Features of the Operation of the Railway Roadbed of the Russian

Federation

Olga Skutina and Alina Akhmetkhanova

Ural State University of Railway Transport, Yekaterinburg, Russia

Keywords: Roadbed, defects and deformations, drainage, geosynthetics.

Abstract: The railway roadbed is a permanent structure that has been in operation for many years. During this time,

under the influence of natural, man-made and operational factors, defects and deformations occur in the

roadbed - diseases of the roadbed, which can lead to a decrease in the safety and continuity of train traffic.

The article deals with the main defects of the roadbed, the most common on the railway network of the Russian

Federation, the analysis of the causes of these deformations. For the Sverdlovsk Railway, data on the condition

of the roadbed and drainage structures along the road as a whole and service regions are given, the most

obvious causes of the main deformations in each of the regions are noted. It is noted that the presence of

defects leads to a decrease in the speed of trains and an increase in operating costs. The data on the measures

that are being taken on the road to improve the condition of the roadbed and recommendations for anti-

deformation measures are given.

1 INTRODUCTION

The basis for the organization of safe and

uninterrupted railway freight and passenger

transportation is high-quality maintenance of the

railway track and, above all, its base and foundation

– the roadbed.

The railway roadbed is a permanent earthwork

that has been in operation for tens or even hundreds

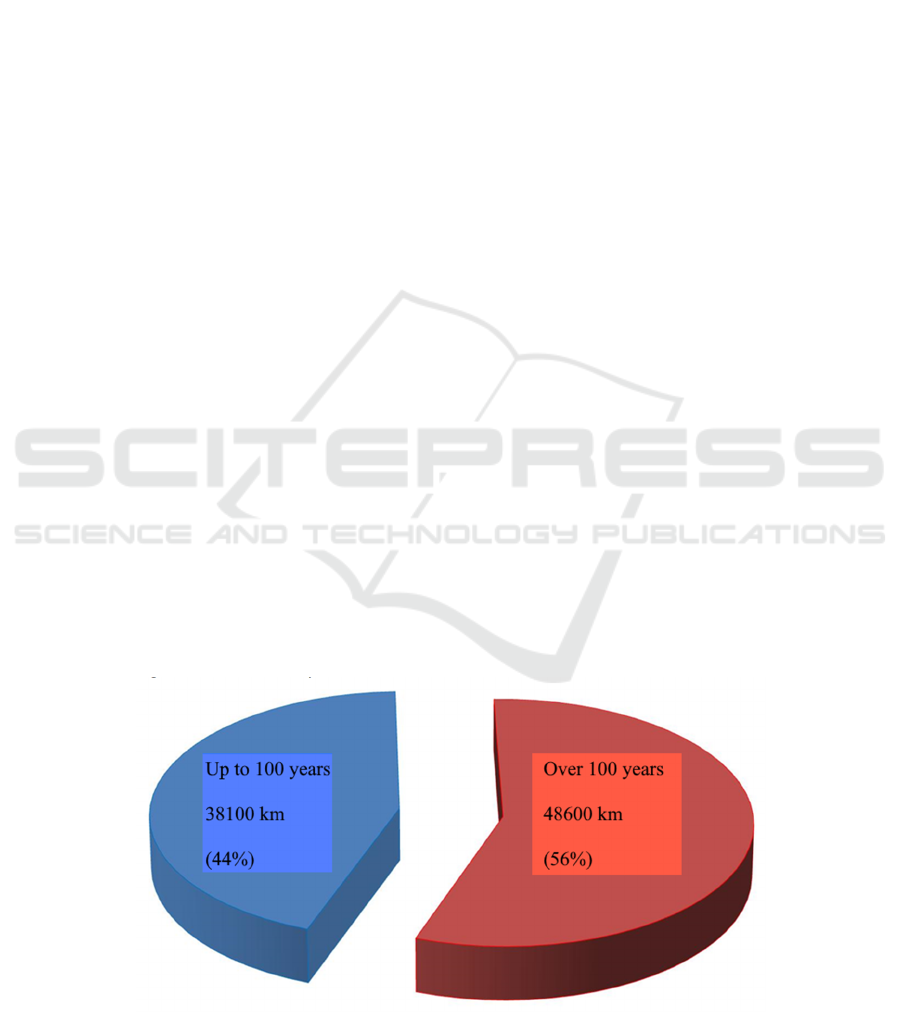

of years. According to Russian Railways JSC, 56% of

the total length of the roadbed has been in operation

for over a hundred years (Fig. 1).

There is no doubt that defects and deformations

occur at such long-term operated facilities. The

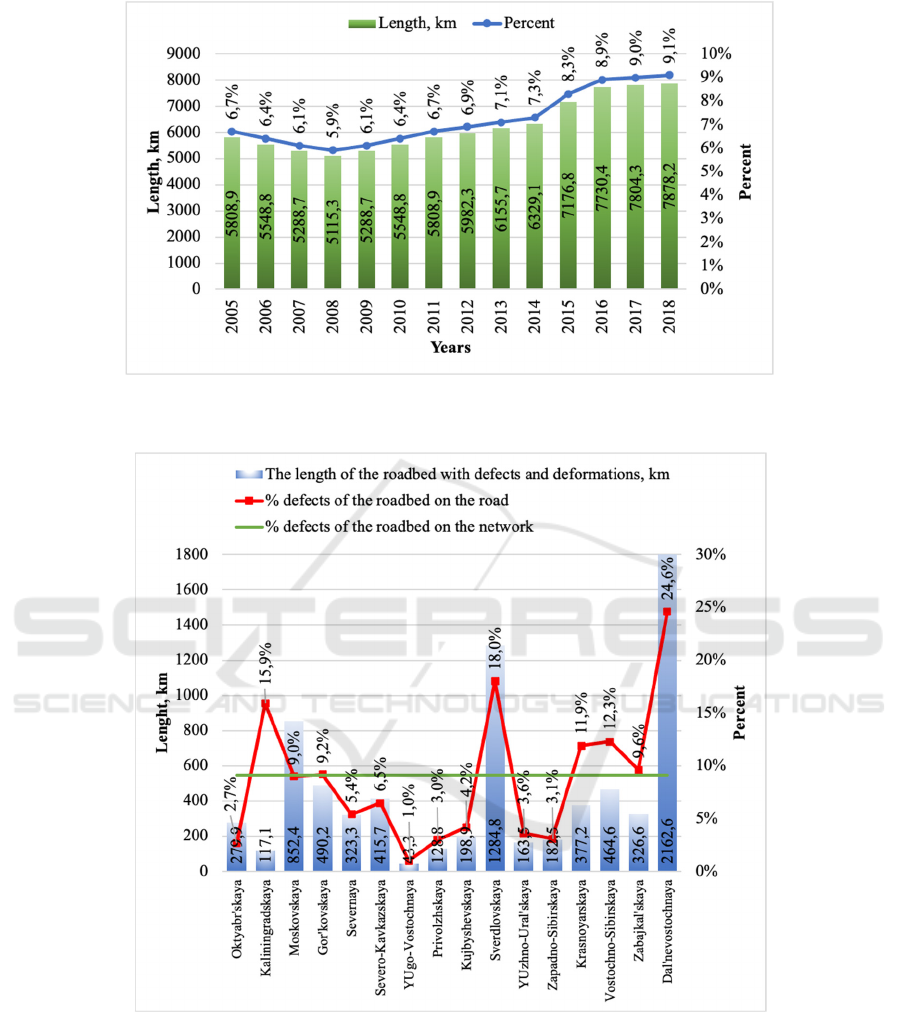

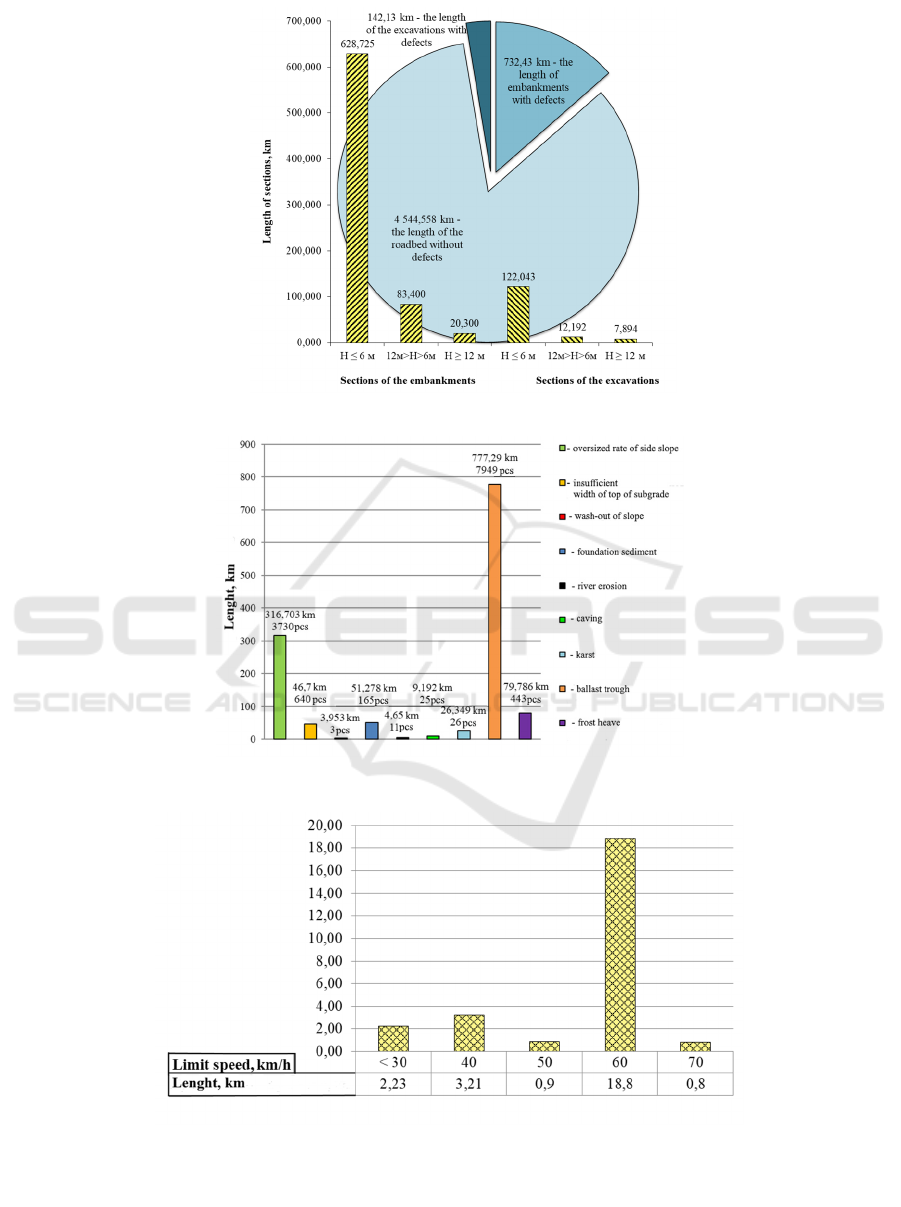

statistical data of Russian Railways JSC indicate that

about 10% of the roadbed has defects and

deformations (Fig. 2, 3), while the dynamics of

changes in the length of the "sick" roadbed is

negative.

Figure 1: The age structure of the roadbed operated by Russian Railways JSC.

Skutina, O. and Akhmetkhanova, A.

Features of the Operation of the Railway Roadbed of the Russian Federation.

DOI: 10.5220/0011582400003527

In Proceedings of the 1st International Scientific and Practical Conference on Transport: Logistics, Construction, Maintenance, Management (TLC2M 2022), pages 245-252

ISBN: 978-989-758-606-4

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

245

Figure 2: Changing the length of the defective and deformable roadbed on the railway network of the Russian Federation for

2005-2018.

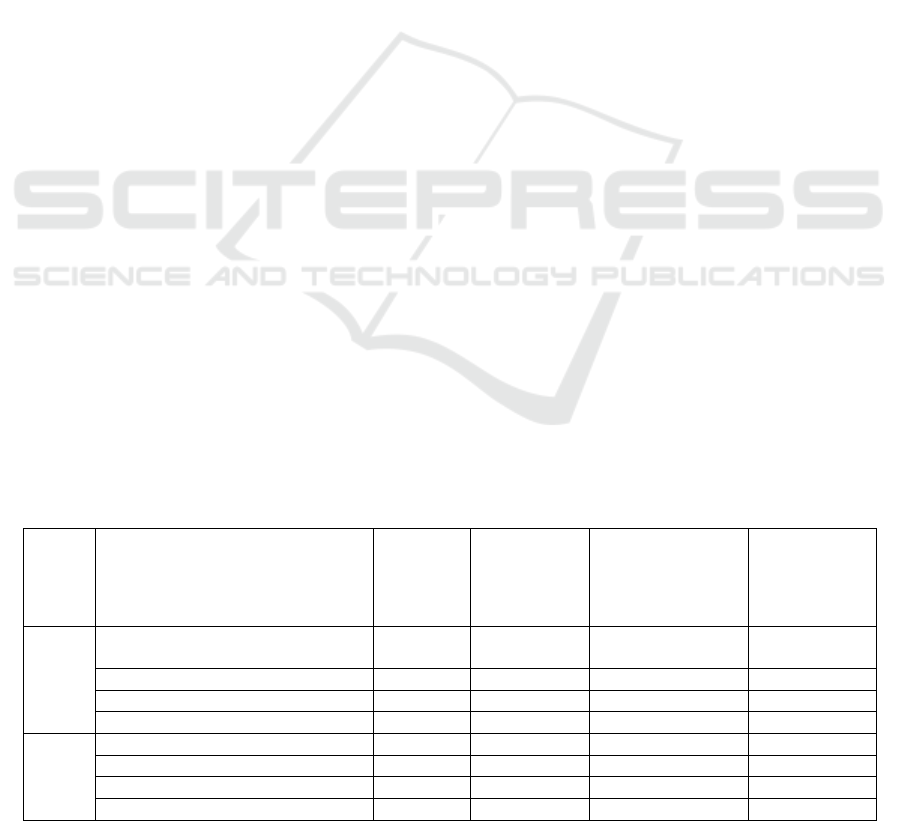

Figure 3: Defectiveness of the roadbed on the railway network of the Russian Federation as of 01.01.2019.

2 MATERIALS AND METHODS

What caused the current situation? This is not

necessarily a long service life. The negative factors

include the difficult natural and climatic conditions

on the territory of the Russian Federation:

− about 60% of the territory are areas with insular

or continuous permafrost, the behavior of

which is sometimes unpredictable;

− wetlands, landslide and karst-prone areas,

slide, avalanche and mudslide-prone areas in

mountainous areas;

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

246

− significant inter-seasonal, intra-seasonal and

daily temperature differences characteristic of

the continental climate of most territories of the

Russian Federation;

− according to ground conditions, 87% of the

roadbed is filled out of cohesive soils with low

drainage properties, prone to frost heaving, as

well as plastic deformations and shifts.

In addition, the roadbed, designed and built

according to the old design standards, does not meet

the new requirements and loads. Currently, heavy

trains, weighing up to 9,000 tons, and more than

1,500 m long, run along the railway lines. Despite the

fact that in such trains the axial loads do not exceed

the average value of 20-23 tf/axis, the duration of the

impact of such loads on the roadbed increases

significantly, and it does not "have time to rest",

process and compensate for fatigue stresses arising in

it. It should be emphasized that an increase in axial

loads will lead to a significant increase in the

deformability of the roadbed and an increase in the

cost of its treatment. Thus, experimental studies

conducted by VNIIZHT in 2018 (Russian Railways

JSC, 2019) on the passage of trains with an axial load

of 27 tf/axis on the Kachkanar-Smychka section of

the Sverdlovsk Railway with a length of 103 km

showed an increase in the cost of operating the track

by 5.8 million rubles per year (in 2017 prices,

excluding VAT), of which 83 thousand rubles – on

the roadbed. At the same time, 19.5 million rubles is

the cost of preparing the infrastructure before the start

of experimental studies.

It should be noted that the causes of deformations

of the roadbed may also be ignorance or non-

compliance with the technology of work on the filling

of the earth, insufficient quantity or lack of necessary

construction equipment, especially for compaction of

soils.

Unfortunately, we have to talk about insufficient

funding for the treatment of diseased areas of the

roadbed. It is clear that such work is very material and

labor-intensive, lengthy and requires significant

financial injections, but you can't do without them, as

they say, "a miser pays twice". The roadbed is like a

living organism in which the disease can slumber and

not manifest itself in any way for many years, but a

small push is enough, the consequences of which can

be catastrophic.

From the analysis of the condition of the roadbed

on the railways of the Russian Federation (Fig. 3), it

follows that the Sverdlovsk Railway, unfortunately,

is not at the forefront, the defectiveness of the

roadbed here is almost twice the average network.

The Sverdlovsk Railway is a powerful transport

complex with great technical and intellectual

potential. The highway connects the European and

Asian parts of Russia, stretches from west to east for

fifteen hundred kilometers. The eastern section of the

road is located in the swampy West Siberian

Lowland, and the western section is located in the

mountainous regions of the Perm Territory. In the

north direction, the road crosses the Arctic Circle and

enters the zone of permafrost soils. This geographical

location largely explains the problems of the roadbed

existing on the road (Tables 1, 2), (Fig. 4, 5).

The most common deformations of the roadbed

on the Sverdlovsk railway are ballast tanks, excessive

steepness of slopes, water-bearing pockets

(Sverdlovsk Railway, https://svzd.rzd.ru). The

occurrence and development of these deformations

are caused by several factors.

Firstly, the Sverdlovsk Railway is a landfill of

heavy traffic (Skutina, 2020). Hydrocarbon trains

Table 1: Summary table of indicators of the roadbed of the Sverdlovsk railway.

No. Indicator UoM Total Incl. defective % defective

1

Embankments, total: km 4861,411 732,425 15,07

including height

from 6 m (excl.) to 12 m (excl.) km 159,548 83,4 52,27

from 12 m

(

incl.

)

and more km 95,31 20,3 21,30

2

Ditch cuts, total:

km 557,701 142,129 25,48

includin

g

de

p

th

from 6 m (incl.) to 10 m (excl.) km 66,032 12,192 18,46

from 10 m (incl.) and more km 33,917 7,894 23,27

Features of the Operation of the Railway Roadbed of the Russian Federation

247

move in the North-South meridional direction, coal

routes move in the East-West direction. The roadbed

is not prepared for increased loads, ballast

depressions are formed on the subgrade, in which

waterlogging of the soil of the roadbed is possible,

and in winter their uneven heaving. The irregularities

of the subgrade lead to drawdowns and distortions of

the path, which are eliminated by adding ballast. As a

result, the ballast bed does not fit on the subgrade, it

begins to slide along the slopes, which leads to the

formation of ballast plumes, the excessive steepness

of the slopes and the narrowed width of the subgrade.

In this regard, the Perm and Sverdlovsk service

regions are particularly distinguished, through which

heavy coal trains move.

Secondly, the roadbed of the Surgut and Tyumen

service regions is located on weak, waterlogged, and

often swampy grounds. This is associated with

hollow spots and bulging of the soil of the base of the

roadbed, in some cases, the spreading of

embankments and, ultimately, the sediment of the

subgrade and lowering the level of the rail head. The

alignment of the path is carried out due to the same

ballast filling, which leads to the formation of ballast

plumes and slope steepening.

Thirdly, the condition of the roadbed is

significantly influenced by the presence and

condition of drainage structures: slope drains, upland

and longitudinal drainage ditches, etc. (Table 3). It

should be noted that drainage structures of the

roadbed are an integral part of the entire structure as

a whole. Their unsatisfactory content leads to the

appearance of ballast tanks, heaving of soils, slope

splits, sedimentation of the base, wash-out of fills,

erosion of slopes. There is an undoubted connection

between the presence of ballast depressions on the

subgrade and the condition of the ditches (SR-1, SR-

2), violations of the outlines of the roadbed and the

condition of drainage ditches (SR-3). The main

reasons for the faulty condition of drainage devices

on the Sverdlovsk railway are: siltation of drainage

channels (20%-50%), destruction of upland ditches

Table 2: Defects and deformations of the roadbed on the Sverdlovsk railway.

No. Defects and deformations

Length by service regions, km

Total by

Infrastructure

Directorate

SR 1

(Perm)

SR 2

(Sverdlo

vsk)

SR 3

(Tyume

n)

SR 4

(Nizhny

Tagil)

SR 5

(Surgut)

Length,

km

Number

of

sections,

pcs.

1

Violation of the outline of the

roadbed:

– excessive steepness of

slopes

167,786 79,169 44,869 5,971 18,908 316,703 3730

– narrowed width of the

sub

g

rade

13,261 6,053 1,120 21,671 4,594 46,7 640

2 Wash-outs 2,297 1,201 0,100 0,042 0,313 3,953 33

3 Sagging 23,378 5,188 0,960 6,872 14,880 51,278 165

4 Water washes 3,650 1,000 - - - 4,650 11

5 Roc

k

-fall sections 3,891 5,301 - - - 9,192 25

6 Karst 24,920 1,429 - - - 26,349 26

7

The length of the track with

b

allast tanks

265,248 134,605 185,929 191,508

-

777,29 7949

8

The length of the soft spots,

total

42,137 24,350 0,000 12,799

-

79,786 443

9

The length of the roadbed

with defects and

deformations of all kinds

546,568 258,296 232,978 238,863 38,695 1315,901 13022

10

The length of the railway line

located on the territory of

p

ermafrost distribution, total

14,547

– including deformable areas

(

PU-9

)

13,947

11

The length of the railway line

passing through the karst

territor

y

557,475

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

248

Figure 4: Summary indicators of the condition of the roadbed of the Sverdlovsk railway (as of 1.01.2020)

Figure 5: Defects and deformations of the roadbed of the Sverdlovsk railway (as of 1.01.2020)

Figure 6: The length of sections with limited train speed according to the condition of the roadbed

Features of the Operation of the Railway Roadbed of the Russian Federation

249

and trays, overgrowth of drainage ditches with

vegetation and clogging with old-year ballast after

capital works. The total length of the sections of the

roadbed with defects is 916.957 km. At the same

time, the length of drainage structures requiring major

repairs and restoration is 1,155.230 km. Comparing

these data, it can be assumed that further development

of defects and deformations is possible.

The presence of defects and deformations of the

roadbed entails the issuance of warnings about the

speed limit, which leads to a decrease in the capacity

of the lines and large interruptions in the train

schedule (Fig. 6). The total length of sections with a

permanent speed limit on 01.01.2020 is 25.98 km.

These speed limits are eliminated, as a rule, according

to individual projects as part of the overhaul of the

roadbed. The projected date of cancellation of these

restrictions is 2025. At the same time, it should be

noted that the initial issuance of warnings in some

areas is dated more than 40 years ago.

3 RESULTS AND DISCUSSION

It should be noted that the Sverdlovsk Railway is

taking the necessary measures to treat and restore the

roadbed (Table 4)

At the same time, modern geosynthetic materials

and advanced technologies for the treatment of the

roadbed are not widely used on the road. The

exception is the use of geotextile as a separation layer

during major repairs of the track and the installation

of thermal insulation coatings made of expanded

polystyrene. However, as of 01.01.2020, there were

only 19 objects of the roadbed reinforced with

reinforced ground and mesh structures with a total

length of 4000 m and a volume of 30,000 m

3

. Within

the Perm and Sverdlovsk service regions, for reasons

of dislocations, landslides and collapses of a

weathered rock slope, trapping and revetment walls

with a total length of 10 km are arranged. As of

01.01.2020, more than 74% of the trapping walls and

more than 90% of the revetment walls require major

repairs.

The problem of eliminating ballast depressions on

the subgrade is acute not only on the Sverdlovsk

railway. According to Russian Railways JSC, more

than 10% of the deformable roadbed on the railway

network are ballast depressions. It is necessary to

radically solve the issue of strengthening the

subgrade, since laying a reinforcing and separating

layer of geotextile is not enough. In this case, it may

be proposed to use a volumetric geogrid with filling

its cells with a sand-gravel-crushed stone mixture;

Table 4: The main engineering structures for the stabilization of the roadbed on the Sverdlovsk railway.

Ser.

No.

Length of sections

Service re

g

ion Total on

Sverdlovsk

Railwa

y

SR 1 SR 2 SR 3 SR 4 SR 5

1

Slots and

drains, km

total 74,072 35,865 12,938 4,890 - 127,765

require major

re

p

airs

7,597 6,188 3,585 1,009 - 18,379

2

Thermal

insulation

pillows, l.m.

total 30302 42832 61101 38727 27470 200432

require major

re

p

airs

- 788 - - - 788

3

Trapping walls,

l.m.

total 3149 - - - - 3149

require major

re

p

airs

2319 - - - - 2319

4

Revetment

walls, sq. m

total 59843 19140 - - - 78983

require major

repairs

53535 9900 - - - 63435

5 Sea walls l.m.

total 309 2500 - - 25960 28769

require major

repairs

- 1100 - - - 1100

6

Counter dams

and bulk

berms, l.m.

total 21344 108218 27852 20195 363212 540821

require major

repairs

- 310 - - - 310

7

Dam dikes,

breakwaters,

l.m.

total - - 3550 - 13601 17151

require major

repairs

- - - - -

-

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

250

laying a geogrid and vibrators; cutting the soil of the

subgrade with replacing it with a draining soil of the

protective layer; soil reclamation; the use of

polyphilizers; arrangement of a sub-ballast layer of

asphalt concrete mixture. The use of hot-mix asphalt

to strengthen the subgrade allows you to provide the

required efficiency of subgrade soil, create a

waterproof layer between the ballast and the roadbed,

prevent the penetration of moisture and weeds into

the roadbed and improve the geometric

characteristics of the track. In general, the use of an

asphalt layer makes it possible to increase the

intervals between the next repair work by 10-20

times.

The length of embankments with an

overestimated slope steepness is about 20% of

deformable areas. Reinforcement the slopes of such

embankments is possible not only with traditional

counter dams. Retaining reinforced ground or gabion

walls should be widely used in sections of culverts,

which will avoid technologically complex and time-

consuming work on lengthening the pipe. In areas of

weak foundations (Surgut and Tyumen service

regions), the filling of counter dams can lead to an

increase in the sediment of the base and additional

deformation of the roadbed, and in areas of

permafrost – to the melting of the foundation soils and

the formation of thermokarsts. In such cases, to

ensure the stability of slopes with ballast loops, it is

advisable to use drill-injection piles, tightening

elements, ground anchors or dowel structures.

Embankment pitching, as well as reinforcement of

the slopes and the bottom of drainage structures in

order to protect them from erosion is possible with

concrete-filled mats, concrete canvas, a volumetric

geogrid with filling its cells with plant soil, crushed

stone, etc. Such means of reinforcement are

technological in installation, economical, have a long

service life. On rock-fall sites, the revetted wire

meshes made of double-braided galvanized wire have

proven themselves well. They prevent scree and rock

falls from the slopes. Retaining anti-collapse walls

are recommended to be made of gabion structures.

The problem of insufficient width of the subgrade

(26% of the deformable roadbed) can be solved by

using support elements equipped with a geogrid in

combination with geotextile, or gabions (Skutina,

2014; Skutina, 2012).

Strengthening of weak bases – vertical drainage

of composite geomaterials, the use of polyphilizers,

thermal ignition, electrochemical fixing of soils, and

on permafrost soils – the use of thermosiphons.

4 CONCLUSIONS

The analysis of the data and recommendations

provided allowed us to draw the following

conclusions:

− defects and deformations of the roadbed

develop in those areas that are designed

according to standards that do not meet modern

requirements;

− the condition of the roadbed is significantly

affected by the quality of work on its

construction and maintenance;

− the appearance and development of

deformations of the roadbed depends on the

terms of its operation, a combination of natural,

man-made and operational conditions;

− common deformations of the roadbed on the

railway network of the Russian Federation are

precipitation, ballast tanks, excessive steepness

of slopes, narrowed width of the subgrade;

− unsatisfactory condition of drainage structures

has a significant impact on the appearance and

development of deformations of the roadbed;

− in order to detect defects and deformations in a

timely manner, it is necessary to widely

implement the monitoring system of the

roadbed (Ashpiz, 2002), comply with the

technological regulations for diagnostics and

routine observations of the roadbed, use

geophysical diagnostic methods, track

measuring cars, cars of engineering-geological

survey of the condition of soils and railway

tracks, etc.;

− when developing measures for the treatment of

the roadbed, use advanced methods for

calculating and designing its parameters

(Skutin, 2014);

− when eliminating defects and deformations of

the roadbed, use modern geosynthetic materials

and structures (Skutin, 2012; Skutin, 2016;

Skutina, 2015).

REFERENCES

The program for the development of heavy traffic on the

railway network of Russian Railways JSC. Russian

Railways JSC. 2019. http://www.rzd-

expo.ru/images/Events-2019/27ts/01.pdf.

The official website of the Sverdlovsk Railway.

https://svzd.rzd.ru/ru/4749.

Skutina, O. L., 2020. Peculiarities of operation of the

railway track on sections of heavy train traffic. Modern

Features of the Operation of the Railway Roadbed of the Russian Federation

251

technologies. System analysis. Modeling. 4 (68). pp. 76-

85.

Skutina, O. L., 2014. Design of the roadbed of the railway

track. Z.R. Abdulkhasanova, O.L. Skutina // Patent of

Russia No. 2557276, 2014.

Skutina, O. L., 2012. Method for the reconstruction of the

railway track (options). Karavaeva O.V., Kravchenko

Y.M., Skutina O.L. // Patent of Russia No. 2501910,

2012.

Ashpiz, E. S., 2002. Monitoring of the roadbed during the

operation of railways. p. 112.

Skutin, A. I., Skutin, D. A., Tabynshchikov, A. I., 2014.

Modeling of a roadbed reinforced with geosynthetic

materials. Designing the development of a regional

railway network: Collection of scientific papers. 2. pp.

144-150.

Skutin, A. I., Skutin, D. A., Tabynshchikov, A. I., 2012.

Increasing the stability of weak soils. RSP Expert. 8. pp.

24-25.

Skutin, A. I., Skutin, D. A., Skutina, O. L, Tabynshchikov,

A. I., 2016. Improving the stability of the roadbed using

reinforcement with geosynthetic materials. Designing

the development of a regional railway network: coll. of

scientific papers. 4. pp. 351-354.

Skutina, O. L., 2015. A method of strengthening the

earthwork of a railway track on a weak foundation

Khabibullina E.S., Skutina O.L. // Patent Russia No.

2593282, 2015.

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

252