Experimental Study of Circular Tunnel of Vertical Axis Wind

Turbine of Savonius Type-U

Delffika Canra

1 a

, Muhammad Luthfi

1 b

, Ruzita Sumiati

2 c

and Adriansyah

2

1

Politeknik Negari Indramayu, Jalan Lohbener Lama no. 8, Indramayu, Indonesia

2

Politeknik Negeri Padang, Kampus Limau Manis Padang, Indonesia

Keywords: Vertical Axis Wind Turbine (Vawt), Savonius Type-U, Circular Tunnel.

Abstract: Much research has been conducted to develop the construction of wind turbine thus produces the optimum

electrical power. The construction development that has been carried out is by varying the shape of blade,

angle of blade, number of blades, staging blade, shield, and deflector. Author tried to optimize the use of

shield construction (guided-box tunnel) by making the variation of circular shape. By guiding wind to the

blade that is dragged can increase turbine power proportional to the torque value. Therefore, the aim of this

research is to find Coefficient of Power (Cp) and torque value of deconstructed Savonius wind blade type U

using circular tunnel. The designed rotor is a savonius type -U of 2 blade rotor. The dimensions of the rotor

are designed to be smaller than the previous research which has the diameter of savonius rotor of 250 mm and

an aspect ratio of 1: 1. Circular tunnel dimensions was slightly widened, with the diameter of 270 mm and

height of 400 mm. Cp with circular tunnel increase 2,5 times of the value Cp without circular tunnel.

Meanwhile, the addition of circular tunnel caused the decrease of torque value even though it was not

significant.

1 INTRODUCTION

The Savonius wind turbine is a type of Vertical Axis

wind Turbine (VAWT). This turbine has been already

studied since 1920 until now by many researchers.

The working principle of this turbine is based on the

difference of drag force that hit the surface of

semicircular of the rotor. The sum of this drag force,

if it is positive, can rotate of the turbine shaft

(D.S.Hasan, et al., 2013). Theoretically, the relation

between Cp value and Tip Speed Ratio (TSR) for

Savonius Turbine is shown in Figure 1.

Much research has been conducted to develop the

construction of wind turbine thus produces the

optimum electrical power. The construction

development that has been carried out is by varying

the shape of blade, angle of blade, number of blades,

staging blade, shield, and deflector. Therefore, there

are many types of blades of this turbine, such as type

U that is the conventional type, type L, twisted blade,

a

https://orcid.org/0000-0002-0298-4627

b

https://orcid.org/0000-0003-2544-7151

c

https://orcid.org/0000-0003-4659-0029

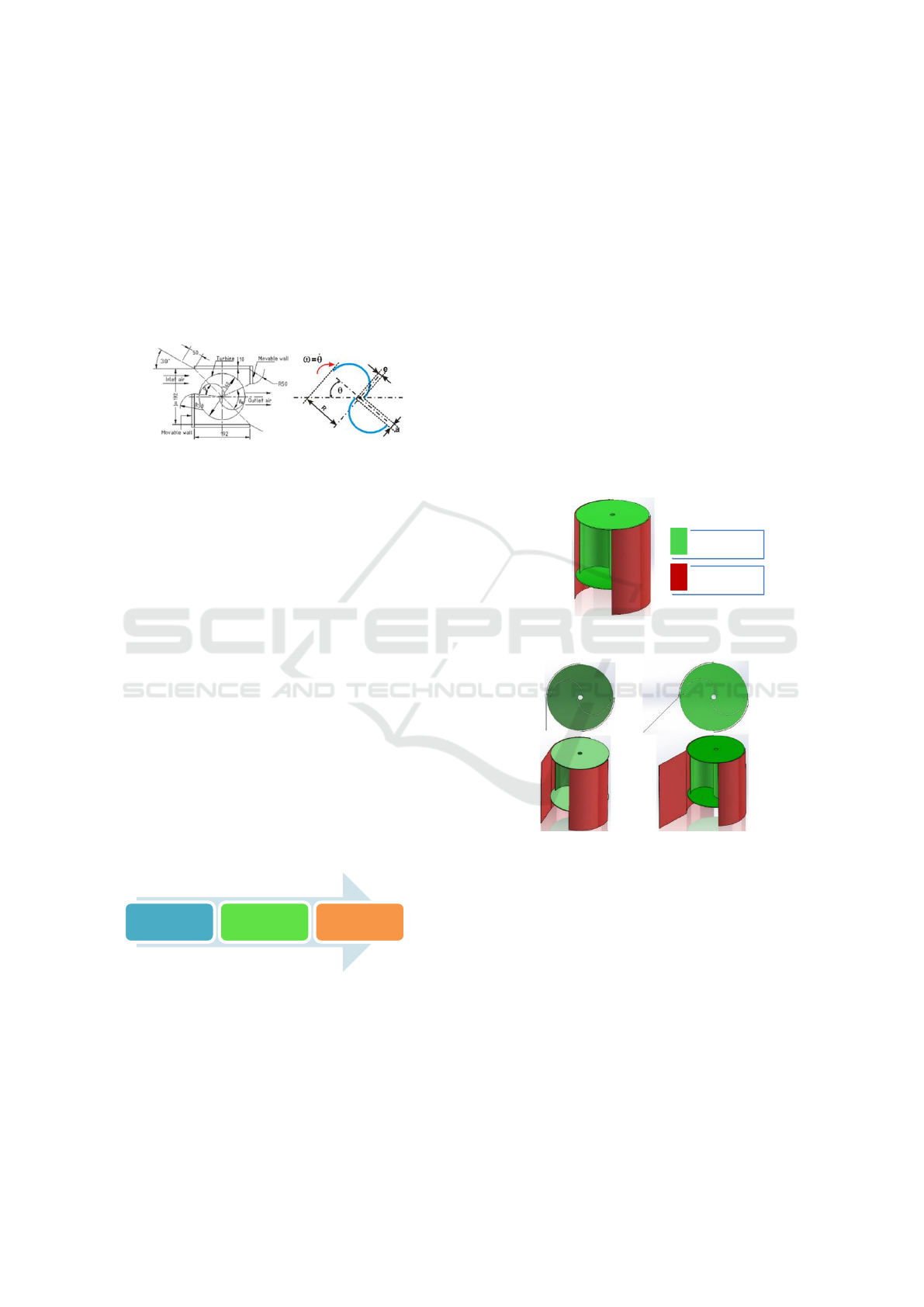

Figure 1: Relation between Cp and TSR.

multistage blade, or various radius and width of the

arc.

There are some methods to increase the

performance of the Savonius U-type wind turbine.

One of which is by applying guide-box tunnel, that

can be seen in Figure 2(a), as wind deflector to

prevent returning blade. By using this type, Cp can

increase until 50% for three blades but the

Canra, D., Luthfi, M., Sumiati, R. and Adriansyah, .

Experimental Study of Circular Tunnel of Vertical Axis Wind Turbine of Savonius Type-U.

DOI: 10.5220/0011758500003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 263-270

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

263

disadvantage of this type is its complex construction.

The sixth method is by modifying the blade by

applying geometrical parameter value difference,

such as overlap and angle between blades as can be

seen in Figure 2(b). This can increase the Cp value up

to 60% dan producing high vibration (Mohamed

Hasan A. M, 2011). The sixth method is always used

to design the turbine blade because it is proven to

increase Cp more significantly than the conventional

blade design (Delffika Canra. et al, 2018).

(a) (b)

Figure 2: (a) Guide-box tunnel (b) Overlap geometri rotor

Author tried to optimize the use of shield

construction (guided-box tunnel) by making the

variation of circular shape. By using this method, it is

intended to increase the Cp and torque value on the

wind blade. This tunnel construction can guide the

wind to the surface of the blade and prevent the wind

to push the returning blade. By guiding wind to the

blade that is dragged can increase turbine power

proportional to the torque value. Therefore, the aim

of this research is to find Cp and torque value of

deconstructed Savonius wind blade type U using

circular tunnel.

2 RESEARCH METHODS AND

PREPARATION

The research method that is used, is experiment with

the steps are explained in Figure 3.

Figure 3: Research flow.

The first step was designing prototype model by

using CAD software to produce design model and

drawing. The drawing is used to make the prototype

(wind turbine). The designed rotor is a savonius type

-U of 2 blade rotor. The dimensions of the rotor are

designed to be smaller than the previous research

which has the diameter of savonius rotor of 250 mm

and an aspect ratio of 1: 1. Circular tunnel dimensions

was slightly widened, with the diameter of 270 mm

and height of 400 mm as shown in Figure 4.

This circular tunnel was varied by applying guide

on the inlet of the wind as seen in Figure 5. There was

variation of guide angle by 0° and 45°. By applying

this guide, it was intended to increase the wind power

to rotate the wind turbine.

Wind tunnel was prepared with the dimension of

750 mm x 20 mm x 250 mm and equipped with

honeycomb inside. The function of honeycomb is to

guide the wind to be homogeneous in one direction.

The material of the rotor that was used was

aluminium due to its lightness and ease of formation

and fabrication. Meanwhile, the material of the

Circular Tunnel was the steel plate with the thickness

of 1 mm.

Figure 4: Design of Rotor and Circular tunnel.

(a) (b)

Figure 5: Variation of Design of Circular tunnel (a) guide

of inlet 0

0

(b) guide of inlet 45

0

.

Prototype design and research was done in the

laboratory of Mechanical Engineering Department of

Polindra while the turbine was manufactured in the

workshop of Mechanical Engineering Department of

Polindra. The process was then continued to the data

retrieval. The wind speed used for this research was

4-9 m/s with the resolution of 0,5 m/s by using Axial

Blower Fan. The wind speed was measured when the

wind flowed through and exited from the rotor by

using anemometer. The other required data was the

rotational speed of rotor by using tachometer.

Meanwhile, to know the produced torque, load

prototype

production

data retrieval

data processing

and analysis

Rotor

Circular Tunnel

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

264

addition to the rotor system was needed and the load

was measured by using small weight scale as can be

seen in Figure 6.

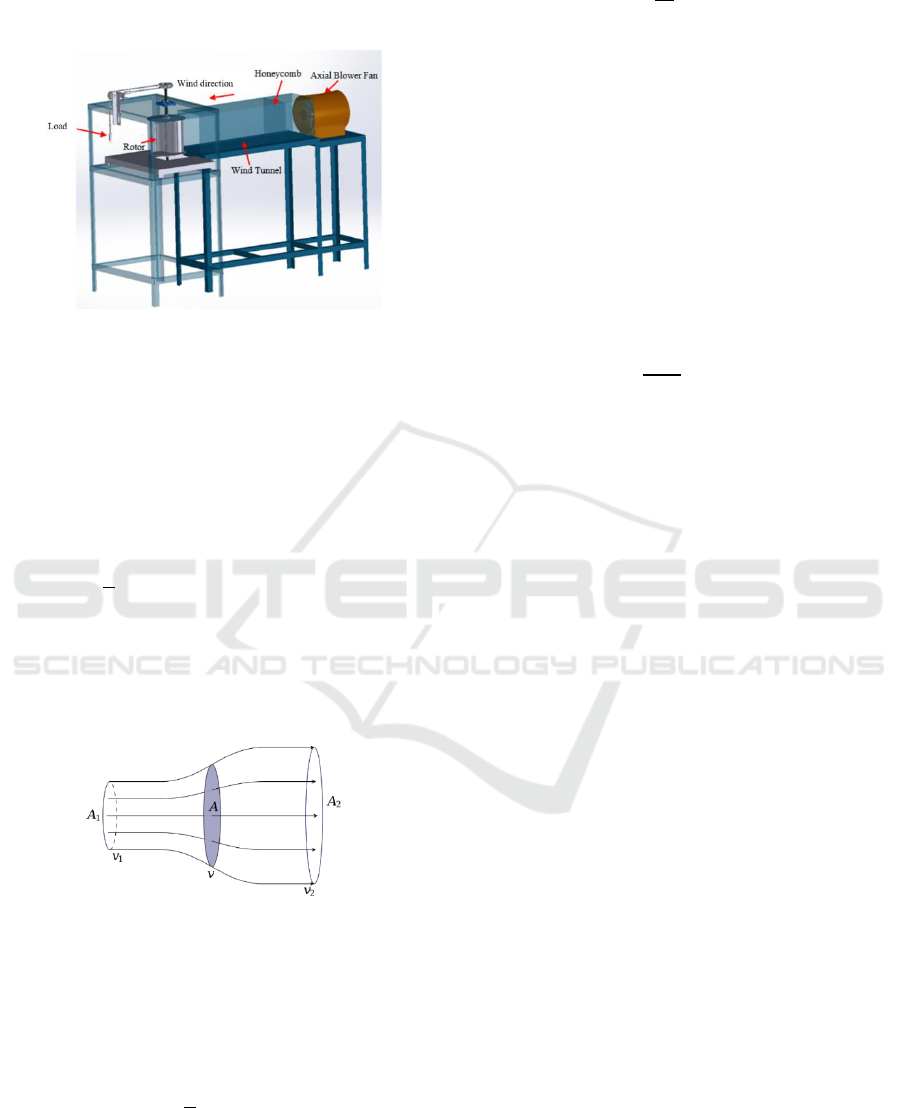

Figure 6: Prototype Design.

The collected data then were processed according

to the basic theory of wind turbine, such as turbine

power calculation, wind power and the produced

torque. By using Betz momentum theory in which the

wind speed v

1

flowing through the turbine blades

experiences the speed change of v

2

, the mechanical

power then could be calculated by using the following

formula.

(1)

Where: P = turbine mechanical power (W)

= density of wind (kg/m

3

)

A = sweep area (m

2

)

v = velocity of wind (m/s)

Figure 7: Change of wind speed after flowing through the

turbine blade.

The Cp defines the performance of the wind

turbine and the wind power defines the amount of

kinetic power of the wind that flow through the wind

turbine blade and can be formulated by

(2)

where

= wind power (W)

Therefore, the Cp of the turbine was calculated by

(3)

Calculating the amount of torque is also

important. Torque can be defined as the measure of

force effectiveness to produce the rotation around the

axis. The amount of torque can be formulated by

(4)

Where : T = Torque (Nm)

m = mass (kg)

r = radius of pulley (m)

g = gravitation (m/s

2

)

Meanwhile the tip speed ratio can be calculated by

(5)

Where : D = diameter of blade (m)

v = velocity of wind (m/s)

n = blade rotation speed (rpm)

3 RESULT AND DISCUSSION

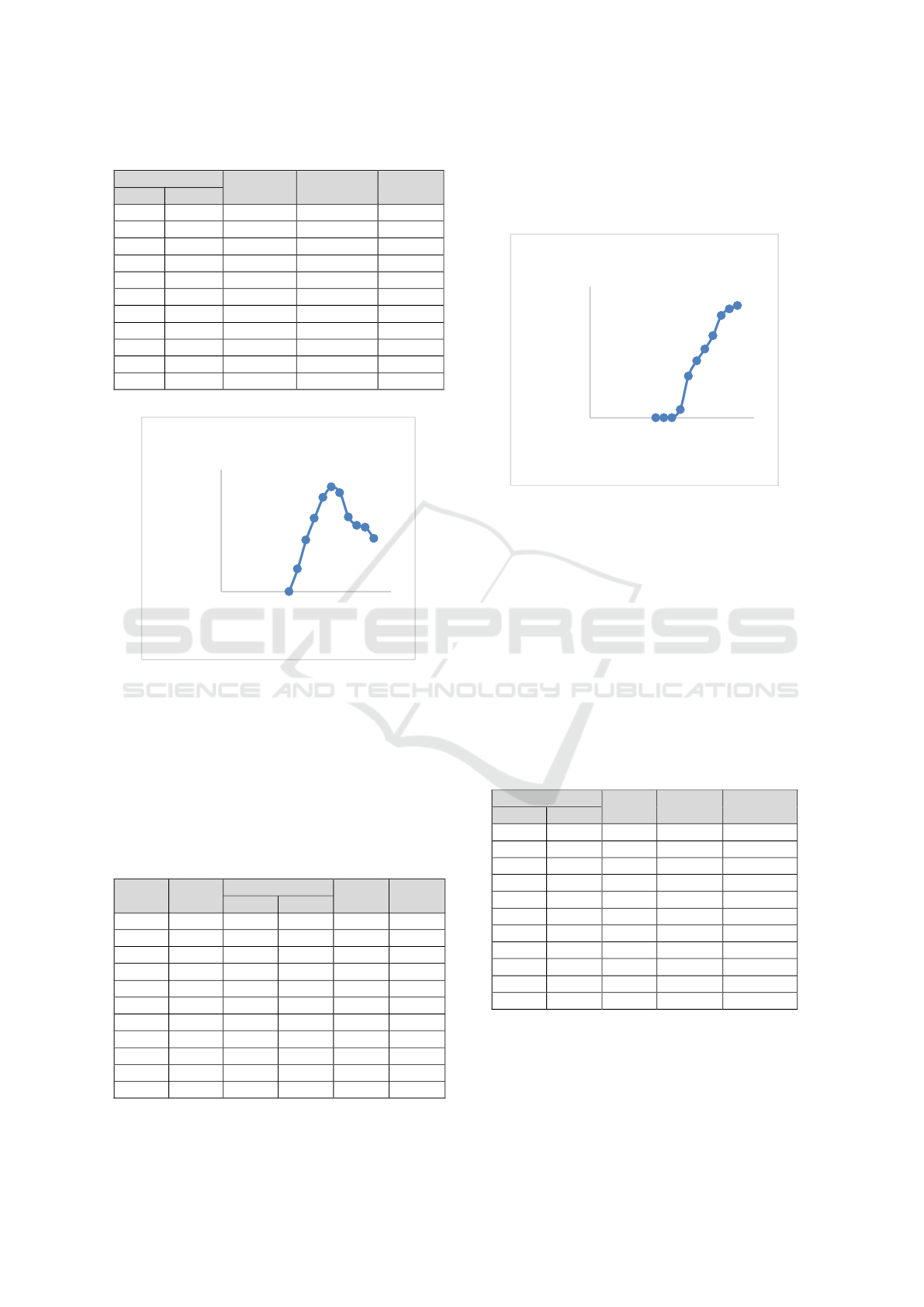

3.1 Experiment-1 (E-1): Rotor Without

Circular Tunnel

The first experiment is testing the turbine withour

using the circular tunnel. The result of data processing

of turbine power, wind power and Coefficient of

Power can be represented in Table 1 and Figure 8,

where the author used Equation 1.

The highest Coefficient of power (Cp) was

obtained at the wind speed of 6,5 m/s. After that, the

Cp decreases as the wind speed increases.

The construction ratio of 1:1 caused the Cp value

lower than that of the construction ratio of 1:4. This

is proven by the highest Cp value that was obtained

was 0,1031. The typical Cp value of Savonius Type

C is usually up to 0,3 (Mohamed Hasan A. M, 2011).

However, in this research, the author focused on the

difference of Cp value in the utilization of circular

tunnel.

Experimental Study of Circular Tunnel of Vertical Axis Wind Turbine of Savonius Type-U

265

Table 1: Data Processing Result of Cp (E-1).

v [m/s]

P

[watt]

P

0

[watt]

Cp

1 (in)

2 (out)

9

6,8

1,5414

29,3878

0,0524

8,5

6,2

1,5674

24,7569

0,0633

8

5,8

1,3463

20,6400

0,0652

7,5

5,3

1,2487

17,0068

0,0734

7

4,6

1,3468

13,8272

0,0974

6,5

4,2

1,1409

11,0708

0,1031

6

4

0,8063

8,7075

0,0926

5,5

3,9

0,4850

6,7070

0,0723

5

3,8

0,2554

5,0391

0,0507

4,5

3,8

0,0820

3,6735

0,0223

4

0

0,0000

2,8500

0,0000

Figure 8: The Graph of the Relation between v

1

and Cp (E-

1).

By using equation 4 and 5, the author processes

the data of wind speed, rotational speed of rotor, and

the given load to the system. The result of this was the

torque value (T) and Tip Speed Ratio (λ) that can be

seen in Table 2 and Figure 9.

Table 2: Result of Data Processing of Torque and TSR (E-

1).

v

1

[m/s]

n

[rpm]

m [kg]

T

[Nm]

λ

(TSR)

m

1

m

2

9

580

0,725

0,39

0,1027

0,9443

8,5

530

0,68

0,355

0,0996

0,9137

8

490

0,645

0,34

0,0935

0,8975

7,5

440

0,545

0,3

0,0751

0,8597

7

359

0,485

0,28

0,0628

0,7515

6,5

280

0,41

0,24

0,0521

0,6312

6

180

0,295

0,17

0,0383

0,4396

5,5

105

0,155

0,13

0,0077

0,2797

5

75

0,07

0,07

0,0000

0,2198

4,5

50

0

0

0,0000

0,1628

4

0

0

0

0,0000

0,0000

The resulted torque increased proportionally as

the inlet wind speed increased, and inversely related

to the increase of Cp. This concluded that the torque

was not affected by Cp.

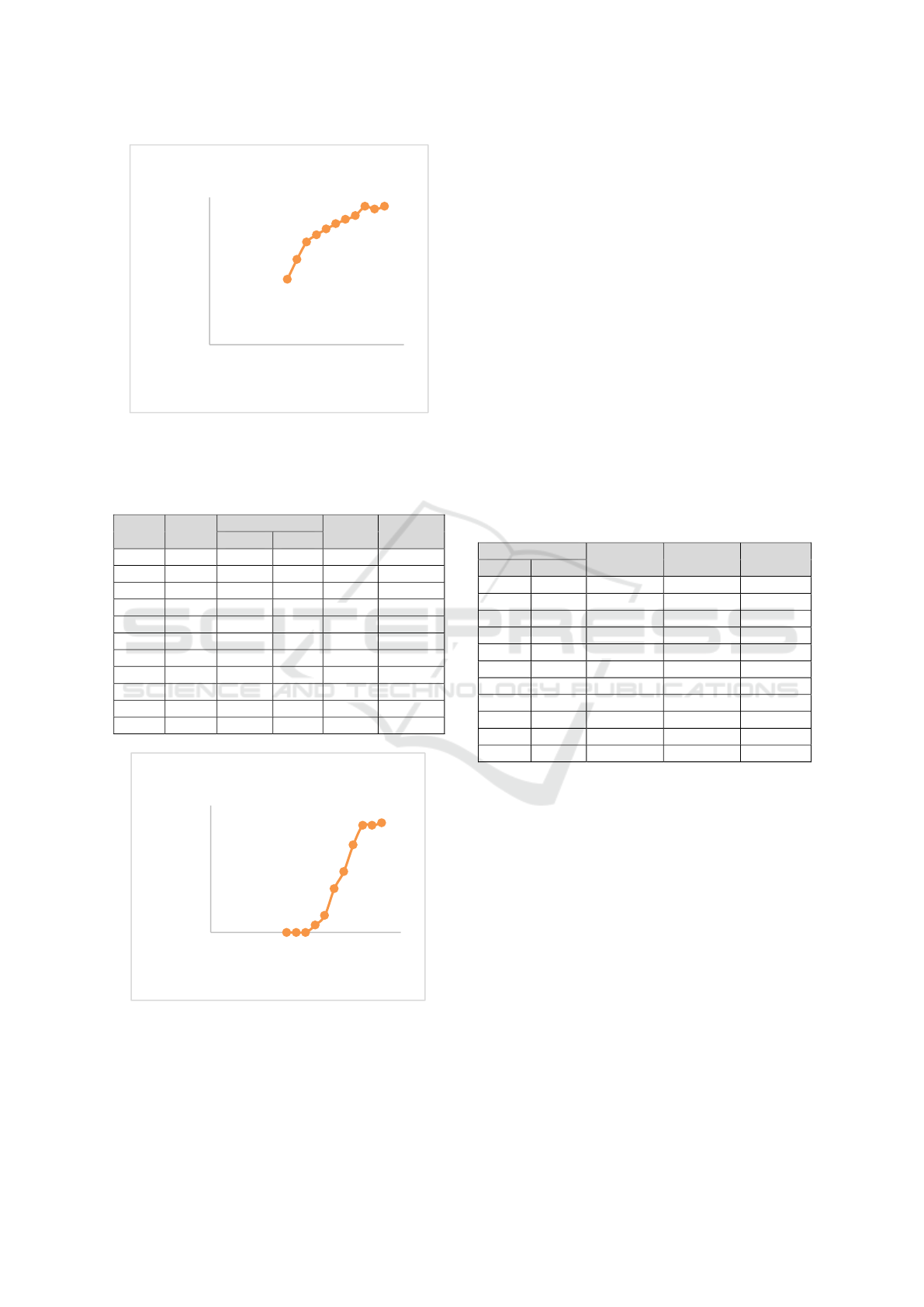

Figure 9: The Graph of the Relation between v

1

and T (E-

1).

The data of the first experiment became the

comparison value to the next experiment.

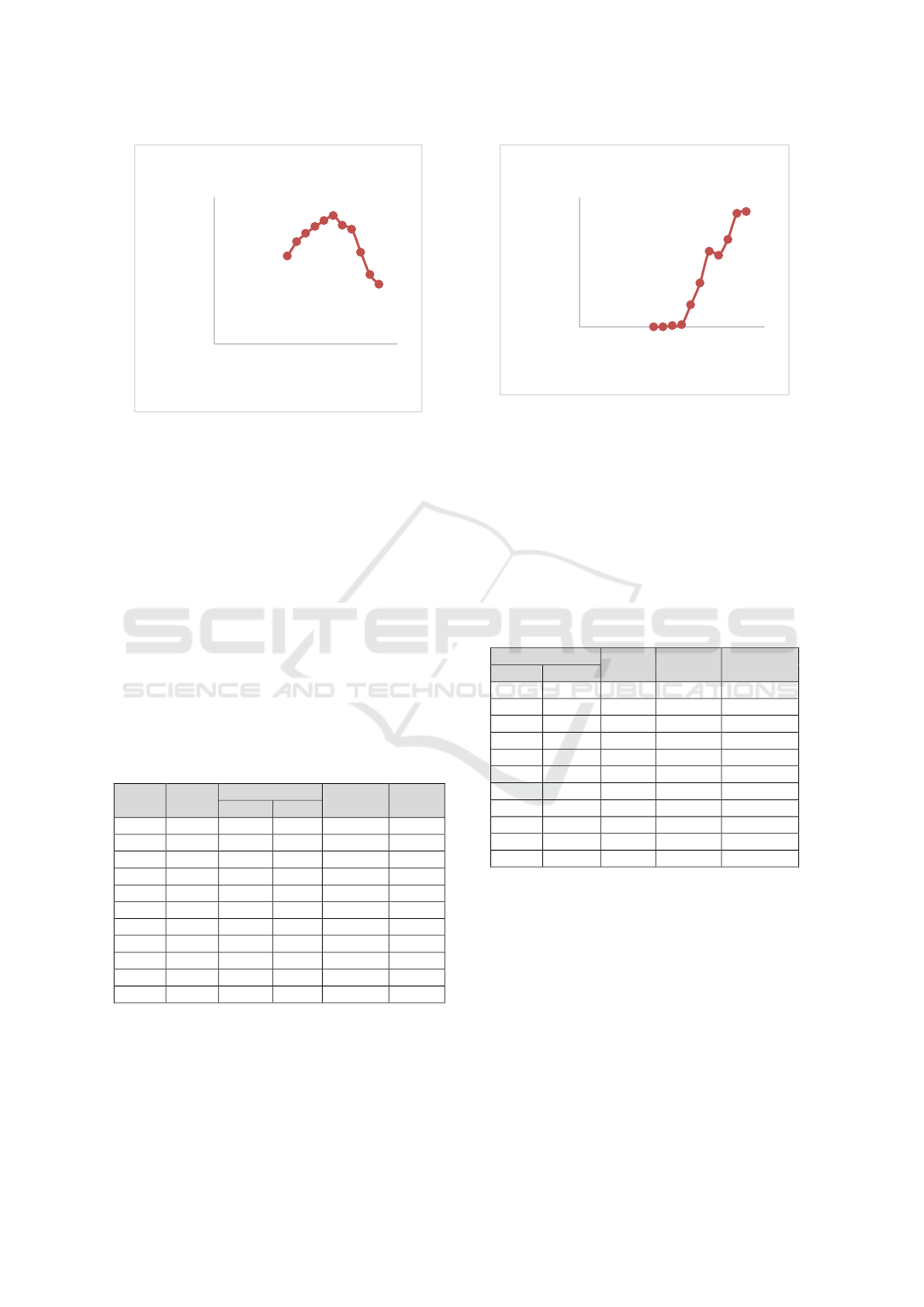

3.2 Experiment-2 (E-2): Rotor with

Circular Tunnel

The second experiment was the turbine simulation

with circular tunnel. The result of data processing of

turbine power, wind power, and Cp can be

represented on Table 3 and Figure 10, where the

equation 1,2, and 3 were used.

Table 3: Data Processing Result of Cp (E-2).

v [m/s]

P

[watt]

P

0

[watt]

Cp

1 (in)

2 (out)

9

5,5

1,7901

14,6939

0,1218

8,5

4,9

1,7502

12,3785

0,1414

8

4

1,9350

10,3200

0,1875

7,5

3,2

1,9939

8,5034

0,2345

7

2,9

1,6772

6,9136

0,2426

6,5

2,5

1,4513

5,5354

0,2622

6

2,4

1,0971

4,3538

0,2520

5,5

2,3

0,8050

3,3535

0,2400

5

2,2

0,5689

2,5195

0,2258

4,5

2,1

0,3831

1,8367

0,2086

4

2,05

0,2318

1,2900

0,1797

The trend of the graph line was not significantly

different from the first experiment, but the highest Cp

value increased by three times at the wind speed of

6,5 m/s. From this data, it could be proven that the

circular tunnel could increase the Cp of turbine.

0

0,02

0,04

0,06

0,08

0,1

0,12

0 2 4 6 8 10

Coefficient of power

(Cp)

Wind-in (V

1

)[m/s]

V

1

vs Cp

0

0,02

0,04

0,06

0,08

0,1

0,12

0 2 4 6 8 10

Torque (T) [Nm]

Wind-in (V

1

)[m/s]

V

1

vs T

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

266

Figure 10: The Graph of the Relation between v

1

and Cp (E-

2).

Torque (T) dan Tip Speed Ratio (λ) result can be

seen in Table 4 and Figure 11. The result of data

processing of wind speed, rotational speed of rotor,

and the given load to the system used Equation 4 and

5.

The second experiment shows that the torque

value increased as the wind speed increased which

was identical with the first experiment. The torque

decreased compared tto the first experiment at the

same wind speed though. This could be caused by the

decrease of wind volume flowing through the turbine

and it was suspected that there was turbulence around

zje circular tunnel plate thus the rotational speed of

rotor decreased dramatically.

Table 4 : Result of Data Processing of Torque and TSR (E-

2).

v

1

[m/s]

n

[rpm]

m [kg]

T

[Nm]

λ

(TSR)

m

1

m

2

9

230

0,5

0,275

0,0690

0,3745

8,5

223

0,475

0,255

0,0674

0,3844

8

206

0,44

0,22

0,0674

0,3773

7,5

188

0,395

0,215

0,0552

0,3673

7

169

0,33

0,205

0,0383

0,3538

6,5

139

0,25

0,16

0,0276

0,3134

6

95

0,155

0,12

0,0107

0,2320

5,5

75

0,08

0,065

0,0046

0,1998

5

63

0

0

0,0000

0,1846

4,5

40

0

0

0,0000

0,1303

4

23

0

0

0,0000

0,0843

Figure 11: The Graph of the Relation between v

1

and T (E-

2).

3.3 Experiment-3 (E-3): Rotor with

Circular Tunnel Inlet 0

0

The third experiment was the turbine simulation with

circular tunnel inlet 0°. The result of data processing

of turbine power, wind power, and Cp can be

represented on Table 5 and Figure 12, where the

equation 1,2, and 3 were used.

Table 5: Data Processing Result of Cp (E-3).

v [m/s]

P

[watt]

P

0

[watt]

Cp

1 (in)

2 (out)

9

4,5

2,7551

14,6939

0,1875

8,5

4,3

2,2756

12,3785

0,1838

8

4

1,9350

10,3200

0,1875

7,5

3,9

1,4890

8,5034

0,1751

7

3,7

1,1743

6,9136

0,1699

6,5

3,5

0,9070

5,5354

0,1639

6

3,3

0,6833

4,3538

0,1569

5,5

3,1

0,4992

3,3535

0,1489

5

2,9

0,3511

2,5195

0,1394

4,5

2,8

0,2126

1,8367

0,1158

4

2,7

0,1141

1,2900

0,0885

Circular tunnel with inlet 0° resulted in the Cp up

to 0,1875 at wind speed of 9 m/s and the trend

increased as the wind speed increased. During the

data collection at simulated turbine, there was indeed

the turbulence that caused the decrease of turbine

power and wind power compared to the second

experiment.

Looking at Figure 12, the Cp increased as the

wind speed increased and there was no decrease sign.

The was possibility that the Cp peak was not reached.

Due to the limitation of axial fan blower, the data

collection could not be proceed further.

0

0,05

0,1

0,15

0,2

0,25

0,3

0 2 4 6 8 10

Coefficient of power

(Cp)

Wind-in (V

1

)[m/s]

V

1

vs Cp

0

0,02

0,04

0,06

0,08

0,1

0 2 4 6 8 10

Torque (T) [Nm]

Wind-in (V

1

)[m/s]

V

1

vs T

Experimental Study of Circular Tunnel of Vertical Axis Wind Turbine of Savonius Type-U

267

Figure 12: The Graph of the Relation between v

1

and Cp (E-

3).

Table 6: Result of Data Processing of Torque and TSR (E-

3).

v

1

[m/s]

n

[rpm]

m [kg]

T

[Nm]

λ

(TSR)

m

1

m

2

9

230

0,5

0,275

0,0690

0,3745

8,5

223

0,475

0,255

0,0674

0,3844

8

206

0,44

0,22

0,0674

0,3773

7,5

188

0,395

0,215

0,0552

0,3673

7

169

0,33

0,205

0,0383

0,3538

6,5

139

0,25

0,16

0,0276

0,3134

6

95

0,155

0,12

0,0107

0,2320

5,5

75

0,08

0,065

0,0046

0,1998

5

63

0

0

0,0000

0,1846

4,5

40

0

0

0,0000

0,1303

4

23

0

0

0,0000

0,0843

Figure 13: The Graph of the Relation between v

1

and T (E-

3).

The third experiment shows that the torque value

increased as the wind speed increased that can be seen

in Figure 13 and was identical with the first and

second experiment. The highest torque value that was

obtained was 0,0690 at the wind speed of 9 m/s that

can be seen in Table 6. The torque decreased

compared to the first experiment at the same wind

speed but equivalent to the torque value of second

experiment.

The resulted torque value of the third experiment was

insignificantly different from that of the second

experiment. By adding the guide of inlet 0°, it caused

more turbulence but did not affect the torque much.

3.4 Experiment-4 (E-4): Rotor with

Circular Tunnel Inlet 45

0

The fourth experiment was the simulation of turbine

by using circular tunnel with inlet 45°. The result of

data processing of turbine power, wind power, and Cp

can be represented on Table 7 and Figure 14, where

the equation 1,2, and 3 were used.

Table 7: Data Processing Result of Cp (E-4).

v [m/s]

P

[watt]

P

0

[watt]

Cp

1 (in)

2 (out)

9

5,3

1,9730

14,6939

0,1343

8,5

5,1

1,5844

12,3785

0,1280

8

4,9

1,2494

10,3200

0,1211

7,5

4,6

1,0256

8,5034

0,1206

7

4,3

0,8302

6,9136

0,1201

6,5

4,1

0,6153

5,5354

0,1112

6

3,8

0,4780

4,3538

0,1098

5,5

3,5

0,3628

3,3535

0,1082

5

3,2

0,2678

2,5195

0,1063

4,5

2,9

0,1909

1,8367

0,1039

4

2,6

0,1304

1,2900

0,1011

Circular tunnel with inlet 45° resulted in the Cp

up to 0,1343 at wind speed of 9 m/s and the trend

increased as the wind speed increased as seen in

Figure 14. This Cp was lower than that of the third

experiment. The same case might occur as the third

experiment that there was much turbulence causing

the decrease of turbine power and wind power.

The result of the fourth experiment was identical

with the third experiment. However, there was

decrease of Cp in the fourth experiment the

experiment cannot be conducted further due to the

limitation of the experiment apparatus.

0

0,05

0,1

0,15

0,2

0 2 4 6 8 10

Coefficient of power

(Cp)

Wind-in (V

1

)[m/s]

V

1

vs Cp

0

0,02

0,04

0,06

0,08

0 2 4 6 8 10

Torque (T) [Nm]

Wind-in (V

1

)[m/s]

V

1

vs T

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

268

Figure 14: The Graph of the Relation between v

1

and Cp (E-

4).

Because the fourth experiment was identical to the

third experiment, the torque value was thus not

different much. The highest torque was 0,0797 at the

maximum wind speed of 9 m/s as seen in Table 8.

This proves that the addition of inlet, either inlet 0° or

inlet 45°, did not affect the torque value even though

the turbulence increased a little.

Table 8: Result of Data Processing of Torque and TSR (E-

4).

v

1

[m/s]

n

[rpm]

m [kg]

T

[Nm]

λ

(TSR)

m

1

m

2

9

290

0,545

0,285

0,0797

0,4722

8,5

250

0,49

0,265

0,0690

0,4310

8

225

0,465

0,24

0,0690

0,4121

7,5

200

0,405

0,2

0,0628

0,3908

7

172

0,345

0,17

0,0536

0,3601

6,5

147

0,325

0,165

0,0491

0,3314

6

115

0,25

0,15

0,0307

0,2809

5,5

96

0,13

0,08

0,0153

0,2558

5

70

0

0

0,0000

0,2051

4,5

52

0

0

0,0000

0,1693

4

32

0

0

0,0000

0,1172

Figure 15 shows the same case as the previous

experiment. There was no significant difference

between them. The torque value increased as the wind

speed increased.

Figure 15: The Graph of the Relation between v

1

and T (E-

4).

3.5 Comparison of all Experiment

Results

As can be represented by Figure 16, the highest Cp

value was obtained in the second experiment by

0,2622 at the wind speed 6,5 m/s while the Cp of

0,1031 was obtained at the same wind speed in the

first experiment. This differed from the third

experiment, where the highest Cp were 0,1875 and

0,1343 respectively.

Figure 16: The Graph of the Relation between v

1

and Cp.

0

0,02

0,04

0,06

0,08

0,1

0,12

0,14

0,16

0 2 4 6 8 10

Coefficient of power

(Cp)

Wind-in (V

1

)[m/s]

V

1

vs Cp

0

0,02

0,04

0,06

0,08

0,1

0 2 4 6 8 10

Torque (T) [Nm]

Wind-in (V

1

)[m/s]

V

1

vs T

0

0,05

0,1

0,15

0,2

0,25

0,3

0 2 4 6 8 10

Coefficient of power

(Cp)

Wind-in (V

1

)[m/s]

V

1

vs Cp

E-1 E-2 E-3 E-4

Experimental Study of Circular Tunnel of Vertical Axis Wind Turbine of Savonius Type-U

269

Figure 17: The Graph of the Relation between v

1

and T.

Figure 18: The Graph of the Relation between λ and Cp.

The torque value in all experiment increased as

the wind speed increased but the highest torque was

obtained in the first experiment as seen in Figure 17.

In the second until the fourth experiment, there was

decrease of torque compared to the first experiment

but this was not significant. This was suspected that

the cause of this was circular tunnel.

Looking at the comparison graph of Cp and TSR

in Figure 18, only the first and second experiment that

had the typical Savonius wind turbine graph

characteristic in general. Meanwhile, in the third and

fourth experiment, there was still possibility of

increase then decrease of value until the TSR reached

1 or more.

4 CONCLUSION

From the result of all experiment, it can be concluded

that the use of circular tunnel affects the Cp increase,

especially in the second experiment, where there was

increase of value of Cp by 2,5 times of the value of

Cp in the first experiment, which was 0,2622 at the

wind speed of 6 m/s. The same case occurred in the

third and fourth experiment, that the obtained Cp was

higher than the Cp in the first experiment by 1,8 and

1,3 times respectively. Another word that Cp with

circular tunnel increase 2,5 times of the value Cp

without circular tunnel.

Meanwhile, the addition of circular tunnel caused

the decrease of torque value even though it was not

significant.

REFERENCES

Ahmad Farid, 2014, " Optimasi Daya Turbin Angin

Savonius dengan Variasi Celah dan Perubahan Jumlah

Sudu", Prosiding SNST ke-5, Fakultas Teknik

Universitas Wahid Hasyim Semarang, ISBN 978-602-

99334-3-7

Burcin Deda A. 2008. “An Experimental study on

improvement of a savonius rotor performance with

curtaining.” Experimental Thermal and Fluid Science.;

l (32) : 1637-1678.

Delffika Canra. dkk, 2018, “ Analisa Aliran Angin Pada

Sudu Turbin Angin Savonius Tipe-U Berbasis Software

“, Jurnal Teknologi Terapan Vol. 4, No. 2, Politeknik

Negeri Indramayu, 2018.

Delffika Canra. dkk, 2019, “ Pengaruh Busur Sudu Turbin

Angin Savonius Tipe-U Menggunakan Perangkat

Lunak “, Jurnal Simetris Vol. 10, No. 1, Universitas

Muria Kudus, 2019

Delffika Canra. dkk, 2021, “ Kaji Eksperimental Turbin

Angin Hybrid Savonius-Darrieus Eggbeater Bertingkat

Banyak “, Prosiding IRWNS ke-12, Politeknik Negeri

Bandung, 2021

M. Haydarul H. dkk, 2013, "Rancang Bangun Turbin Angin

Vertikal Jenis Savonius dengan Variasi Jumlah Blade

Terintegrasi Circular Shield untuk Memperoleh Daya

Maksimum", Jurnal Teknik POMITS Vol. 7, No.7 ,

(2013) 1-6

Mohamed Hasan A. M, 2011, "Design Optimazation of

Savonius and Wells Turbines", Desertation University

of Magdeburg

Nakhoda Y.I.. 2015. “Rancang Bangun Kincir Angin

Sumbu Vertikal Pembangkit Tenaga Listrik Portabel.”

Seminar Nasional Sains dan Teknologi Terapan.; l (3) :

59-67. Institut Teknologi Adhi Tama Surabaya.

D.S.Hasan, dkk., 2013 “Studi Eksperimental Vertical Axis

Wind Turbine Tipe Savonius dengan Variasi Jumlah

Fin pada Sudu,” Jurnal Teknik Pomits, vol. 2 no. 2, pp

B-350-B-355, 2013.

White F.M. Mekanika Fluida. Jilid 3. Edisi Kedua. Penerbit

Erlangga, Jakarta. 2005

0

0,02

0,04

0,06

0,08

0,1

0,12

0 2 4 6 8 10

Torque (T) [Nm]

Wind-in (V

1

)[m/s]

V

1

vs T

E-1 E-2 E-3 E-4

0

0,1

0,2

0,3

0 0,5 1

Coefficient of power

(Cp)

Tip Speed Ratio (λ)

λ vs Cp

E-1 E-2 E-3 E-4

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

270