Table 1

allows to feed simulation tools with real data,

generating a simulation process based on operating

parameters of the real PTC system. Finally, Figure 1

presents the 3D modeling of the real PTC system that

allowed defining the geometric parameters presented

in Table 1.

Table 1: Original PTC system features.

Variable

𝜓 Enge angle

80°

a (Opening width) 550 mm

l (Collector length) 1700 mm

f (Focal length) 164 mm

De

(

Receive

r

tube oute

r

diameter

)

15.87 mm

Di

(

Receive

r

tube Inne

r

diameter

)

13.85 mm

Aa (Collector opening area)

0.935 m

Ar (Receiver tube area)

0.04985 m

Co (Concentration ratio) 11,85 mm

Blac

k

p

aint emissivit

y

0.98

Black paint solar absorptivity 0.98

Figure 1. PTC 3D Modeling.

2.2 Geometric Characteristics of the

PTC Systems to Simulate

Table 2 presents the three geometries proposed to

carry out the simulation processes of the PTC system,

where parameters of the reflection area and

concentration system are modified.

ISAIC 2022 - International Symposium on Automation, Information and Computing

546

Table 2. Characteristics of the three PTC systems proposed to simulate.

Characteristics S

y

stem N°1 S

y

stem N°2 S

y

stem N°3

Receive

r

tube radius [m] 0.0095 0.0095 0.0095

Receive

r

tube len

g

th [m] 2.0000 2.0000 2.0000

Receive

r

tube area [m

]

0.1197 0.1197 0.1197

Sheet width [m] 0.8000 0.7000 0.6000

Mirro

r

width [m] 0.6970 0.6099 0.5227

Mirro

r

len

g

th [m] 2.0000 2.0000 2.0000

Mirro

r

area [m

]

1.3940 1.2198 1.0454

2.3 Geometric Characteristics of the

PTC Systems to Simulate

To develop the optical and thermal analysis process,

the following tools were used:

SolTrace: it is an open access tool that applies the

Monte Ray Tracing methodology based on C ++

code. SolTrace simulates the solar position with

respect to a CSP and projects a series of solar rays

with a specific DNI, this process allows to identify the

intensity of flux on the surfaces of the CSP.

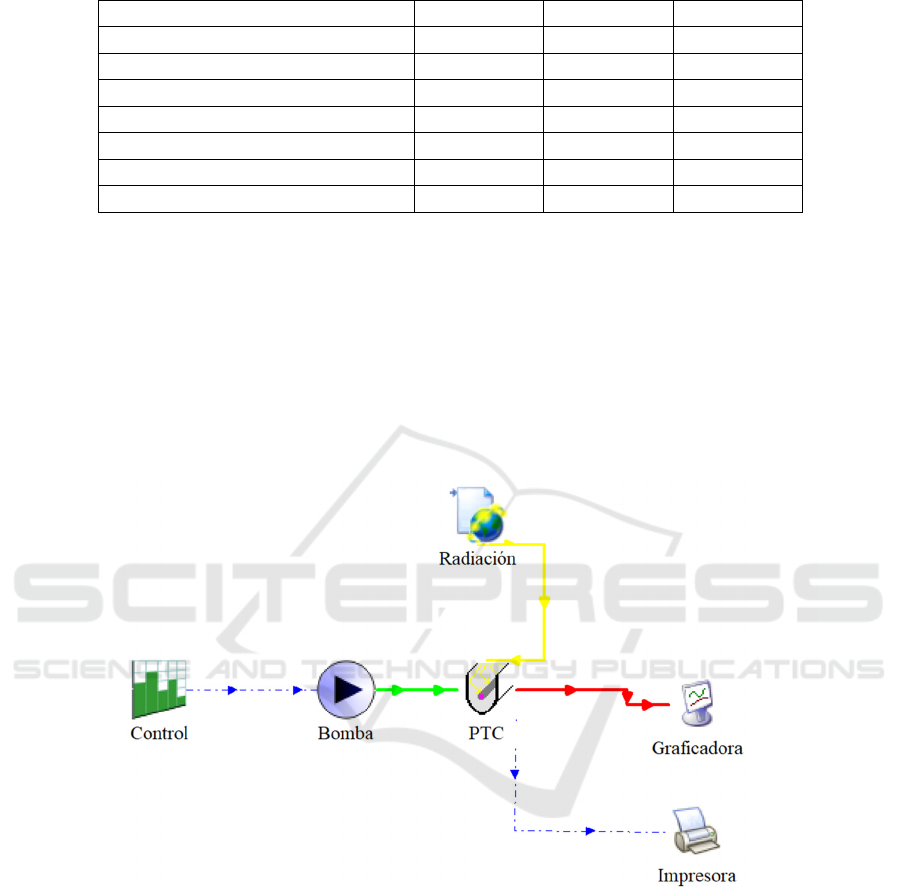

TRNSYS: is a tool that allows to dynamically

simulate renewable energy systems and allows

evaluating the behavior of the systems in defined time

intervals, controlling intrinsic variables in the process

and including geometric parameters and optical

characteristics of the devices. Figure 2 presents the

circuit developed for the analysis of the different

proposed PTC systems.

Figure 2. PTC connection diagram.

3 RESULTS

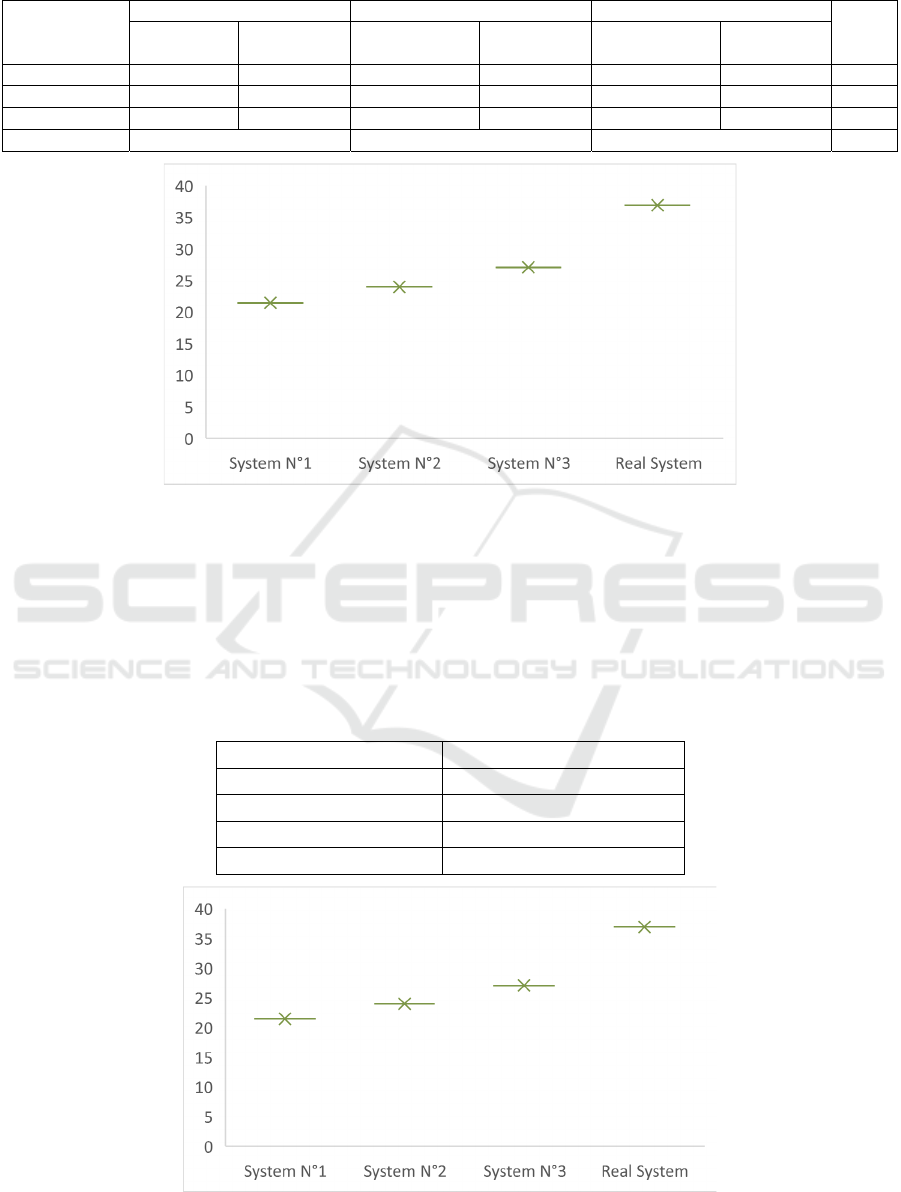

Table 3 presents the results of the simulations carried

out in SolTrace and Figure 3 presents the graph of the

performance of each PTC in its simulation process,

highlighting:

The flow intensities showed higher values in

system 1, which presents the geometric design with

the largest area of reflection. A decreasing trend of

intensity values is reflected as the size of the

reflection area decreases.

The system with the highest performance was the

system with the smallest reflection area of the three

proposed geometries, this is due to the heat transfer

losses to which the device is subjected to a greater

reflection area as it is an artisanal system.

Systems N° 1 and 2 simulated are close to the

performance of the experimental system at 0.5%.

System N ° has values much higher than the

experimental system.

Performance Evaluation of a Parabolic Trough Collector Applying SolTrace and TRNSYS

547

Table 3: SolTrace simulations results.

Variable

S

y

stem N°1 S

y

stem N°2 S

y

stem N°3 Real

Syste

m

Collector

mirro

r

Receiver

tube

Collector

mirro

r

Receiver

tube

Collector

mirro

r

Receiver

tube

Pea

k

flux 2534.81 70961.6 2236.92 70730.7 2382.14 65260.6

/

Min flux 0 0 0 0 0 0

/

Avera

g

e flux 187.294 4334.41 195.537 3864.51 190.571 3351.42

/

Performance 36.27% 36.58% 45.46% 36.9%

Figure 3: Soltrace Simulation Results.

For its part, Table 4 presents the results of the

simulations carried out in TRNSYS and Figure 4

presents the graph of the performance of each PTC in

its simulation process, highlighting:

• The system with the highest performance

was system 3. There is a tendency to

decrease the performance of the unit as the

thickness of the material of the reflection

area increases.

• The difference between the data obtained by

the simulation and the real experimentation

is in the range between 10 and 15%

Table 4. TRNSYS simulations results.

Configuration Annual average efficiency

System N° 1 21.45%

System N° 2 23.98%

System N° 3 27.07%

Real System 36.9 %

Figure 4. TRNSYS simulation results.

ISAIC 2022 - International Symposium on Automation, Information and Computing

548

Finally, the two tools reflect that the system with

the highest performance is system 3. There is a

difference between the values of each tool, but this is

due to the methodology applied by each one. For its

part, SolTrace is a system that stationary evaluates the

operation of the unit, while TRNSYS subjects the

system to a dynamic analysis in a defined time

interval and given meteorological conditions.

4 CONCLUSIONS

The evaluation of thermal performance was

developed based on three improvement proposals,

manipulating physical variables such as the width of

the sheet, length of the collector, entry angle and

radius of the absorber tube, obtaining a considerable

decrease in the factors that address critically collector

performance. Consequently, it was determined that a

collector with a very large area may have a higher

incidence of radiation, however, it has higher losses

in the system. For its part, a collector with a very

small area does not allow optimal use of the heat from

the sun's rays.

In addition, the simulation process of the three

proposals applying Soltrace highlights:

• The proposed geometry corresponding to the

0.8m sheet width, yielded a result in the

thermal performance of 36.28%, observing a

decrease of 0.64% compared to the

performance of the system presented by the

original configuration of the prototype.

• In turn, the proposed geometry

corresponding to the 0.7m sheet width,

yielded a result in the thermal performance

of 36.58%, observing a decrease of 0.34%

compared to the performance of the system

presented by the original configuration of

the prototype.

• Added to this, the proposed geometry

corresponding to the 0.6m width of the

sheet, yielded a result in the thermal

performance of 45.48%, observing an

increase of 8.54% compared to the

performance of the system presented by the

original configuration of the prototype.

• Finally, the proposed geometry that

generated an increase in the thermal

performance of the system for the

simulations in Soltrace, corresponds to the

geometry obtained with the 0.6 mm sheet

width, being an optimal configuration for the

reception of radiation and reduction in heat

losses.

On the other hand, the simulation process of the

three configurations applying the TRNSYS software

highlights:

• The proposed geometry corresponding to the

sheet width of 0.8m, yielded a result in the

thermal performance of 21.45%, observing

an increase of 4.81% compared to the

performance of the system presented by the

original configuration of the prototype.

• In turn, the proposed geometry

corresponding to the 0.7m sheet width,

yielded a result in the thermal performance

of 23.98%, observing an increase of 7.34%

compared to the performance of the system

presented by the original configuration of

the prototype.

• Added to this, the geometry corresponding

to the 0.6 meter sheet width, showed a result

in thermal performance of 27.07%, being

10.43% higher than the performance

presented by the original prototype

configuration.

• Finally, the three proposed configurations

generated an increase in the thermal

performance of the system for the

simulations in TRNSYS, highlighting the

geometry obtained with the 0.6m sheet

width, being an optimal configuration for the

reception of radiation and reduction in the

heat losses, thus confirming the results

obtained in the Soltrace simulations.

Finally, based on the analysis of the results, it was

determined for the three study cases that the

configuration with a smaller area of reflection

generates a significant improvement in the thermal

performance of the system, as can be seen in the

results for the Three proposals for geometric

improvement analyzed, being a viable configuration

to be applied to the current Parabolic Cylinder

Collector prototype. It is important to highlight that

the three configurations have a greater area of

reflection than the current system, so it is concluded

that the increase in the area does affect an increase in

the performance

REFERENCES

Ahlgren, B., Tian, Z., Perers, B., Dragsted, J., Johansson,

E., Lundberg, K., Mossegård, J., Byström, J., & Olsson,

O. (2018). A simplified model for linear correlation

between annual yield and DNI for parabolic trough

collectors. Energy Conversion and Management, 174,

Performance Evaluation of a Parabolic Trough Collector Applying SolTrace and TRNSYS

549

295-308.

https://doi.org/10.1016/j.enconman.2018.08.008

Ballestrín, J., Cumpston, J., & Burgess, G. (2021). Chapter

17—Heat flux and high temperature measurement

technologies for concentrating solar power. En K.

Lovegrove & W. Stein (Eds.), Concentrating Solar

Power Technology (Second Edition) (pp. 633-657).

Woodhead Publishing. https://doi.org/10.1016/B978-0-

12-819970-1.00002-5

Barone, G., Buonomano, A., Forzano, C., & Palombo, A.

(2019). Chapter 6—Solar thermal collectors. En F.

Calise, M. D. D’Accadia, M. Santarelli, A. Lanzini, &

D. Ferrero (Eds.), Solar Hydrogen Production (pp. 151-

178). Academic Press. https://doi.org/10.1016/B978-0-

12-814853-2.00006-0

Crespo, A., Muñoz, I., Platzer, W., & Ibarra, M. (2021).

Integration enhancements of a solar parabolic trough

system in a Chilean juice industry: Methodology and

case study. Solar Energy, 224, 593-606.

https://doi.org/10.1016/j.solener.2021.03.041

Dutta, P. P., Begum, S. S., Jangid, H., Goswami, A. P.,

Doley, T., Bardalai, M., & Dutta, P. P. (2021).

Modeling and performance evaluation of a small solar

parabolic trough collector (PTC) for possible

purification of drained water. Materials Today:

Proceedings.

https://doi.org/10.1016/j.matpr.2021.04.489

Fernández-García, A., Valenzuela, L., Zarza, E., Rojas, E.,

Pérez, M., Hernández-Escobedo, Q., & Manzano-

Agugliaro, F. (2018). SMALL-SIZED parabolic-trough

solar collectors: Development of a test loop and

evaluation of testing conditions. Energy, 152, 401-415.

https://doi.org/10.1016/j.energy.2018.03.160

Forero Monsalve, J. A., & Jaimes Grimaldos, B. A. (2021).

Desarrollo de un sistema automatizado de seguimiento

del sol para dar movimiento a un colector solar cilindro

parabólico a través de la implementación de un chip

Esp32 y un Servomotor monitoreados por un

miniordenador Raspberry.

http://repositorio.uts.edu.co:8080/xmlui/handle/12345

6789/5182

Ghodbane, M., Boumeddane, B., Said, Z., & Bellos, E.

(2019). A numerical simulation of a linear Fresnel solar

reflector directed to produce steam for the power plant.

Journal of Cleaner Production, 231, 494-508.

https://doi.org/10.1016/j.jclepro.2019.05.201

González Martínez, J., & Villabona Niño, Y. C. (2021).

Análisis óptico y térmico de un prototipo de colector de

concentración solar lineal cilíndrico parabólico,

aplicando los softwares Soltrace-Tonatiuh con el fin de

identificar y definir mejoras en el diseño geométrico del

modelo.

http://repositorio.uts.edu.co:8080/xmlui/handle/12345

6789/7228

Gowda, A., Dassappa, S., & Hanumanthrappa, R. (2020).

Theoretical prediction of solar heat flux intensity on

parabolic trough collector systems. Materials Today:

Proceedings, 26, 2231-2236.

https://doi.org/10.1016/j.matpr.2020.02.484

Häberle, A., & Krüger, D. (2021). Chapter 18—

Concentrating solar technologies for industrial process

heat. En K. Lovegrove & W. Stein (Eds.),

Concentrating Solar Power Technology (Second

Edition) (pp. 659-675). Woodhead Publishing.

https://doi.org/10.1016/B978-0-12-819970-1.00011-6

Kouche, A. E., & Gallego, F. O. (2021). Modeling and

numerical simulation of a parabolic trough collector

using an HTF with temperature dependent physical

properties. Mathematics and Computers in Simulation.

https://doi.org/10.1016/j.matcom.2021.09.015

Lovegrove, K., & Pye, J. (2021). Chapter 2—Fundamental

principles of concentrating solar power systems. En K.

Lovegrove & W. Stein (Eds.), Concentrating Solar

Power Technology (Second Edition) (pp. 19-71).

Woodhead Publishing. https://doi.org/10.1016/B978-0-

12-819970-1.00013-X

Lovegrove, K., & Stein, W. (2021). Chapter 1—

Introduction to concentrating solar power technology.

En K. Lovegrove & W. Stein (Eds.), Concentrating

Solar Power Technology (Second Edition) (pp. 3-17).

Woodhead Publishing. https://doi.org/10.1016/B978-0-

12-819970-1.00012-8

Malekan, M., Khosravi, A., & El Haj Assad, M. (2021).

Chapter 6—Parabolic trough solar collectors. En M. E.

H. Assad & M. A. Rosen (Eds.), Design and

Performance Optimization of Renewable Energy

Systems (pp. 85-100). Academic Press.

https://doi.org/10.1016/B978-0-12-821602-6.00007-9

Meyer, R., Schlecht, M., Chhatbar, K., & Weber, S. (2021).

Chapter 3—Solar resources for concentrating solar

power systems. En K. Lovegrove & W. Stein (Eds.),

Concentrating Solar Power Technology (Second

Edition) (pp. 73-98). Woodhead Publishing.

https://doi.org/10.1016/B978-0-12-819970-1.00014-1

Mohammadi, K., Khanmohammadi, S., Immonen, J., &

Powell, K. (2021). Techno-economic analysis and

environmental benefits of solar industrial process

heating based on parabolic trough collectors.

Sustainable Energy Technologies and Assessments, 47,

101412. https://doi.org/10.1016/j.seta.2021.101412

Moya, E. Z. (2021). Chapter 7—Parabolic-trough

concentrating solar power systems. En K. Lovegrove &

W. Stein (Eds.), Concentrating Solar Power

Technology (Second Edition) (pp. 219-266). Woodhead

Publishing. https://doi.org/10.1016/B978-0-12-

819970-1.00009-8

Pitz-Paal, R. (2014). Chapter 19—Solar Energy –

Concentrating Solar Power. En T. M. Letcher (Ed.),

Future Energy (Second Edition) (pp. 405-431).

Elsevier. https://doi.org/10.1016/B978-0-08-099424-

6.00019-3

Schiel, W., & Keck, T. (2021). Chapter 9—Parabolic dish

concentrating solar power systems. En K. Lovegrove &

W. Stein (Eds.), Concentrating Solar Power

Technology (Second Edition) (pp. 311-355). Woodhead

Publishing. https://doi.org/10.1016/B978-0-12-

819970-1.00007-4

Tarazona-Romero, B. E., Campos-Celador, A., Muñoz-

Maldonado, Y. A., Ascanio-Villabona, J. G., Duran-

ISAIC 2022 - International Symposium on Automation, Information and Computing

550

Sarmiento, M. A., & Rincón-Quintero, A. D. (2021a).

Development of a Fresnel Artisanal System for the

Production of Hot Water or Steam. En M. Botto Tobar,

H. Cruz, & A. Díaz Cadena (Eds.), Recent Advances in

Electrical Engineering, Electronics and Energy (pp.

196-209). Springer International Publishing.

https://doi.org/10.1007/978-3-030-72212-8_15

Tarazona-Romero, B. E., Campos-Celador, A., Muñoz-

Maldonado, Y. A., Ascanio-Villabona, J. G., Duran-

Sarmiento, M. A., & Rincón-Quintero, A. D. (2021b).

Development of a Fresnel Artisanal System for the

Production of Hot Water or Steam. En M. Botto Tobar,

H. Cruz, & A. Díaz Cadena (Eds.), Recent Advances in

Electrical Engineering, Electronics and Energy (pp.

196-209). Springer International Publishing.

https://doi.org/10.1007/978-3-030-72212-8_15

Tarazona-Romero, B. E., Campos-Celador, Á., Muñoz-

Maldonado, Y. A., Sandoval-Rodríguez, C. L., &

Ascanio-Villabona, J. G. (2020). Prototype of lineal

solar collector Fresnel: Artesanal system for the

production of hot water and/or water vapor. Visión

Electrónica, 14(1), Art. 1.

https://doi.org/10.14483/22484728.16013

Vant-Hull, L. L. (2021). Chapter 8—Central tower

concentrating solar power systems. En K. Lovegrove &

W. Stein (Eds.), Concentrating Solar Power

Technology (Second Edition) (pp. 267-310). Woodhead

Publishing. https://doi.org/10.1016/B978-0-12-

819970-1.00019-0

Wu, S., Tang, R., & Wang, C. (2021). Numerical

calculation of the intercept factor for parabolic trough

solar collector with secondary mirror. Energy, 233,

121175. https://doi.org/10.1016/j.energy.2021.121175

Yang, M., Moghimi, M. A., Zhu, Y., Qiao, R., Wang, Y., &

Taylor, R. A. (2020). Optical and thermal performance

analysis of a micro parabolic trough collector for

building integration. Applied Energy, 260, 114234.

https://doi.org/10.1016/j.apenergy.2019.114234

Ziyaei, M., Jalili, M., Chitsaz, A., & Alhuyi Nazari, M.

(2021). Dynamic simulation and life cycle cost analysis

of a MSF desalination system driven by solar parabolic

trough collectors using TRNSYS software: A

comparative study in different world regions. Energy

Conversion and Management, 243, 114412.

https://doi.org/10.1016/j.enconman.2021.114412

Performance Evaluation of a Parabolic Trough Collector Applying SolTrace and TRNSYS

551