The Use of Hydrogen in as an Additive to Diesel Fuel on Autonomous

Locomotives

Leila Kurmanova

1a

, Alexey Mishkin

1b

, Sergey Petukhov

1c

and Maxim Erzamaev

2d

1

Samara State University of Railway Transport, Samara, Russia

2

Samara State Agrarian University, Samara, Russia

Keywords: Hydrogen, diesel locomotive, diesel engine, hydrogen generator, harmful emissions, fuel consumption.

Abstract: The article discusses the option of using hydrogen on autonomous locomotives. A comparison of the

efficiency of the main types of fuel is made and a choice is made in favor of hydrogen, which differs

significantly from diesel fuel and other hydrocarbon fuels in three important physical and chemical parameters

of combustion: the required combustion speed, ignition energy and the limit of flammability. There are three

main ways of using hydrogen as fuel for diesel engines of autonomous locomotives. The most promising

method is to supply gas to the cylinders of a diesel locomotive together with the charge air. To ensure reliable

operation of a diesel locomotive when supplying hydrogen, a layout diagram with a developed hydrogen

generator, a system for preparing and supplying hydrogen, as well as a system for measuring the parameters

of a diesel locomotive with a hydrogen generator is presented.

1 INTRODUCTION

In Russia, the consumption of motor fuels annually

amounts to more than 100 million tons, diesel fuel

accounting for about 55 million tons. At the same

time, railway transport is one of the most energy-

intensive areas of industrial production, annually

consuming up to 6% of diesel fuel (Gapanovich,

2012; Grigorovich, 2013; Kavtaradze, 2011).

In the conditions of limited reserves of oil fuel and

its constant rise in price, the issue of using alternative

fuels for JSC "Russian Railways" is relevant.

The reserves of hydrogen on earth are practically

unlimited, so it is reasonably recognized as the fuel of

the future. Hydrogen is not a fuel, but an energy

carrier, since it is not contained in its pure form in

nature. The main advantages of hydrogen: high

specific heat of combustion, unlimited reserves and

environmental safety (Table 1) (Petukhov, 2020;

Nosyrev, 2016; Kamaltdinov, 2008).

In order to reduce the environmental burden on

the environment, JSC "Russian Railways" plans to

purchase locomotives running on natural gas and

a

https://orcid.org/0000-0001-7641-3889

b

https://orcid.org/0000-0002-5444-9087

c

https://orcid.org/0000-0002-3753-348Х

d

https://orcid.org/0000-0003-2843-3513

other alternative energy sources, namely locomotives

with gas-piston, gas-diesel engines, as well as

locomotives running on hydrogen fuel beginning with

2025. By 2030, it is planned to convert 25% of the

fleet to gas (Kamaltdinov, 2008; Nosyrev, 2020;

Fontana, 2002; Shudo, 2002).

The increased interest in the development of

power plants based on hydrogen fuel cells makes it

urgent to develop existing systems for generating

hydrogen.

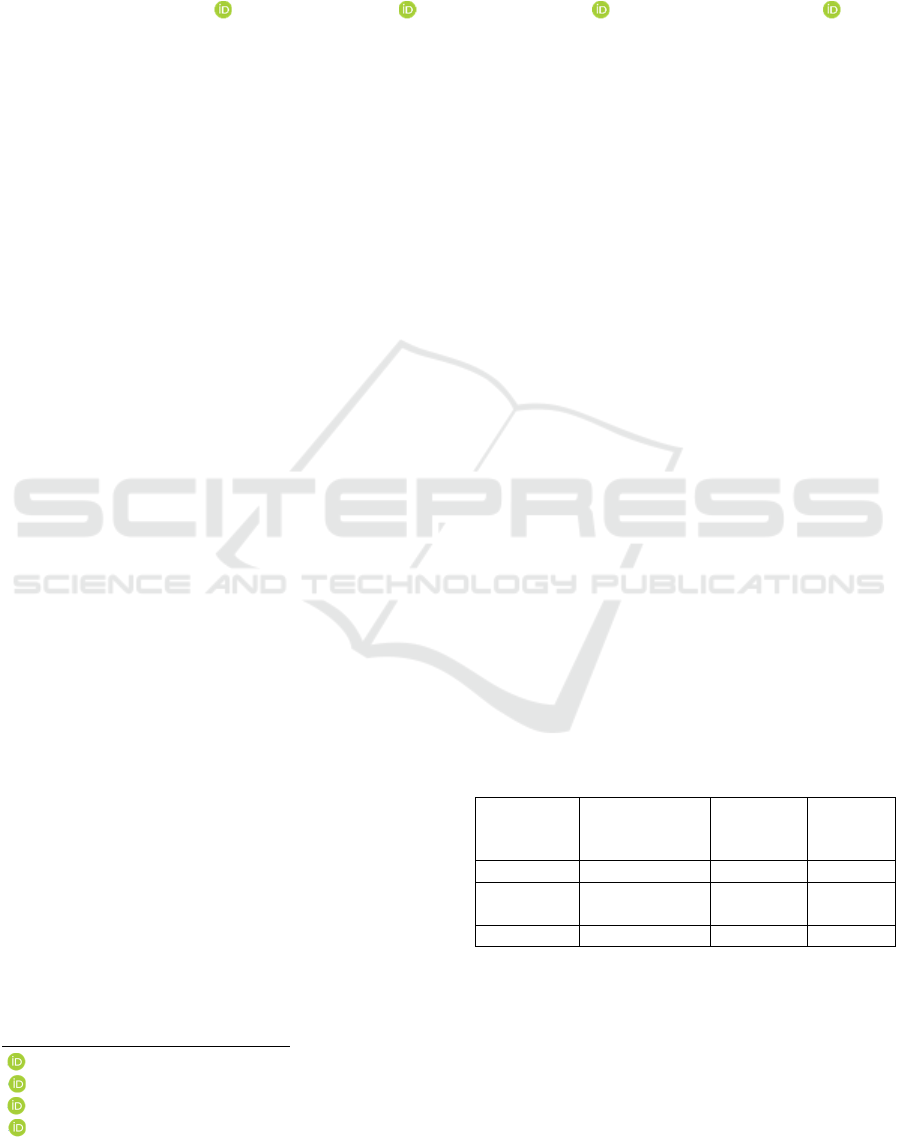

Table 1: Comparison of the efficiency of the main types of

fuel.

Fuel type Specific heat

of combustion,

MJ/k

g

СО

2

emissions,

k

g

Cost,

rub/m3

Hydrogen 120 0 27858

Natural gas 46 2.8 5,28-

6,29

Diesel fuel 41 3.16 24190

There are several ways to produce hydrogen,

including chemical reactions (Figure 1).

28

Kurmanova, L., Mishkin, A., Petukhov, S. and Erzamaev, M.

The Use of Hydrogen in as an Additive to Diesel Fuel on Autonomous Locomotives.

DOI: 10.5220/0011576800003527

In Proceedings of the 1st International Scientific and Practical Conference on Transport: Logistics, Construction, Maintenance, Management (TLC2M 2022), pages 28-31

ISBN: 978-989-758-606-4

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

Figure 1: Methods for producing hydrogen.

2 EXPERIMENT

One of the problems of using hydrogen in power

plants on autonomous locomotives is its placement

and storage directly on board.

The most acceptable method of producing

hydrogen, taking into account the minimum energy

consumption, safety of operation and adaptability in

heavy operating conditions of autonomous

locomotives, is the use of an on-board hydrogen

generator, which implements the chemical reaction of

aluminum hydrolysis in aqueous solutions of salt

alkalis.

The hydrolysis reaction is described in this case

by the equation:

2AI + 2NaOH + 2H

2

О→ 2NaAlO2 + 3H

2

↑

The resulting hydrogen is sent directly to the

diesel engine of the locomotive. This eliminates the

need to use various types of storage systems for

hydrogen on board.

Tests carried out on the D-242 diesel engine in the

laboratory "Locomotive Power Plants" of the

FGBOU VO "SamGUPS" showed that the addition of

hydrogen to diesel fuel in an amount of 2-5%

increases the completeness of combustion and

reduces the levels of emissions of harmful substances

CH, CO, and also reduces the specific effective fuel

consumption ge (Petukhov 2020). Increasing

hydrogen volume fraction in the fuel mixture by more

than 5% is not practical, as in this case the combustion

temperature will rise and NOx emissions will

increase.

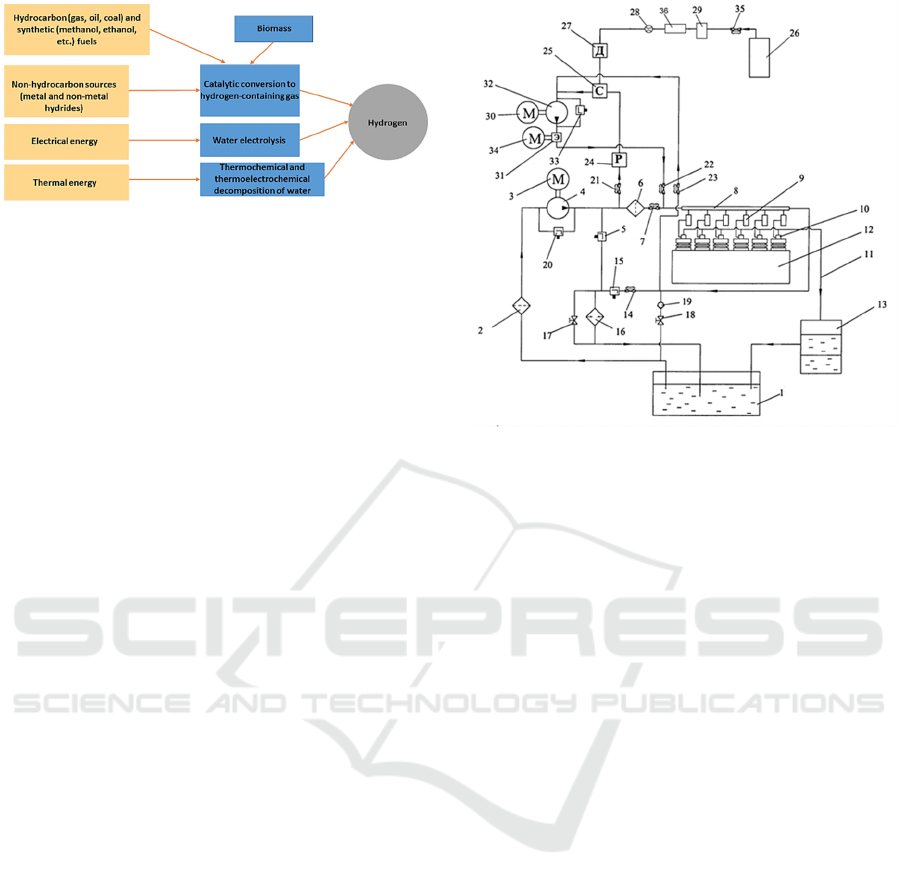

The schematic diagram of the system for

enriching diesel fuel with hydrogen and its

subsequent supply to the internal combustion engine

is shown in Figure 2 and includes a circulation circuit

of hydrogen-enriched diesel fuel with hydro-

mechanical and hydrodynamic mixers (Nosyrev,

2016).

Figure 2: The system of preparation and supply of hydrogen

to the diesel locomotive: 1 - fuel tank; 2 – coarse filter; 3,34,

– electric motors; 4 – fuel pump; 5 – discharge valve; 6 –

fine fuel filters; 7,14,21,22,23,35 – electrically controlled

valves; 8 – fuel collector; 9 – high – pressure fuel pump; 10

– fuel nozzle; 11 – drain tube; 12 – diesel; 13 – sump; 15 -

back – up valve;16 – fuel heater; 17 – fuel bypass valve; 18

– emergency power tap; 19 – return valve; 20,33 – pressure

reducing valves; 24 – fuel flow meter; 25 – hydro –

mechanical mixer; 26 – hydrogen generator; 27 – hydrogen

dispenser; 28 – hydrogen flow meter; 29 – hydrogen

purification filter, 31-hydrodynamic mixer; 32-enriched

with hydrogen fuel supply pump , 36-hydrogen tank.

The circulation circuit allows you to enrich diesel

fuel with hydrogen, directly during the operation of

the diesel engine in the mode of multiple circulation

and eliminates the ingress of hydrogen into the fuel

tank of the locomotive.

For preliminary mixing of fuel with hydrogen

under the action of centrifugal forces, a centrifugal

hydro-mechanical mixer is installed in the system.

The main elements of the hydrogen generation

system are a chemical reactor, in which hydrolysis is

carried out, and a hydrogen storage receiver.

The hydrogen generator solves one of the most

complex problems of fuel systems of hydrogen power

plants – the problem of supplying the initial

components to the chemical reaction zone depending

on the diesel's demand for hydrogen, mixing them and

clearly regulating the performance of the on-board

hydrogen generator by a certain interaction of

"working" reagents depending on the diesel load

mode (Figure 3).

The Use of Hydrogen in as an Additive to Diesel Fuel on Autonomous Locomotives

29

Figure 3: Diagram of the developed continuous-acting

hydrogen generator: 1 – pasty reagent, 2 – reaction vessel,

3 – hydrogen delivery line, 4 – liquid reagent supply line, 5

– control line, 6 – bypass line, 7 – control line insert, 8 –

boost line, 9 – boost line insert, 10 – heat exchanger, 11 –

starting heaters, 12 – bypass tank, 13 – shut – off element,

14 – temperature sensor, 15 – container on legs for

collecting reaction products with holes on the side surface,

16 – inert gas cylinder, 17 – piston, 18 – return spring, 19 –

software device, 20 – control unit, 21 – pressure sensor, 22

– tunable gearbox, 23, 24, 25, 26, 27, 28, 29 – electrically

controlled valves, 30 –consumption capacity, 31–check

valve.

The generator is based on a method for producing

hydrogen by reacting aluminum with an aqueous

solution of alkali (Nosyrev, 2016).

3 RESULTS

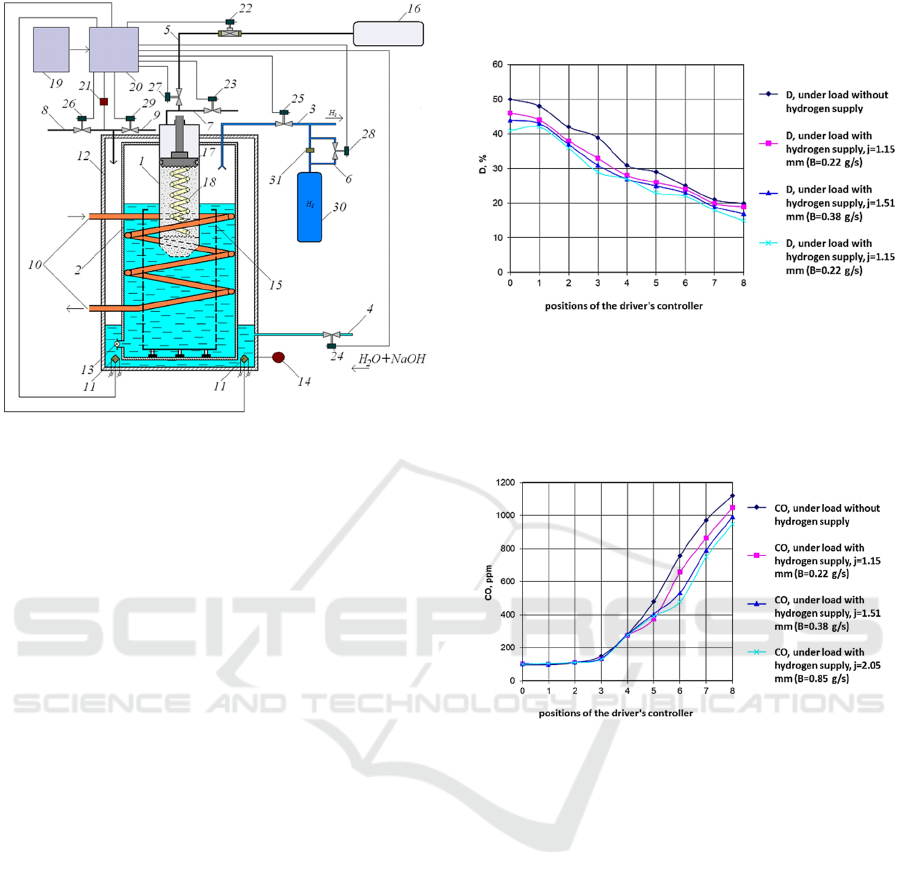

To assess the effect of the addition of hydrogen in an

amount of 5% on the environmental characteristics of

the ChME3 diesel locomotive, tests were carried out

in the conditions of the rheostat testing station and the

environmental control point of the Samara

locomotive depot. Hydrogen was supplied at a

pressure of 0.1-0.4 MPa in an amount of 5% by

weight relative to diesel fuel.

For the supply of hydrogen, jets with hole

diameters of 1.15; 1.51; 2.05 mm were manufactured

to control the flow rate at all positions of the driver's

controller (PCM) of the locomotive. The test results

are shown in Figures 4-6.

The dependences (Fig. 4) show that when the

hydrogen consumption increases to 0.85 g/s, the

maximum effect of reducing the smoke content is

observed.

Figure 4: Dependence of the smoke content D on the PCM

on diesel fuel and with 5% H

2.

The results of measuring carbon monoxide CO

emissions at a hydrogen consumption of 0.22, 0.38,

and 0.85 g/s are shown in Figure 5.

Figure 5: Dependence of CO emission levels on PCM on

diesel fuel and with 5% H

2.

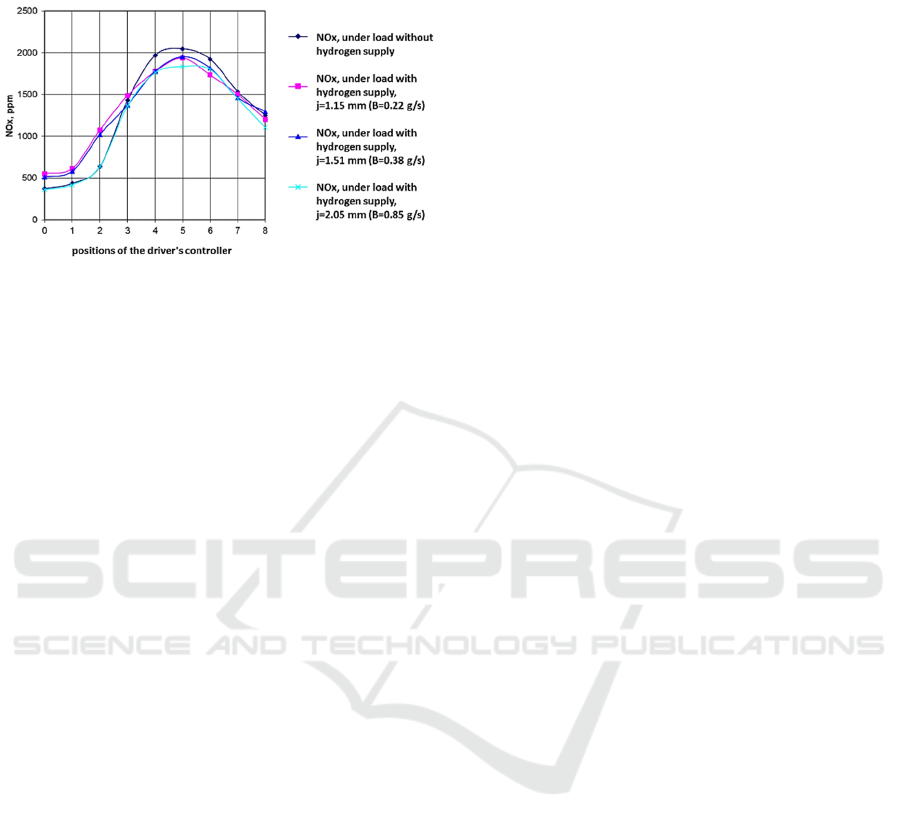

As Figure 6 shows, when the hydrogen

consumption increases to 0.85 g / s, a significant

reduction in CO emissions is observed, which

confirms the influence of hydrogen additives on the

kinetics of the ignition and combustion processes of

hydrocarbon fuels. When hydrogen is supplied,

carbon monoxide CO emissions at 0-4 PCM

practically do not change, and at 5-8 positions they

increased by 16-26%. The results of NOx

measurements during the tests carried out under the

load of the diesel locomotive ChME3 to assess the

effect of the supply of hydrogen to the air receiver are

shown in Figure 6.

As can be seen from Figure 6, emissions of

nitrogen oxides NOx at 0-4 PCM increase by 2-18%,

and at 5-8 positions they decrease by 7-8%,

depending on the hydrogen consumption. The reason

for the increase in NOx emissions was an increase in

the combustion temperature of the fuel-air mixture

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

30

(Szwaja, 2009; Shirk, 2008; Caton, 2009; Chintala,

2017; Ji, 2009; Taxon, 2002).

Figure 6: Dependence of NO

x

emission levels on PCM on

diesel fuel and with 5% H

2.

4 CONCLUSIONS

Thus, the developed hydrogen generator and the

experimental work carried out on the use of hydrogen

fuel allow us to recommend for JSC "Russian

Railways" the use of hydrogen as an additive to diesel

fuel, natural gas and to a gas-diesel mixture on

autonomous locomotives.

REFERENCES

Gapanovich, V. A., Avilov, V. D., Arzhannikov, B. A.,

2012. Energy saving in railway transport: textbook for

universities. MISiS House. p. 620.

Grigorovich, D. N., 2013. Formation of proposals for the

use of hydrogen fuel in railway transport taking into

account the analysis of foreign experience. Bulletin of

the Joint Scientific Council of JSC "Russian Railways".

6. pp. 37-49.

Kavtaradze, R. Z., 2011. Thermophysical processes in

engines converted to natural gas and hydrogen.

Publishing House of the Moscow State Bauman

Technical University. p. 238.

Petukhov, S. A., Lazarev, V. E., Asabin, V. V. et al., 2020.

Resource saving and energy efficiency of diesel

engines: monograph. Samara State University of

Railway Transport, Samara: SamGUPS. p. 138.

Nosyrev, D. Ya., Mishkin, A. A., 2016. Prospects of

application of aluminum-hydrogen energy in railway

transport: monograph. Samara: SamGUPS. p. 160.

Kamaltdinov, V. G., Abeliovich, E. V., 2008. Influence of

the composition of two-component fuel on the

combustion process in an engine with volumetric self-

ignition from compression. Bulletin of SUSU. Series:

Mechanical engineering. 23(123). pp. 46-53.

Nosyrev, D. Ya. et al., 2020. Improving the environmental

safety of diesel locomotives by enriching diesel fuel

with hydrogen. Ecology and Industry of Russia. 24. 5.

pp. 51-57.

Fontana, G., Galloni, E., Jannelli, E. et al., 2002.

Performance and Fuel Consumption Estimation of a

Hydrogen Enriched Gasoline Engine at Part–Load

Operation. SAE Technical Paper Series. 2002-01-2196.

pp. 1-5.

Shudo, T., Ono, Y., 2002. HCCI Combustion of Hydrogen,

Carbon Monoxide and Dimethyl Ether. SAE Technical

Paper Series. 2002-01-0112. pp. 1-6.

Szwaja, S., Rogalinski, K. G., 2009. Hydrogen Combustion

in a Compression Ignition Diesel Engine. International

Journal of Hydrogen Energy. 34. 10. pp. 4413-4421.

Shirk, M. G., McGuire, T. P., Neal, G., Haworth, D. C.,

2008. Investigation of a Hydrogen–Assisted

Combustion System for a Light-Duty Diesel Vehicle.

International Journal of Hydrogen Energy. 33 (23). pp.

7237-7244.

Caton, P. A., Pruitt, J. T., 2009. Homogeneous Charge

Compression Ignition of Hydrogen in a Single-Cylinder

Diesel Engine. International Journal of Engine

Research. 10 (1). pp. 45-63.

Chintala, V. A., Subramanian, K. A., 2017. Comprehensive

Review on Utilization of Hydrogen in a Compression

Ignition Engine under Dual Fuel Mode. Renewable and

Sustainable Energy Reviews. 70, pp. 472-491.

Ji, C., Wang, S., 2009. Effect of Hydrogen Addition on

Combustion and Emissions Performance of a Spark

Ignition Gasoline Engine at Lean Conditions.

International Journal of Hydrogen Energy. 34 (18). pp.

7823-783.

Taxon, M., N., Brueckner, S., R., Bohac, S., V., 2002.

Effect of Fuel Humidity on the Performance of a

Single-Cylinder Research Engine Operating on

Hydrogen. SAE Technical Paper Series. 2002-01-2685.

pp. 1-20.

The Use of Hydrogen in as an Additive to Diesel Fuel on Autonomous Locomotives

31