Heat Pump Drying for Turmeric: A Preview

Putu Wijaya Sunu

1

, Daud Simon Anakottapary

1

, I Dewa Made Susila

1

, Dianta Mustofa Kamal

2

,

Asrori

3

and Andoko

4

1

Mechanical Engineering Department, Bali State Polytechnic, Badung-Bali, 80364, Indonesia

2

Mechanical Engineering Department, Jakarta State Polytechnic, Depok-West Java, Indonesia

3

Mechanical Engineering Department, Malang State Polytechnic, Malang-East Java, Indonesia

4

Mechanical Engineering Department, Malang State University, Malang-East Java, Indonesia

Keywords: Heat Pump Dryer, Closed Air System, Time Series of Weight, Turmeric.

Abstract: Turmeric (Curcuma domestica VAL) is a rhizome plant that is very popular as a spice and as a medicinal

ingredient. The form of turmeric that can be used is in the form of fresh turmeric, dried turmeric, or turmeric

powder. Turmeric drying produces dry turmeric, which has a longer shelf life and makes packaging easier.

One of the dryers that can be used to dry turmeric is a heat pump dryer. In this study, the water content of

the turmeric simplicial product was tested at various heating times, i.e., 1 hour, 2 hours, 3 hours, 4 hours, 5

hours, 6 hours, 7 hours, and 8 hours with a constant temperature of 400C. The final water content of the dry

turmeric product reached 7.53%.

1 INTRODUCTION

One of the medicinal plants that is frequently

utilized as a raw material in Indonesia's herbal and

pharmaceutical industries is turmeric (Curcuma

domestica Val.). The anti-inflammatory, antioxidant,

and blood-clotting properties of turmeric help to

reduce pain and hasten wound healing. One of the

many active components found in turmeric is an

antioxidant. Curcuminoids are the most significant

main antioxidant present in turmeric.

One of the earliest methods of food preservation

is drying. Hot air drying is currently one of the most

developed drying techniques out of the many that

have been created. This drying method provides

advantages in terms of drying time, but it also has

certain drawbacks, such as changes in color and

flavor, a reduction in nutritional content, and a loss

of the product's functional characteristics (Ozkan,

2007). This promotes efforts to create new drying

techniques, one of which is heat pump drying that

integrates the refrigeration system.

In order to increase shelf life and avoid food

spoiling owing to chemical processes and biological

degradation due to the growth of microorganisms, it

is crucial to remove some of the water from the

matrix of agricultural or industrial products during

the drying process (Moradi, 2020). The process of

removing moisture uses two simultaneous

mechanisms: the first involves applying heat to the

product to cause evaporation, and the second

involves mass-transferring moisture from the

product surface to the atmosphere. Heat and mass

transfer refers to this simultaneous process.

Convection, where hot air or gas is blown over

the surface of the product and heat is transferred to

the product, provides the energy required for

evaporation of the moisture present in the food in

this process. This heat raises the temperature of the

product, causing moisture to evaporate as water

vapour and raising the vapor pressure of the product.

The vapor pressure of the product is greater than the

vapor pressure of the surrounding air in this

condition. This pressure difference causes moisture

to evaporate from the product's surface into the air.

This pressure gradient acts as a driving force in the

drying process, removing moisture from the product

as it exits the air. The moisture on the product's

surface is evaporated until it reaches equilibrium

conditions.

Drying is one of the most energy-intensive

operating equipment, accounting for up to 10-20%

of total industrial energy utilization, and most of the

energy in many industrial drying processes is wasted

in the environment (Ogura H, 2005). Batch dryers

were used for small and medium-sized production

342

Wijaya Sunu, P., Simon Anakottapry, D., Susila, I., Kamal, D., Asrori, . and Andoko, .

Heat Pump Drying for Turmeric: A Preview.

DOI: 10.5220/0011770400003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 342-345

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

runs and relatively thin products such as fruits or

vegetables or sliced spice products in research using

heat pump drying methods and equipment in (Kerr,

2013. Cuynet, 2020. Erbay, 2017. Chapchaimoh,

2016. Haonan, 2020. Ta L, 2018). Food is loaded

onto trays in cabinets and left to dry until it is

completely dry. Cabinet dryers typically have low

turnover rates due to their simple design, and the

drying process is not uniform throughout the drying

chamber.

Drying with heat pumps is becoming more

popular in industry due to its low energy

consumption and high drying efficiency (Deng Y,

2015). Energy-saving heat pump drying is based on

the reverse Carnot cycle principle; it can recover

energy from used drying air heat and reuse it in the

drying process, as well as control the temperature

and humidity of the air independently (Chua K J,

2007).

1.1 Experimental Apparatus and

Method

A local market in Denpasar, Bali, Indonesia,

provided fresh turmeric. Before beginning each

experiment, a 25 mm and 2 mm diameter turmeric

was peeled and sliced transversely into 2 mm-thick

slices using a cutting machine. The turmeric used in

this study was fresh turmeric, up to 2100 g, that had

been sorted. In this study, turmeric was sorted,

weighed, and placed on a drying tray, with each tray

weighing 350 g. The drying process was carried out

using a heat pump dryer, with drying times varying

from 1 hour to 2 hours, 3 hours, 4 hours, 5 hours, 6

hours, 7 hours, and 8 hours at a temperature of 40

o

C.

The remaining turmeric weight was measured at the

end of the test and used to calculate the water

content. A psychrometric analysis of the hot air

circulating in the system will also be performed as

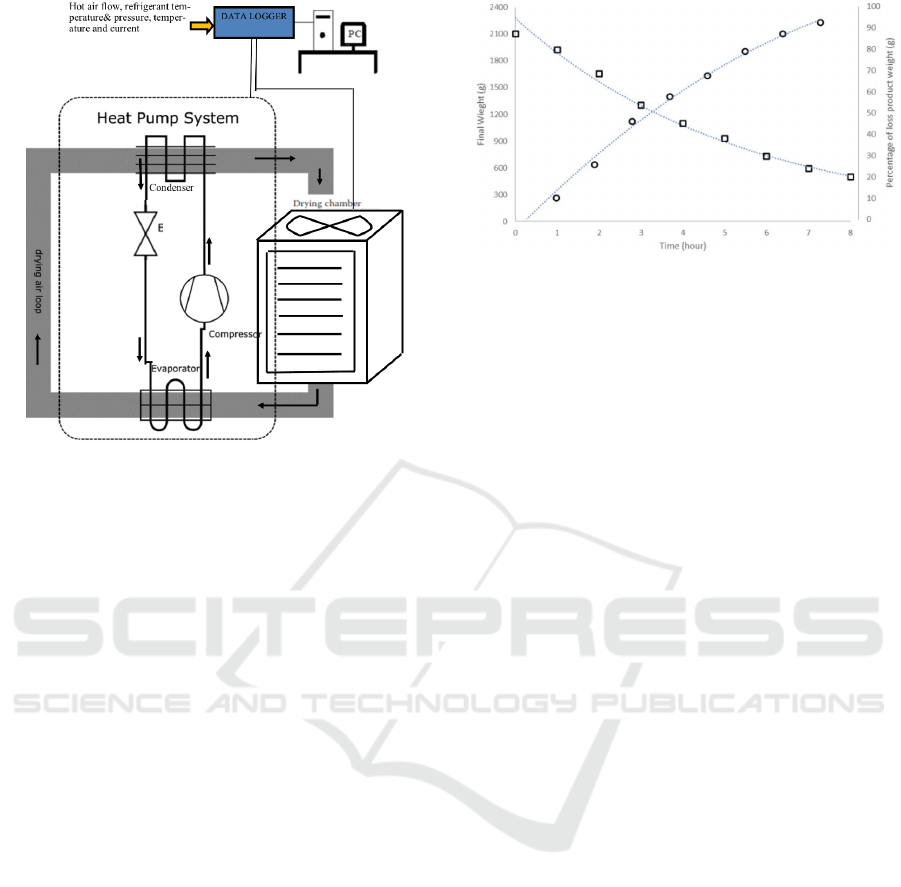

part of this study. Figure 1 depicts the equipment

used in this study, which is a heat pump drying unit.

Controlling the time for the heating process is the

point of comparison in this experiment. The fan

blows hot air into the drying cabin at an average

speed of 1.8 m/s. The main refrigeration components

are listed below.

Figure 1: Heat pump drying machine.

Table 1: Main component.

No Componen

t

Specification

1

Compressor

unit

Hermetic, Rotary

0.25 HP, R134a

refrigeran

t

2

Condenser

uni

t

Fin and tube with

air cooled system.

3

Expansion

device uni

t

Thermostatic

expansion valve

4

Evaporator

unit

Fin and tube

exchanger with air

cooled system.

Heat Pump Drying for Turmeric: A Preview

343

Figure 2: Schematic heat pump drying machine.

The measurement instruments used in this

investigation were a K-type thermocouple,

hygrometer, low and high-pressure gauges,

anemometer, and stopwatch. Using k-type

thermocouples, the temperatures of the refrigerant

R-134a and the air circuit at the inlet/outlet of the air

ducting system were measured. The sensors are

either attached to the outside of the copper tubing

that transports the refrigerant or are built into the

thermal insulation. In the meantime, the electrical

system uses a thermostat unit with a detecting light

to regulate the refrigerant flow's on/off cycles. All

data were logged with a data logger set to 1 Hz and

stored in external memory.

2 RESULT AND DISCUSSION

Turmeric drying was performed using a heat pump

drying device at 40

o

C with varying drying times of 1

hour, 2 hours, 3 hours, 4 hours, 5 hours, 6 hours, 7

hours, and 8 hours respectively. The turmeric drying

method used in this study is a thin layer drying

method in which the turmeric is directly exposed to

the hot air flow from the condenser. Figure 3 depicts

the changes in turmeric weight at the beginning and

end of the drying process.

Figure 3: Weight and water content of turmeric.

This section discusses the performance of the

heat pump drying from the standpoint of the

product's water content. The water content of the

product is one indicator of heat pump drying

performance; their time series data indicate heat

pump drying performance and are discussed below.

According to Figure 3, drying 2100 grams of

turmeric for 8 hours resulted in a residual weight of

498 grams with a remaining water content of 7.53

percent. Data from time series graphs show that the

greater the amount of water evaporated, the longer

the drying time. However, more research is required

to optimize the drying time. The slope of the graph

appears steep before 4 hours at a constant drying

temperature of 40

o

C. The maximum slope value

obtained for the final weight is -353, and the

percentage of remaining water in the product is

20.43. The maximum slope phenomenon occurs

between the second and third hours. Then it drops

slightly in the third and fourth hours. There is a

decrease in slope for times greater than 4 hours. This

phenomenon occurs because the water content is

deep in the product, requiring more time to

evaporate at a constant holding temperature. This

also demonstrates that the rate of reduction of the

product's water vapor content occurs optimally over

a period of 2-4 hours, as shown in Figure 3.

3 CONCLUSIONS

To describe preliminary drying characteristics, an

experimental investigation into the water content of

products dried by a heat pump dryer was carried out.

The heat pump drying method is effective at

decreasing the water content of the product by 7.53

percent after eight hours of drying, with the most

effective drying phenomenon occurring in the

second to third hour

.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

344

ACKNOWLEDGEMENTS

The authors would like to express sincere gratitude

to Direktorat APT, Kemdikbud-Ristek, Republic of

Indonesia for research fund with No.

085/SPK/D4/PPK.01.APTV/VI/2022. Also

Politeknik Negeri Bali with research project number

is No. 3158/PG/PL8/2021.

REFERENCES

Ozkan I A, Akbudak B, Akbudak N 2007 Microwave

Drying Characteristics of Spinach J. Food Eng. 78

577–583.

Moradi M, Azizi S, Niakousari M, Kamgar S, Khaneghah

A M 2020 Drying of Green Bell Pepper Slices Using

an IR-assisted Spouted Bed Dryer: An assessment of

drying kinetics and energy consumption Innovative

Food Science & Emerging Technologies 60 102280.

Moradi M, Fallahi M A, Khaneghah M A 2020 Kinetics

and Mathematical Modeling of Thin Layer Drying of

Mint Leaves by a Hot Water Recirculating Solar Dryer

Journal of Food Process Engineering 43 1 e13181.

Moradi M, Niakousari M, Khaneghah M A 2019 Kinetics

and mathematical modeling of thin layer Drying of

Osmo-Treated Aloe Vera (Aloe barbadensis) Gel

Slices Journal of Food Process Engineering 42 6

e13180.

Ogura H, Yamamoto T, Otsubo Y, Ishida H, Kage H,

Mujumdar A S 2005 A Control Strategy for Chemical

Heat Pump Dryer Drying Technology 23 6 1189–

1203.

Kerr W L 2013 Food Drying and Evaporation Processing

Operations Handbook of Farm, Dairy and Food

Machinery Engineering Second Edition (Academic

Press), Chapter 12 317-354.

Cüneyt T, Doymaz I 2020 Performance Analysis and

Mathematical Modelling of Banana Slices in a Heat

Pump Drying System Renewable Energy 150 918-923.

Erbay Z, Hepbasli A 2017 Exergoeconomic Evaluation of

a Ground-Source Heat Pump Food Dryer at Varying

Dead State Temperatures J. Clean. Prod. 142, 1425-

1435.

Chapchaimoh K, Poomsa-Ad N, Wiset L 2016 Thermal

Characteristics of Heat Pump Dryer for Ginger Drying

Applied Thermal Engineering 95 491-498.

Haonan H, Chen Q, Bi J, Wu X, Jin X, Li X, Lyu Y, Qiao

Y 2020 Understanding Appearance Quality

Improvement of Jujube Slices During Heat Pump

Drying Via Water State and Glass Transition Journal

of Food Engineering 272 109874.

Ta L, Akta M, Gülcü M, Uysal G 2018 Determination of

Drying Kinetics and Quality Parameters of Grape

Pomace Dried with a Heat Pump Dryer Food Chem.

260 152–159.

Deng Y, Luo Y, Wang Y, Zhao, Y 2015. Effect of

Different Drying Methods on The Myosin Structure,

Amino Acid Composition, Protein Digestibility and

Volatile Profile of Squid Fillets Food Chem. 171,

168–176.

Chua K J, Chou S K, Ho J C, Hawlader M N A 2007. Heat

Pump Drying: Recent Developments and Future

Trends Drying Technol. 20 1579–1610.

Heat Pump Drying for Turmeric: A Preview

345