Performance Analysis of Solar Panels on Zinc Roofs

Firman Firman, Nur Hamzah, Muhammad Ruswandi Djalal and Tri Susilo

Department of Mechanical Engineering, State Polytechnic of Ujung Pandang,

Perintis Kemerdekaan km.10 Street, Makassar, Indonesia

Keywords: Solar Panel, Rooftop, Zinc Tile, Temperature, Efficiency.

Abstract: In general, the installation of PLTS Rooftop only considers the power capacity to be installed and the available

roof area and does not consider the type of roofing material where it is installed. Meanwhile, the roof of the

house has the absorption of sunlight and different thermal properties depending on the type of roofing

material. This study aims to observe the temperature characteristics between the solar panels and the roof of

the zinc tile material, where the effect of the height between the solar panels and the roof on the temperature

and its effect on the efficiency of the solar panels. Based on the results of this study, the temperature

characteristics between the solar panels and the roof (T3) various types of materials have an influence on the

efficiency value of the solar panels, where the maximum efficiency value is obtained at a temperature (T3) of

34.14⁰C of 4.67%.

1 INTRODUCTION

Utilization of solar energy as an alternative energy

source for meeting electricity needs in Indonesia is

very appropriate considering the geographical

location in the tropics with solar heat available

throughout the year. Indonesia's natural condition,

which is relatively difficult to reach by a centralized

electricity network, makes the choice of solar energy

a must (Septiadi, Nanlohy, Souissa, & Rumlawang,

2009).

One of the photovoltaic solar energy technologies

that is currently being developed is Rooftop Solar

Power Generation technology or PLTS Rooftop.

Rooftop PLTS is a reliable solution for energy supply

(Peng & Lu, 2013). Some of the advantages of the

PLTS Rooftop system are that it is easy and

inexpensive to integrate with existing electrical

systems and can reduce the burden on the existing

system network. In addition, maintenance and

operation are also easy, but the impact is significant

for reducing pollution and the greenhouse effect

(Castellanos, Sunter, & Kammen, 2017).

Seeing that the potential for solar energy in

Indonesia is very large (NA, 2012), several studies

regarding the use of PLTS Rooftop include (Tarigan,

2018) discussing the potential for implementing

PLTS rooftops in campus buildings. (Hakim, 2017)

examined the design of rooftop off grid solar panels

in residential homes as an alternative source of

electrical energy. (Mintorogo, 2000) investigated the

strategy of applying photovoltaic cells in residential

and commercial buildings. (Syafii, Novizon, Wati, &

Juliandri, 2018) discusses the application of rooftop

solar panels to reduce electricity consumption at peak

load conditions. (Altan et al., 2019; Kotak, Gago,

Mohanty, & Muneer, 2014; Salamanca, Georgescu,

Mahalov, Moustaoui, & Martilli, 2016) discusses the

implementation of rooftop solar panels in buildings.

In general, the installation of PLTS Rooftop only

considers the power capacity to be installed

(Alghamdi, 2019), and the available roof area and

does not consider the type of roofing material where

it is installed. Meanwhile, the roof of the house has

the absorption of sunlight and different thermal

properties depending on the type of roofing material.

The research that has been carried out to determine

the effect of temperature on the roof covering is by

(Rahmat, Prianto, & Sasongko, 2017), (Selparia,

Ginting, & Syech), and (Dominguez, Kleissl, &

Luvall, 2011). (Rahmat et al., 2017) investigated the

thermal conditions of the roof space produced from

various types of roofing materials such as tile,

asbestos and zinc. The results of this study indicate

that the average temperature of the roof space on a tile

roof is 1.91ºC to 2.31ºC lower than that of asbestos

and zinc roofs. Tile roofs are also more resistant to

solar radiation. The average tile roof surface

770

Firman, F., Hamzah, N., Djalal, M. and Susilo, T.

Performance Analysis of Solar Panels on Zinc Roofs.

DOI: 10.5220/0011879900003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 770-776

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

temperature is 0.28ºC lower than the asbestos roof

surface temperature and 1.55ºC lower than the zinc

roof surface temperature. However, the lowest

average roof surface temperature profile during the

day on an asbestos roof is 38.71ºC. Research

conducted by (Selparia et al.) discusses the

manufacture and testing of tools to determine the

conductivity of zinc plate, multiroof, and asbestos.

From these results, it was found that the highest

conductivity value was found on the zinc plate (0.482

W/m°C) and the lowest conductivity value was

multiroof (0.132 W/m°C). (Dominguez et al., 2011)

researched the Effects of Solar Photovoltaic Panels on

Roof Heat Transfer discusses the roof temperature

under PV is 2.5 times cooler than the roof exposed to

sunlight.

Several related studies such as (Odeh, 2018),

which discusses the thermal characteristics of rooftop

PV installations. Several previous studies have

discussed the effect of the type of roofing material

used as a PLTS Rooftop installation on the

temperature between the solar panels and the roof and

have not examined the effect of the distance between

the solar panels and the type of roofing material on

the temperature of the solar panels and have not

discussed its effect on the efficiency of the solar

panels. In research (Firman, Said, & Djalal, 2022),

discussing the performance characteristics of solar

panels on clay and ceramic tile roofing materials,

further research is needed on other types of materials.

Based on this description, this study was made to

observe the temperature characteristics between the

solar panels and the roof of the zinc material. In this

study, the effect of the distance between the solar

panel and the roof on the temperature and its effect on

the efficiency of the solar panel will be observed.

2 METHODS

2.1 Research Instrument Design

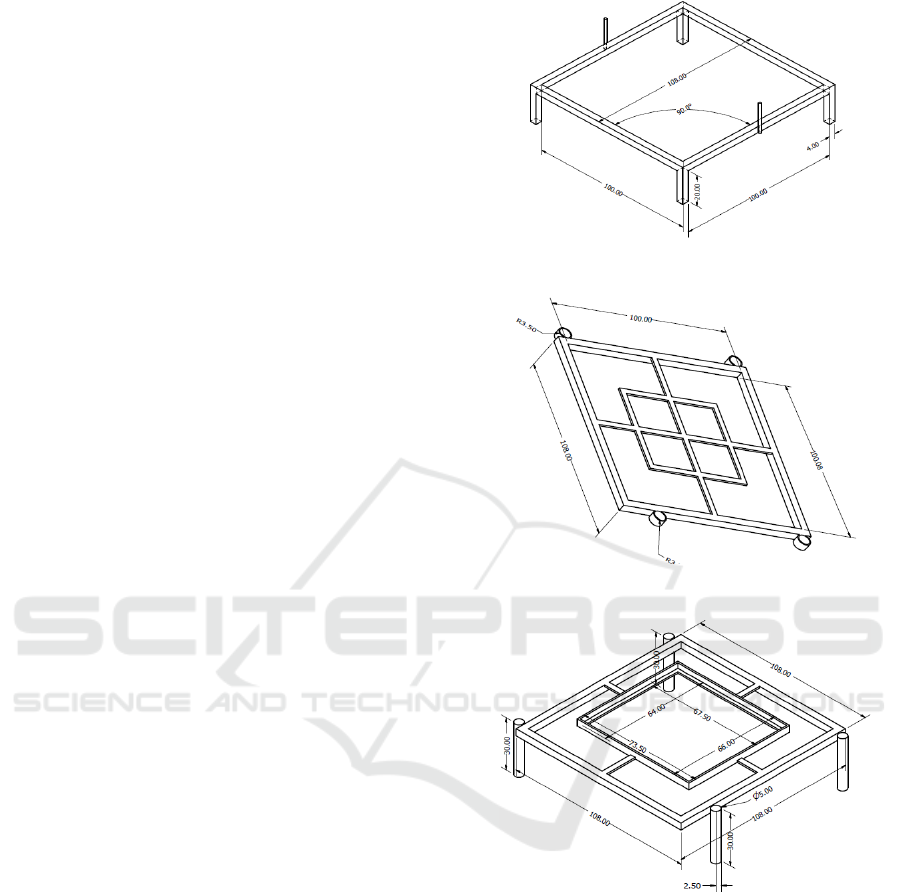

For the frame of the solar panel holder used hollow

iron material measuring 4 x 4 cm and also angled iron

measuring 3 x 3 cm, and for the material on the load

panel used acrylic material. Figure 1 below shows the

design of the solar panel framework and the roof.

Figure 1: Solar panel mounting design.

Figure 2: Tile mount design.

Figure 3: Dimensions of the solar panel framework and

roof.

In designing the load panel as the output of the

solar panel, acrylic material is used with a size of 75

x 60 cm. The following figure 2 shows the design of

the research instrument placement.

Performance Analysis of Solar Panels on Zinc Roofs

771

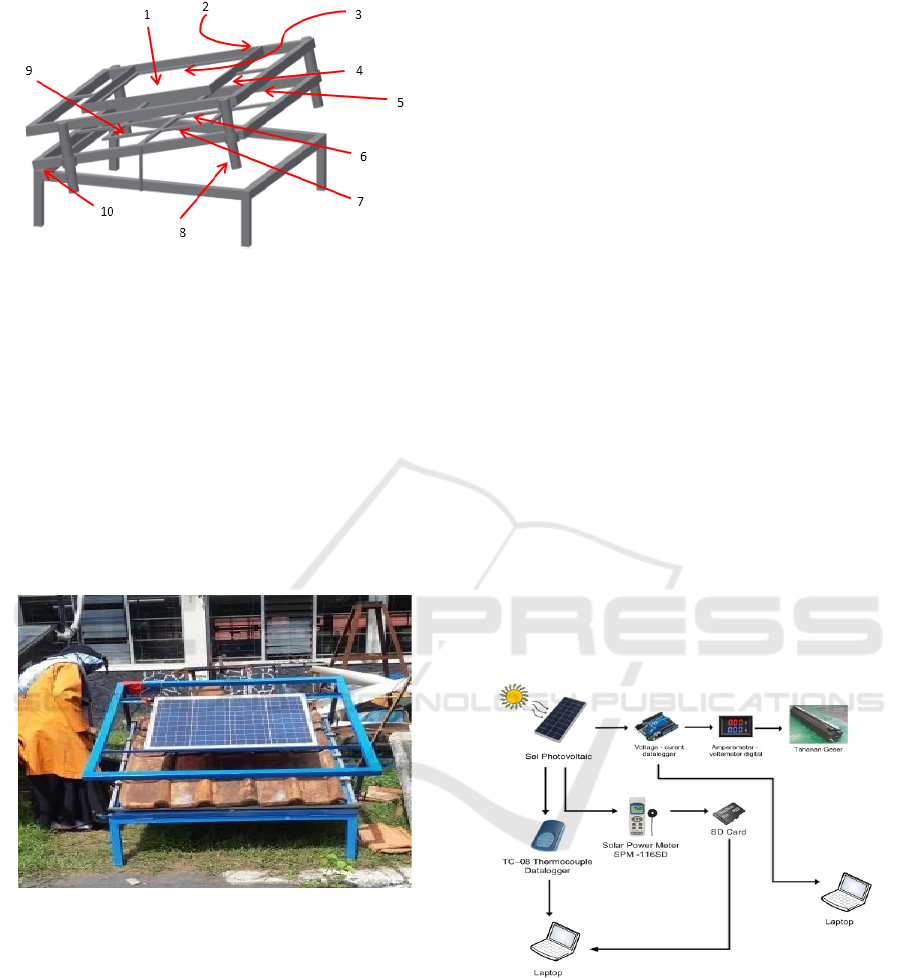

Figure 4: Research instrument placement design.

Information:

1. Solar Panel Mount

2. Solar Simulator Spot

3. Temperature above the solar panel, T1 (℃)

4. Temperature under the solar panel, T2 (℃)

5. Temperature between solar panel and roof,

T3 (℃)

6. Temperature above the roof, T4 (℃)

7. Temperature under the roof, T5 (℃)

8. Distance Variation Adjuster (cm)

9. Roof Mount

10. Tilt Angle (°)

Figure 5: Data collection process.

2.2 Testing Procedure

After the process of making and installing the

research components is complete, then proceed with

the testing procedure. The steps in the testing

procedure are as follows:

1. Testing will be carried out at 09.00 to 15.00 local

time.

2. Adjust the angle of inclination of the solar panels

based on the type of roof used.

3. Install solar panels on the roofing material with a

distance of H1.

4. Measure the distance (cm) between the solar

panels and the roof used.

5. Measure the temperature above the solar panel

(℃) and the temperature between the solar panel

and the roof (℃) using the TC-O8 Thermocouple

Data Logger.

6. Measuring the amount of solar radiation (W/m2)

on the solar panel using the Solar Power Meter

SPM-1116SD measuring instrument.

7. Connect the solar panel output to the load panel

and turn on the toggle switch.

8. Connecting the Voltmeter and Ammeter

Datalogger with a laptop to observe the amount

of current and voltage on the solar panel.

⮚ To ensure the datalogger and measurement

instruments on the load panel are

functioning properly, it can be determined

by turning on the switch on the lamp, then

increasing the voltage by turning the

potentiometer in this case the dimmer to its

maximum condition. The brightness of the

lamp will be directly proportional to the

amount of current and voltage as well as the

intensity of the sun received by the solar

panel. After all the measuring instruments

are functioning properly, then the data

collection can then be carried out.

9. Procedures 1 to 9 are repeated with a distance

of H2 and H3.

Figure 6: PLTS rooftop schematic.

3 RESULTS AND DISCUSSION

The research data contains solar panel parameters

measured on the type of zinc roofing material, the

distance between the solar panels and the roof varies,

including the distances of 35 cm, 30 cm, 25 cm, and

20 cm. In the variation of distance, the research was

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

772

conducted at 3 (three) observation times, namely at

09.30 WITA, 12.30 WITA, and 14.30 WITA.

The measurement data needed in this study

include:

- Solar radiation, G_bt (W/m2)

- Temperature above the solar panel, T1 (℃)

- Temperature under the solar panel, T2 (℃)

- Temperature between solar panel and roof,

T3 (℃)

- Temperature above the roof, T4 (℃)

- Temperature under the roof, T5 (℃)

- Solar panel current, I(A).

- Solar panel voltage, V(V)

- Time, (WITA)

The following is the research data from each of

the above categories taken from the average value of

the measurement results.

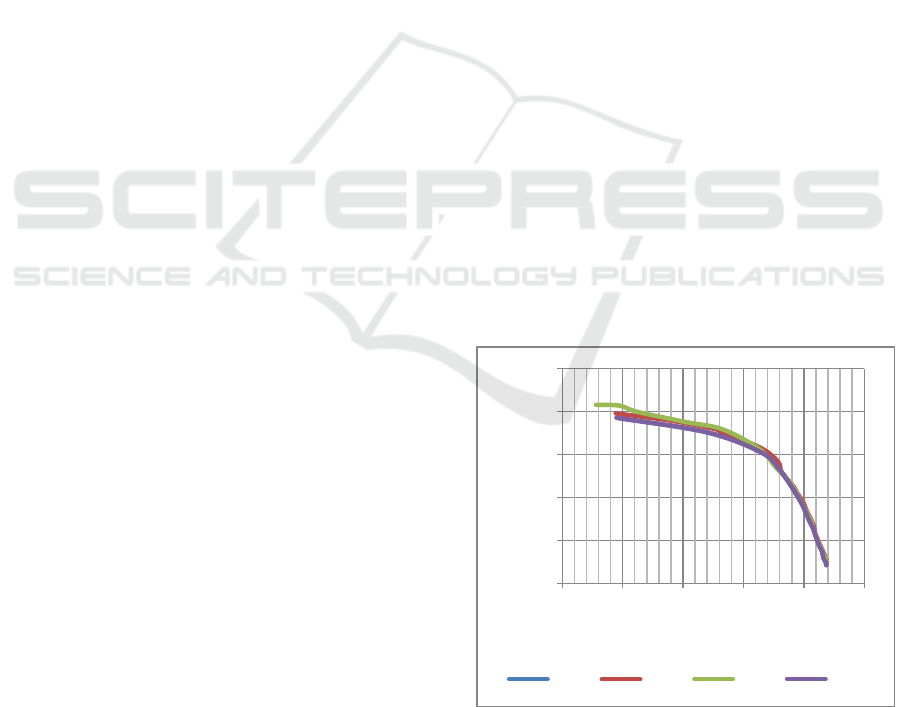

3.1 Characteristics I-V

Figure 5 shows the characteristics of the I-V curve

with various variations in the distance of the solar

panels on the zinc tile for the first experiment. The

graph shows that the voltage generated by the solar

panel is inversely proportional to the amount of

current flowing, where the greater the voltage, the

smaller the current. This is influenced by the resistive

load used in this experiment which varies from the

maximum value to the minimum value for each

variation of the distance between the solar panel and

the zinc tile. In the first experiment, the smallest

voltage value was generated at a distance of 25 cm,

which was 2.79 V with a current value of 2.08 A.

While the largest voltage value was generated at a

distance of 30 cm, which was 21.9 V with a current

value of 0.27 A. In the second experiment, the

smallest voltage value was generated at a distance of

35 cm, which was 0.95 V with a current value of 2.52

A. While the largest voltage value was generated at a

distance of 30 cm, which was 23.93 V with a current

value of 0.29. A. In the third experiment, the smallest

voltage value was generated at a distance of 30 cm,

which was 0.66 V with a current value of 1.74 A.

While the largest voltage value was generated at a

distance of 20 cm, which was 21.88 V with a current

value of 0. 22 A.

Based on Figure 5-7, the battery charging work

area is shown as an output on the solar panel which is

controlled by the BCR (Baterry Control Regulator).

BCR is a battery charging controller circuit in a solar

cell system by regulating the voltage used to charge

the battery in a voltage range of 11.4 V to 14.5 V as

shown in the graph above for charging a 12 V battery.

If the voltage drops to 11.4 V, the controller will

charge the battery if the sun is shining at that time, but

if it is at night, the controller will cut off the supply of

electrical energy. If the voltage rises to 14.5 V, the

controller will stop charging the battery. Overvoltage

in the battery will result in a relatively short battery

life.

From the graph trend of the first experiment, it can

be seen that at a distance of 25 cm the current and

voltage have a minimum value when compared to the

current and voltage values produced at a distance of

20 cm, 30 cm and 35 cm. This is because the effect of

convection heat transfer between the solar panel and

the zinc tile at a distance of 25 cm is greater because

this experiment was carried out when solar radiation

was at its maximum value (daytime). While in the

second experiment, it was seen that at a distance of 35

cm the current and voltage had a minimum value

when compared to the current and voltage values

produced at a distance of 20 cm, 25 cm and 30 cm.

This is because the effect of convective heat transfer

between the solar panel and the zinc tile at a distance

of 35 cm is greater because this experiment was

carried out when solar radiation was at its maximum

value (during the day). Meanwhile, in the third

experiment, it was seen that at a distance of 30 cm the

current and voltage had a minimum value when

compared to the current and voltage values produced

at a distance of 20 cm, 25 cm and 35 cm. This is

because the effect of convection heat transfer between

the solar panel and the zinc tile at a distance of 30 cm

is greater because this experiment was carried out

when solar radiation was at its maximum value

(daytime).

Figure 7: Characteristics of I-V curves with various

distances of solar panels on zinc tile for the first experiment.

0

0,5

1

1,5

2

2,5

0 5 10 15 20 25

Current(A)

Voltage(V)

35cm 30cm 25cm 20cm

Performance Analysis of Solar Panels on Zinc Roofs

773

Figure 8: Characteristics of I-V curves with various

distances of solar panels on zinc tile for the second

experiment.

Figure 9: Characteristics of I-V curves with various

distances of solar panels on zinc roof tiles for the third

experiment.

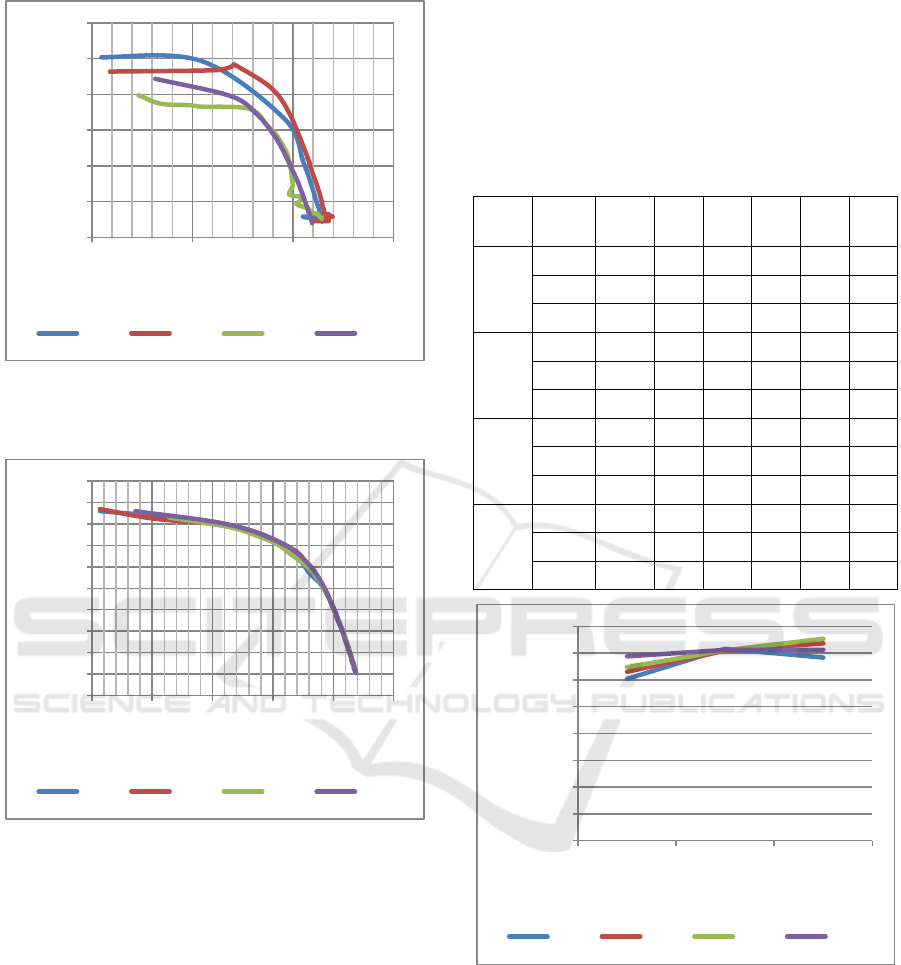

3.2 Solar Panel Temperature

Characteristics

Figure 7 shows a comparison of the temperature

characteristics for several variations of the distance

on the type of zinc tile material. In testing using the

type of zinc tile material, it shows that at a distance of

35 cm, the highest T3 temperature in the test using

zinc tile roofing material was obtained in tests

conducted at 12.30 WITA which was 35.8oC. Next in

the test with a distance of 30 cm, the highest T3

temperature was obtained in the test conducted at

14.30 WITA which was 36.82oC. Next in the test

with a distance of 25 cm, the highest T3 temperature

was obtained in the test conducted at 14.30 WITA

which was 37.67oC. Next in the test with a distance

of 20 cm, the highest T3 temperature was obtained in

the test conducted at 14.30 WITA which was

35.62oC. Table 1 shows the results of testing the

characteristics of solar panels on zinc roof tiles.

Table 1: Temperature characteristics of zinc tile material.

Range

(cm)

Time

(WITA

)

𝐺

(W/m

2

)

𝑇

(℃)

𝑇

(℃)

𝑇

(℃)

𝑇

(℃)

𝑇

(℃)

35

09.30 870.7

56.0

1

47.8

6

30.1

8

35.1

6

34.0

0

12.30 1179

50.6

2

49.4

1

35.8

0

37.5

1

35.6

7

14.30 732

57.4

2

54.3

5

34.1

4

38.2

9

35.6

3

30

09.30 887.2

57.3

0

51.0

4

31.5

1

35.6

7

33.7

6

12.30 1032

56.5

9

43.8

5

35.4

4

38.9

5

37.7

4

14.30 727.2

58.5

1

57.0

6

36.8

2

40.0

2

37.4

9

25

09.30 886.1

51.9

5

48.4

4

32.3

7

36.0

8

35.5

7

12.30 974.2

56.3

6

55.6

5

35.5

1

39.2

0

37.4

8

14.30 732

60.1

3

58.4

0

37.6

7

42.1

1

40.0

2

20

09.30 880.9

58.9

6

54.1

2

34.3

9

37.5

5

36.7

8

12.30 1007

53.7

9

51.4

7

35.5

9

38.7

1

35.0

8

14.30 720.1

58.9

6

56.7

2

35.6

2

41.3

2

39.8

4

Figure 10: Comparison of temperature characteristics for

zinc tile material.

Testing the characteristics of the temperature of

the solar panels on the zinc tile shows an increasing

trend in the temperature graph from 09.30 to 14.30.

This is because zinc tile is a good conductor so the

heat from the roofing material can move to the top of

the solar panels.

0

0,5

1

1,5

2

2,5

3

0102030

Current(A)

Voltage(V)

35cm 30cm 25cm 20cm

0

0,2

0,4

0,6

0,8

1

1,2

1,4

1,6

1,8

2

0 5 10 15 20 25

Current(A)

Voltage(V)

35cm 30cm 25cm 20cm

0

5

10

15

20

25

30

35

40

9,3 12,3 14,3

TemperatureBetweenSolarPanelsand

Roofs,T3(°C)

Time(WITA)

35cm 30cm 25cm 20cm

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

774

3.3 Solar Panel Efficiency

For efficiency analysis, calculations were carried out

by taking the sample data in Table 1 with a distance

of 35 cm at 09.30 WITA. The parameters are as

follows:

● Intensity of solar radiation, G_bt = 870.7 W/m2

● Voltage, V = 20.36 V

● Current, I = 0.51 A

● Cross-sectional area, A = 0.538x0.636 = 0.342 m2

● The temperature above the solar panel, T1 = 56.01

● The temperature under the solar panel, T2 = 47.86

● Temperature between solar panel and roof, T3 =

30.18

● Temperature above the roof, T4 = 35.16

● Temperature under the roof, T5 = 34.00

● Time = 9.30 WITA

Input Power Calculation, 𝑃

𝑊

𝑃

= 𝐺

𝑥

𝐴

= 870,7 𝑊/𝑚

𝑥 0,342 𝑚

= 297,94 𝑊att

(1)

Output Power Calculation, 𝑃

𝑊

𝑃

= 𝑉 𝑥 𝐼

20,36 𝑉 𝑥 0,51

𝐴

= 8,83 𝑊att

(2)

Calculation of Solar Panel Efficiency, 𝜂 (%)

𝜂

𝑥 100%

,

,

𝑥 100%

2,97 %

(3)

Table 2: Power and efficiency of solar panels on zinc tile.

Range

(cm)

Time

(WITA

)

𝐺

(W/m

2

)

𝑉

(V)

𝐼

(A)

𝑃

(W)

𝑃

(W)

ƞ

(%

)

35

09.30 870.7

20.3

6

0.5

1

8.83

297.9

4

2.9

7

12.30 1179

20.2

7

0.7

6

11.9

6

403.5

5

2.9

7

14.30 732

18.1

0

0.7

8

11.7

2

250.6

2

4.6

7

30

09.30 887.2

19.0

1

0.8

5

13.9

9

303.5

7

4.6

1

12.30 1032

20.6

7

0.8

4

14.1

3

353.1

3

4.0

1

14.30 727.2

19.4

5

0.6

0

9.61

248.8

1

3.8

6

25

09.30 886.1

18.5

8

0.7

9

11.2

3

303.2

0

3.7

0

12.30 974.2

19.1

5

0.7

9

12.6

3

333.3

3

3.8

1

14.30 732

19.6

5

0.6

4

11.1

7

247.3

9

4.5

1

20

09.30 880.9

20.3

6

0.5

1

8.83

301.4

3

2.9

3

12.30 1007

20.4

5

0.5

6

9.89

344.5

5

2.8

8

14.30 720.1

20.1

4

0.5

3

9.23

246.4

1

3.7

5

The complete results of the calculation of input

power, output power, and solar panel efficiency are

shown in table 2 for the type of zinc tile material.

Table 3 shows the results of calculating the input

power, output power, and efficiency of solar panels

on zinc roof tiles. To see the comparison visually, the

results of the efficiency calculations are displayed in

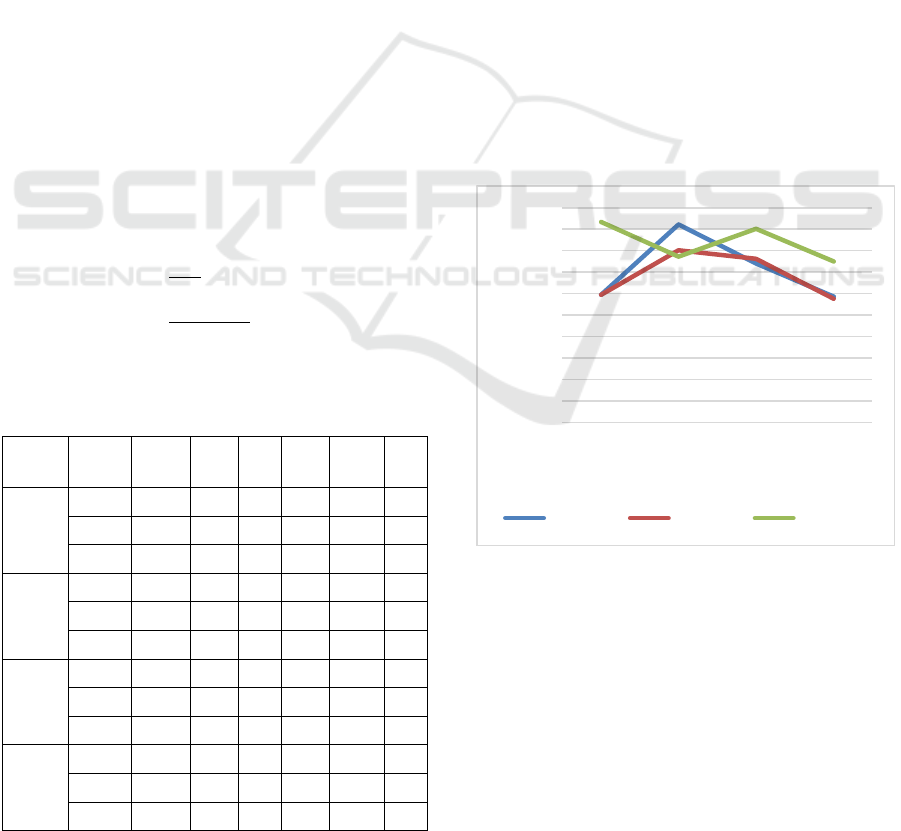

a graphical form as shown in Figure 8. Figure 8 shows

a comparison of the efficiency for several height

variations of the types of zinc tile materials.

The highest efficiency value obtained for a height

of 35 cm is 4.67% at the time of testing at 14.30

WITA. While the lowest efficiency value was

obtained at the time of testing at 12.30 WITA which

was 2.88%. The efficiency value in this experiment is

influenced by the measured value of solar radiation

and temperature based on variations in height

between the roof and solar panels. Other factors that

affect the efficiency of solar panels in this study such

as wind speed and reflectance of sunlight from

roofing materials to solar panels are assumed not to

have much effect on this experiment because the test

framework (solar panels and roofs) are not placed on

tall buildings so that the -these factors are ignored.

Figure 8 below shows the efficiency of each test on

zinc tile material at various height distance variations.

Figure 11: Comparison of efficiency of solar panels types

of zinc tile materials.

4 CONCLUSIONS

Based on the research that has been done, it can be

concluded that:

1. In the first experiment, the smallest voltage value

was generated at a distance of 25 cm, which was

2.79 V with a current value of 2.08 A. While the

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

35 30 25 20

Efficiency(ƞ)

Height(cm)

09.30WITA 12.30WITA 14.30WITA

Performance Analysis of Solar Panels on Zinc Roofs

775

largest voltage value was generated at a distance

of 30 cm, which was 21.9 V with a current value

of 0, 27 A. In the second experiment, the smallest

voltage value was generated at a distance of 35

cm, which was 0.95 V with a current value of

2.52 A. While the largest voltage value was

generated at a distance of 30 cm, which was

23.93 V with a current value of 0. ,29 A. In the

third experiment, the smallest voltage value was

generated at a distance of 30 cm, which was 0.66

V with a current value of 1.74 A. While the

largest voltage value was generated at a distance

of 20 cm, which was 21.88 V with a current value

of 0.22 A.

2. The highest efficiency value obtained for a

height of 35 cm is 4.67% at the time of testing at

14.30 WITA. While the lowest efficiency value

was obtained at the time of testing at 12.30

WITA which was 2.88%.

REFERENCES

Alghamdi, A. S. (2019). Potential for Rooftop-Mounted PV

Power Generation to Meet Domestic Electrical Demand

in Saudi Arabia: Case Study of a Villa in Jeddah.

Energies, 12(23), 4411.

Altan, H., Alshikh, Z., Belpoliti, V., Kim, Y. K., Said, Z.,

& Al-chaderchi, M. (2019). An experimental study of

the impact of cool roof on solar PV electricity

generations on building rooftops in Sharjah, UAE.

International Journal of Low-Carbon Technologies,

14(2), 267-276.

Castellanos, S., Sunter, D. A., & Kammen, D. M. (2017).

Rooftop solar photovoltaic potential in cities: how

scalable are assessment approaches? Environmental

Research Letters, 12(12), 125005.

Dominguez, A., Kleissl, J., & Luvall, J. C. (2011). Effects

of solar photovoltaic panels on roof heat transfer. Solar

Energy, 85(9), 2244-2255.

Firman, F., Said, N. H., & Djalal, M. R. (2022).

Characteristic Analysis of Solar Panels on Clay and

Ceramic Roof Tiles. 2022, 16(3). doi:10.

15866/ireme.v16i3.20004130-138 %J International

Review of Mechanical Engineering (IREME).

Hakim, M. F. (2017). Perancangan Rooftop Off Grid Solar

Panel Pada Rumah Tinggal Sebagai Alternatif Sumber

Energi Listrik. Dinamika DotCom.

Kotak, Y., Gago, E., Mohanty, P., & Muneer, T. (2014).

Installation of roof-top solar PV modules and their

impact on building cooling load. Building Services

Engineering Research & Technology, 35(6).

Mintorogo, D. S. (2000). Strategi aplikasi sel surya

(photovoltaic cells) pada Perumahan dan bangunan

komersial. DIMENSI (Journal of Architecture and Built

Environment), 28(2).

NA, H. (2012). Potency of solar energy applications in

Indonesia. International Journal of Renewable Energy

Development, 1(2), 33-38.

Odeh, S. (2018). Thermal performance of dwellings with

rooftop pv panels and pv/thermal collectors. Energies,

11(7), 1879.

J., & Lu, L. (2013). Investigation on the development

potential of rooftop PV system in Hong Kong and its

environmental benefits. Renewable and Sustainable

Energy Reviews, 27, 149-162.

Rahmat, A., Prianto, E., & Sasongko, S. B. (2017). Study

of The Influence of Roof Covering Materials on

Thermal Conditions in the Roof. Jurnal Arsitektur

ARCADE, 1(1), 35-40.

Salamanca, F., Georgescu, M., Mahalov, A., Moustaoui,

M., & Martilli, A. (2016). Citywide impacts of cool

roof and rooftop solar photovoltaic deployment on

near-surface air temperature and cooling energy

demand. Boundary-Layer Meteorology, 161(1), 203-

221.

Selparia, E., Ginting, M., & Syech, R. Pembuatan Dan

Pengujian Alat Untuk Menentukan Konduktivitas Plat

Seng, Multiroof Dan Asbes. Riau University.

Septiadi, D., Nanlohy, P., Souissa, M., & Rumlawang, F.

Y. (2009). Proyeksi potensi energi surya sebagai energi

terbarukan (Studi wilayah Ambon dan sekitarnya).

Jurnal Meteorologi dan Geofisika, 10(1).

Syafii, S., Novizon, N., Wati, W., & Juliandri, D. (2018).

Feasibility Study of Rooftop Grid Connected PV

System for Peak Load Reduction. Proceeding of the

Electrical Engineering Computer Science and

Informatics, 5(5), 231-235.

Tarigan, E. (2018). Simulation and feasibility studies of

rooftop PV system for university campus buildings in

Surabaya, Indonesia. International Journal of

Renewable Energy Research, 8(2), 895-908.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

776