The Effect of Adding Shrimp Shell Catalyst on the Quality of

Biodiesel from Used Cooking Oil

Ayu Nindyapuspa, Vivin Setiani and Elsa Rafelia

Hartanti

Department of Waste Treatment Engineering, Politeknik Perkapalan Negeri Surabaya,

Jalan Teknik Kimia Kampus ITS Sukolilo, Surabaya, Indonesia

Keywords: Biodiesel, CaO Catalyst, Microwave, Shrimp Shell Waste Cooking Oil.

Abstract: Shrimp shell contains 40-50% calcium carbonate so that it can be used as a CaO catalyst in the manufacture

of biodiesel using waste cooking oil. High levels of free fatty acid in waste cooking oil can be reduced by

the esterification process using an acid catalyst. Biodiesel is produced by transesterification process using a

heterogeneous catalyst of calcium oxide (CaO) from shrimp shells calcined at 1000°C for 3 hours. The

esterification and transesterification processes are carried out using microwaves. The transesterification

process was carried out with a variable weight percent catalyst (0%, 1%, 3%) and microwave power (150 W,

300 W). The characteristics of the biodiesel produced indicate that the parameters of density, flash point,

and sentane number have met the standard, while the parameters of viscosity and water content have not

met the standard. The yield of biodiesel produced increased along with the increase in the percentage of

CaO catalyst concentration of shrimp shell waste and the microwave power used.

1 INTRODUCTION

Vaname shrimp is the product of pond cultivation in

Indonesia. Based on the Central Statistics Agency in

2019, Java Island produced 144,873 tons of vaname

shrimp. The large production of vaname shrimp has

resulted in the generation of shrimp shell waste.

Shrimp shell contains 45%-50% calcium carbonate,

25%-40% protein, and 15%-20% chitin (Sari et al,

2011). The content of the shrimp shells can be used

as a CaO catalyst in the manufacture of biodiesel.

One of the main ingredients for making biodiesel is

used cooking oil.

Used cooking oil is a waste that is often found in

households because of the large use of cooking oil.

The used cooking oil produced can cause problems

to the environment, especially pollution of water

bodies (Glisic and Orlović, 2014). Used cooking oil

contains fatty acids. Fatty acids are reacted with

alcohol to produce esters which are the main

compounds for making biodiesel (Darmawan and

Susila, 2013). Therefore, this study was conducted

to analyze the quality of biodiesel from used

cooking oil using shrimp shell CaO catalyst.

2 METHODS

In this research there were several variables written

in Table 1.

Table 1.

CaO Catalyst

Of Shrimp

shells (%)

Microwave Power

in the

Transesterification

Process (Watts)

150 300

1P1 P2

2P3 P4

3P5 P6

2.1 Production of Leather CaO

Catalyst

Shrimp shells were cleaned using clean water and

heated at 120°C for 1 hour then placed in a

desiccator for 10 minutes (Yasar, 2019). Shrimp

shells were mashed and sieved through a 100 mesh

sieve (Petrus et al., 2015). Shrimp shell powder was

calcined at 1000°C for 3 hours (Khodijah, 2017).

Shrimp shell powder was tested by XRF to

determine the CaO content.

532

Nindyapuspa, A., Setiani, V. and Har tanti, E.

The Effect of Adding Shrimp Shell Catalyst on the Quality of Biodiesel from Used Cooking Oil.

DOI: 10.5220/0011818600003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 532-536

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2.2 Sample Preparation Process

Waste cooking oil was filtered with filter paper to

remove impurities. Then the sample was heated to

remove the water content at a temperature of 105°C

for 1 hour (Sartika et al., 2015).

2.3 Esterification Process

Waste cooking oil was mixed with methanol (mole

oil-methanol ratio 1:5) and 0.5% (w/w) H

2

SO

4

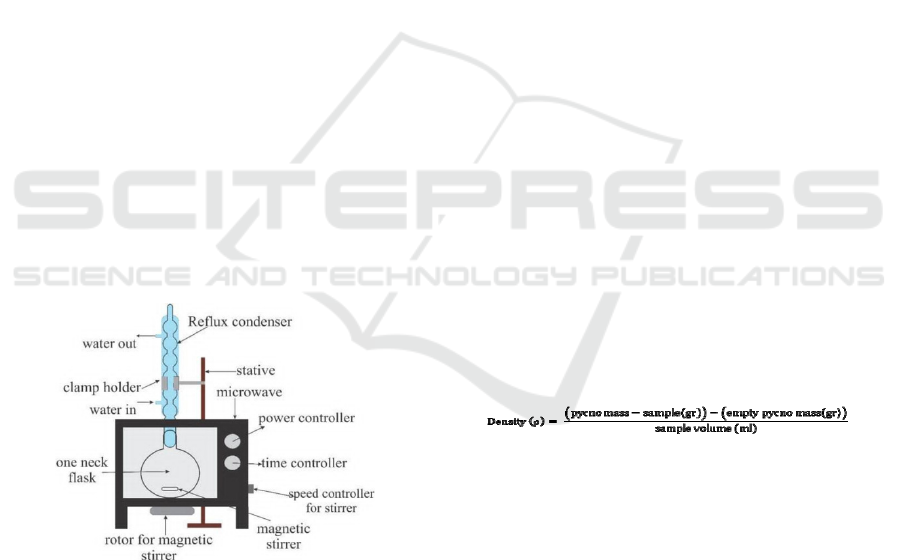

catalyst (Murni et al., 2016) then irradiated by

microwave (Figure 1.) in a microwave for 20

minutes with a power of 450 W and stirred with a

magnetic stirrer. (Ansori and Wibowo, 2018).

Furthermore, the esterification results are left in a

separatory funnel which aims to separate the

methanol, oil, and H2SO4 in the top layer and the

bottom layer was a mixture of oil and methyl ester

(crude biodiesel). Then the crude biodiesel was

washed with warm distilled water (60°C) with a

ratio of product weight and distilled water used 1:1

(Pahlevi et al., 2015) and the top layer in the form of

crude biodiesel was separated from the bottom layer

in the form of washing water containing catalyst and

residues. residual methanol using a separating

funnel. (Pahlevi et al., 2015). Furthermore, the

sample was heated in an oven (110°C) to reduce the

water content in crude biodiesel (Suryanto et al.,

2018). Finally, the samples were measured for

density and % FFA.

Figure 1: Microwave for Esterification.

2.4 Transesterification Process

Crude biodiesel was mixed with a mixture of shrimp

shell CaO catalyst according to the specified

variable with methanol with an oil ratio of 1:9 into a

one neck flask (Ansori and Wibowo, 2018). Then,

the sample was irradiated by microwaves using a

microwave with microwave power according to the

specified variable while stirring with a magnetic

stirrer for 10 minutes. After that, the sample was put

into a separatory funnel and allowed to stand at

room temperature to form two layers (biodiesel and

glycerol) (Sartika et al., 2015). Crude biodiesel was

washed with warm water (60°C) with a ratio of

product weight and distilled water used 1:1 (Pahlevi

et al., 2015) and separation of two layers (crude

biodiesel and biodiesel (FAME) (Pahlevi et al.,

2015). The sample was heated in an oven (110°C) to

reduce the water content in crude biodiesel

(Suryanto et al., 2018) and lastly, the calculation of

biodiesel yield on all variables of this study.

2.5 Analysis of Biodiesel

Characteristics and CaO Catalysts

The characteristics of biodiesel tested in this study

were samples that had the highest yield (3% catalyst

at 300 Watt microwave power). The characteristics

of biodiesel consist of density, viscosity, Free Fatty

Acid (FFA), biodiesel yield, water content, Flash

point, sentane number, X-Ray Fluorence (XRF) and

Gas Chromatography Mass Spectroscopy (GC-MS).

Density testing in this study used a pycnometer.

According to Dewi (2015) and Cahyati and

Pujaningtyas (2017), the working principle of this

test was that a clean and dry pycnometer was

weighed to determine the mass of an empty

pycnometer. First, Crude biodiesel to be tested was

heated at a temperature of 40°C and then put into the

pycnometer until it was full. Close the pycnometer

and make sure there are no bubbles. The sample was

cleaned and the pycnometer containing the sample is

weighed. Then, record the mass of the pycnometer

and the sample.

(1)

Viscosity testing in this study using the Ostwald

viscometer. According to Sinta et al. (2016), the

working principle of this test was the Ostwald

viscometer in a container filled with water at a

temperature of 40°C (artificial water bath) in a

vertical position. A certain amount of sample was

pipetted into reservoir A. The liquid was brought to

reservoir B and its surface crosses the line m, so

reservoir A was still half filled. The viscometer and

its contents were left in a container of water for 10

minutes to reach the desired temperature. Liquid B

was sucked or blown to slightly above the m line.

The liquid was allowed to flow freely. Record the

time it takes for the liquid to flow from M to N, this

step was repeated several times.

The Effect of Adding Shrimp Shell Catalyst on the Quality of Biodiesel from Used Cooking Oil

533

Kinematic viscosit

y

(

μ

k) = C×

t

(2)

Where:

C= Ostwald viscosity constant (0.4994 cSt/second)

t = time required for sample from point A to point B

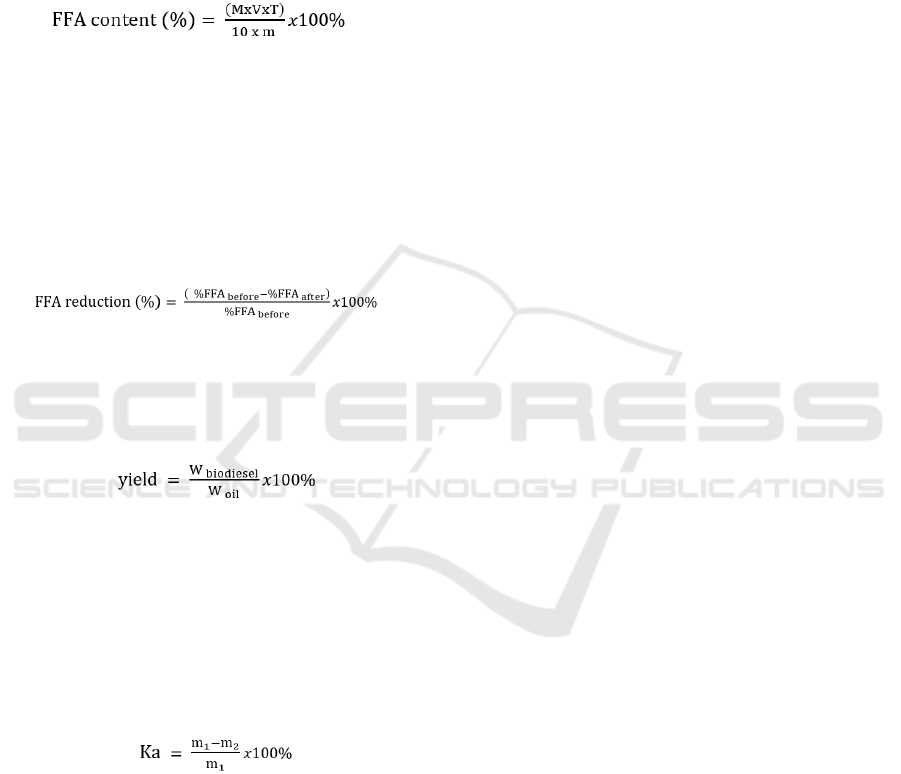

FFA testing was carried out on waste cooking oil

before and after the esterification process.

Determination of FFA levels refers to SNI 01-3555-

1998 concerning Oil and Fat Test Methods.

(3)

Where:

M = molecular weight of fatty acids (grams)

V = volume of NaOH required for titration (ml)

T = normality of NaOH m = weight of sample

(grams)

The calculation of the conversion of reducing

FFA levels in waste cooking oil was carried out to

determine the decrease in FFA levels using the

esterification process.

(4)

1. Biodiesel yield was the percentage of

conversion of oil into biodiesel (Efendi et al., 2018).

The amount of yield produced according to Zuhra et

al. (2015) can be calculated using the following

formula:

(5)

Where:

W

𝑏𝑖𝑜𝑑𝑖𝑒𝑠𝑒𝑙

= weight of methyl ester (biodiesel) from

washing and separation

W

oil

= weight of waste oil and fat used in the reactor

2. Moisture content in waste cooking oil refers

to SNI 01-3555-1998 on Oil and Fat Test Method

using the gravimetric method. Samples that already

have a fixed weight can be calculated for their water

content by the formula:

(6)

Where:

Ka = moisture content (%)

m

1

= sample weight (grams)

m

2

= sample weight after drying (grams)

Flash point testing was used to determine the

indication of the boiling distance. This test was

carried out with reference to SNI 7182:2015

regarding Biodiesel using the ASTM D 93 method.

The tool used for the flash point test was the Pensky-

Martens closed cup tester.

The cetane number test was used to determine

the ability of the fuel to ignite quickly after being

injected. This test was carried out with reference to

SNI 7182:2015 regarding Biodiesel.

XRF test aims to determine the composition of

the elements in the calcined shrimp shell powder.

The most important component in calcined shrimp

shell powder was CaO.

Gas Chromatoraphy Mass Spectroscopy (GC-

MS) Test

Analysis of fatty acid composition in (Waste

Cooking Oil) used GC-MS method.

3 RESULTS AND DISCUSSION

3.1 Density

Testing the density of biodiesel was carried out at a

temperature of 40°C using a pycnometer. The

biodiesel quality requirements for the density

parameter regulated in ISN 7182:2015 are 850 – 890

kg/m

3

. Biodiesel with the highest yield has a density

value of 858.69 kg/m

3

. The density value in this

study has met the standards that have been set. The

smaller density value indicates that there has been a

breakdown of glycerol from triglycerides, so that a

compound with a smaller molecular size is formed

(Petrus et al., 2015).

3.2 Viscosity

Viscosity testing using an Ostwald viscometer at a

temperature of 40°C. Viscosity in biodiesel based on

ISN 7182:2015 concerning biodiesel has a value of

2.3-6 cSt. The result of viscosity testing on biodiesel

waste cooking oil which has the highest % yield is

14.77 cSt. This value is not included in the standard

range that has been set. Triglycerides have a higher

viscosity than methyl esters, this is what causes high

biodiesel viscosity if the transesterification reaction

is not perfect (Zulhardi et al., 2018). Several

approaches have been proposed to reduce the

viscosity of biodiesel so as to improve the flow

properties of biodiesel at low temperatures which

include mixing with diesel fuel, the use of additives,

physical modification, fractionation crystallization,

and winterization (Sukarno, 2012).

3.3 Flash Point

The flash point test refers to ISN 7182:2015

regarding Biodiesel using the ASTM D 93 method.

The tool used for the flash point test is the Pensky-

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

534

Martens closed cup tester. The minimum

requirement for flash point parameters for biodiesel

is 100°C. Flash point test results show 205.83°C.

The test results indicate that the flash point

parameter has met the requirements. According to

Permana et al, (2020), the higher the flash point of

biodiesel, the safer it will be to use because it will

minimize the occurrence of explosions due to

heating.

3.4 Water Content

Testing the water content using the oven drying

method. The water content value that has been

determined in ISN 7182:2015 regarding biodiesel is

a maximum of 0.05%-volume. Based on the research

that has been done, the results obtained water

content of 0.58%. The water content contained in

biodiesel is above the maximum level. The biodiesel

heating process is carried out to evaporate the water

content after the washing process using water in

biodiesel. The results of the water content that

exceeds the standard cannot be used as fuel because

the water content in the methyl ester can form

paraffin crystals at cold temperatures which can clog

the fuel flow. The water content can also cause

corrosion of the engine (Busyairi., et al 2020). One

approach to reduce water content is to use the dry

washing method in the purification process. The dry

washing method uses magnesium silicate as a

substitute for the role of water in absorbing

contaminants in biodiesel (Ayu & Zibbeni, 2012).

3.5 Centane Number

Centane number is one of the test parameters to

determine the quality of diesel fuel combustion. The

minimum requirement for the cetane number for

biodiesel based on ISN 7182: 2015 is 51. The

biodiesel cetane number in this study based on the

test results is 0 because the cetane number value is

outside the test range (20-100). This value is a sign

that biodiesel has a cetane number that is outside the

reading range of the analysis tool, which is between

20 - 100. The raw materials used in this study

contained 52.51% saturated fatty acids and 47.49%

unsaturated fatty acids. According to Damayanti., et

al (2020), a higher content of saturated fatty acids

than unsaturated fatty acids will cause the biodiesel

cetane number in this study to be high (> 100).

Based on these data and the results of previous

studies, it can be used as a reference that the

biodiesel centane number value in this study is

above 100. The resulting centane number value

exceeds the minimum cetane number value in the

specified SNI standard. So that the value of the

centane number in this study has met the standard.

3.6 Fatty Acids Methyl Ester Level

Fatty Acids Methyl Ester analysis was carried out

using Gas Chromatography-Mass Spectrometry

(GC-MS). Based on the results of GC-MS analysis,

the dominant FAME components are Octanoic acid,

methyl ester and Decanoic acid, methyl ester with

area percentages of 46.4% and 43.07%, respectively.

The compounds contained in the GC-MS test results

indicate that the triglycerides contained in the waste

cooking oil have been converted into methyl esters.

According to ISN 7182-2015 regarding biodiesel, it

is stated that the minimum methyl ester content is

96.5%. In this study, the methyl ester content

produced was 95.31%. This value does not meet the

standard so it can be seen that there are still some

triglyceride components that have not been

converted to FAME (Oktavian., et al 2019).

4 CONCLUSIONS

Characteristics of biodiesel produced from used

cooking oil (waste cooking oil) indicates that the

parameters of density, flash point, and the acid

number has met the standard, while the viscosity and

parameters water content does not meet the

standard..

REFERENCES

Ansori, A., & Wibowo, S. A. (2018), Biodiesel Production

from Nyamplung Oil (Calophyllum inophyllum L.)

Using Microwave with Heterogeneous Base Catalyst

(Doctoral dissertation, Sepuluh Nopember Institute of

Technology).

Ayu, D., & Zibbeni, A. (2012), Pengaruh stir washing,

bubble washing, dan dry washing terhadap kadar metil

ester dalam biodiesel dari biji nyamplung

(Calophyllum inophyllum).

Busyairi, M., Za'im Muttaqin, A., Meicahyanti, I., &

Saryadi, S. (2020), "The Potential of Used Cooking

Oil as Biodiesel and the Effect of Catalysts and

Reaction Time on Biodiesel Quality Through the

Transesterification Process". Serambi Engineering

Journal, 5(2).

Cahyati, E. D. and L. Pujaningtyas. (2017), “Producing

Biodiesel from Used Cooking Oil by

Transesterification Process Using KOH Catalyst”.

Thesis. Ten November Institute of Technology.

The Effect of Adding Shrimp Shell Catalyst on the Quality of Biodiesel from Used Cooking Oil

535

Damayanti, R. N., Setiawan, A., & Mayangsari, N. E.

(2020), "Production of Biodiesel from Waste Oil and

Fat in the Dairy Processing Industry Using

Esterification-Transesterification Reaction". In

Conference Proceedings on Waste Treatment

Technology (Vol. 3, No. 1, pp. 227-231).

Darmawan, Ferry Indra dan I wayan Susila. 2013.

“Biodiesel Production Process from Used Cooking Oil

with Dry-Wash System Washing Method”. Jurusan

Teknik Mesin UNESA.

Dewi, D. C. (2015), "Production of Biodiesel from Castor

Oil (Ricinus communis) with Microwave". Thesis.

Semarang State University. Semarang.

Efendi, R., H. A. N. Faiz, and E. R. Firdaus. (2018),

“Producing Cooking Oil Biodiesel Using the

Esterification – Transesterification Method Based on

the Amount of Used Cooking Oil”. 9 th Industrial

Research Workshop and National Seminar (IRONS):

402 – 409.

Glisic, S.B., Orlović, A.M., 2014. “Review of biodiesel

synthesis from waste oil under elevated pressure and

temperature: Phase equilibrium, reaction kinetics,

process design and techno-economic study”. Renew.

Sustain. Energy Rev. 31, 708–725.

Indonesian National Standard. (1998), Oil and Fat Test

Method. Indonesian National Standard 01-3555.

Jakarta.

Indonesian National Standard. (2015), Biodiesel.

Indonesian National Standard 7182. Jakarta.

Khodijah, S. (2017), Making Crude Palm Oil-Based

Biodiesel with Cao Catalyst From Shrimp Shells

Based on Methanol Addition Ratio and

Transesterification Time (Doctoral dissertation,

Sriwijaya State Polytechnic).

Murni, S. W., G. Kusumawardani, and T. Arifin. (2016),

“Producing Biodiesel from Sunan Candlenut Oil with

a Two-Stage Process”. Proceedings of the “Struggle”

National Seminar on Chemical Engineering J11: 1 – 5.

Oktavian, R., Poerwadi, B., Supriyono, S., Septiadi, H. T.,

& Yuniardi, M. I. (2019), Performance Study of

Silica-Based Hydrophobic Membrane in Biodiesel

Purification Process. Journal of Natural Materials

Engineering and Sustainable Energy, 3(1), 20-24.

Pahlevi, M. R., Nurhayati, and S. Anita. (2015),

"Variation of Catalyst Weight and Reaction

Temperature of Crude Palm Oil Transesterification

Using 800°C Calcined Blood Shells Catalyst". JOM

FMIPA 2(1): 186 – 191.

Permana, E., Naswir, M., Sinaga, M. E. T., Alfairuz, A., &

Murti, S. S. (2020), "Quality of Biodiesel from

Cooking Oil Based on Saponification Process and

Without Saponification". JTT (Journal of Applied

Technology), 6(1), 26-31.

Petrus, B., A. P. Sembiring, and M. S. Sinaga. (2015),

“Utilization of Blood Shell Ash (Anadara Granosa) as

a Catalyst in Making Methyl Esters from Waste

Cooking Oil”. USU Journal of Chemical Engineering

4(2): 13 – 19.

Sari T.I., Said M., Summa A.W., Sari A.K. 2011.

“Heterogeneous Base Catalyst Mixed CaO and SrO in

Palm Oil Transesterification Reaction”. Proceeding of

3

rd

AVOER National Conference Seminar Nasional

AVOER, p. 482-493.

Sartika, A., Nurhayati, and Muhdarina. (2015),

“Esterification of Used Cooking Oil with H2SO4

Catalyst and Transesterification with CaO Catalyst

from Blood Clam Shells: Variations in Esterification

Conditions”. JOM FMIPA 2(1): 178 – 185.

Sinta, T., Daniel, and C. Saleh. (2016), “Optimization of

Transesterification Reaction Temperature in Rice

Straw Oil (Oryza sativa L.) into Biodiesel using CaO

Catalyst from Chicken Eggshell”. Journal of

Chemistry Mulawarman 14(1): 19 – 23.

Sukarno, S. (2012), Study of the effect of mixing additives

on biodiesel viscosity at low temperatures (Doctoral

dissertation, Undip Postgraduate Program).

Suryanto, A. (2018), "Study of Biodiesel Production

Process from Castor Oil With the Help of Sound

Waves". Journal of Chemical Process Engineering,

51(54), 2303-3401.

Yasar, F. (2019), Biodiesel Production Via Waste

Eggshell as A Low-Cost Heterogeneous Catalyst: Its

Effect On Some Critical Fuel Properties and

Comparison with CaO. Fuel 225: 1 – 6.

Zulhardi, R., Restuhadi, F., & Zalfiatri, Y. (2018),

"Addition of Methanol in Making Biodiesel from

Waste Cooking Oil with Rubbing Ash Catalyst". vols,

5, 1-10.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

536