Application of a Model Based on Demand Forecasting, ABC

Classification and EOQ in a Gastronomic SME to Improve Inventory

Turnover: Case Study in Peru

Bryan Anthony Cuba Paz

*a

, Piero Enrique Bazan Cabezas

†b

and Alberto Flores-Perez

c

Facultad de Ingenieria y Arquitectura, Universidad de Lima, Lima, Peru

Keywords: ABC Classification, EOQ, Demand Forecasting, Restaurant, Inventory, Small and Medium Enterprise.

Abstract: The Small and Medium Enterprise (SME) and gastronomic sector suffered a great negative impact due to the

crisis caused by the pandemic, resulting in the search for solutions to minimize costs internally in order to

survive the changes of the new economic environment. Therefore, the application of a methodology consisting

of demand forecasting, ABC classification and EOQ was proposed to improve inventory turnover in this

sector. Several research articles were reviewed, from which the success cases and their methodologies to solve

the problem were interpreted. In this case the main problem is the low inventory turnover due to inefficient

demand forecasting, inadequate planning of purchases of inputs and poor prioritization of these, which

generated losses to the SME studied. For the validation of the contribution, the Arena simulator was used,

showing a turnover similar to that of the case study and giving positive results after the application of the

contribution, empirically, improving the proposed indicators, such as; the variation of times of purchase of

inputs, which increased by 8.57%, the average inventory, which decreased by 22.67%, the level of service,

which improved by 5.29% and the main indicator, the inventory turnover, which improved by 40.02%.

1 INTRODUCTION

The economic crisis generated by the last pandemic

affected all companies regardless of their size and

sector, which caused them to make changes in their

different business strategies in order to reduce their

expenses, survive and adapt to changes in the

economic environment (Giles, 2020). In Peru, this

crisis seriously affected the SME sector, where they

presented a 59.2% decrease in annual sales with

respect to what was reported in 2019, registering the

lowest value in recent years, resulting in 60,489

million PEN, equivalent to 8% of the Peruvian gross

domestic product (GDP) in the year under study

(Confederación Nacional de Instituciones

Empresariales Privadas [CONFIEP], 2021). The

participation of this sector has been quantitatively

important within the Peruvian business sector, since

it has maintained a participation of over 92.7% over

the last few years.

a

https://orcid.org/0000-0002-6301-6224

b

https://orcid.org/0000-0002-3204-2366

c

https://orcid.org/0000-0003-0813-0662

One of the most important sectors within the

Peruvian Small and Medium Enterprises (SMEs) is

the gastronomic sector, which, until before the

pandemic, 2019, represented 3.2% of the total

Peruvian GDP, and although it has suffered a fall of

30.6%, this has been increasing since the beginning

of 2021 (Sociedad de Comercio Exterior del Peru

[COMEXPERU], 2022). Such is the importance of

this sector that the Peruvian government made

proposals for economic reactivation in the restaurant

sector, where facilities were provided for the use of

own or third party delivery, which led to a different

behavior than usual, due to the constant variation in

production (COMEXPERU, 2021).

Therefore, the key problem of the case study is the

company's capacity to possess the necessary inputs

for the preparation of the dishes, since, being an

atypical situation, it generated losses of inputs due to

poor storage, overstocking of inputs with low

demand, stock breakage of the most relevant inputs,

as well as inadequate inventory control and

434

Cuba Paz, B., Bazan Cabezas, P. and Flores-Perez, A.

Application of a Model Based on Demand Forecasting, ABC Classification and EOQ in a Gastronomic SME to Improve Inventory Turnover: Case Study in Peru.

DOI: 10.5220/0011950400003612

In Proceedings of the 3rd International Symposium on Automation, Information and Computing (ISAIC 2022), pages 434-439

ISBN: 978-989-758-622-4; ISSN: 2975-9463

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

purchasing management procedures. In addition, the

inadequate management of the company's inventory,

regardless of its size, drastically affects its annual

revenue (Villón, 2021). This affects directly with the

level of satisfaction provided to customers, since the

requested order cannot be delivered, therefore, the

perceived income is diminished. Therefore, to

analyse the results of the model, indicators such as

inventory turnover, average inventory, service level

and variation in the quantity of input purchases were

proposed. In addition, a correct control of

merchandise will generate a positive impact on the

growth and liquidity of the cash flow of companies,

since inventories are considered a key factor in the

competitiveness factors that every company,

including SMEs, must manage (Serna et al., 2018). In

this sense, several authors have appeared who sought

to solve this problem.

On the one hand, in one of the papers studied, the

inventory management of a Cuban commercial chain

classified its products based on the ABC tool and

analysed historical data to obtain a demand forecast,

since the company did not have an efficient

management model to generate orders (Bofill et al.,

2017). In addition, it uses the EOQ system to obtain

the order quantity while minimizing warehouse costs.

It ends up with a remarkable improvement in the

service level and a better utilization of the products in

the warehouse. On the other hand, in a footwear

trading company, the use of ABC and EOQ tools is

carried out to classify according to their importance

in the warehouse and to identify the order (Causado,

2015). In this case, the most important products in the

warehouse are obtained as a result of the Pareto

diagram. After that, a series of calculations are

performed to obtain the order cost and quantities of

these. In addition, the author recommends the use of

software to manage the information and its

application in the company under study, since it has

several products with a lot of stock that take a long

time to leave the warehouse and a high opportunity

cost is obtained. As mentioned above, the sector in

the case study presents failures in inventory

management due to poor demand forecasting, lack of

information in records and poor planning of

warehouse management so that an improvement in its

model is needed to generate effective solutions to this

problem.

It was proposed to create a working model where

the company's database is organized to categorize the

most relevant dishes with the ABC classification.

After that, a demand forecast with simple exponential

smoothing was applied to forecast the next period's

demand and to know the required quantity of each

input used in the dishes. In addition, these inputs were

then sorted by ABC classification, taking into account

only products from zone A. Finally, the EOQ tool was

used, which allows us to obtain the lowest possible

inventory cost by using the costs of ordering and

keeping these inputs in the warehouse. The decision

to make this proposal was made because no other

scientific article was found that uses the tools together

and presents our improvement proposal for SMEs in

the gastronomic sector.

2 STATE OF THE ART

2.1 Demand Forecasting

This tool has been considered by numerous

researchers as fundamental in different improvement

proposals, since it is a vital point for making decisions

in the company on logistics issues that have

repercussions on the other activities to be carried out

with respect to inventory purchasing

(Gonzáles,2020). In addition, it is easily integrated

into the models proposed for warehouse management,

which also has a high impact on the aggregate

planning of companies. As can be seen in the papers

reviewed, the authors highlight the added value of

implementing this tool for decision making and

improving the desired results (Madariaga et al.,

2022).

2.2 ABC Classification

Its main objective is to classify a large number of

items by grouping them into the same family, since it

allows them to be grouped by different criteria that

they have in common (Rivera et al, 2019). Based on

this methodology for the selection of items, which has

been widely used by different organizations due to its

versatility of implementation regardless of the sector

in which it is found, its presence and use has been

seen in hospitals, clinics, insurance companies, coffee

companies, hotels, education, electronic companies,

among others. In this sense, as has been proven in a

case study, this methodology is characterized by

allowing the organization to obtain better control in

warehouse management, focusing on what is most

important for the company, according to their

interests and minimizing costs, although, even so,

there is still a resistance by companies to change in its

use due to lack of knowledge of its management

(Escobar et al, 2021).

Application of a Model Based on Demand Forecasting, ABC Classification and EOQ in a Gastronomic SME to Improve Inventory

Turnover: Case Study in Peru

435

2.3 EOQ (Economic Order Quantity)

This tool provides us with the optimal value of the

quantity to order to avoid stock breaks and to make

the management of the company's economic

resources more efficient (Rodriguez et al, 2018). In

addition, its main objective is to obtain the balance

between fixed costs and costs related to the inventory

held, so it is present in various case studies operating

in different sectors, as in the case of a paper with a

model based on this tool applied to the automotive

sector, where it guided its warehouse managers to

improve their logistics planning and ensure customer

demands without generating surpluses, offering a

better level of service (Contreras, et al 2019).

3 BASIS OF THE MODEL

In our case study we evidenced problems in inventory

control that were repeated in different SMEs based on

the literature due to the lack of tools for its

management and training. Therefore, we propose an

improvement proposal for storage management,

taking as a guide the different proposals analyzed in

papers on inventories that were implemented in

SMEs. The papers studied detail their proposals based

on components such as those shown in Table 1.

Unlike other models applied in sectors other than

restaurants, the proposed model includes demand

forecasting to obtain the optimal demand for the

following period, ABC classification that will

improve the results expected from the categorization

of supplies in the storage area and the EOQ tool for

planning the purchase of those categorized in zone A.

Table 1: Comparison matrix.

Causes Deficient

inventory

purchase

planning

Inefficient

demand

planning

Incorrect

decision on

the

importance

of inputs

Authors

Madariaga F.,

Carlos et al

(2020)

Demand

forecasting –

ABC

Classification

Artificial

Neural

Network

Rodríguez L.,

Guillermo et

al (2018)

EOQ ABC

Classification

Carreño D.,

Diego et al

(2019)

Demand

forecasting -

EOQ

Proposed

Model

Demand

forecasting -

EOQ

Demand

forecasting –

ABC

Classification

ABC

Classification

4 PROPOSED MODEL

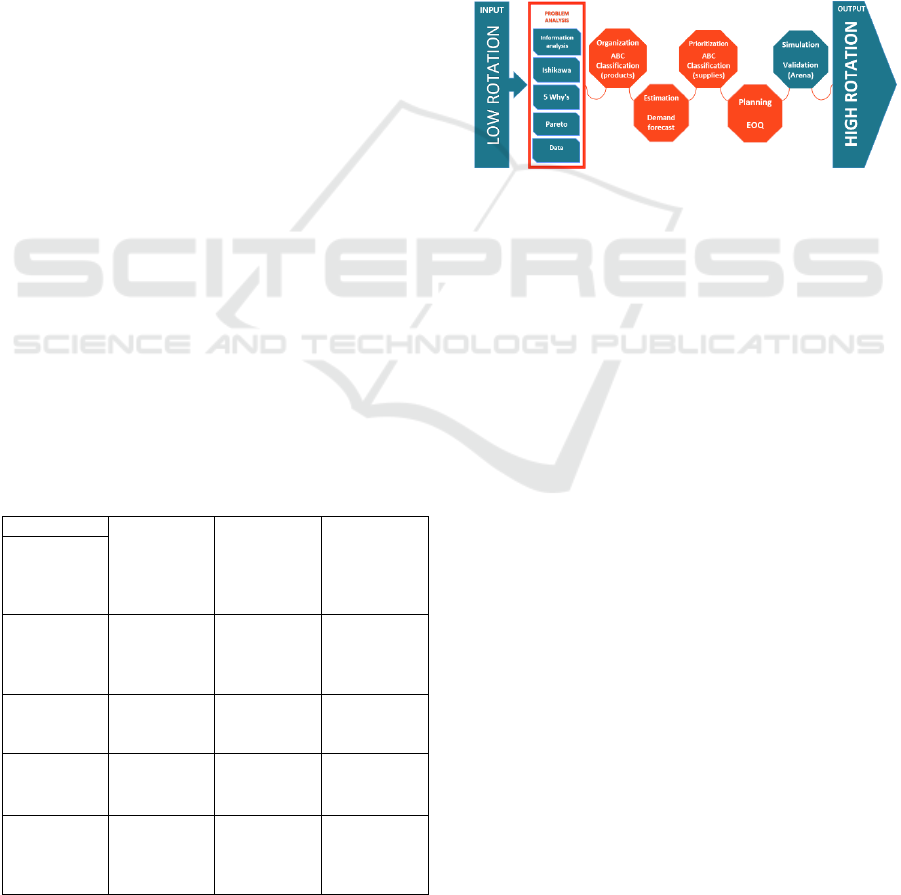

Based on our review of different scientific articles on

our research topic, our proposal is made to improve

storage management using demand forecasting, ABC

classification and EOQ to increase inventory turnover

and the objective indicators of the proposed model.

First we have a low inventory turnover, and the

analysis of the problem is performed along with the

collection of data, then we move to the phases of the

model that have as name; organization, estimation,

prioritization and planning, finally an analysis of the

indicators in the validation, obtaining as a result an

improved inventory turnover.

4.1 Components

At the beginning of the proposed contribution, we

analyse the information provided in the case study

with a root cause or Ishikawa diagram, in order to

highlight the possible causes of the main problem.

After that, the 5 Whys tool is used in different

personnel of the company to validate the information,

in addition to a Pareto diagram highlighting the most

relevant events. After having reviewed the

information and having verified it, we collected data

relevant to the main axis of the problems that will be

used in the following components.

In phase 0, we began with the collection of the

necessary data for the use of the input tools, so we

worked together with the company to obtain the

required data. Among the data needed for the

implementation we have; list of the restaurant's

dishes; sales in units per month and cost of each dish.

In phase 1, called Organization, the categorization

of all the existing dishes in the company was carried

out. They are classified according to their units sold

by their unit cost in the same time range. After that,

we selected only the dishes categorized in zone A,

which represent the 80% with the highest utilization

value.

In phase 2, called Estimation, we proceeded to run

the demand forecasting tool for the dishes exclusively

in zone A, using the historical demand for each dish,

Figure 1: Proposed model

ISAIC 2022 - International Symposium on Automation, Information and Computing

436

the type of forecast selected for our contribution is

simple exponential smoothing to ensure that the

forecast is the most accurate [12]. The following

formula will be used;

𝐹t =𝐹t-1+∝(

𝐴

t-1 −𝐹t-1)

(1)

Ft = Average number of products sold in a given

period t.

Ft-1 = Average number of products sold in a given

period t-1.

At-1= Quantity of products sold in a period t-1.

∝ = Smoothing coefficient between 0 and 1.

In phase 3, called Prioritization, a new

categorization was carried out by disaggregating the

inputs of each plate to obtain a general list of the

inputs used. In this list, the ABC classification tool

was used again to obtain the inputs that represent 80%

of the total in order to continue with the following

tool.

In phase 4, called Planning, EOQ was performed

to obtain accurate data on order quantity, time

between orders and reorder point, then evaluate the

results with indicators in the next phase. For this we

need to obtain data such as:

Q* = Optimal number of units to order (EOQ)

D = Monthly demand in units

St = Ordering Cost ($)

Ht = Cost of maintaining inventory ($)

s = Unit order cost for each order ($)

h = % of cost of holding inventory

c = Unit cost of product ($)

R = Reorder Point

Lt = Monthly Lead Time

𝑄* =

2𝐷∗ 𝑠

ℎ∗𝑐

; N=

𝐷

𝑄*

;T=

30

𝑁

; 𝑅=𝐷 ∗ 𝐿𝑡

(2)

𝑆t =

𝐷

𝑄*

∗

(

𝑠

)

; 𝐻t =

𝑄*

2

(

ℎ∗𝑐

)

(3)

Finally, in this phase, the indicators selected for

monitoring the proposed model were inspected to

analyze the performance of the results found after its

application, having previously carried out a previous

evaluation of the same indicators at the beginning of

the application of the tools, for comparison in the

simulator. All this will be recorded in order to

continuously improve the processes and obtain

opportunities for improvement. The main indicator of

this article is the inventory turnover, then we have

proposed the evaluation of related indicators such as

average inventory, service level and the variation of

times of purchase of inputs, all shown in Table 2 with

their respective formulas and uses.

Table 2: Indicators

Indicator Formula

Inventory turnover

𝐶𝑜𝑠𝑡 𝑜𝑓 𝑠𝑎𝑙𝑒𝑠

𝐴𝑣𝑒𝑟𝑎𝑔𝑒 𝐼𝑛𝑣𝑒𝑛𝑡𝑜𝑟𝑦

Average inventory

𝐵𝑒𝑔𝑖𝑛𝑛𝑖𝑛𝑔 𝐼𝑛𝑣.+Ending Inv.

2

Service Level

𝐶𝑜𝑚𝑝𝑙𝑒𝑡𝑒𝑑 𝑜𝑟𝑑𝑒𝑟𝑠

𝑂𝑟𝑑𝑒𝑟𝑠 𝑟𝑒𝑐𝑒𝑖𝑣𝑒𝑑

Variation of times

of purchase of

su

pp

lies

#purch.𝑡−# 𝑝𝑢𝑟𝑐ℎ.(𝑡−1)

# 𝑝𝑢𝑟𝑐ℎ.(𝑡− 1)

5 VALIDATION

5.1 Initial Diagnosis

The data obtained from the case study provide us with

a technical gap with respect to the industry standard

inventory turnover, whose value is 11.23 (Company,

Sector, Industry and Market Analysis [CSI Market]

2021). The company under study has an inventory

turnover level of 8.20, which generates an operating

cost representing 11.21% of the company's

profitability in the case study. The main reasons for

this problem are: (a) overstocking due to low number

of purchase times, (b) loss of sales due to lack of

required inputs, (c) poor product categorization

approach.

5.2 Validation Design and Comparison

The technique selected for our validation will be the

simulation and it will be performed in the simulator

program called Arena, since it has the advantage of

representing the systems and reports in a more

dynamic way, giving reports on the functionality of

the system within the restrictions used. For this we

use the historical data of the company as the arrival

of orders, the number of dishes, the type of dishes to

choose, among others. All this information was

necessary for the application of the tools proposed in

our contribution. These are ABC classification for

both dishes and inputs, demand forecasting and EOQ.

This will be done in order to corroborate the

efficiency of the application of our proposal in the

case study, mentioning some previous considerations

for its development.

We consider in this section both the input

variables, which were analyzed by the Input

Application of a Model Based on Demand Forecasting, ABC Classification and EOQ in a Gastronomic SME to Improve Inventory

Turnover: Case Study in Peru

437

Analyzer, the scope of the system, the calculation of

the sample size giving more confidence to the

simulation results, entities and constraints, as well as,

the period applicable to the simulator, improvements

and recommendations. Finally, we will show the

metrics of the results obtained.

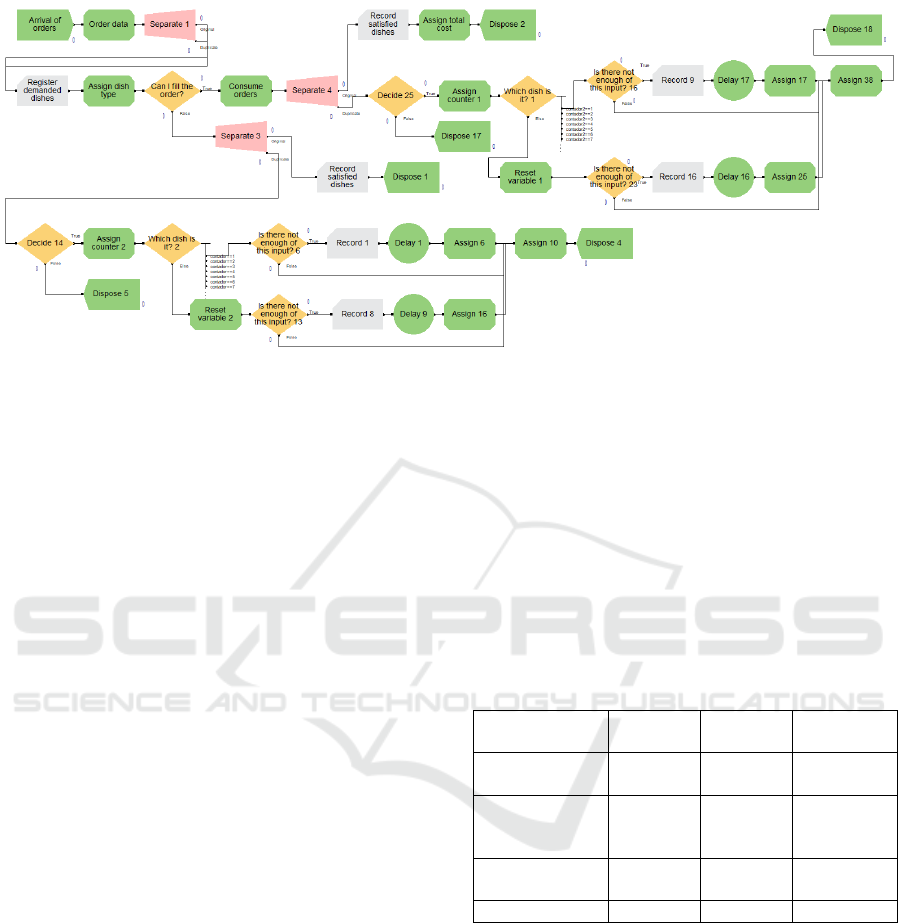

5.3 Simulation of the Proposal Model

The simulation of the inventory management process

for our case study begins with the entry of orders,

where the amount of dishes to choose is obtained as

input data; as well as the type of dish. After that, the

order is generated to the kitchen for the preparation

where the stock of inputs is discounted and the order

is delivered to the customer. If the order is not

fulfilled due to lack of supplies, an unexpected

purchase order will be generated for replenishment

during the course of the day. Therefore, the customer

cannot be served until the required supplies are

replenished and it will be considered as an unfilled

order. Each day a review of the inputs is carried out,

verifying the reorder point of each input, if it does not

meet this condition, a purchase order is generated

with a lot size determined by the company, where a

one-day delay time restriction for resupplying all

inputs has been taken as a restriction.

The restrictions of this simulation are based on the

10 dishes obtained within zone A of the ABC

classification applied among the restaurant's dishes,

since they are the ones that represent the most value

and relevance for the company. In addition, it should

be considered that the simulation will use only the

most used inputs for the group of dishes resulting

above, obtaining the 8 most relevant inputs, since an

ABC classification was also performed to give more

focus to these inputs, which represent 80% of the total

value of inputs used in their preparation.

It was also considered that the working time is 10

hours per day in an applicable period of one month.

In addition, there are two branches, one for inventory

replenishment due to stock-outs and the other with

planned purchase orders. After the application of the

simulation, either in the current situation and in the

proposed model, the results detailed in Table 3 are

shown.

Table 3: Simulation results of the initial model and the

proposed model.

Indicator Units Initial

Situation

Improved

situation

Inventory

turnove

r

Times 9.12 12.77

Variation of

purchases of

su

pp

lies

+/- % - + 8.57%

Average

inventor

y

$ 1230.14 951.27

Service Level % 72.80% 78.09%

6 CONCLUSIONS

In the first place, we were able to improve the process

of the case study by obtaining a better inventory

turnover, which was our objective, and this was due

to the correct implementation of the tools in the

inventory management process, and all this without

modifying the structure of the current process, but

with a better planning of its purchasing strategies. As

a result, we obtained a remarkable improvement of

40.02% of our main problem over the indicator of the

current situation.

Figure 2: System representation in the Arena simulator

ISAIC 2022 - International Symposium on Automation, Information and Computing

438

In second place, it is evident in the case study that

there are SMEs that do not give greater relevance to

their inventory control and the monetary loss that this

represents, since the main causes of their low turnover

can be solved by obtaining a positive economic

impact on the company's capital.

Thirdly, the application of the improvement

proposal is effective in different scenarios according

to the simulations made, which demonstrates the

robustness of our proposal, which could be replicated

in other related or similar areas.

Finally, tools such as ABC classification allowed

us to categorize a large number of items, which

facilitated the prioritization of these items and

allowed a better quality of data for the demand

forecast. In this way, the EOQ tool was executed,

with which we obtained the quantity to be purchased

per lot, the amount of re-order, as well as the exact

time to generate the order. However, more research

should be done on the use of EOQ with products with

expiration dates and it should be coupled to the model

to achieve a greater impact on inventory turnover and

on the company's future planning with respect to its

inventories.

REFERENCES

Acevedo Yepez, E., 2014. Herramienta para la gestión de

inventarios según distribución ABC basado en ventas a

proyectar para el Supermercado Cocot. Universidad de

Costa Rica.

Bofill Placeres, A., Sablón Cossío, N., & Florido García,

R., 2017. Procedimiento Para La Gestión De Inventario

En El Almacén Central De Una Cadena Comercial

Cubana. Universidad y Sociedad, 9(1), 41–51.

Carreño Dueñas, D. A., Amaya González, L. F., Ruiz

Orjuela, E. T., & Javier Tiboche, F., 2019. Diseño de

un sistema para la gestión de inventarios de las pymes

en el sector alimentario. Industrial Data, 22(1), 113–

132. https://doi.org/10.15381/idata.v22i1.16530

Causado Rodríguez, E., 2015. Modelo de inventarios para

control económico de pedidos en empresa

comercializadora de alimentos. Revista Ingenierías

Universidad de Medellín, 14(27), 163–178.

https://doi.org/10.22395/rium.v14n27a10

Confederación Nacional de Instituciones Empresariales

Privadas, 2021. PYMES: El motor del crecimiento en

el Perú. https://www.confiep.org.pe/confiep-tv/pymes-

el-motor-del-crecimiento-en-el-peru/

Contreras, A., Escalante, M., Cortes, I., & Baños, F., 2019.

Modelo de lote económico de pedido EOQ en el

inventario de partes de servicio automotriz. Ingenio y

Conciencia Boletín Científico de La Escuela Superior

Ciudad Sahagún, 6(12), 90–94.

https://doi.org/10.29057/escs.v6i12.4159

CSIMarket, 2021. Restaurant Industry: Efficiency

information & Trends.

https://csimarket.com/Industry/industry_Efficiency.ph

p?ind=914

Escobar-Mamani, F., Argota-Pérez, G., Ayaviri Nina, V.

D., Aguilar-Pinto, S. L., Quispe Fernández, G. M., &

Arellano Cepeda, O. E., 2021. Costeo basado en

actividades (ABC) en las PYMES e iniciativas

innovadoras: ¿opción posible o caduca? Revista de

Investigaciones Altoandinas - Journal of High Andean

Research, 23(3), 171–180.

https://doi.org/10.18271/ria.2021.321

Giles Navarro, C. A., 2020. Recomendaciones para las

MIPyME ¿Qué hacer para sobrevivir a la pandemia del

Covid-19? Notas Estratégicas, 13.

González, Adolfo, 2020. Un modelo de gestión de

inventarios basado en estrategia competitiva. Ingeniare.

Revista chilena de ingeniería, 28(1), 133-142.

https://dx.doi.org/10.4067/S0718-

33052020000100133

Madariaga Fernández, C. J., Lao León, Y. O., Curra Sosa,

D. A., & Lorenzo Martín, R., 2020. Metodología para

pronosticar demanda y clasificar inventarios en

empresas comercializadoras de productos mayoristas.

Retos de La Dirección, 14(2), 354–37316

Morejón, D. et al., 2018. Modelo de inventario para el

control económico de pedidos en Microempresa de

Calzado. Revista Científica Mundo de La Investigación

y El Conocimiento.

Rivera Gómez, H., Fragoso Cruz, P. L., Garnica González,

J., & Montufar Benítez, M. A., 2019. Aplicación de

Técnicas de Planeación de la Producción a una Empresa

de Prefabricados de Concreto. Conciencia Tecnológica,

58.

Rodríguez-López, G., Salazar-Vázquez, F., & González-

Urgiles, J., 2018. Control de inventarios con ajuste

dinámico del punto de reorden - Un caso de estudio para

empresas con productos perecibles y no perecibles,

usando técnicas computacionales. Advance Research

Journal of Multi-Disciplinary Discoveries I, 23(1), 13–

20. www.journalresearchijf.com

Serna, D. y Rivera, Y., 2018. Dinámica de sistemas en la

gestión de inventarios. Ingenierías USBMed, 9(1), 75-

85. https://doi.org/10.21500/20275846.3305

Sociedad de Comercio Exterior del Perú, 2021.

Alojamiento y restaurantes; transporte; y manufactura

entre los sectores con mayor urgencia de reactivación

económica.

Sociedad de Comercio Exterior del Perú. 2022. El

Subsector Restaurantes registró un crecimiento

interanual del 92.06% en febrero de 2022.

Villón Tigrero, A. M., 2021. Rotación de inventario y su

importancia en la aplicación en el sector comercial.

Universidad Estatal Península de Santa Elena.

Zuluaga, C. A. C., Eafit, U., & Escobar, S. C. B., 2012.

Metodología para la selección del parámetro alpha en el

modelo de Suavización Exponencial: Un enfoque

empírico. 10 Latin American and Caribbean

Conference for Engineering and Technology, 1–10.

Application of a Model Based on Demand Forecasting, ABC Classification and EOQ in a Gastronomic SME to Improve Inventory

Turnover: Case Study in Peru

439