A New Method in Performance Test of Electric Vehicle Battery

Using Water Rheostat

I Wayan Jondra

1a

, I Gusti Agung Made Sunaya

1

, I Gusti Putu Arka

1

, I Gusti Ketut Abasana

1

and I Wayan Sudiarsa

2

1

Electrical Department, Politeknik Negeri Bali, Jalan Kampus Bukit Jimbaran, Kabupaten Badung, Indonesia

2

Computer System Department, Institut Bisnis dan Teknologi Indonesia,

Jl. Tukad Pakerisan No. 97 Denpasar, Bali, Indonesia

Keywords: Water, Resistance, Load.

Abstract: Nowadays, the electric vehicles uses is increased, both for private and public transportation. The electric

vehicles increasing is supported by the battery technology innovation. A reliable, inexpensive and large

capacity of the battery are created but less attend to battery instrument to review the real battery performance.

This paper are discussion a new method in performance test of electric vehicle battery using water rheostat

to review the real battery performance. The water rheostat are consist of two set aluminum electrode plate.

To increase the current discharge value is done by added water to soak the electrode plate. The data logger

collected the voltage, and discharge current of times. The data analysis indicated this water rheostat dummy

load have a good performance to instrumented the battery performance. The finding of this paper is: 1. The

discharge current are inversely proportional with the battery terminal voltage. 2. On the discharge current

value is 2.17 Ampere in voltage 83.64 volt, the water resistivity is 2,698.06 Ohm-meters and than go down

to 73.87 Ohm-meters on the voltage value 46.00 Volt and the discharge current 43.53 Ampere. 3. The

discharge current a inversely with the area of electrode. 4. The water resistivity are linear function to the

resistance of water rheostat. 5. Water rheostat with two sets of electrodes dimensions of 35 x 36 centimeters

can be use as a dummy load of up to 2.3 KW in a voltage of 66 Volt DC.

1 INTRODUCTION

Nowadays, the use of electric vehicles is growing,

both for private and public transportation. The

electric vehicles using is in line to the Bali State

Polytechnic as a centre of excellence for green

tourism technology. Electric vehicles are chosen at

this time because they do not cause noise pollution,

low operating costs, and light vehicles (Srinivas,

2019). The growth in the use of electric vehicles

contributes to pollution reduction, cost efficiency,

reducing road damage due to lighter electric vehicles

(Sudjoko,2021). The very worrying pollution caused

by the vehicles age and engine combustion system

has a strong correlation in producing CO and HC

values (Dinda et al., 2020). Electric vehicles would

reduces air pollution like nitric oxide (Daniel et al.,

2021; Ernani F. at al., 2020)

a

https://orcid.org/0000-0001-6800-6415

Pollution remains unresolved even though efforts

have been made to utilize the radiator heat as a heat

source to heat the combustion system (Wiryanta,

2019). The electric vihicle must growing, the electric

vehicles growth is supported by the growing of cheap

design of batteries, so that the price is cheap, large

capacity and long life (Michael et.al, 2018). Various

shapes, types and capacities of batteries are made by

industry. The dimensions of the battery are smaller

but with greater capacity. To support the performance

of electric vehicle batteries, smart charging has been

designed to improve battery performance (Bowen,

2019). The greater battery capacity, affect to the

longer times to use the battery for the same load.

There are also a lot of batteries sold in retail, so

technicians can assemble custom batteries as needed.

Vehicle battery customized can be done in terms of

shape and capacity requirements.

Jondra, I., Sunaya, I., Arka, I., Abasana, I. and Sudiarsa, I.

A New Method in Performance Test of Electric Vehicle Battery Using Water Rheostat.

DOI: 10.5220/0011759500003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 271-277

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

271

The electric vehicles growing, has been supported

by the construction of charging centers also (Zhuk A

and Buzoverov E, 2018). The inventions of design

and control batteries charging gave rise to

increasingly sophisticated charging stations. The

current sophistication of charging stations makes it

easy for electric vehicle users to recharge their

batteries. Ease is felt in the ease of connection without

having to open the battery. The sophistication of the

charging station is also evidenced by the shorter

charging time of the battery for the same capacity.

The sophistication of the charging station is also

supported by the sophistication of the control battery

management system (BMS) which can control the

condition of the battery carefully and smartly because

through a bluetooth device the battery condition

status can be monitored remotely from a smart phone.

Industries and researchers, while that instrument is

very important to guarantee the quality of batteries,

because the battery has come from various factories.

Battery is also to many much implemented for solar

power generation (Wirajati et al., 2021) . The Dummy

Load as described in this paper is a solution to get a

battery capacity test instrument.

2 RESEARCH METHOD

2.1 Research Approach and Concept

This research was designed as a quantitative approach

study to find the design of a water rheostat, which can

be used as an artificial load in testing battery quality.

This water rheostat is designed by utilizing the

resistivity of water to soak two positive and negative

electrode plates.

The concept of this research is applied research,

by applying the basic law of Ohm's law and the

resistance formula, into a water rheostat, the area of

this resistor is largely determined by the area of the

electrode plate and the limit distance from the

electrode plate, to solve the problem of the absence of

a battery test instrument with inexpensive but large

capacity. The wider the plate electrode affect to

decreasing the resistance value, this ratio is in line to

the conductor, the wider area of the conductor affect

to the smaller of the resistance value. Likewise, the

smaller the distance between the negative plate and

the positive plate affect to the decreasing the

resistance value, this is in line with the conductor, the

shorter of the conductor affect to the smaller of the

resistance value. The small resistance of the water

rheostat will be a big load for the battery, the parallel

connection of several electrodes decreases resistance

value.

2.2 Total Sample

This research was conducted with a sample of water

rheostat, the collection was carried out with a total of

20 data for each indicator. To take the 20 of data is

done by regulated the water level from zero to

maximum and measured the value of voltage and

current flow to the water rheostat.

2.3 Variable Operational Definition

The focus of this study to observing the magnitude

of the variable of this research, that are : The first

independent variable is the area of the electrode that

is soak in the water, and the second is the time of

testing. Meanwhile, the first dependent variable is the

discharge current of the battery increases caused by

the increased the area of the electrode soak in water,

and the second dependent variable is the voltage are

decreases caused by the increases of discharge current

of the battery. Voltage is amount in volt of potential

test voltage between two terminal of the battery. The

current is amount in ampere of electron flow to the

electrode. The area of the electrode in square meters

is obtained by measuring the depth of the water

multiplied by the width of the electrode plate

multiplied by the number of electrodes inserted into

the water.

2.4 Data Analysis

Data obtained from the test results are processed

quantitatively. Data is processed mathematically and

statistically by finding the data variation on the step

by step the water level. The data are processed

mathematically to obtain the voltage and current

discharge at the initial of the test, and finally when the

water box is fully, the test is stop. The output

mathematically data is processed trough statistically

to obtain the average data, data sequence, which is

also displayed graphically.

3 WATER RESISTIVITY

All of materials have electrical properties

characteristic, such as resistivity, likewise water has

resistivity properties. The resistivity of water causes

an low electric flow current in the water even though

that it is not as smooth as an electric current flowed

in gold or copper. This water resistance property can

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

272

be utilized for low resistors with large power

capacities.

The resistivity of water used in low voltage power

machinery and other heavy equipment laboratories,

there is a universal need for a compact, rugged, yet

flexible and continuously variable rheostat (Engle,

1952). This water rheostat are available for so many

applications as: dc motor starting, dc and ac single

and 3-phase loading, wound-rotor induction motor

speed control. Water rheostat like balanced 3-phase

load, that is equivalent delta AC circuit, water

rheostat which also may be used in DC and AC

single-phase circuits. The untreated city tap water that

has an average resistivity of 4,600 ohms per inch cube

at 20° Centigrade, and for a single rheostat unit will

dissipate up to 75 kw (Engle, 1952). The resistivity of

water is strongly influenced by the substances

contained. Water with a higher salt content will have

a lower resistivity. The low resistivity of this water

can be used to make a water rheostat with a higher

capacity.

Water rheostat has the potential as an dummy load

with a very large capacity if a large capacity water

reservoir is provided. to increase the capacity can be

done by expanding the electrodes used, increasing the

volume of water. Because the water resistance (R) is

strongly influenced by the resistivity of water (𝜌, the

area of the electrode (A) and the distance between the

electrodes(𝑙, which can be explained by the formula

below.

𝑅

𝜌. 𝑙

A

(1)

Based on formula (1) above, it can be explained

that to get a low resistance (R) of the water rheostat,

it can be done by expanding the surface area of the

water (A) in contact with the electrode surface. On the

other hand, to get a higher resistance (R) of the water

rheostat, it can be done by narrowing the surface area

of the water (A) in contact with the electrode surface.

While Ohm's law states that voltage (V) is strongly

influenced by current (I) and resistance (I), if a

substitution is made, the amount of current (I) that

flows is strongly influenced by voltage (V) and is best

proportional to resistance (R). The substitution results

for Ohm's law can be assumed by formula (2) below.

𝐼

𝑉

R

(2)

Meanwhile, the power (P) released by the battery

is strongly influenced by the current flowing (I) and

the resistance value (R) through which the current

flows, this opinion can be explained by the formula

below.

𝑃𝑉.𝐼

(3)

Based on formula (3) it can be explained that to

be able to discharge the electric power (P) in the

battery, it is done by increasing the current (I) flowing

at the same voltage (V). So to regulate the amount of

discharge power is done by increasing the flowing

current. while in ohm's law as outlined in formula (2)

the value of the current (I) that flows will be greatly

influenced by the resistance value (R), the smaller the

resistance value, the current value will increase at the

same voltage. So based on formulas (1) (2) and (3) it

can be understood that to be able to deliver a large

discharge power (P) it can be done by reducing the

resistance value by expanding the surface (A).

4 THE WATER RHEOSTAT

DESIGN

To make a water rheostat, components are needed,

including: water box, electrode plate, plate barrier, tie

fasteners, nuts and bolts, cables and cable shoes. Data

Logger is used to record the value of current and

voltage within a certain time interval. The shape of

the water rheostat can be depicted in the following

figure at below.

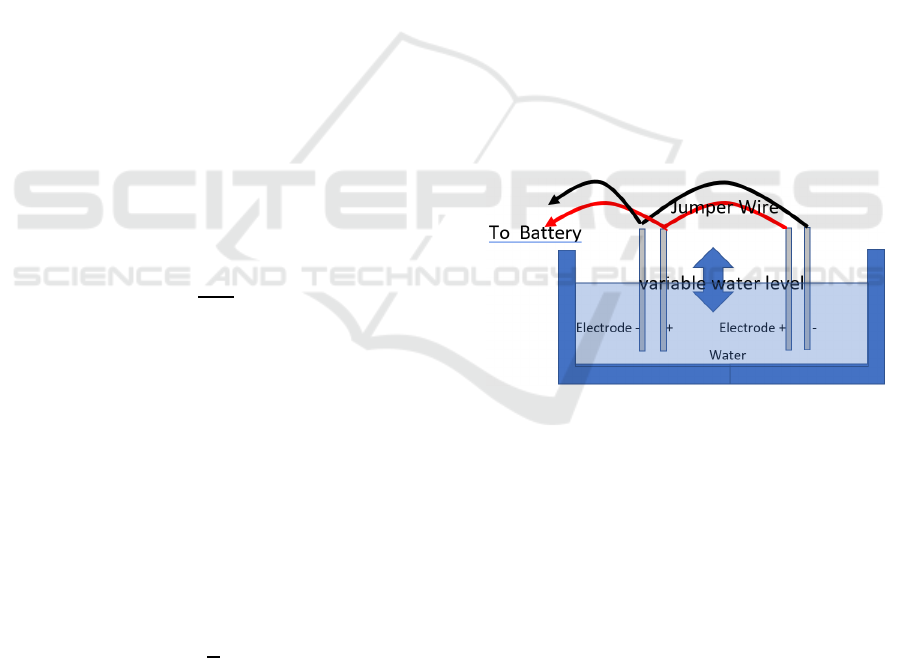

Figure 1: Water rheostat diagram.

Like in the figure 1 can be describe the red cable

is connected to positive of the battery terminal and

electrode, the black one is connected to negative of

the battery terminal. In the connected condition

between the battery terminal with the wet electrode,

the current will be flowed from positive terminal to

the positive electrode, trough the water from positive

to negative electrode, the finally to negative terminal

of the battery. This current flowed process will

discharge the energy in the battery.

The high or low current flowed affected to the

duration time of discharge process(Ioannou et all.,

2017). The high flowed current affected to the faster

discharge, and than the low current flowed affected to

the lower discharge process. The high of the current

flow depend the water rheostat resistance. The low of

A New Method in Performance Test of Electric Vehicle Battery Using Water Rheostat

273

water rheostat resistance affect to the high current

flow, and the high water rheostat resistance affect to

low current flow.

The high or low of water rheostat resistance

depended of the water level to burial the electrode in

the fixed of the space between positive electrode dan

negative electrode. The high of water level will be

reduced the water rheostat resistance and the lower

one will be upgrade the resistance. Like as described

to fix water rheostat resistance, must be keep the

water level. The water rheostat must be designed by

the system to keep the water level like in figure at

below.

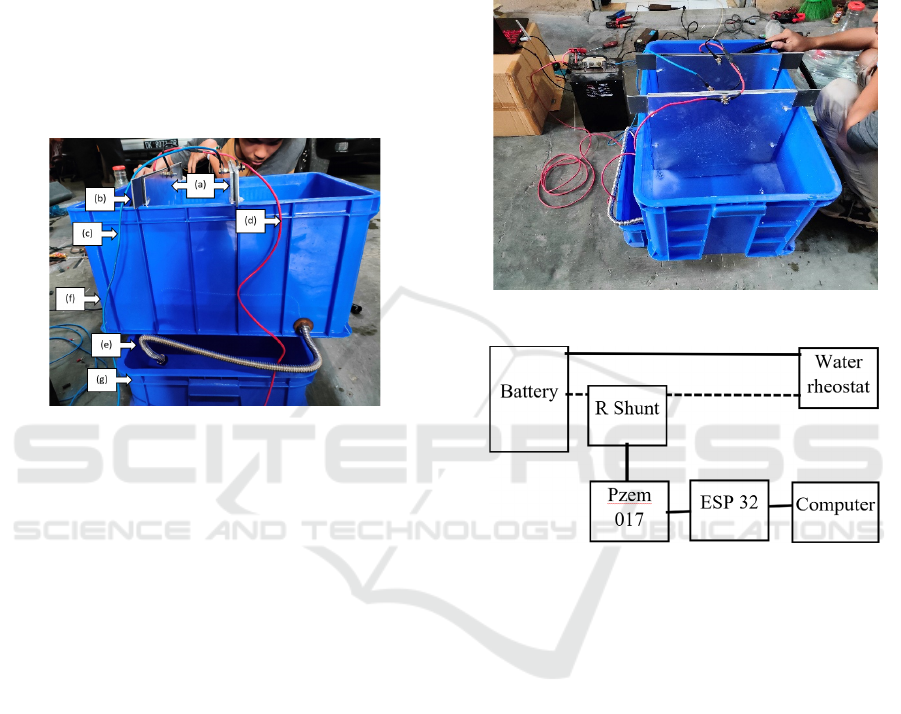

Figure 2: Water rheostat design.

As shown in the figure 2, the main component of

water rheostat consists of: electrode, water and box.

The detail of the water rheostat design consists of: (a)

two set electrode as dummy load, (b) fresh water

supply pipe to keep the water level, (c) negative cable

to connected the battery terminal, (d) positive cable to

connected the battery terminal, (e) overflow pipe to

control the level of water, (f) main water box to

collect the water capacity, (g) reservoir to collect the

over flow water.

5 RESULT AND DISCUSSION

The results of the research are shown in numbers

arranged in a table. The data from the test results are

discussed by analysing mathematically and

statistically, which is finally displayed in the form of

a graph.

5.1 Result

The study was conducted by testing a battery with a

voltage stated on the nameplate of 72 Volt 30 amperes

hours. The battery is charged first to full, after being

fully charged the battery is discharged by connecting

the battery to a water rheostat via a miniature circuit

breaker as shown in the figure below.

The test is carried out as shown in Figure 3 below.

The red wire is connected to a positive voltage source,

while the black wire is connected to a negative

voltage source. The test was carried out using two sets

of water rheostat electrodes.

Figure 3: Tested process.

Figure 4: Block diagram.

The analogue Voltage and current flowing to the

electrodes are converted to digital by a DC

communication module which can measure DC

power up to 300 VDC and current measurement in an

external shunt mounting range of 50A to 300A. The

measurement results are processed by the Pzem-017

converter and read by the ESP-32 data logger, the

data is then sent to the Blynk application on the

computer to displayed the value of the voltage,

current, Power, energy, time at below and also on

Google Spread Sheet as shown at the figure 5. The

data from this spreadsheet is then taken as much as 20

data according to the water level step in the box as

describe on the table 1. The electrode used in this

study is aluminium material, with a thickness of 3.5

cm.

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

274

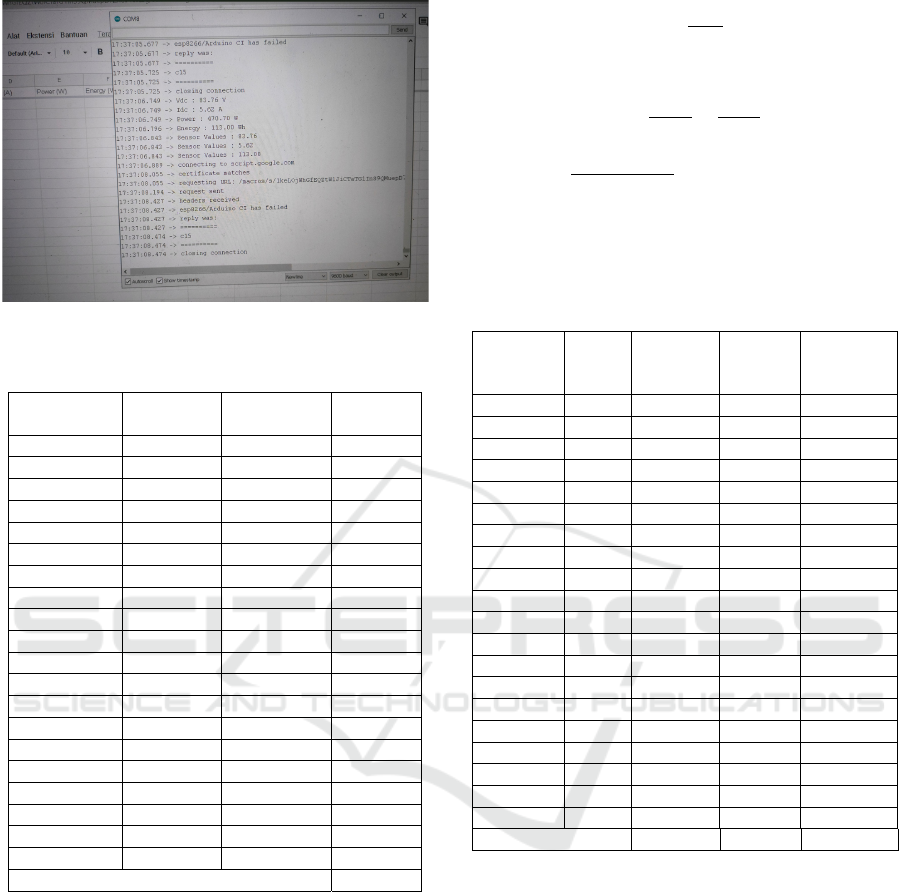

Figure 5: Measurement display.

Table 1: Test result.

Voltage

(

Volt

)

Current

(

Am

p)

Water Deep

(

M

)

Duration

(

second

)

83.64 2.17 0.02 180

82.62 4.35 0.04 180

81.60 6.53 0.06 180

80.61 8.71 0.08 180

79.62 10.89 0.1 180

78.64 13.07 0.12 180

77.68 15.25 0.14 180

76.73 17.43 0.16 180

75.79 19.61 0.18 180

74.86 21.79 0.2 180

73.94 23.97 0.22 180

73.03 26.15 0.24 180

72.14 28.33 0.26 180

71.25 30.51 0.28 180

68.00 32.69 0.3 180

66.00 34.87 0.32 180

60.00 37.05 0.34 180

56.00 39.23 0.36 180

50.00 41.41 0.38 180

46.00 43.59 0.4 180

Total 3600

5.2 Discussion

Based on the data in table 1, the area of the submerged

electrode can be calculated as follows:

Electrode width : 0.35 meters

Water deep : 0.02 meters

The area is = 0.35 x 0.02

= 0,007 ~ 0,01 meter

2

The power discharge of the battery can be

explained by the formula below.

𝑃𝑉.𝐼

𝑃 66 𝑥 34.87: 1000 2,3 𝐾𝑊

Resistance which can be explained by the formula

below.

𝑅

𝜌 . 𝑙

A

The water resistivity which can be explained by the

formula below.

𝜌

𝑅 . 𝐴

𝑙

𝑉 . 𝐴

I . 𝑙

𝜌

83.64 . 0.01

2.17 . 0.001

385 𝑂ℎ𝑚 𝑀𝑒𝑡𝑒𝑟

Through the same analysis as above, this study

found the value of electrode area, water resistivity,

and load like in the table 2 at below.

Table 2: Analysed electrode area and water resistivity.

Electrode

Area

(M

2

)

Load

(KW)

Voltage

(Volt)

Current

(Amp)

Water

Resistivity

(Ohm-m)

0.01 0.18 83.64 2.17 2698.06

0.03 0.36 82.62 4.35 1329.46

0.04 0.53 81.60 6.53 874.78

0.06 0.70 80.61 8.71 647.81

0.07 0.87 79.62 10.89 511.78

0.08 1.03 78.64 13.07 421.19

0.10 1.18 77.68 15.25 356.56

0.11 1.34 76.73 17.43 308.14

0.13 1.49 75.79 19.61 270.53

0.14 1.63 74.86 21.79 240.48

0.15 1.77 73.94 23.97 215.92

0.17 1.91 73.03 26.15 195.50

0.18 2.04 72.14 28.33 178.24

0.20 2.17 71.25 30.51 163.47

0.21 2.22 68.00 32.69 145.61

0.22 2.30 66.00 34.87 132.49

0.24 2.22 60.00 37.05 113.36

0.25 2.20 56.00 39.23 99.92

0.27 2.07 50.00 41.41 84.52

0.28 2.00 46.00 43.53 73.87

Average 71.41 22.88 453.08

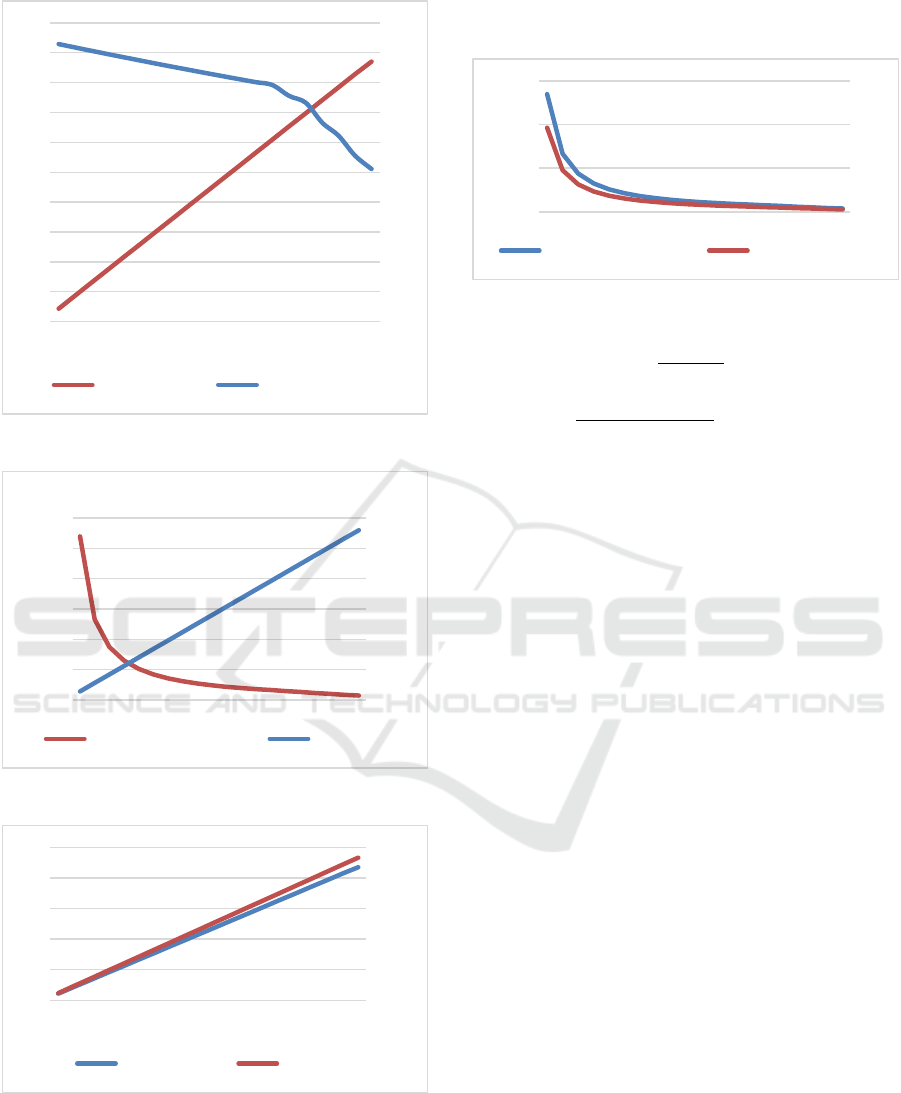

Figure 6 shows that when the discharge current

increases, the battery voltage drops(Changseng L.

and Xingxing Z., 2022). Drastic drop in battery

voltage at loads above nominal battery current. The

loading is done repeatedly like figure 6, it is estimated

that the discharge current will decrease, so that can be

predicted of the life cycle of the battery.

A New Method in Performance Test of Electric Vehicle Battery Using Water Rheostat

275

Figure 6: Voltage and current are inverseley proportional.

Figure 7: Water resistivity graph.

Figure 8: Current and Area Linearity.

The battery sample tested in this study was a 72

Volt (30 Ah) battery. Based on table 2, the average

battery voltage is 71.41 Volts, with an average

discharge current of 22.88 Amperes, within 1 hour, so

the real battery capacity being tested is according to

the calculation below.

Figure 9: Water resistivity and resistance of water rheostat.

𝑊

%

𝑉1. 𝐼1. 𝑡

𝑉2. 𝐼2. 𝑡

𝑥100%

𝑊

%

72 𝑥 30 𝑥 1

71.41 𝑥 22.28𝑥1

𝑥100% 74.59%

If this test is done repeatedly, it will result in a

decrease in battery performance, so that the battery

life can be predicted graphically (David, 2019).

6 CONCLUSIONS

Based on the results of testing and analysis can be

concluded as follows:

1. The discharge current are inversely

proportional with the battery terminal

voltage.

2. Portion the discharge current value is 2.17

Amperes in voltage 83.64 volt, the water

resistivity is

2, 698.06 Ohm-meters and than

go down to 73.87 Ohm-meters on voltage

46.00 Volt and the discharge current 43.53

Amperes.

3. The discharge current a inversely with the

area of electrode.

4. The water resistivity are linear fuction to the

resistance of water rheostat.

5. Water rheostat with two sets of electrodes

dimensions of 35 x 36 centimeters can be

use as a dummy load of up to 2.3 KW in a

voltage of 66 Volt DC.

ACKNOWLEDGEMENTS

This research was funded by DIPA Politeknik Negeri

Bali Year 2021. We thank Director of Politeknik

Negeri Bali for his support to this research..

0

10

20

30

40

50

60

70

80

90

0

5

10

15

20

25

30

35

40

45

50

1 3 5 7 9 1113151719

CURRENT(A) VOLTAGE(VOLT)

0,00

0,05

0,10

0,15

0,20

0,25

0,30

0

500

1000

1500

2000

2500

3000

135791113151719

RESISTIVITY(OHM‐M) AREA(M2)

0,00

0,05

0,10

0,15

0,20

0,25

0,30

0

10

20

30

40

50

135791113151719

CURRENT(A) AREA(M2)

0

20

40

60

0

1000

2000

3000

RESISTIVITY(OHM‐M) Resistance(ohm)

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

276

REFERENCES

Bowen Xu. (2019). Research on Charging Strategy

Optimization of Electric Vehicle based on AGA. 5th

International Conference on Vehicle, Mechanical and

Electrical Engineering, ICVMEE 2019. Copyright ©

2020 by SCITEPRESS – Science and Technology

Publications, Lda.

Changseng L. and Xingxing Z. (2022). Lithium-ion battery

capacity configuration strategy for photovoltaic

microgrid. International Journal of Low-Carbon

Technologies 2022, 17, 850–855.

Daniel E H., Jordan L Schnell, Daniel R Peters, David C

Wong, Xi Lu, Hao Gao, Hongliang Zhang, Patrick L

Kinney. (2021). Effect of adoption of electric vehicles

on public health and air pollution in China: a modelling

study. The Lancet Planetary Health, Volume 5, Special

Issue, S8, APRIL 01.

David A. Howey. (2019). Tools for battery health

diagnostics and prediction. The Electrochemical

Society Interface, Volume 28, Number 1. URL: Tools

for Battery Health Diagnostics and Prediction -

IOPscience.

Dinda One Mulyaningtyas, I Ketut Widnyana, and Sang

Putu Kaler Surata. (2020). The impact of motorized

vehicle activity on the level of air pollution in bali

island. Granthaalayah International Journal of

Research, Vol.8 (Iss.4): April 2020. URL :

https://www.granthaalayahpublication.org/journals/ind

ex.php/granthaalayah/article/view/IJRG20_B04_3299

Engle J. F..(1952). A water rheostat using untreated water.

In Transactions of the American Institute of Electrical

Engineers Part III: Power Apparatus and Systems, vol.

71, no. 1, pp. 18-21, Jan. 1952.

URL: https://ieeexplore.ieee.org/stamp/stamp.jsp?tp=

&arnumber=4498441&isnumber=4498435.

Ernani F.Chomaa, John S.Evans, James K.Hammitt, José

A.Gómez-Ibáñez, John D.Spengler. (2020). Assessing

the health impacts of electric vehicles through air

pollution in the United States. Environment

International, Volume 144.106015

Ioannou S., K. Dalamagkidis, E. K. Stefanakos, K. P.

Valavanis, and P. H. Wiley. (2017). Runtime, Capacity

and Discharge Current Relationship for Lead Acid and

Lithium Batteries. Researchgate. https://www.

researchgate.net/publication/301496300

Michael J. Safoutin, Joseph McDonald and Ben Ellies.

(2018). Predicting the Future Manufacturing Cost of

Batteries for Plug-In Vehicles for the U.S.

Environmental Protection Agency (EPA) 2017–2025

Light-Duty Greenhouse Gas Standards. In World

Electric Vehicle Journal, 2018, 9, 42.

Srinivas Mutyala, M.Tech. (2019). Design And

Development Of Electric Motorbike. In International

Research Journal of Engineering and Technology

(IRJET),Volume: 06 Issue: 12. www.irjet.net.

C Sudjoko et al. (2021). Utilization of electric vehicles as

an energy alternative to reduce carbon emissions. IOP

Conf. Ser.: Earth Environ. Sci. 926 012094

Wirajati I G. A. B., I Dewa Made Cipta Santosa, I Bagus

Aditya Jaya Pramana, I Putu Gede Suka Haryasa, Ida

Ayu Gede Bintang Madrini. (2021). Solar Power

System Design Applications For Pool Water Pump

Operation At Tourist Accomodation. LOGIC Jurnal

Rancang Bangun dan Teknologi Vol. 21 No. 3

November 2021

Wiryanta, .... (2019). Redesign of Clove Dryer Simulation

Machine Using Heat Waste of Radiator as the Heat

Source. Logic : Jurnal Rancang Bangun Dan

Teknologi, 19(1), 7-13. doi:10.31940/logic.v19i1.1101.

Zhuk A and Buzoverov E. (2018). The impact of electric

vehicles on the outlook of future energy system. IOP

Conf. Series: Materials Science and Engineering, 315

(2018) 012032. doi:10.1088/1757-899X/315/1/012032.

A New Method in Performance Test of Electric Vehicle Battery Using Water Rheostat

277