Study of Refrigerator Performance Through Variation of Capiler

Pipe Length

Jufra D. J. Abanat, Jhon Arnoldos Wabang and Edwin P. D. Hattu

Machine Engineering, State Polytechnics of Kupang, Adisucipto Street, Kupang, Indonesia

Keywords: Cooling System, Capillarity Tube.

Abstract: In the cooling system (AC), there are a series of main components to support the working system, namely the

compressor, condenser, filter drayer, capillary pipe or expansion valve and evaporator. The five components

of concern in this study are the capillary tube. The function of the capillary tube is to lower the pressure and

lower the temperature of the system. The results showed that the performance of the refrigerator with length

of capillary pipe 150 cm, diameter 0.031 inch, Coeficient of Performance (COP) was 3.28, Refrigeration

Efficiency 86.47%, refrigeration effect 130.17 kJ/kg. and pressure ratio 6,22. For refrigerator with length of

capillary pipe 200 cm, diameter 0.031 inch, Coeficient of Performance (COP) was 3.41, Refrigeration

Efficiency 79.68%, refrigeration effect 128.66 kJ/kg. and pressure ratio 6,33. In refrigerator with length of

capillary pipe 250 cm, diameter 0.031 inch, Coeficient of Performance (COP) was 3.25, Refrigeration

Efficiency 77.27%, refrigeration effect 127.02 kJ/kg. and pressure ratio 6,77. Based on the results of the

analysis of the three types of capillary pipes, capillaries with a length of 150 mm have better performance

than the other two types of capillary pipes.

1 INTRODUCTION

Air conditioning is a condition that continues to be a

concern because this system is needed in almost all

fields, therefore the application of components that

can work effectively and efficiently continues to be

researched in order to get an AC working system that

can provide comfort for users in their daily activities

all day and every where (Anwar et al., 2010).

In the cooling system, a series of main

components to support the working system, namely

the compressor, condenser, filter drayer, expansion

valve or capillary tube and evaporator.The five

components that are of concern in this study are the

variation of length of capillary tube. this is due to the

difference that there are several refrigerators that have

capillary pipe sizes that are not the same length

(Anwar, 2010); (Bowo, 2013).

In this study using variations of three types of pipe

lengths, namely capillary pipes with a length of 150

mm, 200 mm and 250 mm respectively with the same

diameter, namely 0.031 inchi.

These three types of capillary tube will be tested

using the refrigerators. The refrigerant material used

is refrigerant (R234a) (Wang et al., 2017). The basis

for choosing this material is because the refrigerators

compressor is only suitable for using R134a.

The test model used is to vary the three types of

capillary tube to determine the performance of the

system in the form of Coeficient of Performance

(COP), refrigeration effect, system efficiency and

pressure ratio (Wardika, 2018).

2 RESEARCH METHODOLOGY

This research was conducted in the Refrigeration

Engineering laboratory, with the set up as follows:

Figure 1: Set Up Experimental.

154

Abanat, J., Wabang, J. and Hattu, E.

Study of Refrigerator Performance Through Variation of Capiler Pipe Length.

DOI: 10.5220/0011729700003575

In Proceedings of the 5th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2022), pages 154-157

ISBN: 978-989-758-619-4; ISSN: 2975-8246

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

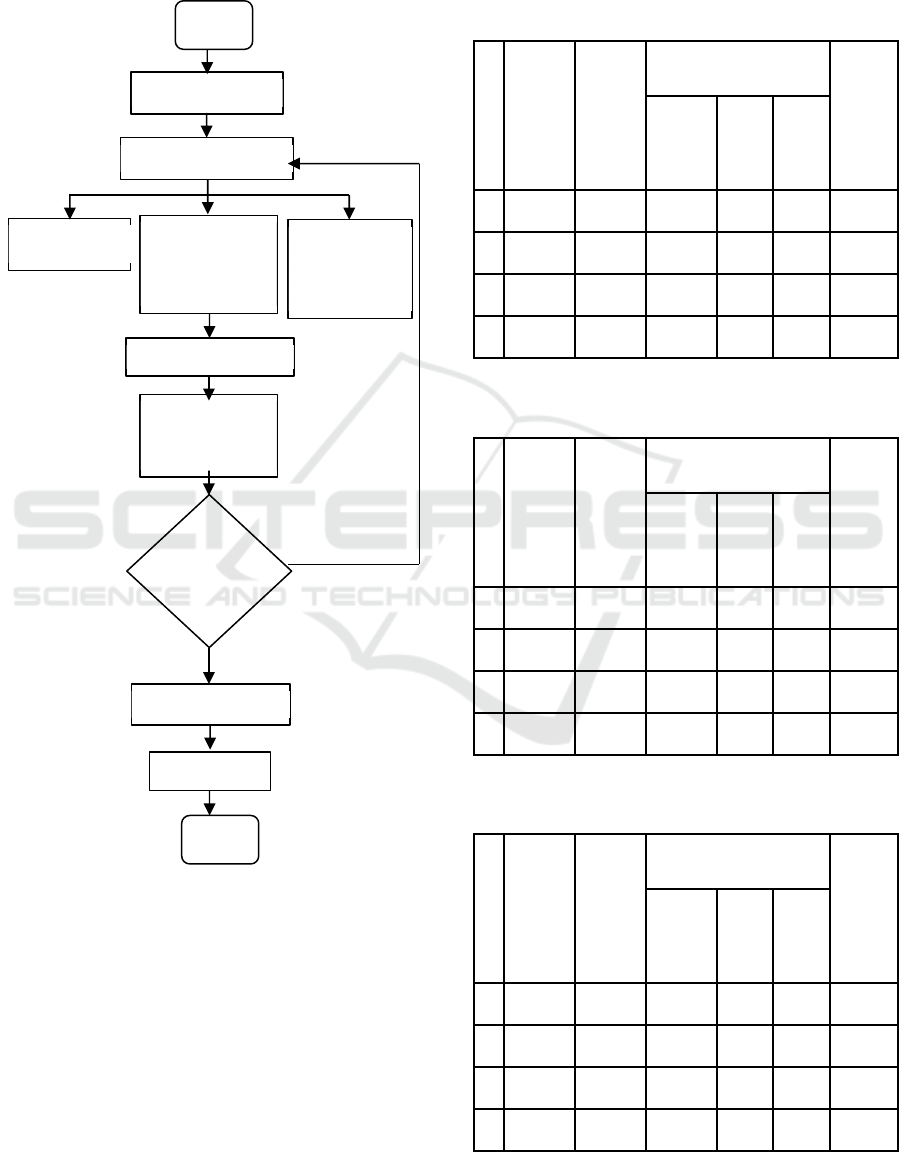

The implementation of this research followed the

flow chart as shown below in fig.2. From this set up

of experiments, a system test is performed with steps

such as the following flow chart:

Figure 2: Flow Charts.

3 RESULT AND DISCUSSION

3.1 Result

This test is carried out on a split AC with the

following specifications:

1. The mass of refrigerant = 40gr

2. Testing time = 120 Minutes

Based on the research flow, the test results of the three

type of length of capillary pipe can be seen in the

following table below :

Table 1: Test results for length of capillary pipe 150 cm,

diameter 0.031 inch.

No

Time

(Men

ute)

Mass

refrig

erant

(gr)

Temperature ( ᵒC )

Low

Press

ure

(psi)

Evap

orator

Con

den

ser

Env

iron

men

t

1

30 10 18,5 33,1 30,8 -10

2

30 20 16 34,2 31 0

3

30 30 -11,7 38,8 31,2 3

4

30 40 -13 42,5 31 9

Table 2: Test results for length of capillary pipe 200 cm,

diameter 0.031 inch.

No

Time

(Men

ute)

Mass

refrig

erant

(gr)

Temperature ( ᵒC )

Low

Press

ure

(psi)

Evap

orator

Con

den

ser

Env

iron

men

t

1

30 10 15,7 33,5 31 -6

2

30 20 -11,4 38 30,9 0

3

30 30 -16 42,1 30,9 5

4

30 40 -16,5 43,5 30,9 10

Table 3: Test results for length of capillary pipe 250 cm,

diameter 0.031 inch.

No

Time

(Men

ute)

Mass

refrig

erant

(gr)

Temperature ( ᵒC )

Low

Press

ure

(psi)

Evap

orator

Con

den

ser

Env

iron

men

t

1

30 10 13,1 33,8 30,7 -8

2

30 20 -6,2 36 30 -2

3

30 30 -18,5 42,6 30,5 5

4

30 40 -19 41,4 30,2 8

Start

System Check

Test Preparation

Refrigerant

R134a

Measuring

Instruments

(Pressure,

humidity,

Refrigerator

(includes

Variation in

length of

Refrigerant

Charging and

System

Vacuum S

y

stem

Test

Result

Data

Report

Data Analysis

End

Study of Refrigerator Performance Through Variation of Capiler Pipe Length

155

3.2 Discussion

The test results based on variations in the length of

the capillary tube in the table 1, table 2 and table 3

above can be calculated the performance of

refrigerator with R134a refrigerant as follows:

a. Length of capillary pipe 150 cm, diameter 0.031

inch.

Based on the test results in the table 1 above, it

appears that at minute 120 with a refrigerant mass of

40 gr, the evaporator temperature reaches a

temperature of -13 at a low pressure of 9 Psi.

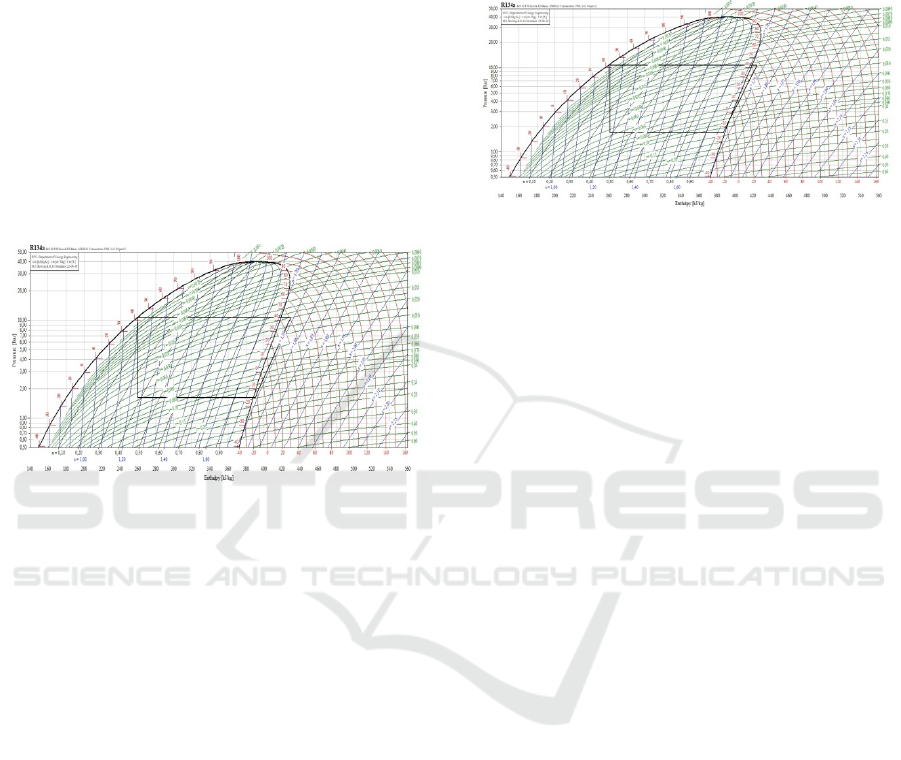

The data from this test, plotted in the coolpack

application, obtained a graph as shown in the figure

below:

Figure 3: Graph of p-h diagram for Length of capillary pipe

150 cm, diameter 0.031 inch.

The graph in this figure shows the enthalpy values as

follows:

h

1

= 390.09 kJ/kg h

3

= 259,92 kJ/kg

h

2

= 429,75 kJ/kg h

4

= 259,92 kJ/kg

The performance of the refrigerator based on the

eltalpy values is as follows:

1. Specific work by the Compressor (Q

w

).

39,66 kJ/kg

2. The heat is released by the condenser (q

k

)

169,83 kJ/kg

3. Refrigeration Effect (q

e

)

130,17 kJ/kg

4. Coeffisient Of Performance(COP)

a. COP

aktual

= 3,28

b. COP

carnot

= 3.79

5. Refrigeration Efficiency (η)

86,47%

6. Pressure Ratio:

6,22,

b. Length of capillary pipe 200 cm, diameter 0.031

inch.

The test results in the table 2 above, it appears that

at 120 minutes with a refrigerant mass of 40 g, the

evaporator temperature reaches a temperature of -

16.5 at a low pressure of 10 Psi.

The data from this test, plotted in the coolpack

application, obtained a graph as shown in the figure

below:

Figure 4: Graph of p-h diagram for Length of capillary pipe

200 cm, diameter 0.031 inch.

The graph in this figure shows the enthalpy values as

follows:

h

1

= 386,87 kJ/kg h

3

= 261,43 kJ/kg

h

2

= 424,64 kJ/kg h

4

= 261,43 kJ/kg

The performance of the refrigerator based on the

enthalpy values is as follows:

1. Specific work by the Compressor (Q

w

).

37,77 kJ/kg

2. The heat is released by the condenser (q

k

)

163,21 kJ/kg

3. Refrigeration Effect (q

e

)

128,66 kJ/kg

4. Coeffisient Of Performance(COP)

a. COP

aktual

= 3,41

b. COP

carnot

= 4.28

5. Refrigeration Efficiency (η)

79,68%

6. Pressure Ratio:

6,33

c. Length of capillary pipe 250 cm, diameter 0.031

inch.

In the table above, it appears that at minute 120 with

a refrigerant mass of 40 g, the evaporator temperature

reaches a temperature of -19 at a low pressure of 8

Psi.

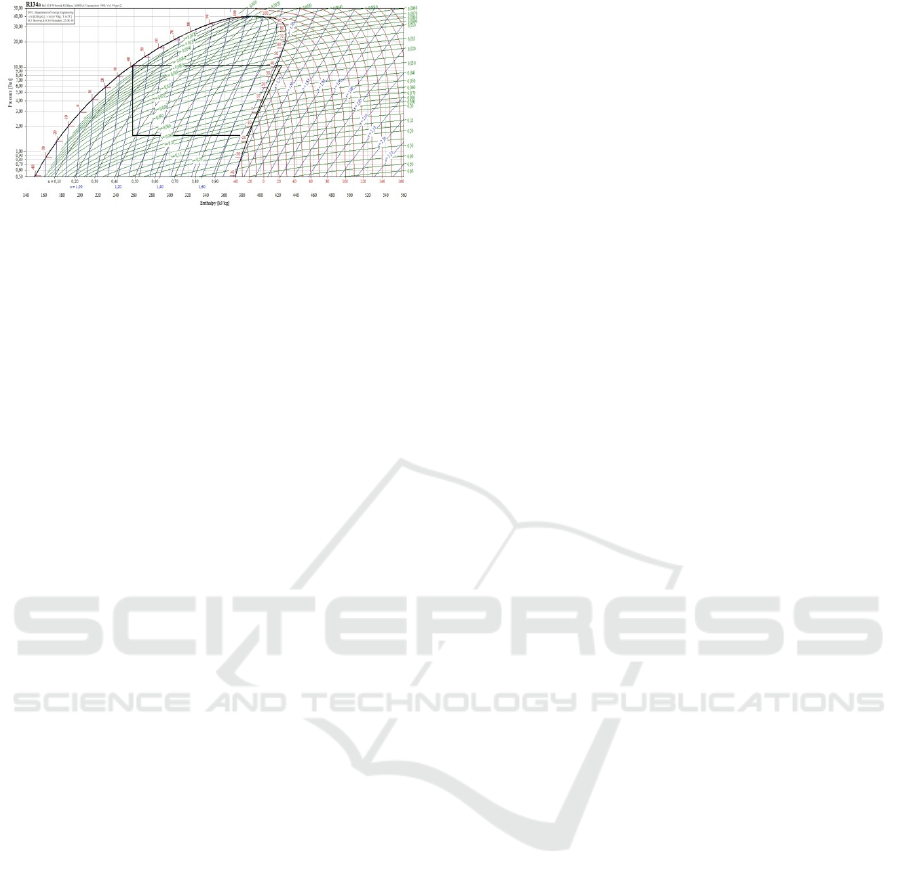

The data from this test, plotted in the coolpack

application, obtained a graph as shown in the image

below:

iCAST-ES 2022 - International Conference on Applied Science and Technology on Engineering Science

156

Figure 5: Graph of p-h diagram for Length of capillary pipe

250 cm, diameter 0.031 inch.

The graph in this figure shows the enthalpy values as

follows:

h

1

= 385,28 kJ/kg h

3

= 258,26 kJ/kg

h

2

= 424,37 kJ/kg h

4

= 258,26 kJ/kg

Refrigerator performance based on enthalpy values

are as follows:

1. Specific work by the Compressor (Q

w

).

39,09 kJ/kg

2. The heat is released by the condenser (q

k

)

166,38 kJ/kg

3. Refrigeration Effect (q

e

)

127,02 kJ/kg

4. Coeffisient Of Performance(COP)

a. COP

aktual

= 3.25

b. COP

carnot

= 4.21

5. Refrigeration Efficiency (η)

77,27%

6. Pressure Ratio :

6,77.

4 CONCLUSION

Based on the results of the study in table above, it can

be concluded as follows:

1. The results showed that the performance of the

length of capillary pipe 150 cm, diameter 0.031

inch, Coeficient of Performance (COP) was 3.28,

Refrigeration Efficiency 86.47%,, and

refrigeration effect 130.17 kJ/kg.

2. For length of capillary pipe 200 cm, diameter

0.031 inch, Coeficient of Performance (COP) was

3.41, Refrigeration Efficiency 79.68%,, and

refrigeration effect 128.66 kJ/kg.

3. In length of capillary pipe 250 cm, diameter 0.031

inch, the Coeficient of Performance (COP) is

3.25, Refrigeration Efficiency 77,27%, and

refrigeration effect 127,02 kJ/kg.

ACKNOWLEDGEMENTS

The authors would like to thank State Politeknik of

Kupang for the financial support through the RUTIN

Research Programme. A thank you also goes to

Wilmar Sagala for their help to record the values of

performance of refrigerator system based on variation

of length of capillary pipe using manifold gauge and

electrical equipments.

REFERENCES

Anwar K, Arif E, Piarah W, (2010), Effect of Capillary

Pipe Temperature on Cooling Engine Performance,

Department of Mechanical Engineering, Faculty of

Engineering, University of Tadulako Palu, Central

Sulawesi.

Anwar K, (2010), Cooling Load on Cooling Machines,

Department of Mechanical Engineering, Faculty of

Engineering, Tadulako University, Palu, Central

Sulawesi

ASHRAE, (2010), Refrigeration, American Society of

Heating, Refrigeration And Air Conditioning

Engineers, USA.

Bowo, (2013). Cooling Engine Load Against Changes in

Capillary Pipe Length.

Cengel, (2005) dan Incropera, (2011). Vapor Compression

System Against the value of Coefficient Of

Performance (COP).

Wang, Z., Wang, F., Wang, X., Ma, Z., Wu, X., & Song,

M. (2017). Dynamic character investigation and

optimization of a novel air-source heat pump system.

Applied Thermal Engineering, 111, 122-133.

Miller, (2006). Characteristics of Refrigerant Usage in

Refrigeration Systems

Vinsensius Rio Pangestus Bowo, (2013). Characteristics of

a Refrigerator Machine with a Capillary Pipe Length of

150 centimeters. Department of Mechanical

Engineering, University of Sanata, Yogyakarta.

Wardika, W. (2018). Effect of Evaporator Blower Rotation

Speed on Car AC Performance,JTT, Journal of Applied

Technology Indramayu Polytechnic, Vol V. NO.2

2018.

Study of Refrigerator Performance Through Variation of Capiler Pipe Length

157