Analysis of the Effect of AISI 1005 Grain Structure and Cutting

Angle on Springback Using the V-Bending Method

Heri Setiawan, Rani Nopriyanti and Selvi Novita S.

Politeknik Manufaktur Bandung, Jl. Kanayakan No.21, Dago, Kota Bandung, Jawa Barat, Indonesia

Keywords: Springback, V-Bending, Direction Bending.

Abstract: Many considerations exist in a process of bending, plate material (product) will change the angle and radius

bend dimension called springback. As a result, the process of forming the product experiences a

mismatch/change in terms of dimensions. The direction of cutting the rolling plate for the product is often

ignored by the operator in the manufacturing process. However, the use of grain structure parameters in the

direction of cutting the rolling plate may have an effect to minimize the amount of springback. Springback

itself occurs in almost all forming processes (bending, forming, deep drawing, etc.) on sheet metal. The

analysis was carried out by v -bending using the test using a test specimen that has dimensions of 1.87 × 35

× 150, bending angle of 90°, bending radius of R8.465 mm, and clearance between punch bending and die

bending is equal to the plate thickness (1.87 mm), and with plate material AISI 1005, and tested with variable

cutting angles from the direction of rolling the plates using the machine press AIDA direct servo formers

DSF-C1-A series. The results of the analysis state that the amount of springback due to the variable cutting

angle from the rolling direction of the plate affects the amount of springback. The amount of springback from

the direction parallel to the rolling angle of the plate gets a positive value of 1.148°, then the perpendicular

angle with a value of negative 1.431°, and the springback largest is 45° from rolling with a value of negative

1.716°.

1 INTRODUCTION

In the manufacturing industry, technology is growing

rapidly. One of them is the development in the field

of sheet metal. The manufacture of sheet metal

products has now penetrated almost all fields, and the

results of the output are very varied, ranging from

simple shapes to complex shapes, from low accuracy

to high accuracy. The achievement of the product in

any way is the main goal of manufacturers in

producing their products. To maintain product

achievement in terms of form, the technology press is

a tool used by manufacturers to produce their

products. A press tool is a tool for shaping, cutting, or

both by applying an emphasis to the material in the

form of tool shapes sheet metal, the press can produce

objects from simple shapes to complex.

Many considerations exist in plate manufacture or

formation, one of which is the parameter of the plate

rolling grain structure. The direction of cutting the

rolling plate for the product is often ignored by the

operator in the manufacturing process. However, the

use of grain structure parameters in the direction of

cutting the rolling plate may have an effect to

minimize the amount of springback. Springback is a

reverse force caused by the effect of the elasticity of

the plate material undergoing the forming

process. Springback itself occurs in almost all

forming processes (bending, forming, deep drawing,

etc.) on sheet metal.

Figure 1: Springback.

Therefore, knowledge about springback and

analysis of springback is needed to determine the

behavior of springback. One of the methods used to

analyze the springback is by testing the bending by

paying attention to the grain structure variable

towards the cutting direction of the plate rolling. The

results of this trial will produce varied data so that it

Setiawan, H., Nopriyanti, R. and S., S.

Analysis of the Effect of AISI 1005 Grain Structure and Cutting Angle on Springback Using the V-Bending Method.

DOI: 10.5220/0011821600003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 567-572

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

567

can find out the amount of deviation that occurs by

springback with predetermined variables and is used

as a reference or reference for grain structure settings

and the direction of cutting the rolling plate in plate

formation.

2 METHODOLOGY

2.1 Bending Material Specifications

The material that is used for this v-test bending is

AISI 1005, with plate dimensions 150 × 35 × 1.87

(mm). The specimen is bent at 90° with an inner

radius of R8.465 and an outer radius of R10.32 and

the rolling direction is transverse, perpendicular and

45° with the direction of rolling as in Figure 2 and

Figure 3, and its mechanical properties are known as

follows.

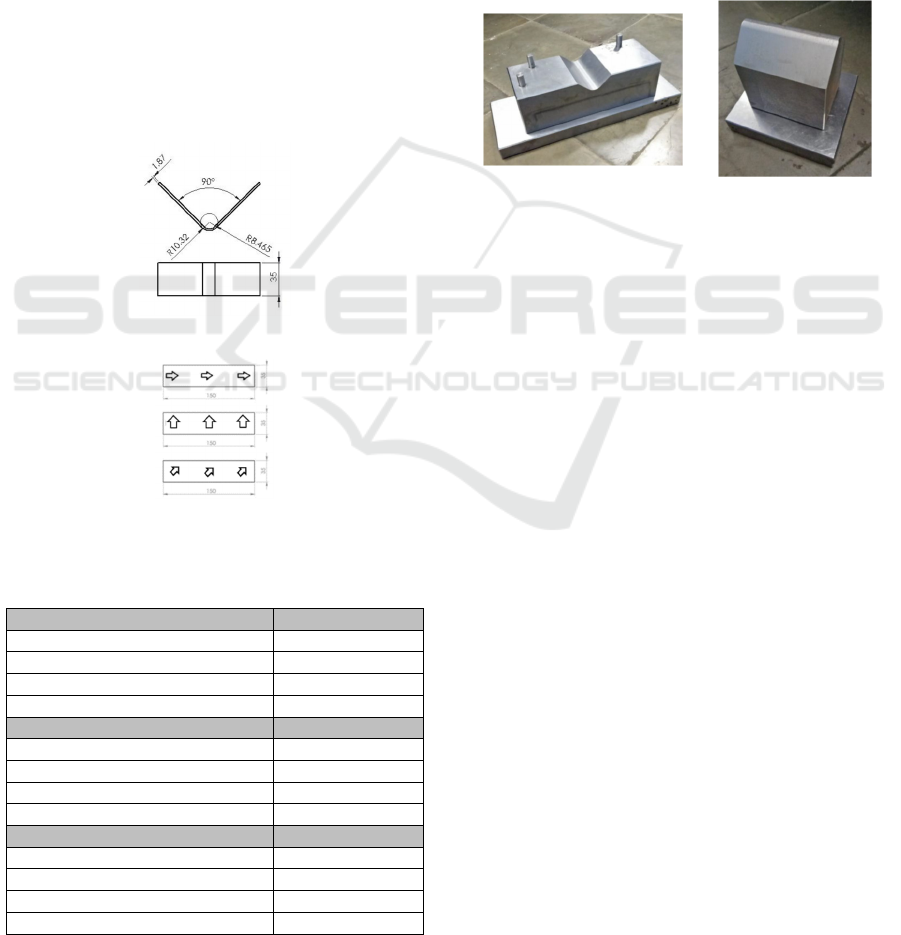

Figure 2: Specimen specifications.

Figure 3: Direction of cutting the rolling plate of the

bending specimen.

Table 1: Data plate material with the direction of rolling.

Parameters Measurement Avera

g

e Avera

g

e

0.2% Y.S. [N/mm

2

] 221.967

Yield Stren

g

th

(γ)

[N/mm

2

] 223.697

Tensile Strength (σ) [N/mm

2

] 299.347

Elongation (ε) [%] 52.97

Parameters Measurement Average

0.2% Y.S. [N/mm

2

] 268.413

Yield Stren

g

th

(γ)

[N/mm

2

] 270.35

Tensile Stren

g

th

(

σ

)

[N/mm

2

] 324.11

Elongation (ε) [%] 51.593

Parameters Measurement Average

0.2% Y.S. [N/mm

2

] 253.543

Yield Stren

g

th

(γ)

[N/mm

2

] 259.226

Tensile Stren

g

th

(

σ

)

[N/mm

2

] 317.306

Elongation (ε) [%] 56.453

2.2 Making Tools

Tools made are vbending tools consisting of the 4

main components, namely, upper late with DIN

1.0037 material, punch bending with DIN 1.2510

material, die bending with DIN 1.2510 material, and

DIN 1.0037 bottom plate. Tools that made were

divided into 2 main parts, namely the bottom of the

tools and the top of the tools. The lower part of the

tools consists of the base plate, die bending an, and d

pin locator and the upper part consists of the upper

plate and the bending punch. The tools were made as

follows:

Figure 4: (a) The bottom of the tools, (b) The top of the

tools.

2.3 Testing and Measurement

Testing was carried out on the machine AIDA press

direct servo formers DSF-C1-A series Manufacturing

Engineering Laboratory Manufacturing Bandung.

This machine press uses a servo motor main drive so

that it allows for large presses and stable pressing

speeds

In the testing process, the engine speed used was

56 strokes/minute, and the holding time was 0

seconds. Furthermore, the angle formed in the

specimen is measured using a CMM (Coordinate

Measuring Machine) machine in the measurement

laboratory, in Manufacture Engineering Department.

3 CALCULATION AND

ANALYSIS

3.1 Prediction of Springback with

Formulas

The first step is using the formula of springback to

calculate the modulus of elasticity of the specimens

bending, for the calculation of elongation is used the

comparison formula between elongation peak before

breaking plates and elongation after plate breaks. The

calculations are as follows.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

568

• Parallel

𝜀=

=

.%

.%

=1.33% (1)

• Perpendicular

𝜀=

=

.%

.%

=1.37% (2)

• 45°

𝜀=

=

.%

%

=1.38% (3)

So that the modulus of elasticity obtained is as

follows.

• Parallel

𝐸=

=

.

.%

=16689.25 𝑁/𝑚𝑚

2

(4)

• Perpendicular

𝐸=

=

.

.%

=19592.19 𝑁/𝑚𝑚

2

(5)

• 45°

𝐸=

=

.

.%

=18372.68 𝑁/𝑚𝑚

2

(6)

Next is calculating elastic modulus by entered the

formula springback to predict the final radius. Here

is the calculation of the springback final radius:

• Parallel

=4(

.

.

)

−3(

.

.

)+1 (7)

.

= 4(

.×.

.×.

)

−3(

.×.

.×.

) +1

.

=0.819

𝑅𝑓=10.317

• Perpendicular

=4(

.

.

)

−3(

.

.

)+1 (8)

.

=4(

.×.

. ×.

)

−3(

.×.

. ×.

) +1

.

=0.813

𝑅𝑓=10.412

• 45°

=4(

.

.

)

−3(

.

.

)+1 (9)

.

=4(

.×.

.×.

)

−3(

.×.

.×.

) +1

.

=0.809

𝑅𝑓=10.458

The next step is to calculate the amount of

springback using the formula for the k factor equation

of springback. Where it is known that the initial bend

angle (α

i

) is 180° minus the bending angle (89.98°) so

that the initial bend angle (αi) is 90.02° or 1,571

radians, so the calculation is as follows.

• Parallel

𝐾𝑠=

=

(10)

𝛼𝑓=1.571 𝑥

(

×.

.

)

(

×.

.

)

𝛼𝑓=1.312≈75.172°

• Perpendicular

𝐾𝑠=

=

(11)

𝛼𝑓=1.571 𝑥

(

×.

.

)

(

×.

.

)

𝛼𝑓=1.301≈74.542°

• 45°

𝐾𝑠=

=

(12)

𝛼𝑓=1.571 𝑥

(

×.

.

)

(

×.

.

)

𝛼𝑓=1.296≈74.255°

So that the magnitude of the prediction springback is

the difference between α

i

and α

f

.

• 𝑆𝑝𝑟𝑖𝑛𝑔𝑏𝑎𝑐𝑘 Parallel = 𝛼𝑖–𝛼𝑓=90.02°− 75.172° =

14.848°

• Perpendicular=𝛼𝑖−𝛼𝑓=90.02°−74.542°= 15.478°

• 𝑆𝑝𝑟𝑖𝑛𝑔𝑏𝑎𝑐𝑘 45° = 𝛼𝑖−𝛼𝑓 = 90.02° − 74.255°

=15.765°

The initial and final radius and the magnitudes of

the bend angle known as initial(α

i

) and bend angle

final (α

f

) can be used to calculate the k size of the

springback factor. The following is the calculation of

the k factor of springback.

• Parallel

𝐾𝑠=

=

(13)

𝐾𝑠=

=

.

.

=0.835

• Perpendicular

𝐾𝑠=

=

(14)

𝐾𝑠=

=

.

.

=0.828

• 45°

𝐾𝑠=

=

(15)

𝐾𝑠=

=

.

.

=0.825

Analysis of the Effect of AISI 1005 Grain Structure and Cutting Angle on Springback Using the V-Bending Method

569

3.2 Prediction of Springback with

Tables

Figure 5 and table 2 below is a table to predict the

amount of springback with the influence of plate

material, radius punch and thickness of the plate.

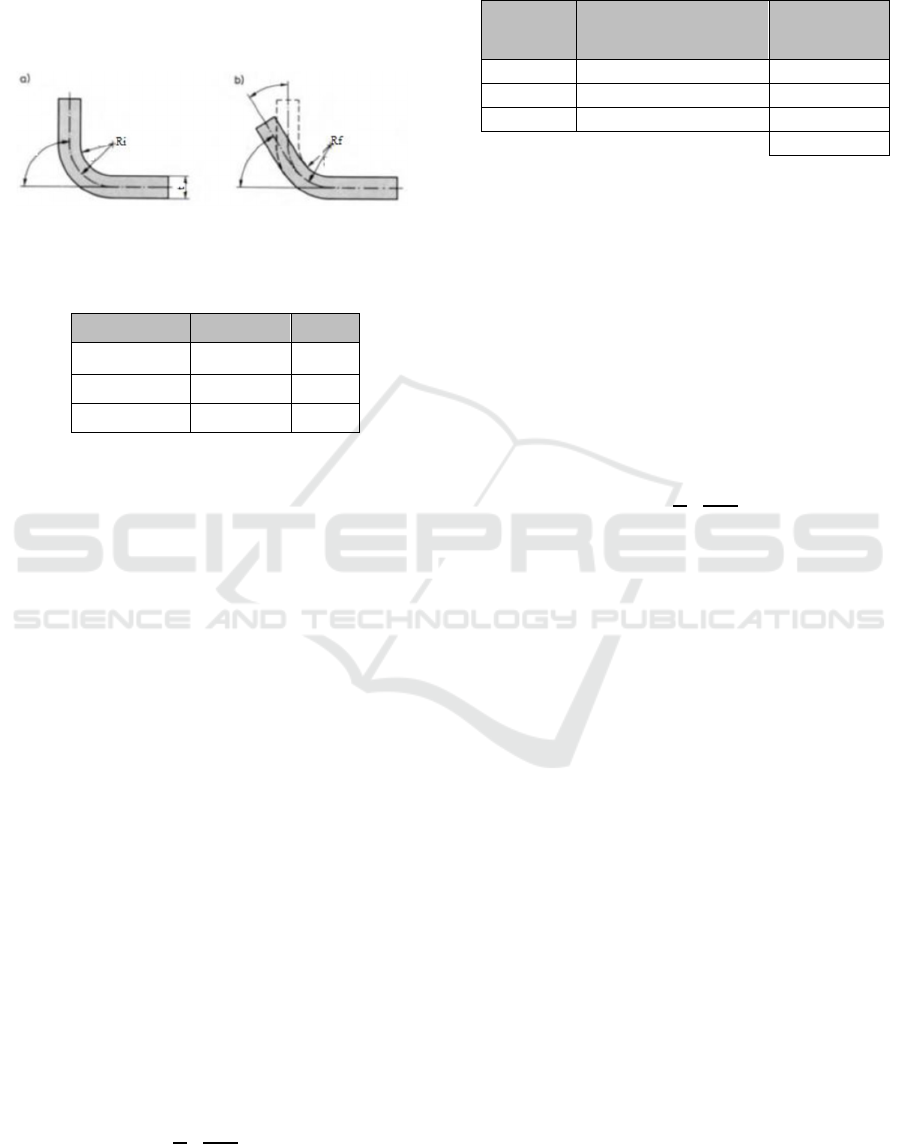

Figure 5: Springback on bending (a) Before springback, (b)

After Springback.

Table 2: Table Springback (β).

t(mm) Ri(mm) β (°)

0.5 s.d. 0.7 1t s.d. 5t 5

0.8 s.d. 1.9 1t s.d. 5t 3

2 s.d. 4 1t s.d. 5t 1

So, to predict the amount of springback with this

analysis design, we can refer to the previous table 2.

Here is a prediction using table springback. It is

known:

AISI 1005 material parallel = 299,347 N / mm

2

(σ)

Perpendicular AISI 1005 material = 324.11 N / mm

2

(σ)

AISI 1005 material 45 ° = 317,306 N / mm

2

(σ)

Material thickness (t) = 1.87 mm.

Bending radius (radius punch) = R8.465 mm.

So that:

• Predict the size using the table, springback which

is 3°. Furthermore, to determine the magnitude of

the influence of the prediction springback using

table springback this, the next step is to calculate

the k factor of springback. The following is a

calculation of the k factor for springback using the

table springback.

𝑆𝑝𝑟𝑖𝑛𝑔𝑏𝑎𝑐𝑘=3°≈ 0.052 𝑟𝑎𝑑𝑖𝑎𝑛 (16)

• So that the magnitude of the bend angle final (αf)

is the difference between the bendsangel initial

(αi) and magnitude springback, with magnitude αi

= 90.02 ° or 1,571 radians. Here is a calculation to

find the size of αf and k factor springback.

𝑠𝑝𝑟𝑖𝑛𝑔𝑏𝑎𝑐𝑘= 𝛼𝑖−𝛼𝑓 (17)

𝛼𝑓=𝛼𝑖−𝑠𝑝𝑟𝑖𝑛𝑔𝑏𝑎𝑐𝑘=1.571−0.052=1.519 𝑟𝑎𝑑𝑖𝑎𝑛

𝐾𝑠=

=

.

.

=0.967

3.3 Analysis of Measurement Results

Table 3: The results of measurements.

No Cutting direction Average

1 Parallel 1.148

2 Perpendicula

r

-1.431

3 45° -1.716

-0.666

Next, the calculation of the k factor of springback

from the total average springback using v-bending

with the bend angle initial(αi) = 90.02 ° or 1,571

radians. Here is the calculation of the k factor for

springback.

𝑇𝑜𝑡𝑎𝑙 average 𝑠𝑝𝑟𝑖𝑛𝑔𝑏𝑎𝑐𝑘 = -0.666°

≈ -0.0116 𝑟𝑎𝑑

𝑠𝑝𝑟𝑖𝑛𝑔𝑏𝑎𝑐𝑘 = 𝛼

𝑖

−𝛼

𝑓

(18)

𝛼

𝑓

= 𝛼𝑖−𝑠𝑝𝑟𝑖𝑛𝑔𝑏𝑎𝑐𝑘 = 1.571−(-0.0116)

= 1.583 𝑟𝑎𝑑𝑖𝑎𝑛

𝐾𝑠=

=

.

.

=1.007

So that the results of the trials carried out are

different from the results using the formula

springback and the table springback as shown in table

4.1 above and can also be seen in the k factor of

springback. So that the magnitude of the value of

springback with the difference in the cutting angle of

the plate is quite influencing on the amount

of springback,

3.4 Calculation of Metal

Microstructure

After obtaining AISI 1005 metallographic data, then

quantitative metallographic analysis was carried out

to determine the average grain size of the 500x

magnification microstructure using the Planimetry

(Jeffries) method according to the ASTM E112

standard. As for below, the results of the calculation

of the grain size using the Planimetry method

(Jeffries).

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

570

Table 4: Microstructure before the test bending and after the

test bending.

Before the

tes

t

Visual

After the

tes

t

Visual

Parallel

Parallel

Perpendicul

ar

Perpendicul

ar

45

0

45

0

Table 5: The results of the calculation of the grain size

before the test grain bending and after the test bending.

Before

the tes

t

Visual

After

the tes

t

Visual

Parallel

Parallel

Perpendi

cular

Perpend

icular

45

0

45

0

Information:

= Whole grain

= Clipped grain

(EXAMPLE)

Before bending the

parallel cutting It is known: Whole(n

1

) = 36

clipped grains (n

2

) = 24

Magnification (M) = 500x

Asked: ……… d?

f =

=

= 50

𝑁

𝑓 𝑛

𝑛

2

50 36

24

2

= 50 (48) = 2400/mm

2

G = [3,322 log N

A

] – 2,95

= [3,322 log 2400] – 2,95

= 11,23 – 2,95 = 8,28

Then from this G value is compared with the existing

standard in ASTM 112-12 for know the average grain

diameter size.

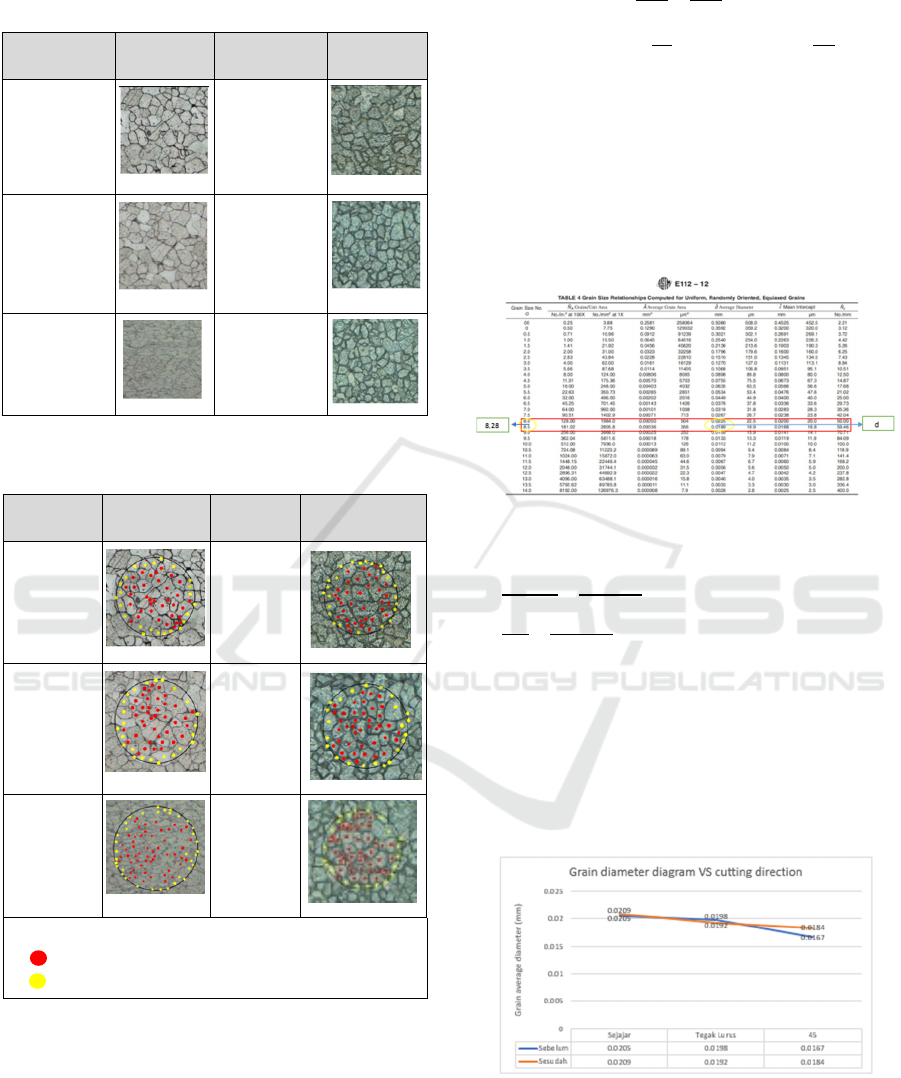

Figure 6: Grain Size Relationship Computed for Uniform,

Randomly Oriented, Equalaxed Grains in ASTM 112-12.

,,

,,

=

,

,

,

,

=

,

,

0,28d - 0.005292 = 0.00495 – 0,22d

0,5d = 0.010242

d = 0,0205 mm

From the ASTM E112-12 table for the value of G =

8.28, the average grain diameter is obtained of 0.0205

mm.

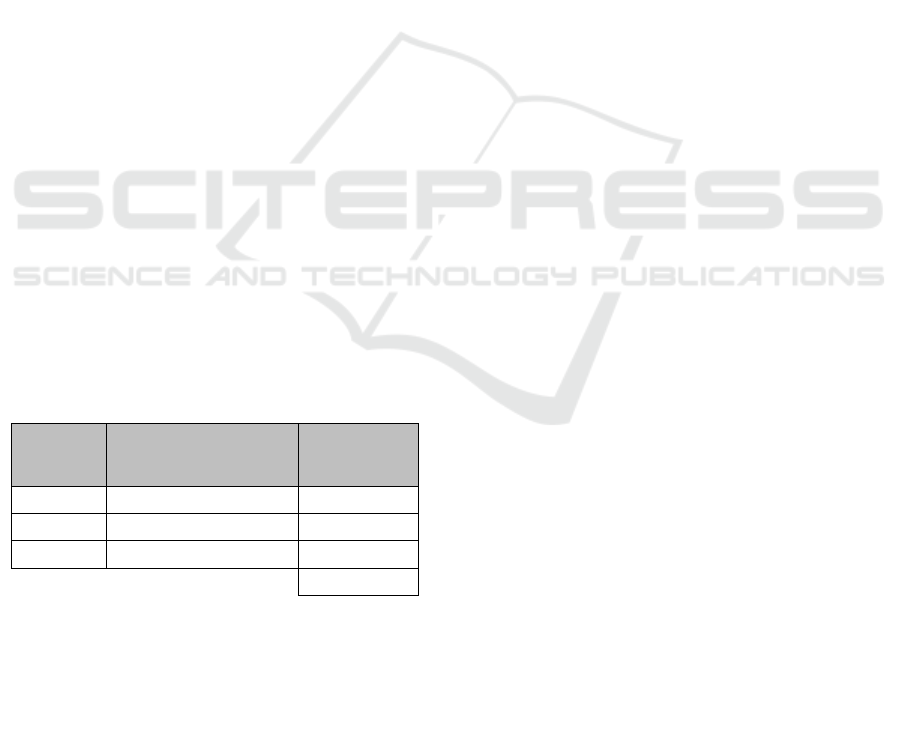

Figure 7: The effect of cutting direction on grain diameter.

From the results of the diagram above shows that

different cutting directions greatly affect the grain

size. In the AISI 1005 specimen before bending, it

shows that the grain with the largest diameter is

Analysis of the Effect of AISI 1005 Grain Structure and Cutting Angle on Springback Using the V-Bending Method

571

indicated by the grain with a parallel cutting direction

of 0.0205 mm, and the smallest grain is 0.0167 mm

with 45° cutting. Then the AISI 1005 specimen after

bending shows that the grain with the largest diameter

is shown by the grain with a parallel cutting direction

of 0.0209 mm, and the smallest grain is 0.0184 mm

with 45° cutting.

The effect of bending also affects grain size and

grain roughness. When the specimen is bent it will

make the average grain size larger. It can be seen that

in the parallel cutting direction, the grain size before

bending was 0.0205 mm, while the size after bending

was 0.0209 mm, there was an increase even though

the deviation was very slight by 4 x 10

-4

mm. At the

direction of cutting 45° is also the same, before

dibending grain size of 0.0167 mm while the size

after dibending of 0.0184 mm, an increase although

the deviation is very small at 17 x 10

-4

mm. However,

in the perpendicular cutting direction, there was an

increase in the average grain size, before bending by

0.0198 mm, while the size after bending was 0.0192

mm, there was a reduction even though the deviation

was very little by 6 x10

-4

mm.

4 CONCLUSIONS

Based on the results of the analysis in the previous

chapter, there are several conclusions including:

1. The cutting angle that produces springback with the

smallest deviation is parallel to the plate rolling angle

with a positive value of 1.148°, then the perpendicular

angle with a negative value of 1.431° and the largest

is 45° rolling with a negative value of 1.716°.

Table 6: Comparison of springback result.

No Cutting direction Average

1 Parallel 1.148

2 Perpendicular -1.431

3 45° -1.716

-0.666

So that the bending process is better to use a plate

with an angle in the direction of rolling between the

three angles that are used as a reference for the study.

2. The microstructure result is in Table 4.4 shows that

after doing bending all results in all directions cutting

have relatively the same grain shape, the direction of

cutting 45° deformed original grains become

relatively flat irregularly rounded. In the results

before bending, the grain boundaries are still tight, the

items between the items are still not stretched.

However, after bending, the grain experiences a

strain. The grain surface also undergoes roughening.

3. The grain with the largest grain diameter is

indicated by the grain with a parallel cutting direction

of 0.0205 mm, and the smallest grain is 0.0167 mm

with 45° cut. Then the AISI 1005 specimen after

bending shows that the grain with the largest grain

size is shown by the grain with a parallel cutting

direction of 0.0209 mm, and the smallest grain is

0.0184 mm with 45°cutting.

REFERENCES

Luchsinger, H.R. (1984). Tool design 2. Bandung:

Politeknik Mekanik Swiss-ITB.

Tschaetsch, H. Metal forming practise. Dresden: View

Verlag.

Suchy, I. (2006). Handbook of die design. New york: Mc

Graw-Hill Hand Books.

Budiarto. (2012). Sheet metal forming 2. Bandung:

Politeknik Manufaktur Bandung.

Kalpakjian, S. dan Schmid, S.R. (2008). Manufacturing

processes for engineering and technology. Jurong:

Pearson Education South Asia Pte Ltd.

Choudhury, LA. dan Ghomi, V. (2013). Springback

reduction of aluminium sheet in v-bending dies.

(jurnal). Kuala lumpur: SAGE.

Suprianto, J. (2000). Statistik-teori dan aplikasi. Jakarta:

Erlangga.

Kutner Nachtsheim, Neter, Li. (2004). Applied linier

statistical models. New york: Mc Graw Hill Book

Company.

Dieter, G.E. (1987). Mechanical Metallurgy. New York :

Mc Graw Hill Book Company.

Ostegaard, D.E. (1963). Basic die making.USA: McGraw-

Hill Book Company.

Rahmani, B. Alinejad, G. dkk. (2009). An investigation on

springback/negative springback phenomena using

finite element method and experimental approach.

(jurnal). Mazandaran: SAGE.

Vander Voort G.F, (1984). Metallography Principle and

Practice, McGrawHill. P.215,632.

Dieter, G. E.,& Bacon, D. (1988), Mechanical Metallurgy

SI Metric Edition. Journal of the Franklin Institue, 189.

Rodriguez, J. L., Perez-Benitez, J. A., Capo-Sanchez, J.,

Padovese, L. R., & Betancourt-Riera, R. (2008).

Dependence of Barkhausen jump shape on

microstructure in carbon steel. Revista mexicana de

física, 54, 127-129.

STANDARD, A. S. T. M., et al. Standard test methods for

determining average grain size. ASTM International,

West Chonshohocke, PA, 2013.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

572