Analysis of Causes ETS Generator Protection Failure Using Root

Causes Failure Analysis and Root Causes Problem Solving Methods

and Their Effect on the EAF Value of PLTU Anggrek

Fifi Hesty Sholihah, Andiko Adi Pratama and Hendrik Elvian Gayuh Prasetya

Powerplant Engineering Department, Politeknik Elektronika Negeri Surabaya, Surabaya, Indonesia

Keywords: ETS Generator Trip, RCFA and RCPS, EAF.

Abstract: Anggrek Powerplant experienced a failure in the form of active ETS Generator Trip protection. From the

results of observations on the panel, it is obtained "AVR Trip" and "Stator Earth Fault" notifications.

Therefore, a system is needed to assess these problems appropriately so that when the failure occurs, it does

not take too much time and costs a lot of repairs. Therefore, the author uses the RCFA (Root Causes Failure

Analysis) and RCPS (Root Causes Problem Solving) methods to find the root cause and solutions to the root

of the problem This paper also compares the value of EAF (Equivalent Availability Factor) PLTU Anggrek

after and before doing RCFA. From the result of the failure analysis using RCFA In the AVR trip, six root

causes were found, while in Earth Stator Fault there were thirteen root causes. The EAF value before doing

RCFA is 74.78%, while after doing RCFA it has an EAF value of 86.31%. From the cost benefit analysis,

after doing RCFA, a saving of Rp. 1,935,382,700..

1 INTRODUCTION

Anggrek Power Plant is a coal-fired steam power

plant located in Ilangata village, Anggrek district,

North Gorontalo district, with a production capacity

of 2 x 25 MW and as a power producer to cover

electricity needs in Gorontalo and North Sulawesi

Provinces. In operating the PLTU Anggrek unit, it is

able to reduce the basic cost of providing electricity

to the North Sulawesi and Gorontalo network systems

by up to 46 IDR/Kwh or 8.6 billion per month. In

supporting the reliability, operation, and security of

the Anggrek Power Plant unit, there is a protection

system for the main equipment of Boilers, Turbines,

and Generators. This is done to prevent severe

damage to equipment that can cause production to

stop for a long period of time and the high cost of

equipment repairs that must be done.

At Anggrek Power Plant, ETS Generator Trip is a

trip system that is on the generator and distribution

system. This safety system will be active if a

disturbance is detected in the generator and

distribution equipment. On June 15, 2020, there was

an active tripping ETS Generator protection at the

Anggrek Power Plant, where it tripped, and the unit

stopped operating. The operator tries to sync five

times, but GCB (Generator Circuit Breaker) opens

again. In the 1, 2, and 3 synchronization experiments

on the panel, it shows the “AVR Trip” protection is

active, and when the 4 and 5 synchronizations show

the “Stator Earth fault” protection is active.

Therefore, Anggrek Power Plant experienced a

shutdown for seven days, eleven hours one minutes,

and experienced a loss opportunity of 179.01 MWh.

Therefore, it is necessary to evaluate the failure in

an appropriate and structured way so that it does not

take up too much time, energy, and costs. RCFA

(Root Causes Failure Analysis) is a step-by-step

method that leads to the main cause or root cause of

failure. If the cause of the failure is not found

correctly, then there is a possibility that the failure

will occur again and cause production losses and

increased maintenance costs. RCFA is a structured

method to get to the root cause, making it easier to

identify the causes and symptoms that affect the

problem (Zavagnin, 2008). The author also includes

corrective actions using the RCPS (Root Causes

Problem Solving) method, where the method has an

appropriate action planning implementation based on

the root of the problem. After that, the author

simulates the value of EAF (Equivalent Avalability

Factor) after and before doing RCFA.

Sholihah, F., Pratama, A. and Prasetya, H.

Analysis of Causes ETS Generator Protection Failure Using Root Causes Failure Analysis and Root Causes Problem Solving Methods and Their Effect on the EAF Value of PLTU Anggrek.

DOI: 10.5220/0011877000003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 757-763

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

757

2 ANALYSIS METOD

2.1 Fault Tree Analysis

The FTA method is often used to analyze system

failures. Fault Tree Analysis (FTA) is an analysis

method where there is an unwanted event called an

Undsired Event that occurs in the system, the system

is then analyzed with existing environmental and

operational conditions to find all possible ways could

lead to an undesired event.

2.2 RCFA (Root Causes Failure

Analysis)

Root Causes Failure Analysis (RCFA) is a failure

cause analysis tool that refers to an interest in a

proactive basic view that causes failure of facility

equipment. The main purpose of the RCFA is to find

out the cause of a problem efficiently and

economically, correct the cause of the problem, not

only its effectiveness, but also to fix it, and prepare

data that can be useful in overcoming the problem

(Wisudana, 2015).

RCFA concentrates on proactively finding the

cause of failure. The difference with Failed Item

Analysis is that RCFA performs proactive activities

before and after a failure occurs, while Failed Item

Analysis is absolute after a failure occurs. The main

purpose of RCFA is to find the cause of inefficiency

and uneconomical, correct the cause of failure (not

only concentrate on the effect), generate enthusiasm

for continuous improvement, and provide data to

prevent failure. The accuracy of the RCFA results is

very dependent on the perception, assumptions, depth

level of logic quality and maturity of a resource

person (Gulati, 2008).

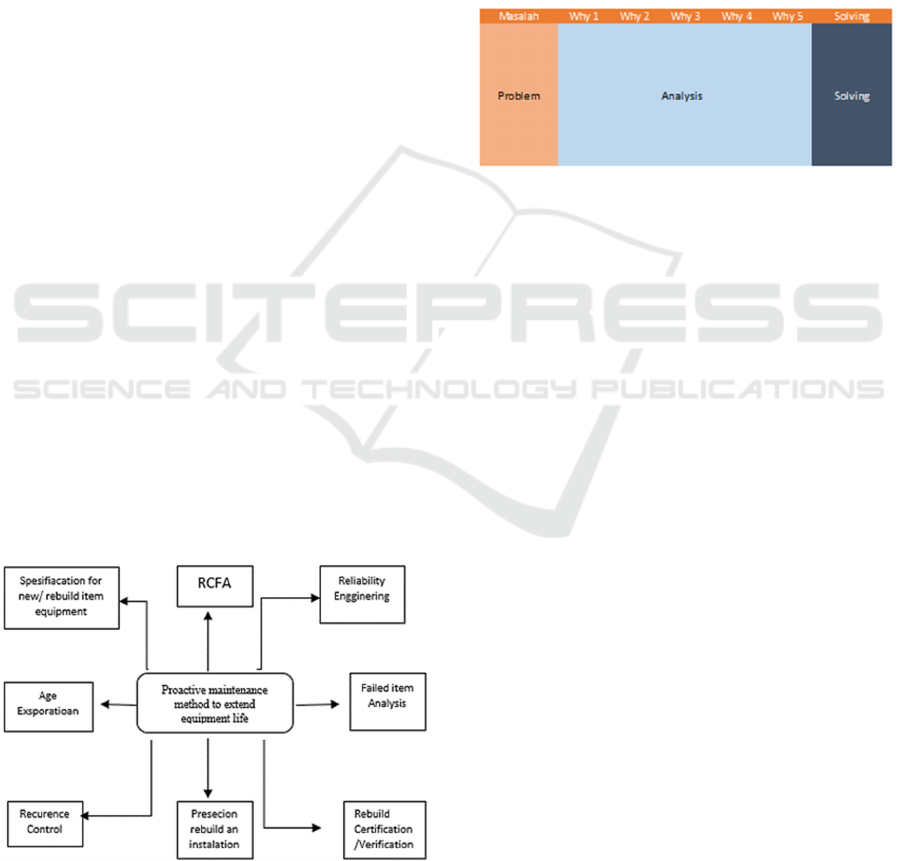

Figure 1: Proactive maintenance.

RCFA can be displayed in a variety of diagrams,

including RCA Diagrams, FTA Diagrams,

Ishikawa/Fishbone Diagrams, Flowchart Process and

Causes mapping, and 5 Why's analysis each of which

has the same perspective but differs in the focus of the

problem (Gulati, 2008).

2.3 RCPS (Root Cause Problem Solving)

Root Causes Problem Solving (RCPS) is a method

used to find the root cause of a problem in depth by

considering all the possibilities that exist and

determining the type of improvement to a problem.

Figure 2: RCPS.

2.4 EAF (Equivalent Avalability

Factor)

Equivalent Availability Factor (EAF) is an indicator

of the availability of power plants that have taken into

account the impact of generator derating. The EAF

value is a comparison obtained from the readiness of

the plant to operate divided by time.

In Indonesia, EAF is used not only as a parameter

of good or bad performance but also as a source of

revenue for the generator itself. This is because the

electricity system in Indonesia uses electricity tariffs

to PLN, assessed from two things, namely EAF

(Equivalent Availability Factor) and sales of

electrical energy. The formula for calculating EAF is:

EAF = (AH – (EUDH + EPDH + EMDH +

ESDH) / PH) x 100%

(1)

AH = PH – ( SH + RSH ) (2)

SH = FOH + MOH + POH (3)

Where:

EAF = Equivalent Availability Factor (%)

AH = Availability Hours (h)

PH = Plan Hours (h)

SH = Service Hours (h)

RSH = Reverse Shutdowh Hours (h)

EUDH = Equvalent Unplaned Derating Hours

EPDH = Equivalent Planed Derating Hours

EFDH = Equivalent Forced Derating Hours

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

758

ESDH = Equivalent Schedule Derated Hours

FOH = Forced Outage Hours (h)

MOH = Maintenace Outage Hours (h)

POH = Planed Outage Hours (h)

NMC = Net Maximum Capacity

3 RESULT

3.1 Cronology of Events

On June 15, 2020 there was a failure in the form of an

active ETS Generator, causing Unit 1 to Trip for 7

days 11 hours 01 minutes. This causes the PLTU

Anggrek to experience a lost opportunity of 179.01

MW. Based on the information obtained from the

trend data results in DCS (Distribution Control

System) and field checks, the following data were

obtained:

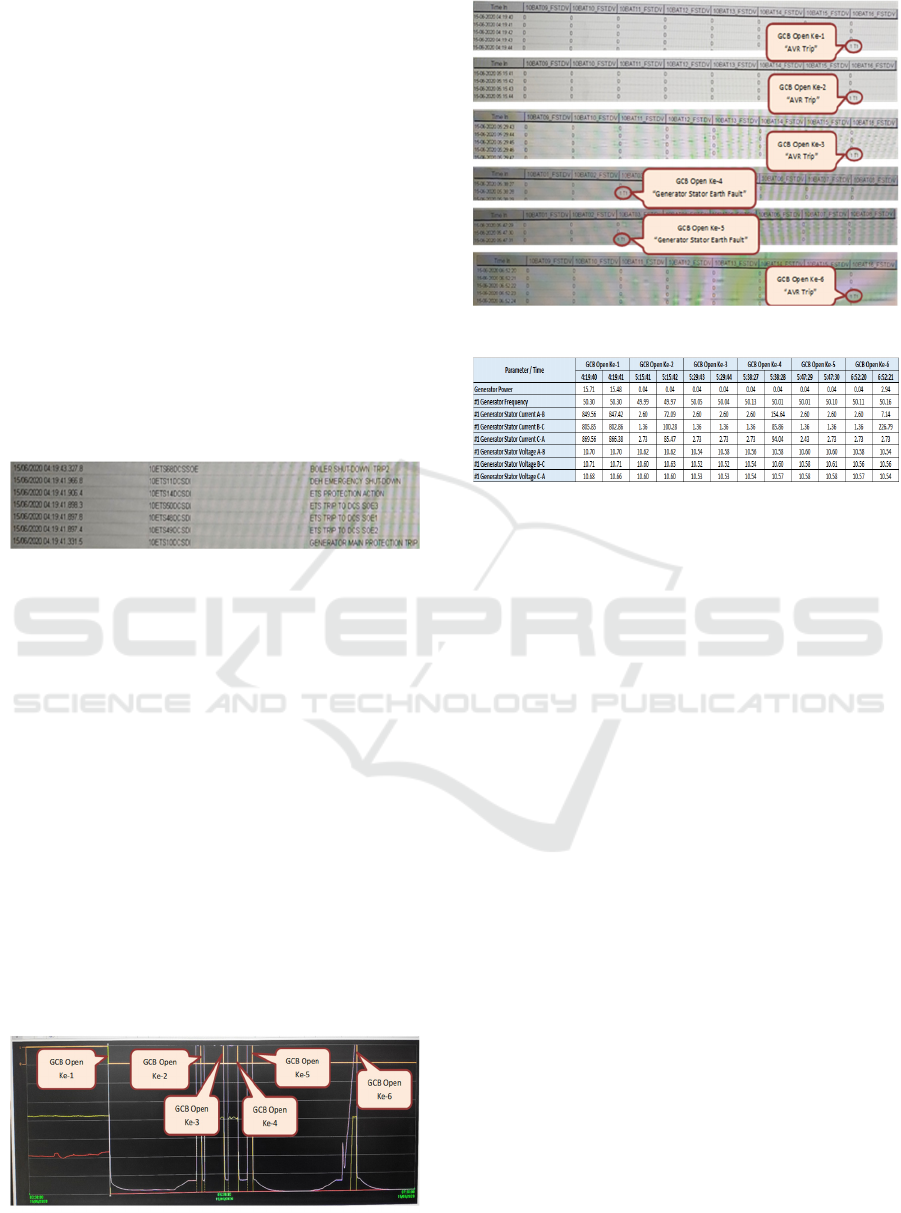

Figure 3: SOE units 1 Anggrek powerplant.

Based on the SOE table data, the following

information is obtained:

• Generator Protection Main Protection unit 1 is

active.

• ETS Trip To DCS SOE2 protection is on.

• ETS Trip To DCS SOE1 protection is on.

• ETS Trip To DCS SOE3 Protection On

• Protect ETS Protection Action

• DEH Emergency Shut-down protection is

active.

• Trip2 Boiler Shut-down Protection is active

Furthermore, the data obtained from the panel

display shows that the GCB is open during

synchronization 6 times.

Figure 4: Trend GCB opens.

Figure 5: Trend data ETS generator protection.

Figure 6: Data trend GCB opens.

In Figure 4-6, information on unit 1 data after

the Generator Trip disturbance is obtained as follows:

• The first disturbance occurred at 4:19:41,

which caused the GCB Unit 1 to Open.

• In the first fault, it can be seen that when the

ETS protection "Generator Trip" is active,

the "AVR Trip" protection generator is active

at the same time (04:19:43).

• Then the operator normalized and tried again

to sync at 5:15:41 but the sync failed, and

GCB opened again.

• Synchronous experiments were carried out

five times, but synchronous still could not be

carried out. In synchronous experiments 3 and

4, GCB unit 1 opens again with the appearance

of Generator Protection "Stator Earth Fault"

active.

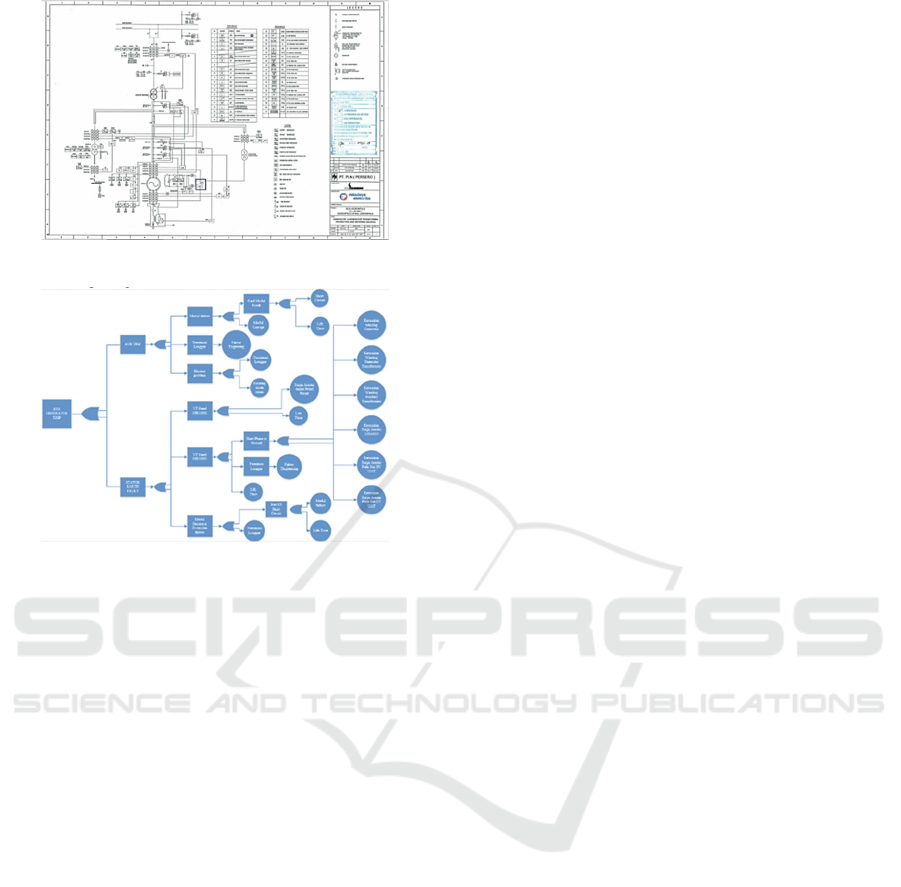

3.2 FTA (Fault Tree Analysis)

There are also results from the fault tree based on

interviews with field supervisors and literature

studies:

Analysis of Causes ETS Generator Protection Failure Using Root Causes Failure Analysis and Root Causes Problem Solving Methods and

Their Effect on the EAF Value of PLTU Anggrek

759

Figure 7: Generator & generator transformers protection

and metering diagram.

Figure 8: FTA (Fault Tree Analysis) of ETS generator trip.

3.3 RCFA (Root Cause Failure

Analysis)

The results of the RCFA from the chronology of

events that have been analyzed resulted in 2 main

problems, namely the failure of the AVR and the

grounding system so that there are notifications in the

form of "AVR Trip" and "Earth Stator Fault" in the

trend menu of the Generator main protection data.

1) AVR Trip

In the AVR Trip problem that appears in the 1,

2, and 3 synchronizations, there are three main root

causes that were found using the Fault tree analysis

method, including:

a) Module Failure

The module is a component of the AVR process

in the module, and there is a card that functions as an

IC or as a data processor from the field to the display.

Module failure can be affected due to damage to the

card module or IC module. This can happen because

of the indication of a short circuit on the module and

the lifetime of the module.

b) Loose Termination

A loose termination is an event where the

connecting port is loose so that the data from the field

is not conveyed to the display. This is a possible

failure of the AVR system.

c) Excitation Problem

Excitation is a process that functions to supply

direct voltage (DC) to a generator so that a generator

can produce large amounts of electrical energy. This

excitation process is actually the task of the AVR

system, which functions as a regulator of the

excitation voltage. The excitation voltage can fail

because the connection between the rotating diode

and the ports leading to the module is loose or even

disconnected. The main thing that causes the

excitation voltage problem is a damaged rotating

diode. A rotating diode is the main component of

creating direct voltage (DC) on the generator.

2) Earth Stator Fault

In the Earth Stator Fault problem that appears in

the fourth and fifth synchronization, three main root

causes were found using the Fault Tree Analysis

method, including:

a) PT10BAB02

PT10BAB02 is a potential transformer that

measures the current in the grounding system. From

the results of the chronology, there is an error in the

stator earth fault, which is also a grounding system.

What can be identified is the presence of a voltage

that penetrates the potential transformer

PT10BAB02, which should have a safety system in

the form of a surge arrester for each potential

transformer. The surge arrester in the panel is

damaged because the voltage penetrates to the stator

earth fault or grounding system. Another possibility

is the lifetime of PT10BAB02.

b) PT10BAB03

PT10BAB03 is a potential transformer that

measures the voltage on the bus side of 10.5 Kv. In

the chronology of events, there is network instability

which causes the operator to adjust the settings of the

charger tap to lower the voltage on the generator side

of the transformers. Then check the PT10BAB03

potential transformers side. An active overvoltage

alarm is seen. The value that is read on the indicator

when the alarm is active is 120.01 V. The ratio of the

potential transformer measurement is 10.5 Kv/ 100 V,

which means the actual value on the Bus has a value

of 12.001Kv. In fault tree analysis, overvoltage

conditions can be caused by a short phase to ground

or breakdown voltage on the equipment connected to

PT10BAB03. From the results of the analysis, the

first indication of damage or short on the winding

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

760

generator, winding generator transformers, and

winding auxiliary transformers. The second is

damage to the protection system in the form of a surge

arrester in several components that have a surge

arrester and are connected to PT10BAB03 because,

in the specifications, the surge arrester component is

only able to receive a voltage of 12Kv. The following

are the specifications for the surge arrester of the

PLTU Anggrek.

Table 1: Spesifications of surge arester.

Equipment

Name

Specification

Surge

Arrester

HE: 12

Ur = 12 kV

Uc= 10.2 kV

Is = 20 kA

F = 50/60 Hz

Manufacture: Tridelta Varisil

So it can be concluded that when the overvoltage

condition on the 10.5 Kv line, the surge arrester

contained in the connected component on the 10.5 Kv

line is damaged because the maximum specification

is 12Kv. The following from the analysis of the fault

tree components that were damaged include damage

to the surge arrester PT10BAB03, damage to the

surge arrester on the HV UAT (Auxilary

transformers) side, and damage to the surge arrester

on the LV UAT (Auxilary Transformers) side.

The next factor that causes overvoltage is the

termination of the system that is loose or not installed

accurately can also cause the system to be unstable.

Then the last factor is the lifetime factor of

PTBAB1003 equipment.

c) Module Generator Protection Failure

The generator failure protection module is a

module for safety when an error occurs in the

generator. In the generator protection system there are

connecting ports and modules that process data so

that if the damage is detected on the generator, the

module will send a command to the main system to

open the 10.5Kv CB. This can be a problem due to a

damaged port or a damaged module due to failure,

and a lifetime can send commands to open a 10.5 Kv

CB with a certain error, but the system is actually still

working very well. This has happened to the PLTU

Anggrek so that in the fault tree analysis, the authors

review and enter the problem into the fault tree. Next

is a loose termination. This can cause the system not

to work according to standards and can cause errors

during operation.

3.4 RCPS (Root Cause Problem

Solving)

The results of the analysis of the RCPS (Root Causes

Problem Solving), which is the selection of solution

actions based on "5 Why’s analysis" to find the right

solution according to the problems that occur.

Table 2: RCPS of ETS generator trip.

Root Cause Problem Solving (RCPS)

Problem Why 1 Why 2 Why 3 Solutions

AVR

Trip

Modul

failure

Module card

is broken

Short circuit Replacing the

damaged card

module with a new

card module

Life time

Modul

Corupt

Repair the module if

it can still be used by

checking

com

p

onents

Loose

Termination

Thightening

Factor

Checking or

repairing

connections between

p

orts on the AVR

Problem

Excitation

Loose

Termination

Check and repair

between ports on

connection and

excitation s

y

stem

Rotating

Diode is

b

roken

Replacement of

rotating diode

com

p

onents

Stator

Earth

Fault

VT Panel

10BAB02

The surge

arrester

inside the

panel is

broken

Check the surge

arrester with the IR

test, if the results

show no voltage

then the surge

arrester is re

p

laced

life time

Change of VT Panel

10BAB02

VT Panel

10BAB03

Short Phase

to ground

Generator

winding

damage

Replacing the

damaged component

of the winding

g

enerator

Transformers

winding

generator

damage

Replacing the

damaged

components of the

winding Generator

transformers

Damage to

winding

auxiliary

transformers

Replacing the

damaged Auxillary

Transformers

windin

g

com

p

onents

Damage to

surge arrester

PT 10BAB03

Replacing a faulty

surge arrester

Damage to

the surge

arrester on

the HV UAT

Replacing a faulty

surge arrester

Damage to

surge arrester

on LV side of

UAT

Replacing a faulty

surge arrester

Loose

termination

Thightening

factor

Checking and

reconnecting ports

and loose

connections

life time

Change of VT Panel

10BAB03

Modul

Generator

Protection

failure

Port IO

circuit

Modul failure

Replace the failed

module

life time

change port or

connection

Loose

termination

Checking and

reconnecting ports

and loose

connections

Analysis of Causes ETS Generator Protection Failure Using Root Causes Failure Analysis and Root Causes Problem Solving Methods and

Their Effect on the EAF Value of PLTU Anggrek

761

3.5 EAF (Equivalent Avalability

Factor)

From the results of interviews and discussions with

field supervisors, PLTU Anggrek has a work contract

with PLN where the contract discusses the regulations

for taking shutdown hours, where the shutdown hours

are calculated daily. So in planning improvements by

conducting RCFA first, it takes 4 days to work (based

on interviews with field supervisors). Whereas before

doing RCFA, it takes 7 days to work.

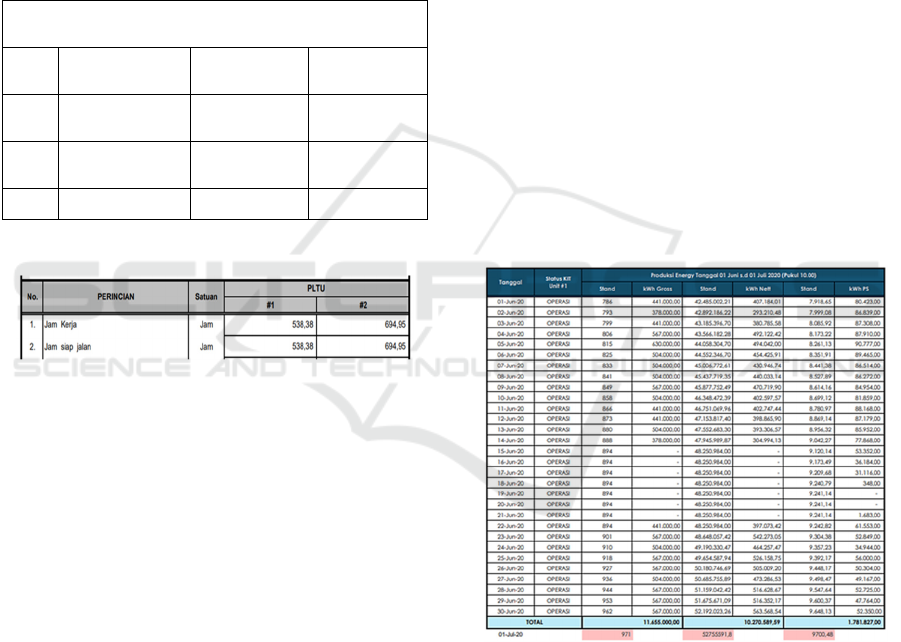

Table 3: Comparison of SH anggrek powerplant unit 1 June

2020.

Comparison of shutdown hours of PLTU Anggrek

in June 2020

No Problem

Before doing

RCFA (h)

After doing

RCFA (h)

1

ETS

Generator Trip

179.02 96

2

Low Vaccum

Condense

r

2.6 2.6

Total 181.62 98.6

a) Calculating June EAF before doing RCFA

Figure 9: Data for AH Anggrek powerplant for June 2020.

It is known in Figure 14 that the working hours

of PLTU Anggrek Unit 1 in June are 538.38 hours,

so :

EAF = (AH – (EUDH + EPDH + EMDH +

ESDH) / PH) x 100%

EAF = ((538.38 -(0))/720)X 100%

EAF = 74.78% (4)

b) Calculating June EAF after doing RCFA

From table 4, the value of SH (Shutdown Hours)

of Anggrek Powerplant during June 2020 is 98.8

hours. The AH (Availability Hours) value is

calculated using the formula:

AH = PH-(SH+RSH )

= 720-(98.8+0 )

= 621.2 (5)

Then the EAF value is:

EAF = (AH – (EUDH + EPDH + EMDH +

ESDH) / PH) x 100%

EAF=((621.2 -(0))/720)X 100%

EAF = 86.62% (6)

From the results of the EAF value of the Anggrek

Powerplant in June 2020 which has been calculated,

the value before doing RCFA on the ETS Generator

trip problem is 74.78%, while after doing RCFA the

value is 86.28%. Compiling a repair plan using RCFA

can increase the EAF value by 12.1%. The EAF value

after carrying out the RCFA exceeds the EAF value

set by PJB as a work contact to the PLTU Anggrek,

which must be above 82.72% for semester 1 (January-

June), while for semester 2 (July-August), it must

have a value above 71.5%.

3.6 Cost Benefit Analysis

After analyzing the EAF value, it is necessary to

calculate how much profit is obtained when

conducting RCFA analysis after the ETS Generator

Trip event. The following is the electricity production

data for unit 1 PLTU Anggrek in the month of june

2020:

Figure 10: Electricity production unit 1 PLTU Anggrek in

June 2020.

From the figure, the value of electricity

production per day by PLTU Anggrek is obtained,

which is distributed to 150 KV substations. Before

doing the RCFA analysis, it is worth 10,270,598.59

Kwh. Meanwhile, the average daily production of

PLTU Anggrek is 446,547.76 Kwh. Then the

Powerplant income is calculated before conducting

the RCFA:

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

762

Price of electricity/Kwh: Rp. 1,444.70

1 month income = 10,270,598.59 x 1,444.70

= Rp. 14,837,933,800 (7)

Meanwhile, the revenue for the PLTU Anggrek

after RCFA is:

Average daily electricity production = 446,547.76

Kwh

Total production for 1 month = 10,270,598.59 +

(446,547.76 x 3)

=11.610.241.9 Kwh (8)

Price of electricity/Kwh = Rp. 1.444,70

1 month income = 11.610.241,9 x 1.444.70

=Rp. 16.773.316.500 (9)

From the cost-benefit analysis, it is found that

doing RCFA will increase generator income by Rp.

1,935,382,700.

4 CONCLUSIONS

1) In calculating PLTU Anggrek could not reach

the target set by PJB, namely EAF in semester 1

(January-June) of 82.72%, but when have done

RCFA, the EAF value has increased by 12.1% so that

it is worth 86.28% and has reached the target set by

PJB.

2) From the income calculation, it was found that

doing RCFA at the ETS Generator Trip event was

able to increase revenue by Rp. 1,935,382,700.

REFERENCES

Zavagnin, R. (2008). An overview of a Root Cause Failure

Analysis (RCFA) process. Paper presented at the Banff,

Canada: IPEIA Conference.

Dono, M. W. (2017). Implementasi Reliability Centered

Maintenance (RCM) II Pada Boiler B-1102 Di Pabrik I

PT. PETROKIMIA GRESIK (Doctoral dissertation,

Institut Teknologi Sepuluh Nopember).

Pambudi, A. (2004). Analisa Kerusakan Regulator A1 AVR

Diesel Generator Pada Kapal Patroli Tipe KCR (Kapal

Cepat Rudal) (Doctoral dissertation, Institut Teknologi

Sepuluh Nopember).

Reimert, D. 2006. Protective Relaying for Generation

System. England: CRC Press.

Trisya Wulandari. 2011. Analisa Kegagalan Sistem dengan

Fault Tree. Depok: Tugas Akhir Universitas Indonesia.

Amalia, Z. (2016). Perancangan Sistem Pemeliharaan Pada

Turbin 103-Jt Mengggunakan Metode Reliability

Centered Maintenance (Rcm) (Studi Kasus: Pt.

Petrokimia Gresik Unik Amonia Pabrik I) (Doctoral

dissertation, Institut Teknologi Sepuluh Nopember

Surabaya).

Wisudana, D. H. (2015). Evaluasi Reliability dengan

Metode Kuantitatif dan Kualitatif RCFA pada Unit

Superheater, Desuperheater dan Exhaust Damper

HRSG 3.1 di PT. PJB UP. Gresik (Doctoral

dissertation, Institut Teknologi Sepuluh Nopember).

Gulati, Ramesh., 2008. Maintenance & Reliability Best

Practice Handbook. New York: Industrial Press. Inc,

2008.

Sukendar, I., Syahkroni, A., & Prasetyo, B. T. (2019).

ANALISA Kebocoran Pada Body Mill/Pulverizer

Menggunakan Metoda Root Cause Failure Analysis

(RCFA). Applied Industrial Engineering Journal, 3(2),

12-21.

Analysis of Causes ETS Generator Protection Failure Using Root Causes Failure Analysis and Root Causes Problem Solving Methods and

Their Effect on the EAF Value of PLTU Anggrek

763