Microstructure, Microhardness and Thermal Properties of

Aluminum with Multi-Walled Carbon Nanotubes Composites

Prepared by Liquid State Processing

I Dewa Made Pancarana and I Nyoman Budiarthana

Politeknik Negeri Bali, Jimbaran, Bali, Indonesia

Keywords: Microstructure, Microhardness, Thermal Conductiviy, Composites, Aluminum, Multi-Walled Carbon

Nanotubes.

Abstract: Aluminum matrix composites reinforced with 0-10 wt.% copper-coated multiwalled carbon nanotubes

(Cu/MWNTs) were produced by liquid state processing. The composites with < 10 wt.% Cu/MWNTs

additions had higher thermal conductivity than the pure aluminum produced by the same liquid state

processing. The Cu/MWNTs/Al composites exhibited the maximum thermal conductivity of 442.32 W/m/K

at 8 wt.% Cu/MWNTs. The enhancement of thermal conductivity is supported by the measured

microhardness. The Cu/MWNTs/Al composites exhibited the maximum microhardness 91,3 HV also at 10

wt.% Cu/MWNTs. The contribution of carbon nanotubes to thermal conductivity of the composites was

demonstrated by theoretical analysis. The results show that copper-coated multiwalled carbon nanotubes

(Cu/MWNTs) reinforced aluminum matrix composite is a potential material for high thermal conductivity

applications.

1 INTRODUCTON

The increase in heat from electronic components is a

major problem faced in electronic technology

because of the miniaturization of these components

(Ashby, et al., 2004). Heat sinks are used to dissipate

the heat generated by these electronic components. A

heat sink is described as an object that disperses or

dissipates heat from another object. Usually heat

sinks are widely used in computers and

microelectronics as well as other applications (Reddy

and Gupta, 2010).

Aluminum is the most commonly used material

for heat sinks due to its light weight, lower cost,

manufacturing capability, and infrastructure (Keller,

1998). The thermal conductivity of aluminum is

about 220 W/mK (Dogruoz and Arik, 2008). The

higher this number the more heat the material is able

to conduct. In addition, copper can be used for the

production of heat sinks because of its high thermal

conductivity value of around 400 W/mK (Gallagher,

et al., 1998). Its main disadvantage over aluminum is

that it is three times heavier and more expensive.

Materials with high thermal conductivity (TC)

and low coefficient of thermal expansion (CTE) are

the choice for laptop computer heat sinks. A material

suitable for this purpose must combine two basic

properties: it must have a high thermal conductivity

(TC) and a suitable coefficient of thermal expansion

(CTE) (similar to semiconductors used in the

manufacture of electronic circuits).

Carbon nanotubes (CNTs) with outstanding

mechanical properties, very low thermal expansion

(CTE≈0), and high thermal conductivity (Dai, 2002),

are potential reinforcement materials for use in

composites. According to theoretical predictions and

experimental measurements, the thermal conductivity

of CNTs reaches as high as 3000–6600 W/m/K (Kim,

et al., 2001). Aluminum is one of the most important

matrix materials for MMC.

So far, only a few studies have discussed the

thermal conduction behavior of CNT/Al composites.

Bakshi, et al., 2010 produced a composite of 10 wt.%

CNTs/Al using plasma spraying and the thermal

conductivity was only 25.4 W/m/K, much less than

pure Al. Yamanaka et al. Yamanaka, et al., 2006,

reported that the thermal conductivity of CNTs/Al

composites decreased with increasing CNT content.

The reported thermal conductivity for CNTs/Cu

composites (Chu, et al., 2010 also showed a

850

Pancarana, I. and Budiartana, I.

Microstructure, Microhardness and Thermal Properties of Aluminum with Multi-Walled Carbon Nanotubes Composites Prepared by Liquid State Processing.

DOI: 10.5220/0011894000003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 850-856

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

decreasing trend compared to pure Cu. The decrease

in thermal conductivity was mainly related to the

agglomeration of CNTs which resulted in the thermal

resistance of the interface into the composite.

This research focuses on the thermal conduction

behavior of aluminum matrix composites reinforced

with multiwall nanotubes (MWNTs/Al composites)

produced by the stir casting process. Stir casting

processing is a very useful technique for bonding

non-sinterable materials such as carbon nanotubes. In

order to produce a homogeneous dispersion of carbon

nanotubes in an aluminum matrix, the powdered

carbon nanotubes were first modified before being

incorporated into the aluminum melt.

2 MATERIALS AND

EXPERIMENTALS

PROCEDURES

2.1 Materials

Multiwalled carbon nanotubes supplied by Chengdu

Organic Chemicals Co. Ltd., China (OD: 10 - 20 nm,

length: 10 - 30 m and purity > 98% ) were used in

the present study. The colloidal palladium-tin

activator made with a composition of 0.5 g

palladium chloride (PdCl2), 50 ml 37%

hydrochloride acid (HCl), 200 ml deionised water,

25 g stannous chloride. Cupric Sulphate

Pentahydrate (98.5% Assay) and Sodium Carbonate

Anhydrous (99.5% Assay) were supplied by Bofa

Laboratotium. Sodium Hydroxide (99% Assay) was

supplied by Bofa Laboratotium. Pottasium Sodium

Tartrate Tetrahydrate or what is known as Rochelle

salt (99% Assay) was supplied by Bofa

Laboratotium. Cobalt (II) Chloride Hexahydrate

(99% Assay) was supplied by Bofa Laboratotium.

Formaldehyde 37% in aqueous solution was

supplied by Bofa Laboratotium.

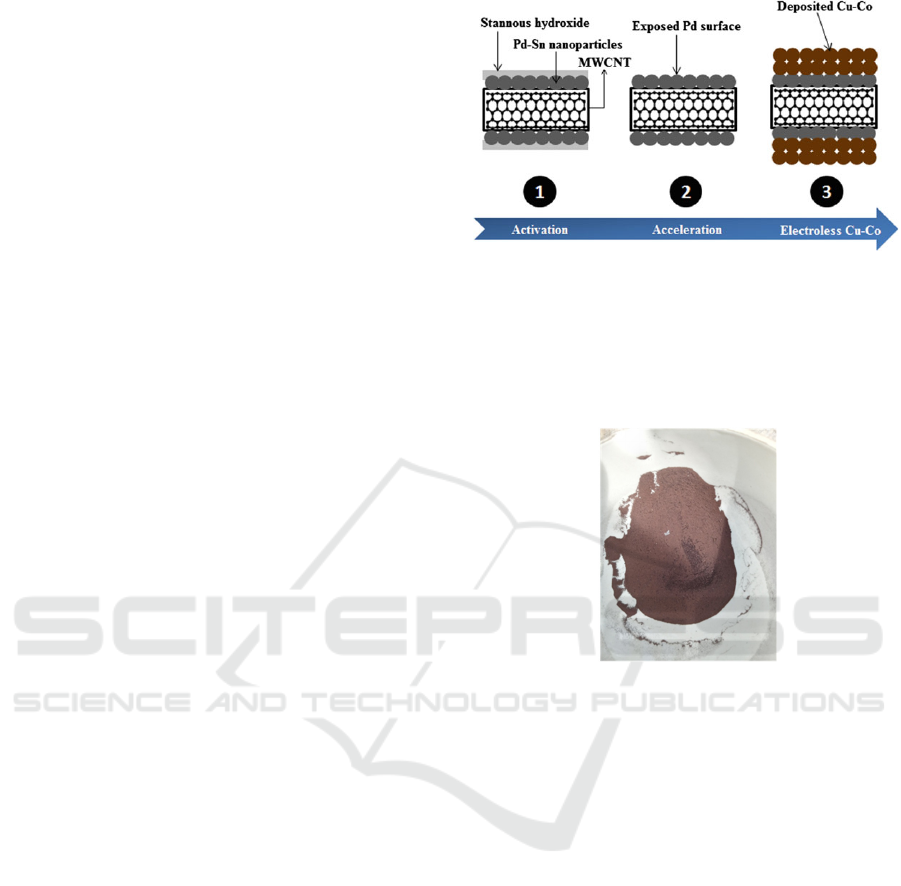

2.2 Experimental Procedures

The metallization of MWCNTs by copper was

conducted in three steps. The process started by the

activation of MWCNTs surface using colloidal Pd-

Sn particles followed by the acceleration step to

remove stannous hydroxide deposits on top of the

activated surface. Finally, The electroless plating of

Cu-Co on top of MWCNTs was performed as shown

Figure. 1.

Figure 1: General scheme of Cu-Co electroless plating on

MWCNTs.

In more detail, the procedure for coating WMCNTs

with copper refers to the literature (Elsharkawi, 2018).

Figure 2 shows the color of the obtained copper

coated MWCNTs powder.

Figure 2: Filtered copper coated MWCNT’s of a brown

color.

The copper coated MWCNTs were characterized

using scanning electron microscopy (SEM) analysis

using (JEOL-JSM 6510 A) at the Materials Labora-

tory of Mechanical Engineering Udayana University.

2.2.1 Al-MWCNTs Composite

Manufacturing Process

Materials for composites, aluminum and multiwall

carbon nanotubes with varying compositions (0% ;

2%; 4%; 6%; 8% and 10% by weight MWCNTs)

were included in the smelting kowi. Heated to a

temperature of 700 oC with a time of 20 minutes and

a stirrer speed of 200 rpm. The composite melt is

poured into a cylindrical metal (steel) mold at room

temperature.

2.2.2 Density of Al-Cu/MWCNTs

Composites

The measurement of the density of the Al-

Cu/MWCNTs composite material is a test object

resulting from the stir casting process.

Microstructure, Microhardness and Thermal Properties of Aluminum with Multi-Walled Carbon Nanotubes Composites Prepared by Liquid

State Processing

851

By knowing these quantities, the density of the Al-

Cu/MWCNTs composite material can be determined

using the equation (Birkeland, 1984),

ρ=

𝑚

𝑚

−𝑚

−𝑚

𝑥 𝜌 𝐻

𝑂

with,

ρ = bulk density (gram/cm

3

)

m

s

= mass of the sample after drying in the oven

(grams)

m

g

= mass of sample suspended in water (grams)

m

k

= mass of sample hanging wire (grams)

ρ H

2

O = density of water = 1 gram/cm

3

2.2.3 Porosity of Al-Cu/MWCNTs

Composites

By knowing these quantities, the porosity of the Al-

Cu/MWCNTs composite material can be determined

using the equation (Birkeland, 1984),

ρ=

𝑚

− 𝑚

𝑚

−𝑚

−𝑚

𝑥 100%

with,

ρ = bulk density (gram/cm

3

)

m

s

= mass of the sample after drying in the oven

(grams)

m

b

= mass of the sample after soaking in water /

saturated (grams)

m

g

= mass of sample suspended in water (grams)

m

k

= mass of sample hanging wire (grams)

2.2.4 Hardness of Al-Cu/MWCNTs

Composite (Vickers Hardness Test)

The hardness of the Al-Cu/MWCNTs composite

material was tested at the Metallurgical Laboratory of

Mechanical Engineering, State University of Malang

using a Microhardness Tester (ESEWAY, Model

EW421AAT), and the test refers to the standard

(Dowling, E.N., 1999); ASTM E 18 - 02.

Measure the diagonal length of each pressing

result and the hardness value of the tested sample can

be read directly on the microhardness tester monitor,

perform at least 3 repetitions for each sample tested.

The hardness value of the Al-Cu/MWCNTs

composite material can also be calculated using the

following equation (Dowling, 1999).

𝑉𝐻𝑁 =

2 𝑃

𝑑

sin

𝛼

2

= 1,8564

𝑃

𝑑

with:

VHN = Vickers hardness value (kgf/mm

2

)

P = pressing load (kgf)

d = average diagonal length (mm)

α = angle between diamond faces (136

o

)

2.2.5 Thermal Conductivity

In this study, for the thermal conductivity test, Linear

Heat Conduction Devices (TD1002a) were used.

Figure 3: Linear Heat Conduction Experiment (TD1002a).

The test object consists of Aluminum- MWCNTs

composites with a thickness of 20 mm and a diameter

of 30 mm

The energy that occurs in the heater is given by

the equation:

W = V x I

With ,

W = Electrical power (watts)

V = Voltage (volts)

I = Electric current (amperes)

Heat transfer that occurs:

𝑞 = 𝑘. 𝐴.

𝑑𝑇

𝑑𝑥

With ,

𝑞 =

= heat transfer rate (Watts)

K = conduction heat transfer coefficient (Watt/m.K)

A = Cross-sectional area of metal test object (m

2

)

dT = temperature difference (K)

dx = distance between test points (T

1

and T

2

)

for this case W = q

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

852

3 RESULTS AND DISCUSSION

3.1 Products of Al – MWCNTs

Composites

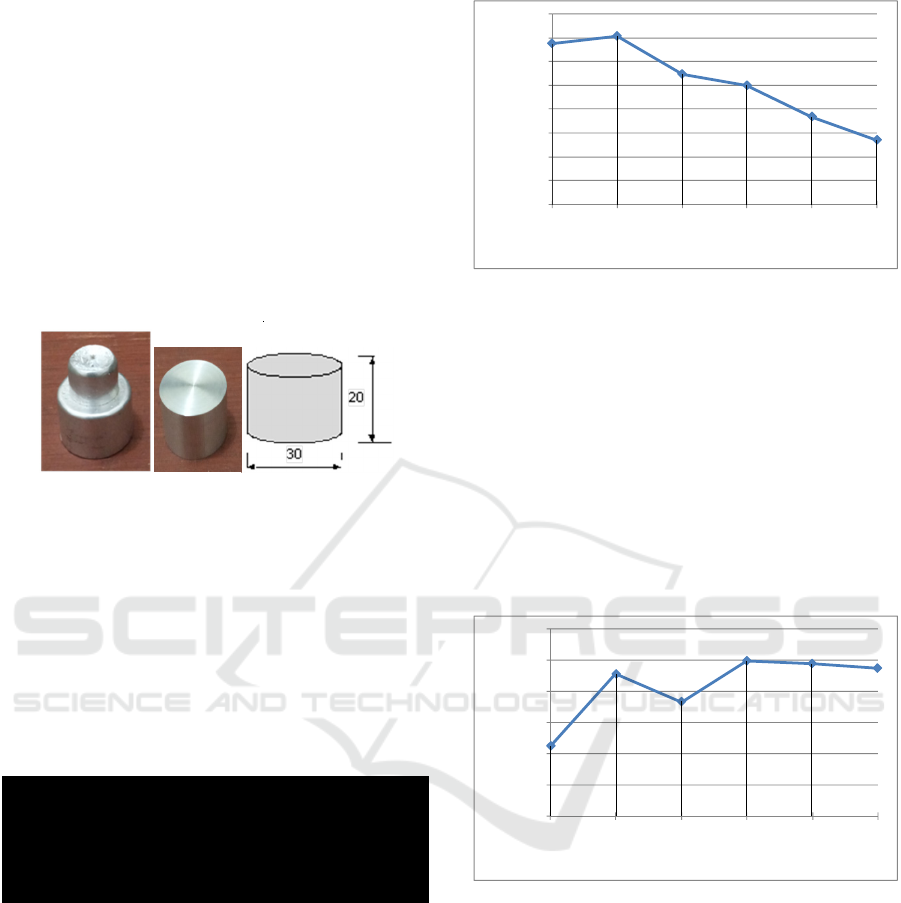

The results of the Al – MWCNTs composite casting

process with various compositions are shown in

Figure 4.

Furthermore, the results of the Al - MWCNTs

composite casting are formed (lathe process) into a

diameter of 30 mm and a thickness of 20 mm, for the

process of testing physical properties, morphological

characterization and thermal conductivity, Figure 4.

Figure 4: Al – MWCNTs composite casting product.

3.2 Physical Properties of

Al –MWCNTs Composites

Based on the results of calculations using equation (1)

for the density test, equation (2) for the porosity test,

as well as testing the hardness properties of

Aluminum – Multiwall Carbon Nanotube

composites, which were carried out in the Lab.

Metallurgy Mechanical Engineering, Udayana

University, obtained data as shown in figure 5.

Figure 5: Physical Test Data for Al – MWCNTs

Composites.

3.2.1 Effect of Reinforcing MWCNTs on

Aluminum on Density

Based on Figure 6, it can be seen that with increasing

MWCNTs content in Al – MWCNTs composites, the

composite density tends to decrease. The lowest

composite density of 2.535 g/cm

3

occurred when the

MWCNTs content was 10% by weight. Meanwhile,

the highest composite density of 2.754 gr/cm

3

occurred when the MWCNTs content was 2% by

weight.

Figure 6: Graph of the relationship between density and

composition.

3.2.2 Effect of Reinforcing MWCNTs on

Aluminum on Porosity

Based on Figure 7, it can be seen that with increasing

MWCNTs content in the Al – MWCNTs composite,

the porosity of the composite tends to increase. The

lowest composite porosity of 4.51% occurred when

the MWCNTs content was 0% by weight.

Meanwhile, the highest composite porosity of 9.96%

occurred when the MWCNTs content was 6% by

weight.

Figure 7: Graph of the relationship between porosity and

composition.

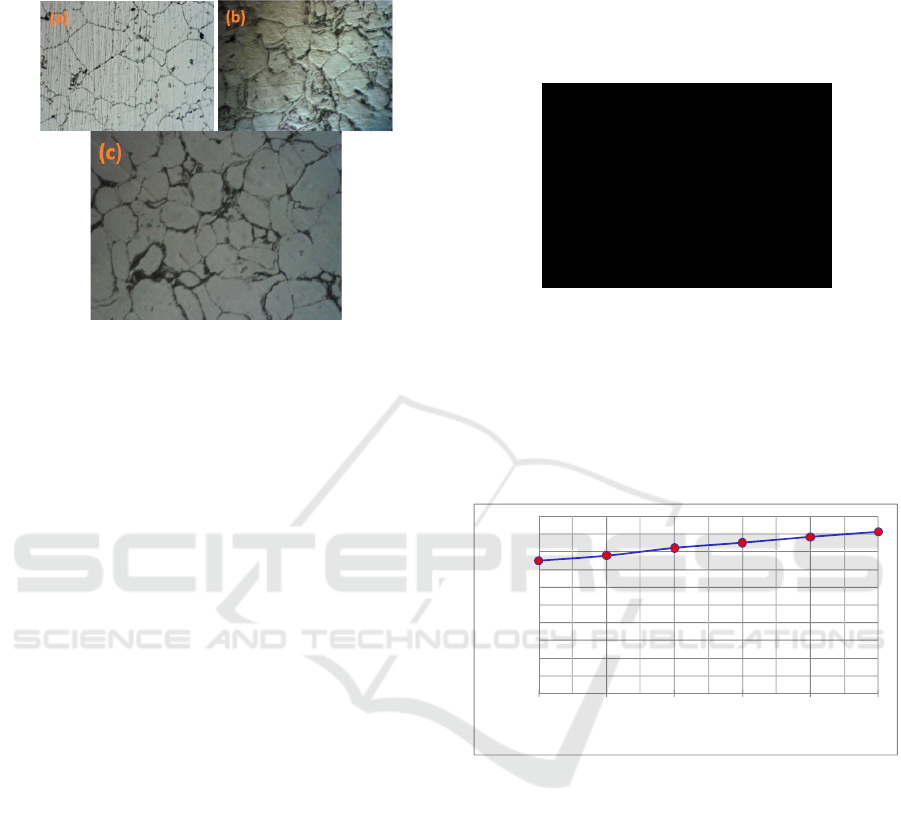

3.3 Microstructure of Al-MWCNTs

Composites

In the sample of the cast Al - Cu/MWCNTs

composite, the Al grain morphology did not change

much compared to Al fine, as shown in Fig. 3.4. This

is because gravity casting is applied during the

formation of the composite, which benefits the

plasticizing of the powder to achieve full density.

Grain boundaries are seen more clearly after repeated

etching. In the pure Al samples, small grain growth

m

s

m

g

m

k

m

b

ρ Η

2

Ο

ρ

P

(gr) (gr) (gr) (gr)

(gr/cm

3

)(gr/cm

3

)

%

0 MWCNTs 100 Al 38,83 25,65 1 39,5 1 2,738 4,512

2 MWCNTs 98 Al 37,92 25,15 1 39,3 1 2,754 9,109

4 MWCNTs 96 Al 37,78 24,65 1 38,9 1 2,674 7,344

6 MWCNTs 94 Al 37,15 24,13 1 38,7 1 2,650 9,955

8 MWCNTs 92 Al 36,95 23,65 1 38,5 1 2,584 9,779

10 MWCNTs 90 Al 36,78 23,27 1 38,3 1 2,535 9,482

Composition specimen

(% weight)

2,738

2,754

2,674

2,650

2,584

2,535

2,400

2,450

2,500

2,550

2,600

2,650

2,700

2,750

2,800

0246810

Density (gr/cm3)

Composition MWCNT (%)

4,51

9,11

7,34

9,96

9,78

9,48

0,00

2,00

4,00

6,00

8,00

10,00

12,00

0246810

Porosity (%)

Composition MWCNTs (%)

Microstructure, Microhardness and Thermal Properties of Aluminum with Multi-Walled Carbon Nanotubes Composites Prepared by Liquid

State Processing

853

(Fig. 8a) and equiaxed grains were observed in all

composites (Fig. 8b and 8c).

Figure 8: Microstructure image etched (a) pure Al, 1.0 wt.%

(b) MWCNT/Al uncoated composite and (c) MWCNT/Al .

Cu-coated composite.

In the composite sample, the MWCNTs were

homogeneously dispersed at the grain boundaries and

within the Al particles. By comparing the grain size

of the composite samples (Fig. 3.5b and 3.5c) with the

Al powder particles, it can be seen that the particle

growth is very small. This is due to the embedding

effect of MWCNTs which inhibits particle growth. It

is important to note that the effect of Cu-coated

MWCNTs increases more of the Al matrix binding

interface. Therefore, small grain sizes were obtained

in the Cu-coated MWCNTs/Al composites compared

to the uncoated MWCNTs/Al composites, where little

grain growth resulting in relatively larger grains was

observed. Due to poor wettability in uncoated

MWCNTs, the embedding of MWCNTs in Al

particles was less during casting compared to Cu-

coated MWCNTs/Al composites.

3.4 Effect of Reinforcing MWCNTs on

Hardness

As previously mentioned, copper coated MWCNTs

are added in varying percentages to the pure

aluminum melt using casting techniques. The aim

was to improve the wettability and dispersion

between aluminum and MWCNTs which was

reported to be very poor in a previous review

(Agarwal, A., et al., 2011). The hardness of the

sample was tested using a Vickers hardness tester.

About 3 penetrations were carried out on a different

area of each sample. The small variability of the

Vickers hardness between the different indentations

is indicative of the homogeneous distribution of Cu

coated MWCNTs in the aluminum matrix. The results

of the Vickers hardness number for various

percentages of copper coated MWCNTs are

presented in Table 1.

Table 1: Hardness test result data.

Based on Figure 9, it can be seen that with

increasing MWCNTs content in Al – MWCNTs

composites, the composite hardness tends to increase.

The lowest composite hardness of 75 HV occurred

when the MWCNTs content was 0% by weight.

Meanwhile, the highest composite hardness of 91.3

HV occurred when the MWCNTs content was 10%

by weight.

Figure 9: Graph of the relationship between hardness and

composition.

It was found that adding 2, 4, 6, 8 and 10%

copper-coated MWCNTs to pure aluminum resulted

in an increase in Vickers hardness of 4.13 ; 9.87 ;

13.73 ; 18.00 and 21.73% are significant especially

that, for example, 2% copper-clad MWCNTs have

less than 0.1% of MWCNTs. This confirms the

potential of the process used in producing good

quality cast composites from Al-Cu/MWCNTs.

Efforts are underway to optimize the casting process

and to fully investigate the mechanical behavior of

the composite.

Hardness

(HV)

0 MWCNTs 100 Al 75

2 MWCNTs 98 Al 78,1

4 MWCNTs 96 Al 82,4

6 MWCNTs 94 Al 85,3

8 MWCNTs 92 Al 88,5

10 MWCNTs 90 Al 91,3

Composition specimen

(% weight)

75

78,1

82,4

85,3

88,5

91,3

0

10

20

30

40

50

60

70

80

90

100

0246810

Hardness (HV)

Composition MWCNTs (% weight)

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

854

3.5 Thermal Conductivity Test Results

For the thermal conductivity test, Linear Heat

Conduction Devices (TD1002a) were used which was

carried out in the Lab. The Basic Phenomenon of

Mechanical Engineering, Udayana University. The

size of the test object is 30 mm in diameter and 20

mm thick, with a power input of 50 Watt. Based on

the test results and the calculation of the thermal

conductivity of the Aluminum – Multiwall Carbon

Nanotube composite, the data is obtained as shown in

table 2.

Table 2: Data from the heat conductivity test.

Based on Figure 3.6, it can be seen that as the

MWCNTs content increases in the Al-MWCNTs

composite, the thermal conductivity of the Al-

MWCNTs composite tends to increase. The lowest

composite thermal conductivity of 252.42 W/m.K

occurred when the MWCNTs content was 0% by

weight. Meanwhile, the highest composite thermal

conductivity of 442.32 W/m.K occurred when the

MWCNTs content was 8% by weight.

Figure 10: Graph of the relationship between thermal

conductivity and composition.

4 CONCLUSION

In the process of making Al-MWCNTs composites

with a stir casting process, it can be concluded that:

a. The higher the MWCNTs content, the density of

the Al-MWCNTs composite decreased, while the

porosity of the Al-MWCNTs composite increased.

b. The higher the MWCNTs content, the hardness

and thermal conductivity of the Al-MWCNTs

composite tend to increase.

c. The distribution of MWCNT in the aluminum

matrix was uneven and agglomeration of MWCNT

occurred at several locations.

d. Composites with the addition of <10 wt.%

Cu/MWNTs have higher thermal conductivity

than pure aluminum produced by the same liquid

state processing.

e. The Cu/MWNTs/Al composites showed a

maximum thermal conductivity of 442.32 W/m/K

at 8 wt.% Cu/MWNTs. The increase in thermal

conductivity is supported by the measured

microhardness. The Cu/MWNTs/Al composites

showed a maximum microhardness of 91.3 HV

also at 10 wt.% Cu/MWNTs.

f. The results showed that the aluminum matrix

composite reinforced with copper-coated

multiwalled carbon nanotubes (Cu/MWNTs) is a

potential material for high thermal conductivity

applications.

ACKNOWLEDGEMENTS

The researcher expresses his gratitude for the funding

assistance from the Bali State Polytechnic DIPA

2022, so that this research can be completed properly

and can publish this paper.

REFERENCES

Agarwal, A., Bakshi, S.R., and Lahiri, D. (2011),

Processing techniques. Carbon nanotubes: reinforced

metal matrix composites, CRC Press-Taylor & Francis,

Boca Raton, Florida, pp 30–33.

Ashby, M.F., Brechet Y.J.M., Cebon D., and Salvo, L.

(2004). Selection strategies for materials and processes.

Materials and Design. Vol. 35, No. 1, pp. 51-67.

Bakshi, S.R., Patel, R.R., and Agarwal, A. (2010), Thermal

conductivity of carbon nanotube reinforced aluminum

composites: a multi-scale study using object oriented

finite element method. Comput Mater Sci; 50:419–28.

Chu, K., Wu, Q.Y., Jia, C.C., Liang, X.B., Nie, J.H., and

Tian, W.H., (2010). Fabrication and effective thermal

conductivity of multi-walled carbon nanotubes

reinforced Cu matrix composites for heat sink

applications. Compos Sci Technol;70:298–304.

Dai, H., (2002), Carbon nanotubes: opportunities and

challenges, Surface Science, Vo. 500, Issues 1–3, pp.

Thermal Conductivity

(W/m.K)

0 MWCNTs 100 Al 252,42

2 MWCNTs 98 Al 318,47

4 MWCNTs 96 Al 330,27

6 MWCNTs 94 Al 350,49

8 MWCNTs 92 Al 442,32

10 MWCNTs 90 Al 294,88

Specimen Composition

(% weight)

252,42

318,47

330,27

350,49

442,32

294,88

0,00

50,00

100,00

150,00

200,00

250,00

300,00

350,00

400,00

450,00

500,00

0246810

Thermal conductivity (W/m.K)

Compositio n MWCNTs(% weight)

Microstructure, Microhardness and Thermal Properties of Aluminum with Multi-Walled Carbon Nanotubes Composites Prepared by Liquid

State Processing

855

218-241, https://doi.org/10.1016/S0039-6028(01)015

58-8

Dogruoz, M. B. and Arik, M. (2008). An investigation on

the conduction and convection heat transfer from

advanced heat sinks. IEEE. Vol. 1, No. 1, pp. 367-372.

Elsharkawi, M. & Esawi, A.M.K. (2018). Development of

an Electroless Plating Process for Multi-wall Carbon

Nanotubes (MWCNTS) to Improve Their Dispersion

and Wettability in Molten Aluminum, The Minerals,

Metals & Materials Society, pp. 29-39,

https://doi.org/10.1007/978-3-319-72853-7_3

Gallagher, Shearer, B. and Matijasevic, G., (1998),

Materials Selection Issues for High Operating

Temperature (HOT) Electronic Packaging. lEE. Vol. 1,

No. 1, pp. 180-189.

Keller, K. P. (1998). Cast heat sink design advantages.

IEEE Intersociety Conference on Thermal Phenomena.

Vol. 1, No. 1, pp. 112-117.

Kim, P., Shi, L., Majumdar, A., and McEuen, P.L., (2001),

Thermal transport measurements of individual

multiwalled nanotubes. Phys Rev Lett; 87:215502.

Reddy, P. G., and Gupta, N. (2010), Material Selection for

Microelectronic Heat Sink: An Application of the

Ashby Approach. Materials and Design. Vol. 31, No. 1,

pp. 113-117.

Yamanaka, S., Kadokura, H., Kawasaki, A., Sakamoto, H.,

Mekuchi, Y., and Kuno, M., (2006). Fabrication and

thermal evaluation of carbon nanotube/aluminium

composite by spark plasma sintering method. J Jpn Soc

Powder Powder Metall ;53(12):965–70.

Zanetti, L. J., Potemra, T. A., Iijima, T., Baumjohann, W.,

& Bythrow, P. F. (1984). Ionospheric and Birkeland

current distributions for northward interplanetary

magnetic field: Inferred polar convection. Journal of

Geophysical Research: Space Physics, 89(A9), 7453-

7458.

Schmitt, E. A., & Dowling, J. E. (1999). Early retinal

development in the zebrafish, Danio rerio: light and

electron microscopic analyses. Journal of Comparative

Neurology, 404(4), 515-536.

Birkeland, P. W. (1984). Soils and geomorphology. Oxford

university press.

Dowling, A. P. (1999). A kinematic model of a ducted

flame. Journal of fluid mechanics, 394, 51-72.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

856