Results of the Study of the Causes of Injuries of Shunting Masters

Sunnatulla Sulaymanov

1

, Miraziz Mirkadirovich Talipov

1a

, Shavkat Khakimovich Abdazimov

1

and Oleg Rashitovich Ilyasov

2

1

Tashkent State Transport University, Temiryulchilar-1 Street, Tashkent, Uzbekistan

2

Ural State University of Railway Transport, Kolmogorov Street-66, Yekaterinburg, Russia

Keywords: shunting masters, professional suitability, phobia, muscle strength, movement speed, agility, performance,

survey, station, workplace, injury.

Abstract: In the conditions of train movement and shunting work, train compilers are exposed to great danger, which

increases when trains move forward, as well as in the case of a mismatch of physical and mental fitness,

shunting masters have a dangerous state in their work, which, due to insufficient qualities of human movement,

can lead to dangerous cases, while increasing the likelihood of accidents involving occupational injuries of

various kinds. This article presents the results of a survey conducted to determine and study the causes of

injuries among the shunting masters of the Khamza station of the Tashkent Regional Railway Junction.

1 INTRODUCTION

The workplaces of shunting masters are located inside

the rail track or in the immediate vicinity of it and on

the rolling stock (Instructions, Republic of

Uzbekistan; Rules of technical operation, Republic of

Uzbekistan.). In conditions of train movement and

shunting work, these persons are exposed to great

danger, which increases when trains move forward

with wagons (Zhukov, 2014; Evseeva, 2002;

Kaptsov, 2000). It is known that the causes of injuries

are conditionally divided into objective and

subjective (Vilk, 2001). For example, intense noises

muffle warning signals; lack of training of workers in

safe working methods; discrepancy between the

qualifications and health status of the worker to the

work performed by him; performing complex and

dangerous operations without the participation of the

work manager; low labor discipline; unsatisfactory

quality (or absence) of workwear, shoes and personal

protective equipment; violation of work and rest

regime; insufficient and irrational lighting of

workplaces and station tracks; unfavorable

meteorological conditions (low temperature, wind,

precipitation, blizzard, etc.); noise that drowns out

warning signals about danger; short-term

unreasonably increased labor intensity; absence or

unsatisfactory condition of welfare spaces. The

a

https://orcid.org/0000-0003-0396-4043

subjective reasons are: carelessness (mind-

wandering, distraction, etc.), unsatisfactory quality of

movement (muscle strength, speed, agility, flexibility

and efficiency) of the shunting master (Zhukov, 2014;

Vilk, 2001; Kaskov, 2006), the presence of various

phobias (agoraphobia, acrophobia, aichmophobia,

acoustic phobia, amatophobia, claustrophobia,

nyctophobia, etc.), fatigue, awkwardness

(Sulaimanov, 2021a; Suleymanov, 2021b;

Suleymanov, 2021c). With careful analysis, usually

the presence of objective reasons from the shunting

master requires a quick response in the course of work

to evolving, changing situations (Suleymanov,

2021c; Sulaymanov, 2021d; Sulaymanov, 2019). In

the case of a discrepancy between the physical

(Resolution of the Cabinet of Ministers of the

Republic of Uzbekistan, 2019) and mental

preparedness of the shunting master, a dangerous

state occurs in work, which, due to insufficient

qualities of human movement, can lead to dangerous

cases, while increasing the likelihood of accidents

with occupational injuries of various kinds (Kopeikin,

2011; Sulaimanov, 2021).

10

Sulaymanov, S., Talipov, M., Abdazimov, S. and Ilyasov, O.

Results of the Study of the Causes of Injuries of Shunting Masters.

DOI: 10.5220/0011576400003527

In Proceedings of the 1st International Scientific and Practical Conference on Transport: Logistics, Construction, Maintenance, Management (TLC2M 2022), pages 10-15

ISBN: 978-989-758-606-4

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2 MAIN PART

To determine or study the causes of injuries among

shunting masters, a survey was conducted among the

shunters of the Khamza station of the Tashkent

Regional Railway Junction. The following questions

were included in the questionnaires (Sulaymanov,

2019):

1. Have you been injured in the course of your

work;

2. In what circumstances did the occupational

injury occur;

3. Do you know the cause of the injury;

4. Which part or organ of your body has been

injured;

5. Do you know what kind of injury you received;

6. After how many days did you return to work;

7. How and who chooses special footwear;

8. What personal protective equipment do you

use;

9. How to choose gloves and their material;

10. Dimensions of stair handrail (diameter, shape,

surface roughness, etc.);

11. Dimensions of the ladder tread (width, length,

material, surface roughness);

12. Dimensions and indicators of brake shoe

(handle dimeter, weight, etc.);

13. Does the shunter need a radiotelephone;

14. What are the disadvantages of the shunter's

workwear;

15. What are the suggestions for reducing

occupational injuries;

16. What suggestions are there to improve the

working conditions of the shunter;

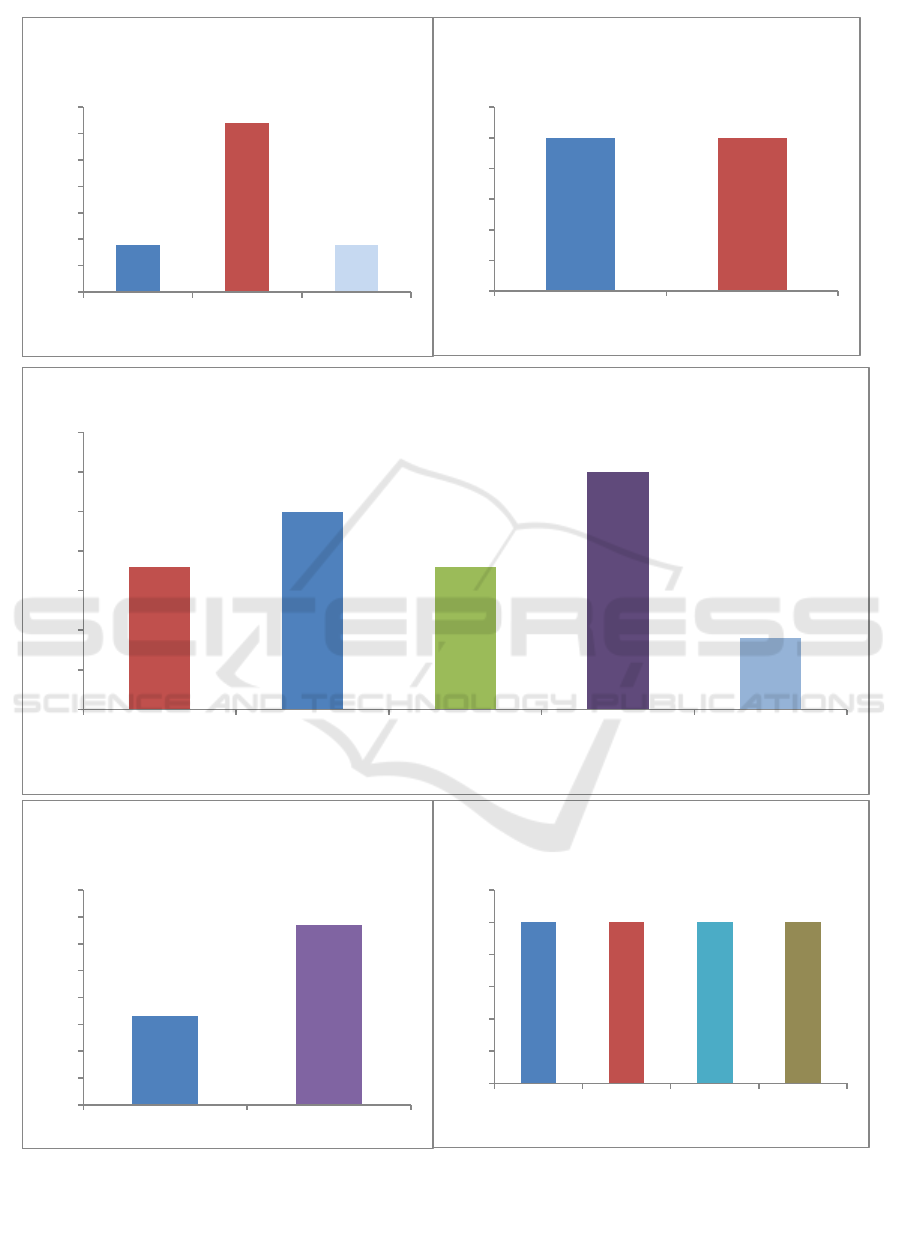

Histograms are constructed based on the data

obtained after their processing (Fig. 1-16).

The analysis of the obtained results shows that

18% of shunting masters with 5 or more years of

experience received various injuries. Injuries to

various limbs (upper and lower) mainly occurred

when falling from the steps of the car (30%), while

climbing the steps of the car (25%), while crossing

the railway track and descending from the steps of the

car (18%). The causes of injury are considered by

shunting masters to be 50% to 50%. The knee joint

(67%), elbow and head (33%) were mostly injured in

all the surveyed shunters. The resulting injuries lead

to 25% strained muscles, bone fracture of the upper

and lower limbs, head injury, etc. 68% injuries of

shunting masters lead to the temporary incapacitation

from 7 days to 1 month and are moderate injuries.

Considering that, 50% of the injury is due to slippery

steps of cars. The question of who and how chooses

the special footwear of the shunting master was

studied, and it was revealed that 67% of the shunters

do not know how to choose shoes taking into account

the sole material in order to prevent slipping when

walking on the steps. 67% of shunting masters do not

use personal protective equipment for individual parts

of the human body (knee pads, elbow pads and hard

helmets), the materials of gloves by the value of their

sliding coefficient on metal handrails does not allow

strong fixation of hands. According to the survey

materials, the dimensions of the handrail (diameter,

shape, surface roughness, etc.) are not convenient for

moving up stairs, ramps and for reliable fixation of

the human body on the steps of freight cars when it

moves. All the shunting masters surveyed consider

shoes not comfortable and heavy, as well as 20% of

shunters consider radiotelephones unnecessary and

interfere with work. 50% of the shunters consider

glove materials slippery and, in their opinion, special

clothing wears out quickly, the soles of shoes are

slippery and not convenient to work with. According

to the results of surveys, shunting masters propose to

improve the design of stairs, steps, handles, to

develop norms and requirements for the shunter's

workwear. In addition, it is proposed to normalize

sanitary and hygienic working conditions (Kaskov,

2006) (fig. 1-3).

3 CONCLUSIONS

In general, the results of studying the causes of

injuries among shunting masters showed that they are

injured due to a fall when descending from a moving

car, due to the lack of development of movement

qualities and non-compliance of the basic physical

and mechanical indicators of special clothing and

shoes. In addition, the causes of injuries to shunting

masters may be various phobias that individuals who

work as shunting masters have (Evseeva, 2002;

Kaptsov, 2000; Sulaymanov, 2021d). In order to

eliminate the causes of injuries among shunting

masters associated with physical inconsistencies in

human motor qualities (speed, strength, agility,

flexibility, efficiency) (Sulaimanov, 2021) and the

stability of psychology to various phobias generated

by working conditions, it is necessary to develop a

methodology for assessing the professional suitability

of shunting masters for high-quality professional

selection (Kaptsov, 2000; Kaskov, 2006). High-

quality professional selection of the shunting master

will significantly reduce the likelihood of accidents at

work.

Results of the Study of the Causes of Injuries of Shunting Masters

11

Figure 1: Questions 1-5.

18%

64%

18%

0%

10%

20%

30%

40%

50%

60%

70%

Yes No I don't

remember

Have you been injured in the

course of your work activities

50% 50%

0%

10%

20%

30%

40%

50%

60%

slippery step surface fatigue at the end of

work

Do you know the cause of the

injury

18%

25%

18%

30%

9%

0%

5%

10%

15%

20%

25%

30%

35%

while crossing the

railroad track

while climbing the

steps of the carriage

during the descent

from the steps of the

carriage

Falling from the step

of the car while

moving

I don't remember

In what circumstances did the injury occur

33%

67%

0%

10%

20%

30%

40%

50%

60%

70%

80%

elbow and head knee joint

What part or organ of your body

was injured

25% 25% 25% 25%

0%

5%

10%

15%

20%

25%

30%

tendon

sprain

fracture head bruise other

Do you know what kind of injury

you received

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

12

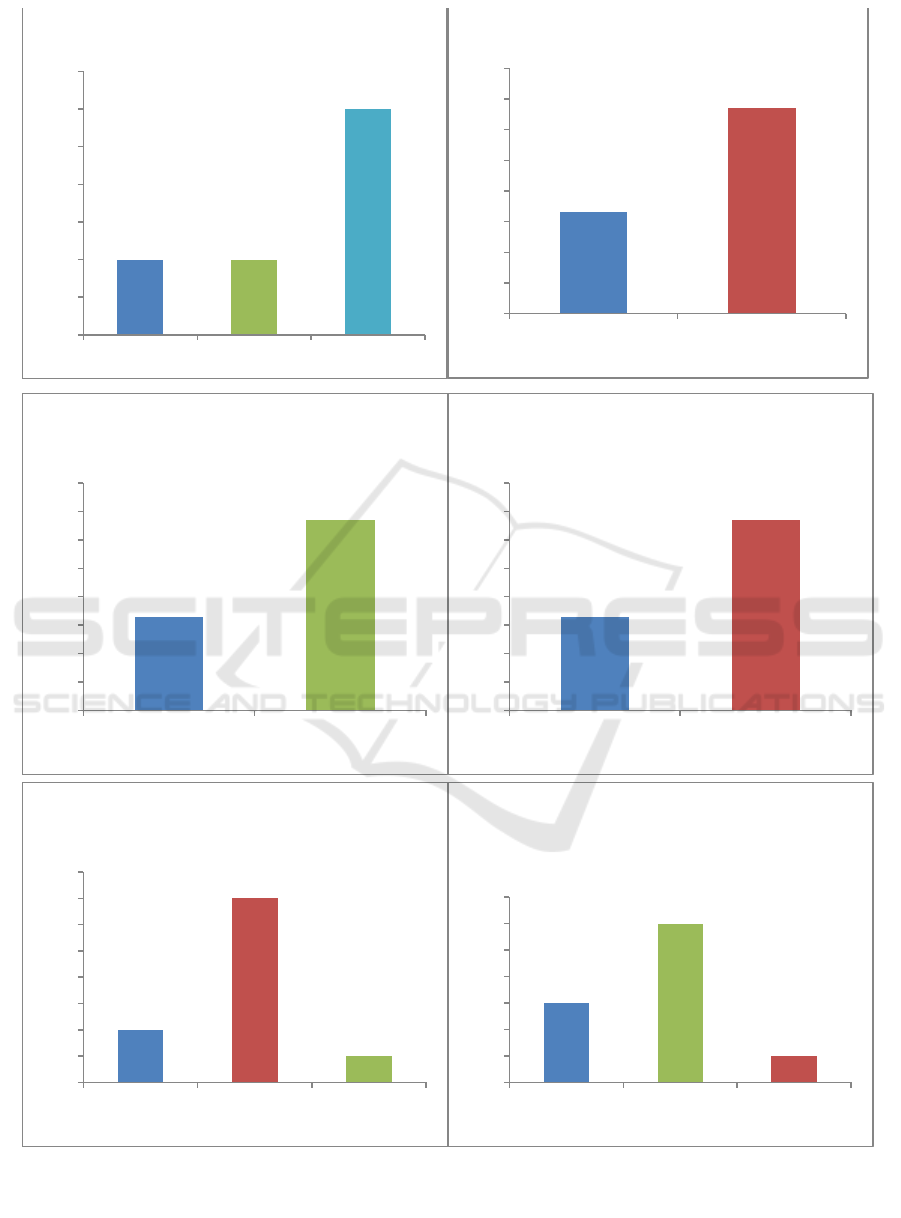

Figure 2: Questions 6-11.

32% 32%

36%

30%

31%

32%

33%

34%

35%

36%

37%

in 3-5 days in a week in a month

After how many days back to work

33%

67%

0%

10%

20%

30%

40%

50%

60%

70%

80%

given the season of the

year

I don't know

How and who chooses work shoes

33%

67%

0%

10%

20%

30%

40%

50%

60%

70%

80%

Helmet to protect the

head and jaw

I don't use

What personal protective

equipment do you use

33%

67%

0%

10%

20%

30%

40%

50%

60%

70%

80%

on the advice of

experts

I buy it myself

How to choose gloves and their

material

20%

70%

10%

0%

10%

20%

30%

40%

50%

60%

70%

80%

completely

satisfied

are not

comfortable

slippery

Handrail dimensions (diameter,

shape, surface roughness, etc.)

30%

60%

10%

0%

10%

20%

30%

40%

50%

60%

70%

completely

satisfied

are not

comfortable

slippery

Stair step dimensions (width,

length, material, surface

roughness)

Results of the Study of the Causes of Injuries of Shunting Masters

13

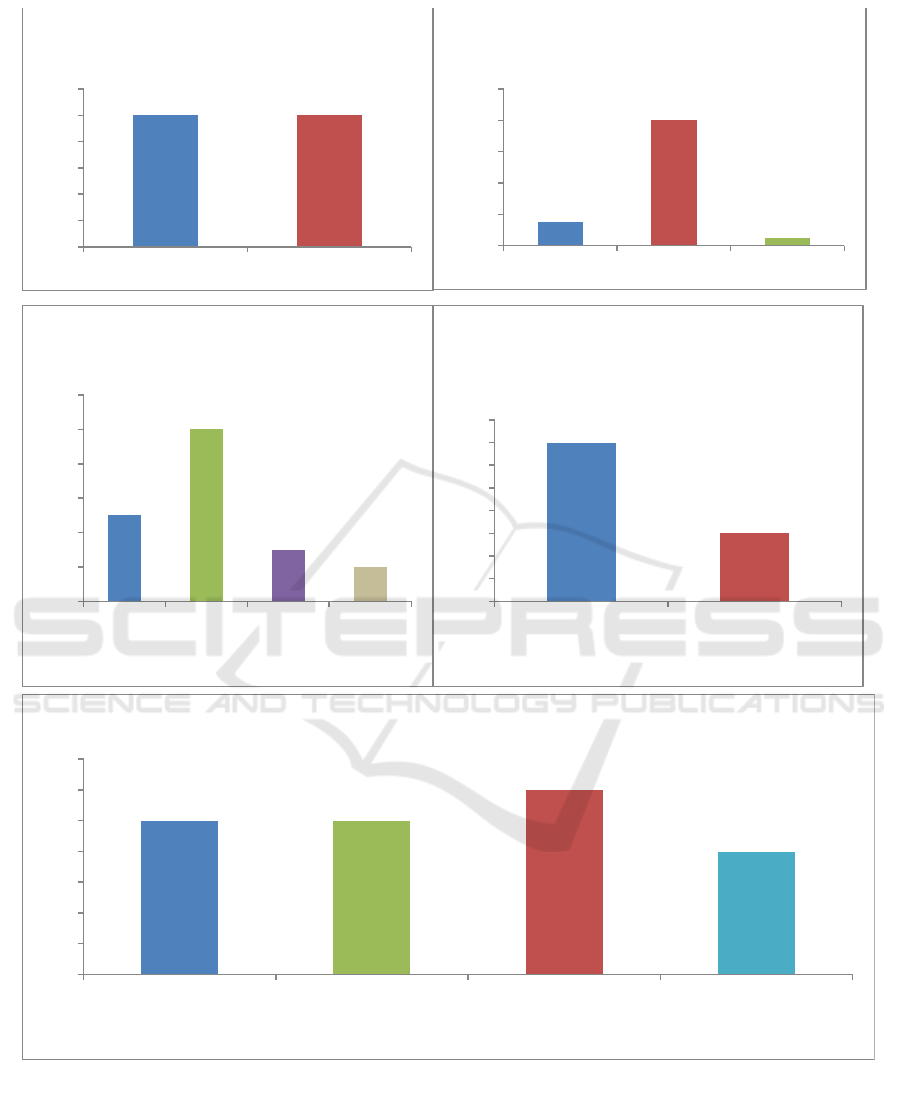

Figure 3: Questions 12-16.

50% 50%

0%

10%

20%

30%

40%

50%

60%

are not comfortable heavy

Shoe size and performance

(handle dimeter, weight, etc.)

15%

80%

5%

0%

20%

40%

60%

80%

100%

I don't need it. Needed Interferes

Does the compiler need a radio

phone

25%

50%

15%

10%

0%

10%

20%

30%

40%

50%

60%

wears out

quickly

slippery

glove

material

slippery

soles

not easy to

work with

What are the disadvantages of the

overalls of the compiler

70%

30%

0%

10%

20%

30%

40%

50%

60%

70%

80%

normalization of

sanitary and hygienic

working conditions

no offers

What suggestions are there for

improving the working conditions

of the compiler

25% 25%

30%

20%

0%

5%

10%

15%

20%

25%

30%

35%

improve the design of

stairs

Cover the surfaces of

handles and steps with

non-slip material

develop norms and

requirements for the

overalls of the maker

no offers

What are some suggestions for reducing workplace injuries

TLC2M 2022 - INTERNATIONAL SCIENTIFIC AND PRACTICAL CONFERENCE TLC2M TRANSPORT: LOGISTICS,

CONSTRUCTION, MAINTENANCE, MANAGEMENT

14

REFERENCES

Zhukov, V. I., 2014. Life safety.

Instructions for the movement of trains and shunting work

on industrial railway transport of the Republic of

Uzbekistan.

Rules of technical operation of railways of the Republic of

Uzbekistan.

Resolution of the Cabinet of Ministers of the Republic of

Uzbekistan "On wide promotion of a healthy lifestyle

and involvement of the population in physical culture

and mass sports in Uzbekistan" No. 65 dated

29.01.2019.

Evseeva, I. V., 2002. Medical and social assessment of the

health of railway workers of various professional

groups. Abstract of the dissertation of the Candidate of

Medical Sciences. p. 22.

Kaptsov, V. А., Troitskaya, A. Yu., Pankova, V. B., 2000.

New organizational and methodological approaches to

preventive medical examinations on railway transport.

Hygiene and sanitation. 2. pp. 66-70.

Vilk, M. F., Kaptsov, V. A., Pankova, V. B., 2001.

Professional risk of railway transport workers.

Kaskov, Yu. N., 2006. Hygienic justification of the risk of

developing occupational diseases in railway transport

workers (on the example of workers of locomotive

crews). Abstract of the dissertation of the Candidate of

Medical Sciences.

Kopeikin, N. F., Stankevich, A. I., Bondareva, A. R.,

Boeva, I. A., 2011. Hypertension as occupational

disease of locomotive crew workers. Hygiene and

sanitation. 3. pp. 28-29.

Sulaimanov, S. S., Talipov, M. M., 2021. Assessment of

professional suitability of shunting masters taking into

account physical exertion. Actual problems of

development and improvement of the system of physical

education for training specialists in the transport

industry: Collection of materials of the III International

scientific and practical conference dedicated to the

90th anniversary of the Department of Physical Culture

and Sport. Moscow: Russian University of Transport.

pp. 175-184.

Sulaimanov, S., Talipov, M. M., 2021a. Professional

suitability of shunting masters, taking into account the

energy consumption of the work performed. Academic

research in educational sciences. 2(9). pp. 1108-1113.

Suleymanov, S., Talipov, M. M., 2021b. Аssеssmеnt оf thе

prоfеssiоnаl suitаbility оf shunting master tаking intо

аccоunt physicаl еxеrtiоn. Philosophical Readings.

XIII(4). pp. 2046–2053.

Suleymanov, S., Talipov, M. M., 2021c. Actions of the

shunting master in non-standard and emergency

situations. European Journal of Life Safety and

Stability. 2660-9630. pp. 126-130.

Sulaymanov, S., Talipov, M. M., 2021d. Development of a

methodology for the assessment of the professional

competence of railway personnel. Scientific and

technical journal of Namangan institute of engineering

and technology. 2181-8622. pp. 115-121.

Sulaymanov, S., Kamilov, Kh. M., 2019. Analysis of video

monitoring of results of labor activities of train

dispatcher (as a traffic dispatcher of the single dispatch

center of the joint-stock company "Uzbekistan temir

yollari". Journal of Tashkent Institute of Railway

Engineers. 15(2). 28.

Results of the Study of the Causes of Injuries of Shunting Masters

15