Performance Evaluation of a Linear Fresnel Concentrator Applying

Numerical Simulation

B. E. Tarazona-Romero

1,2 a

, C. L. Sandoval-Rodriguez

1,3 b

O. Lengerke-Pérez

1c

,

J. S. Becerra-Reyes

1

and A. Velandia-Esparza

1

1

Automation and Control Energy Systems Research Group (GISEAC), Faculty of Natural Sciences and Engineering,

Electromechanical engineering, Unidades Tecnológicas de Santander (UTS), Student Street No 9-82, 680005,

Bucaramanga, Colombia

2

Energy in Building research group (ENEDI), Doctoral Program in Energy Efficiency and Sustainability in Engineering

and Architecture, Department of Machines and Thermal Engines, University of the Basque Country (UPV / EHU),

Engineer Torres Quevedo Square, 1, 48013, Bilbao, BI, Spain

3

Doctoral Program in Electronic and Communications, Department of Communications Engineering, University of the

Basque Country, UPV/EHU, 48013 Bilbao, Spain

Keywords: Lineal Fresnel Concentrator, Numerical Simulation, Performance, Renewable Energy.

Abstract: This work performs an optical analysis of an artisanal system of Linear Fresnel con.centrates developed by

the Research Group in energy, automation and control systems of the Technological Units of Santander. For

this, the numerical simulation methodology was applied by means of the Engineering Equation Solver

software. The analysis carried out found that the angle of incidence Theta has a direct relationship with the

optical performance of the system, affecting it when the angular inclination is not correct. Additionally, the

system increases its performance when the speed and flow of the heat transfer fluid decrease. Finally, the

evaluation made to the device despite having a percentage difference with the performance of the real device,

serves as a reference to predict the behavior of the system and identify the critical operating characteristics

that affect it.

1 INTRODUCTION

Solar energy is a renewable energy source and an

alternative to reduce the consumption of fossil fuels

and combat the environmental crisis that the world is

currently experiencing. Generally, global crises have

been the drivers of the growth of renewable energy

and solar energy (Moghimi et al., 2017). For

example, in 1973-1979 there was the oil and energy

crisis, which led to the development of scientific work

in order to find reliable sources of alternative energy

(Ross, 2016). As a result of these scientific works, the

first constructions of solar concentration systems

(CSP) began (Pitz-Paal, 2014).

Solar concentration technology is currently one of

the most interesting options to reduce the

consumption of fossil fuels and greenhouse gas

a

https://orcid.org/0000-0003-3508-3160

b

https://orcid.org/0000-0001-8584-0137

c

https://orcid.org/0000-0001-9360-7319

emissions, widely applied centrally for the production

of thermal and electrical energy (Lovegrove & Pye,

2021). CSP systems are based on reflecting direct

normal radiation (DNI) through a surface or area of

reflection at a focal point of small aperture

concentration (Lovegrove & Stein, 2021). A heat

transfer liquid circulates through the concentration

point that reaches high temperatures, which feed

processes with demand for thermal energy or

conventional thermodynamic cycles to generate

electricity (J. J. C. S. Santos et al., 2018). In general,

there are four classes of CSP technologies (Pitz-Paal,

2020): central tower (CT) (Vant-Hull, 2021),

Parabolic disk (PD) (Schiel & Keck, 2021),

parabolic-trough (PTC) (Moya, 2021) and Linear

Fresnel (LFC) (Tarazona-Romero et al., 2021).

Eventually, Linear Fresnel-type Solar

Concentrators (LFC) are currently a promising

Tarazona-Romero, B., Sandoval-Rodriguez, C., Lengerke-PÃl’rez, O., Becerra-Reyes, J. and Velandia-Esparza, A.

Performance Evaluation of a Linear Fresnel Concentrator Applying Numerical Simulation.

DOI: 10.5220/0011826500003612

In Proceedings of the 3rd International Symposium on Automation, Information and Computing (ISAIC 2022), pages 37-43

ISBN: 978-989-758-622-4; ISSN: 2975-9463

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

37

alternative for the future, due to their simplicity in

construction and cost reduction, compared to other

CSP technologies. However, they lack popularity and

are less mature than PTC systems (Schlecht & Meyer,

2021) (López et al., 2021). The LFC systems have

been applied centrally with success, but it still

requires more technological developments and

research, to overcome the problems that it currently

presents (de Sá et al., 2021). Los sistemas LFC están

compuestos por filas de espejos planos o levemente

curvados (Reflector primario) en dirección

transversal y montados sobre una estructura metálica

de base, cercano al suelo (Platzer et al., 2021). LFC

systems are made up of rows of flat or slightly curved

mirrors (primary reflector) in a transverse direction

and mounted on a base metal structure, close to the

ground (Mills, 2012). The working fluid, generally

water, is pumped through the absorber tubes and

heated by concentrated solar energy until it partially

or totally changes its phase, increasing its enthalpy

(Bellos, 2019).

On the other hand, the decentralized LFC system

offers advantages over other CSP technologies due to

its easy construction, easy access to local resources,

modularity, simple operation and maintenance, cost

reduction and application of thermosyphon systems,

to solve the need of pumping systems (Tarazona-

Romero et al., 2021) (Souza et al., 2021). However,

these advantages incur a considerable decrease in the

efficiency of the system. This makes CFL systems

attractive for applications in isolated areas with

poverty and high intensity in solar radiation

(Tarazona-Romero et al., 2020) (Famiglietti &

Lecuona, 2021).

As for the efficiency of a LFC depends strongly

on the optical performance of the collector and the

thermodynamic behavior of the working fluid in the

absorber, the latter not only allows predicting the

working conditions of the system, but also allows

generating control strategies for avoid equipment

damage (A. V. Santos et al., 2021) (Said et al., 2019).

The analysis of the performance of the systems can be

predicted by means of optical and thermal analyzes

through the application of software (Rungasamy

et al., 2021). The simulation methods for this type of

study can be classified in (Bellos et al., 2019): CFD

modeling (Rungasamy et al., 2015), Monte Carlo ray

Tracing method (de Sá et al., 2021) and numerical

simulations, the latter being the most widely applied,

due to the fact that they allow to evaluate and predict

the behavior of the device by means of the

construction of an algorithm (Ajdad et al., 2019).

Consequently, the research group in energy,

automation and control systems (GISEAC) of the

Unidades Tecnológicas de Santander (UTS), built and

experimented with a LFC artisan prototype developed

under the concept of Appropriate Technology for

water heating (Tarazona-Romero et al., 2021)

(Tarazona-Romero et al., 2020) and its integration

with a desalination system by Humidification-

dehumidification. The system is currently in the

process of improvement and requires analysis of the

optical and thermal performance, which allows

predicting its operation and eventually identifying

improvement options for its implementation. Based

on this, this work develops a numerical simulation of

the behavior of the prototype developed by GISEAC

in order to evaluate its optical and thermal efficiency.

2 METHODS AND MATERIALS

2.1 Fresnel System Characteristics

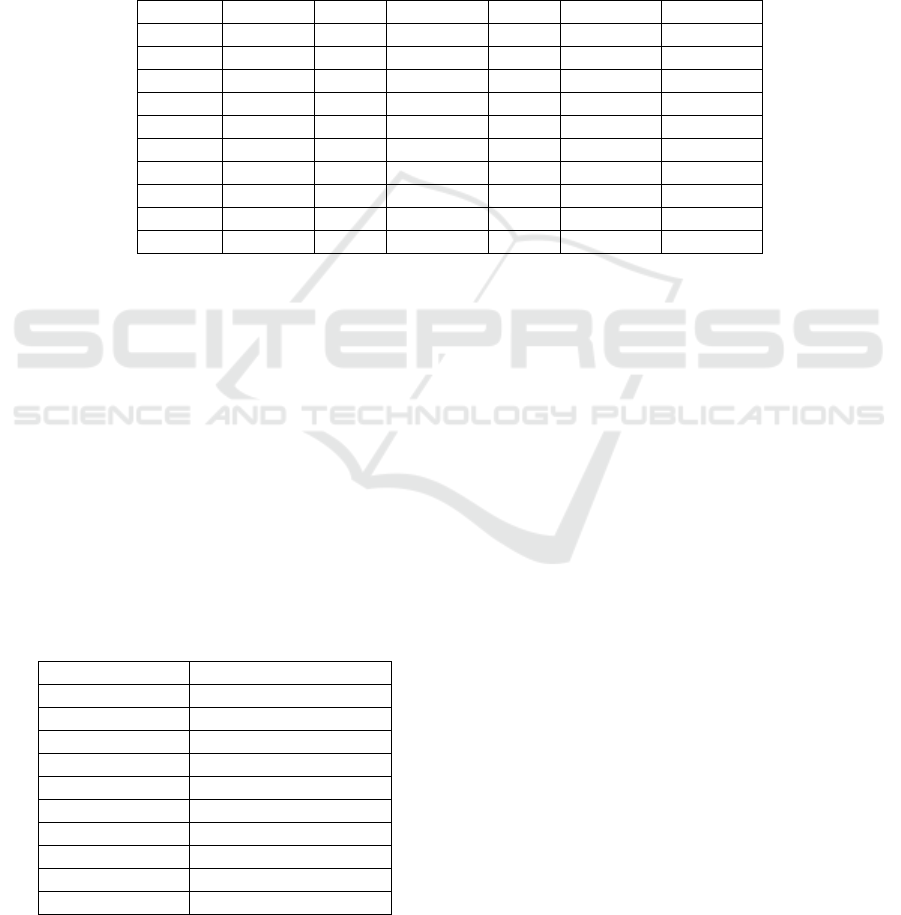

In order to carry out an appropriate mathematical

model of the system, it is necessary to extract data

from the planes of the geometry of the system, Table

1 presents a summary of the dimensions of the

evaluated LFC prototype. The real LFC system has an

efficiency of7.19%

Table 1. LFC system dimensions.

Component Dimensions

Number of Reflective Mirrors 10

Reflective Mirror Length 1 m

Reflective Mirror Width 0.1 m

Number of Absorber Tubes

2

Receiver Tube Outside Diameter

0.003175m

Receiver Tube Inner Diameter

0.0004699m

Absorbent Tubes Length 1.2m

Focal distancie 0.75m

Source: Table Prepared by the authors and information

taken from (Tarazona-Romero et al., 2021)

Additionally, Table 2 presents another important

factor for the development of the simulations and

these are the thermodynamic properties of the

components of the LFC prototype.

Table 2. Propiedades Termodinámicas Componentes

Colector Lineal Fresnel.

Coefficients Value

Copper tube conduction coefficient 0.8

Copper tube emissivity 0.12

Reflectors mirror reflectance

0.712

Aluminum foil reflectance

0,799

Secondary reflector absorption coefficient

0.93

Source: Table Prepared by the authors and information

taken from (Tarazona-Romero et al., 2021)

ISAIC 2022 - International Symposium on Automation, Information and Computing

38

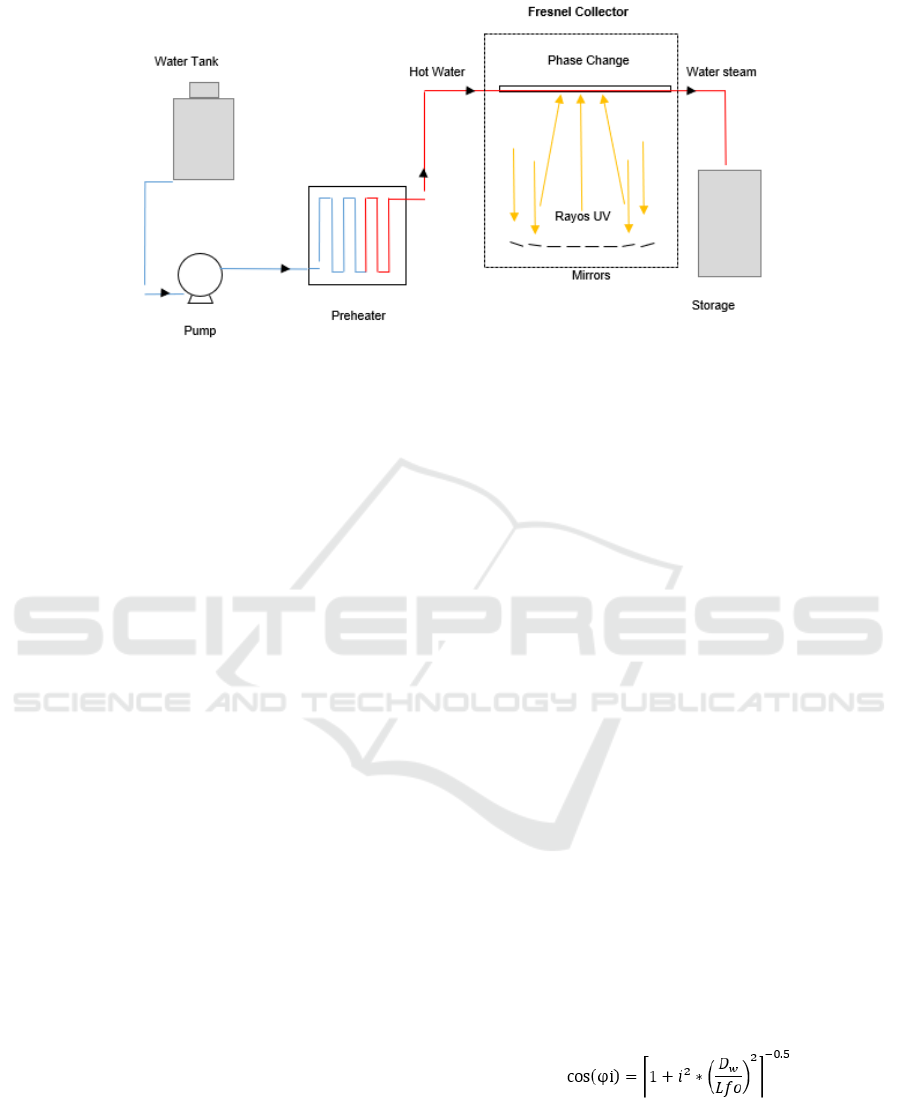

Figure 1: Diagrama prototipo LFC.

Finally, Figure 1 presents the schematization of

the evaluated LFC system.

2.2 Simulation Code Considerations

To develop the code corresponding to the behavior of

the LFC prototype, the Engineering Equation Solver

(EES) software was used and the following

considerations were taken into account:

Dry bulb temperature 25 °C

Wet Bulb Temperature 22°C

Humidity 0.72

Fluid Velocity 0.1 m/s

Convection heat transfer coefficient 1000

(W/m

2

-ºC)

Inlet temperature10 °C

Outlet temperature90°

Theta

T

[20, 23, 25, 40, 60]º

Theta

L

[5, 10, 15, 20, 25]º

The simulation process required a series of

mathematical models to simulate the behavior of the

elements that make up the LFC prototype. The

mathematical expression that allows predicting the

behavior of the preheater is evidenced in equation 1

(Tarazona-Romero et al., 2021).

𝑄=𝑞

∗𝐿 (1)

Where, q

l

is the heat absorbed by the fluid in

(W/m), and L is the length of the fluid's path in (m).

The heat absorbed by the fluid can be determined

from equation 2.

𝑞

=𝜋∗

𝑇

−𝑇

∗ℎ∗𝑑𝑖𝑎𝑚

(2)

Where, T

p

is the temperature of the wall, T

f

is the

temperature of the fluid, h is the heat transfer

coefficient of film and diam

tube

represent the

diameter of the pipe.

For the analysis of the geometry of the LFC

system(Tarazona-Romero et al., 2021), the opening

of the collector is taken into account, which is given

by the following equation:

𝐴

=𝑊

∗𝑁∗𝐿 (3)

Where, A

ac

is the total opening of the collector,

W

0

is the width of the mirrors and N refers to the total

number of mirrors in the system

Additionally, the width of each reflector must be

considered, which is determined from:

𝑊

=𝑊+𝑊

(4)

𝑊=2∗𝑁∗𝐷

(5)

In turn, the focal length of each mirror is given by

equation 6:

𝐿

𝑓

𝑜

=

𝐿

𝑓

𝑜

+𝑖

+𝐷

(6)

Where F is the focal height, on the other hand, i is

the mirror counter.

Regarding the angle of position of the absorber

(φi) it is determined from equation 7:

(7)

On the other hand, the optical efficiency (η

Optima

)

of the system is calculated by applying equation 8:

𝜂

=𝛼∗𝛾∗𝜌∗𝜏∗𝐾 (8)

Performance Evaluation of a Linear Fresnel Concentrator Applying Numerical Simulation

39

Where, α is the absorber absorptivity, 𝜸 the

interception factor, 𝝆 the reflectivity of the mirrors, 𝝉

transmittance value and K is the angle of incidence.

The following values are determined within the

software:

α Alpha=0,9

𝝉 Tau=0,9

𝝆 Rho=0,95

𝜸 Gamma=0,9

The incident angle has two components, one of

them is the longitudinal θ

L

and the other is the

transversal θ

T

, then (Ghodbane et al., 2019):

(9)

(10)

Additionally, the critical angle (θ

T

critic) can be

determined by means of the expression (Ghodbane

et al., 2019):

θ

=94,46 − 2,519∗

𝑊

𝐷

−55,71∗

𝑊

𝐷

−0,48∗𝜑

+1,77∗

𝜑

1000

+1,15∗

𝑊

𝐷

∗𝜑

(11)

And the slope of the mirror is determined through

equation 12:

𝜓=

𝜙−𝜃

2

(12)

Finally, the thermal efficiency of the system is

determined by applying the following equation [27]:

(13)

Where, η

termica

is the thermal efficiency of the

system, Q

u

the useful heat and Q

s

is the available solar

irradiation.

3 RESULTS

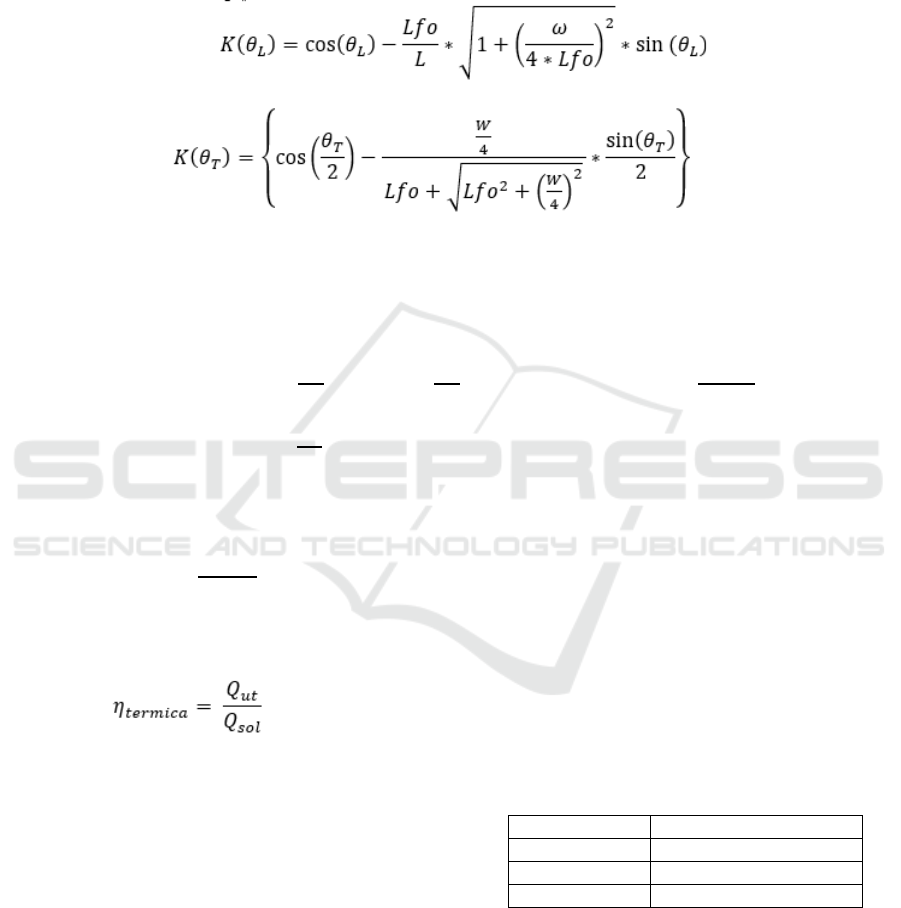

The simulation process developed in the ESS tool

allowed to evaluate the performance of the LFC

device. Table 3 presents the values estimated by the

data processing code and highlights:

The heat absorbed (q

l

) by the heat transfer fluid

at the focal point or solar concentration was

1396 W/m, highlighting that the temperature of

the wall of the material through which the fluid

circulates was included.

For its part, the heat density (Q

abs,flow

) through

the fluid was 1459 W and the critical theta

Angle (Θ

critic

), is presented by the system when

it is at an Angle of72.12°.

Table 3. Results q

l

, Q

abs,flow and

Θ

critic.

Variable Results EES

q

l

1396 [W/m]

Q

abs,flow

1459 [W]

Θ

critic

72,12 º

Additionally,

Table

4 presents the Results of the ESS for Φ

i,

Θ

T,

K

T,

Θ

L,

K

L,

K

a,

highlighting:

Theta

T

(Θ

T

) which is defined as the transverse

incident angle and K

T

which is the component

of the transverse direction of the total incident

angle K

a

, shows in the data of

ISAIC 2022 - International Symposium on Automation, Information and Computing

40

Table 4 a slight reduction in K

T

when Theta

T

takes values close to each other, but when

Theta

T

has values that stray too far or takes

higher values, K

T

is drastically reduced.

For the angle Theta

L

(Θ

L

) which is

defined as the longitudinal incident angle since

the projection of the incident angle in the plane

is along the length of the collector and K

L

is the

component of the longitudinal direction of the

total incident angle K

a

show in the data in Table

4 a slight reduction in K

L

with a linear trend.

Finally, the modifier of the incident angle Ka or

also known as (IAM) was determined, which is

used to consider the variation of the optical

efficiency for the different positions of the sun, it

is clear to remember that K

a

is made up of the

longitudinal and transversal components (K

L

y

K

T

) and that the optical efficiency equation is

determined based on it.

Table 4. Results Φ

i ,

Θ

T,

K

T,

Θ

L,

K

L,

K

a.

Item Φ

i

Θ

T

K

T

Θ

L

K

L

K

a

1 11,31 20 0,9129 5 0,9038 0,825

2 21,8 23 0,8973 10 0.8006 0,7184

3 30,96 25 0,8866 15 0,6914 0,613

4 38,66 40 0,798 20 0,5769 0,4604

5 45 60 0,6589 25 0,4581 0,3018

6 45 60 0,6589 25 0,4581 0,3018

7 38,66 40 0,798 20 0,5769 0,4604

8 30,96 25 0,8866 15 0,6914 0,613

9 21,8 23 0,8973 10 0.8006 0,7184

10 11,31 20 0,9129 5 0,9038 0,825

On the other hand, Table 5 presents the optical

efficiency values of the LFC system and highlights:

The representation of the optical efficiency of

the sample presented in Table 5, decreases

somewhat because the angles of Theta

T

(𝜃

)

were taken less than the value of ThetaCritic

(𝜃

) whose value corresponds to 72,12 º.

The incidence of the angle ThetaT on the

efficiency of the system is maximum as the

angle is close to the value of zero (0), however,

as ThetaT increases, the efficiency values will

decrease, therefore, there is a relationship

inversely proportional between angles and

optical efficiency

Table 5. Optical Performance of the simulated LFC system.

Theta

T

Angle

Optical Performance

20º 57,14%

23º 49,76%

25º 42,46%

40º 31,88%

60º 20,9%

60º 20,9%

40º 31,88%

25º 42,46%

23º 49,76%

20º 57,14%

Finally, the thermal efficiency of the system is

determined from the ratio of useful heat and the heat

of solar irradiation, the efficiency value presented by

the system was 19.32%.

4 CONCLUSIONS

The incidence of the Theta angle is clearly an

important factor to take into account when evaluating

optical performance, because its variation directly

affects other factors inherent to the system's

operation. For evaluation of the angle at 20 °, an

optical performance of 57.14% was obtained and for

the evaluation of the system with an angle of 60 °, an

optical performance of 20.9% was obtained,

evidencing the direct relationship between the

incidence of the angle and the optical performance of

the device.

On the other hand, the speed of the fluid directly

influences the overall performance of the device. The

current analysis was carried out with a fixed speed of

0.1 m / sec and the thermal efficiency value was

19.32%. The system was evaluated in parallel with a

speed of 0.025 m / sec and the performance of the

system was 45%, evidencing a direct relationship

between performance and flow, that is, the higher the

flow, the lower the performance and the lower the

flow, the higher the performance. The latter is due to

Performance Evaluation of a Linear Fresnel Concentrator Applying Numerical Simulation

41

the fact that the device is designed in a traditional way

to handle low flow rates from thermosyphons or small

pumping systems.

There is a difference of 12.13% between the

efficiency of the real system and the simulation

carried out. This is because the simulation method

applied to the present analysis could be considered

static, as it does not evaluate the system in real time

intervals, subjecting the code to solar radiation data

that vary with time. However, the development of this

type of evaluations allows generating estimates of the

behavior in an approximate way.

Finally, the thermodynamic libraries of the ESS

software differ a little compared to the

thermodynamic tables provided in the bibliography,

this may present small changes in calculations made

through tools that do not have thermodynamic

libraries and require declaring those values manually,

for the development of the simulations.

REFERENCES

Ajdad, H., Filali Baba, Y., Al Mers, A., Merroun, O.,

Bouatem, A., & Boutammachte, N. (2019). Particle

swarm optimization algorithm for optical-geometric

optimization of linear fresnel solar concentrators.

Renewable Energy, 130, 992-1001.

https://doi.org/10.1016/j.renene.2018.07.001

Bellos, E. (2019). Progress in the design and the

applications of linear Fresnel reflectors – A critical

review. Thermal Science and Engineering Progress,

10, 112-137. https://doi.org/10.1016/j.tsep.2019.01.014

Bellos, E., Tzivanidis, C., & Moghimi, M. A. (2019).

Reducing the optical end losses of a linear Fresnel

reflector using novel techniques. Solar Energy, 186,

247-256. https://doi.org/10.1016/j.solener.2019.05.020

de Sá, A. B., Pigozzo Filho, V. C., Tadrist, L., & Passos, J.

C. (2021). Experimental study of a linear Fresnel

concentrator: A new procedure for optical and heat

losses characterization. Energy, 232, 121019.

https://doi.org/10.1016/j.energy.2021.121019

Famiglietti, A., & Lecuona, A. (2021). Small-scale linear

Fresnel collector using air as heat transfer fluid:

Experimental characterization. Renewable Energy, 176,

459-474. https://doi.org/10.1016/j.renene.2021.05.048

Ghodbane, M., Boumeddane, B., Said, Z., & Bellos, E.

(2019). A numerical simulation of a linear Fresnel solar

reflector directed to produce steam for the power plant.

Journal of Cleaner Production, 231, 494-508.

https://doi.org/10.1016/j.jclepro.2019.05.201

López, J. C., Escobar, A., Cárdenas, D. A., & Restrepo, Á.

(2021). Parabolic trough or linear fresnel solar

collectors? An exergy comparison of a solar-assisted

sugarcane cogeneration power plant. Renewable

Energy, 165, 139-150.

https://doi.org/10.1016/j.renene.2020.10.138

Lovegrove, K., & Pye, J. (2021). Chapter 2—Fundamental

principles of concentrating solar power systems. En K.

Lovegrove & W. Stein (Eds.), Concentrating Solar

Power Technology (Second Edition) (pp. 19-71).

Woodhead Publishing. https://doi.org/10.1016/B978-0-

12-819970-1.00013-X

Lovegrove, K., & Stein, W. (2021). Chapter 1—

Introduction to concentrating solar power technology.

En K. Lovegrove & W. Stein (Eds.), Concentrating

Solar Power Technology (Second Edition) (pp. 3-17).

Woodhead Publishing. https://doi.org/10.1016/B978-0-

12-819970-1.00012-8

Mills, D. R. (2012). 6—Linear Fresnel reflector (LFR)

technology. En K. Lovegrove & W. Stein (Eds.),

Concentrating Solar Power Technology (pp. 153-196).

Woodhead Publishing.

https://doi.org/10.1533/9780857096173.2.153

Moghimi, M. A., Craig, K. J., & Meyer, J. P. (2017).

Simulation-based optimisation of a linear Fresnel

collector mirror field and receiver for optical, thermal

and economic performance. Solar Energy, 153, 655-

678. https://doi.org/10.1016/j.solener.2017.06.001

Moya, E. Z. (2021). Chapter 7—Parabolic-trough

concentrating solar power systems. En K. Lovegrove &

W. Stein (Eds.), Concentrating Solar Power

Technology (Second Edition) (pp. 219-266). Woodhead

Publishing. https://doi.org/10.1016/B978-0-12-

819970-1.00009-8

Pitz-Paal, R. (2014). Chapter 19—Solar Energy –

Concentrating Solar Power. En T. M. Letcher (Ed.),

Future Energy (Second Edition) (pp. 405-431).

Elsevier. https://doi.org/10.1016/B978-0-08-099424-

6.00019-3

Pitz-Paal, R. (2020). 19—Concentrating Solar Power. En T.

M. Letcher (Ed.), Future Energy (Third Edition) (pp.

413-430). Elsevier. https://doi.org/10.1016/B978-0-08-

102886-5.00019-0

Platzer, W. J., Mills, D., & Gardner, W. (2021). Chapter

6—Linear Fresnel Collector (LFC) solar thermal

technology. En K. Lovegrove & W. Stein (Eds.),

Concentrating Solar Power Technology (Second

Edition) (pp. 165-217). Woodhead Publishing.

https://doi.org/10.1016/B978-0-12-819970-1.00006-2

Ross, M. L. (2016). How the 1973 Oil Embargo Saved the

Planet. Foreign Affaris, 5.

Rungasamy, A. E., Craig, K. J., & Meyer, J. P. (2015). 3-D

CFD Modeling of a Slanted Receiver in a Compact

Linear Fresnel Plant with Etendue-Matched Mirror

Field. Energy Procedia, 69, 188-197.

https://doi.org/10.1016/j.egypro.2015.03.022

Rungasamy, A. E., Craig, K. J., & Meyer, J. P. (2021). A

review of linear Fresnel primary optical design

methodologies. Solar Energy, 224, 833-854.

https://doi.org/10.1016/j.solener.2021.06.021

Said, Z., Ghodbane, M., Hachicha, A. A., & Boumeddane,

B. (2019). Optical performance assessment of a small

experimental prototype of linear Fresnel reflector. Case

Studies in Thermal Engineering, 16, 100541.

https://doi.org/10.1016/j.csite.2019.100541

ISAIC 2022 - International Symposium on Automation, Information and Computing

42

Santos, A. V., Canavarro, D., Horta, P., & Collares-Pereira,

M. (2021). An analytical method for the optical analysis

of Linear Fresnel Reflectors with a flat receiver. Solar

Energy, 227, 203-216.

https://doi.org/10.1016/j.solener.2021.08.085

Santos, J. J. C. S., Palacio, J. C. E., Reyes, A. M. M.,

Carvalho, M., Freire, A. J. R., & Barone, M. A. (2018).

Chapter 12—Concentrating Solar Power. En I.

Yahyaoui (Ed.), Advances in Renewable Energies and

Power Technologies (pp. 373-402). Elsevier.

https://doi.org/10.1016/B978-0-12-812959-3.00012-5

Schiel, W., & Keck, T. (2021). Chapter 9—Parabolic dish

concentrating solar power systems. En K. Lovegrove &

W. Stein (Eds.), Concentrating Solar Power

Technology (Second Edition) (pp. 311-355). Woodhead

Publishing. https://doi.org/10.1016/B978-0-12-

819970-1.00007-4

Schlecht, M., & Meyer, R. (2021). Chapter 4—Site

selection and feasibility analysis for concentrating solar

power systems. En K. Lovegrove & W. Stein (Eds.),

Concentrating Solar Power Technology (Second

Edition) (pp. 99-125). Woodhead Publishing.

https://doi.org/10.1016/B978-0-12-819970-1.00015-3

Souza, L. F. L. de, Fraidenraich, N., Tiba, C., & Gordon, J.

M. (2021). Linear aplanatic Fresnel reflector for

practical high-performance solar concentration. Solar

Energy, 222, 259-268.

https://doi.org/10.1016/j.solener.2021.05.002

Tarazona-Romero, B. E., Campos-Celador, A., Muñoz-

Maldonado, Y. A., Ascanio-Villabona, J. G., Duran-

Sarmiento, M. A., & Rincón-Quintero, A. D. (2021).

Development of a Fresnel Artisanal System for the

Production of Hot Water or Steam. En M. Botto Tobar,

H. Cruz, & A. Díaz Cadena (Eds.), Recent Advances in

Electrical Engineering, Electronics and Energy (pp.

196-209). Springer International Publishing.

https://doi.org/10.1007/978-3-030-72212-8_15

Tarazona-Romero, B. E., Campos-Celador, Á., Muñoz-

Maldonado, Y. A., Sandoval-Rodríguez, C. L., &

Ascanio-Villabona, J. G. (2020). Prototype of lineal

solar collector Fresnel: Artesanal system for the

production of hot water and/or water vapor. Visión

Electrónica, 14(1), Art. 1.

https://doi.org/10.14483/22484728.16013

Vant-Hull, L. L. (2021). Chapter 8—Central tower

concentrating solar power systems. En K. Lovegrove &

W. Stein (Eds.), Concentrating Solar Power

Technology (Second Edition) (pp. 267-310). Woodhead

Publishing. https://doi.org/10.1016/B978-0-12-

819970-1.00019-0

Performance Evaluation of a Linear Fresnel Concentrator Applying Numerical Simulation

43