Sludge-lignin of the Baikal Pulp and Paper Mill as a Substrate for

Generating Electric Energy in MFC

G. O. Zhdanova

1a

, D. I. Stom

1,2,3 b

, S. V. Alferov

4c

, N. Yu. Yudina

4d

,

A. B. Kupchinsky

2e

and T. S. Lozovaya

3

1

Irkutsk State University, Irkutsk, Russia

2

Baikal Museum of the SB RAS, Listvyanka, Russia

3

Irkutsk National Research Technical University, Irkutsk, Russia

4

Tula State University, Tula, Russia

Keywords: Electric current generation, biofuel cells, biotechnology, lignin sludge, Baikal pulp and paper mill.

Abstract: We studied the performance of microbial fuel cells (MFCs) based on 1) strain Cl. acetobutylicum VKPM-

4786; 2) a complex commercial biological product for cesspools and septic tanks "Doctor Robik 109". Lignin

sludge from the Baikal Pulp and Paper Mill was a substrate for microorganisms in the MFC. Strain Cl.

acetobutylicum VKPM-4786 was distinguished by a higher efficiency in the MFC from the tested bioagents.

The voltage generated by this bacterium upon the addition of 2.0 g/l of sludge-lignin reached 402 mV in 123

h, and the current strength was 742 μA. The microbiological preparation "Doctor Robik 109K" generated a

voltage of up to 387 mV (for 117 h) in the MFC with the addition of 1 g/l of lignin sludge. The current strength

reached 400 μA. The generated values were significantly lower when lower (0.1 g/l) and higher concentrations

of lignin sludge (2 and 5 g/l) were introduced into the MFC.

1 INTRODUCTION

The problem of global depletion of fossil resources

encourages the search for cheap and renewable

energy sources. Such a resource can be waste from

the pulp and paper industry, as well as agricultural

and industrial waste. According to general

calculations, up to 300 million tons of cellulose-

containing industrial (hydrolyzed lignin), agricultural

(straw, stems, cake, fruit pits, nutshells and others)

and even up to 50 million tons of household organic

waste (paper, cardboard) (Gromova 2012). On the

one hand, they act as pollutants, and on the other

hand, they are potential sources of raw materials.

Cellulose-containing waste decomposes under

natural conditions for a rather long period of time.

One of the largest pollutants in the Angara region

is the waste from the enterprises of the sulphate-pulp

industry (Nikonorov et al. 2012). The problem with

a

http://orcid.org/0000-0002-8355-9517

b

http://orcid.org/0000-0001-9496-2961

c

http://orcid.org/0000-0002-5217-7815

d

https://orcid.org/0000-0002-4054-9642

e

https://orcid.org/0000-0001-8884-8636

the waste of the Baikal Pulp and Paper Mill, located

right on the shore of Lake Baikal, is also very acute at

the present time. This business is currently closed.

However, its sludge reservoirs are filled with gigantic

volumes (6.2 million m

3

) of toxic waste. On the

territory of the Baikal Pulp and Paper Mill, a huge

mass of lignin sludge poses a special danger. Due to

the increased seismicity and climatic features of the

region, the sludge-lignin accumulated in the maps can

at any time get into the open Baikal. A promising

method for the disposal of various organ-containing

wastes with simultaneous generation of electricity is

microbial fuel cells (MFCs) (Varanasi et al. 2015).

The purpose of this work was to study the

possibility of using lignin sludge from the Baikal Pulp

and Paper Mill as a substrate in MFC.

316

Zhdanova, G., Stom, D., Alferov, S., Yudina, N., Kupchinsky, A. and Lozovaya, T.

Sludge-lignin of the Baikal Pulp and Paper Mill as a Substrate for Generating Electric Energy in MFC.

DOI: 10.5220/0011571100003524

In Proceedings of the 1st International Conference on Methods, Models, Technologies for Sustainable Development (MMTGE 2022) - Agroclimatic Projects and Carbon Neutrality, pages

316-321

ISBN: 978-989-758-608-8

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

2 MATERIALS AND METHODS

2.1 Microbial Fuel Cell (MFC)

The generation of current by microorganisms using

sludge-lignin was studied in two-chamber MFCs, the

design of which is described in (Stom et al. 2017)

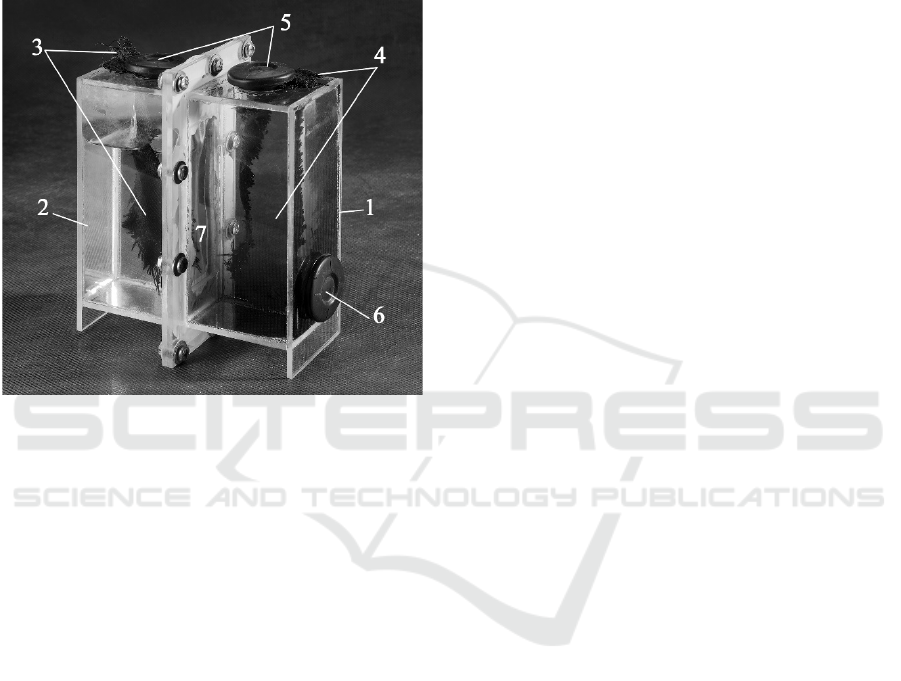

(Fig. 1).

Figure 1: Microbial fuel cell (1 – anode chamber; 2 –

cathode chamber; 3 – cathode electrode; 4 – anode

electrode; 5 – rubber covers of the anode and cathode

chambers; 6 – rubber plug for introducing components and

sampling)

The carbon cloth URAL T-22R A (OAO

Svetlogorskkhimvolokno, Republic of Belarus)

served as electrodes in the MFC. For the manufacture

of electrodes, the fabric was cut into strips 15 × 4 cm

in size. The main working medium in the MFC was

model waste water (MWW) of the following

composition (g/l): Na

2

CO

3

- 0.05; KH

2

PO

4

- 0.03;

CaCl

2

- 0.01; MgSO

4

× 7H

2

O - 0.01. The preliminary

sterilization of the medium was carried out by

autoclaving at 1 atm for 45 min.

The lignin sludge from the Baikal Pulp and Paper

Mill served as a substrate for microorganisms. This

waste is a jelly-like product. Its main component is

insoluble substances formed at the stages of chemical

and biological wastewater treatment of enterprises

producing bleached pulp using the sulphate method.

Great difficulties with its disposal are caused by high

humidity (more than 90%). Lignin sludge samples

were taken from the map of sludge collector No. 2 of

the Baikal Pulp and Paper Mill of the Irkutsk Region

(Baikalsk). Waste was introduced into the MFC at

concentrations of 0.1; 1.0; 2.0; 5.0 g/l.

2.2 Microorganisms

The following microorganisms acted as bioagents in

MFC:

1) Complex commercial microbiological

preparation "Doctor Robik 109K" (manufactured by

LLC "VIPECO", Russia, Moscow). Designed for

cesspools and septic tanks. Contains a mixture of

microorganisms of the genus Bacillus. Before adding

the drug to the MFC, it was added in an amount of 2

g to 100 ml of saline. solution and placed on a

magnetic stirrer for 15 minutes. Thanks to this

operation, bacterial cells and spores were separated

from the carrier (sawdust) on which they were

adsorbed. The resulting suspension of bacteria was

introduced into the MFC (3 ml per cell).

2) Clostridium acetobutylicum VKPM-4786

strain. Taken from the All-Russian Collection of

Industrial Microorganisms (Federal State Unitary

Enterprise GosNIIgenetika, Ministry of Education

and Science of Russia BRC VKPM). The strain was

cultivated in a liquid nutrient medium of the

following composition (g/l): KH

2

PO

4

– 0.7; K

2

HPO

4

- 0.7; MgSO

4

× 7H

2

O - 0.1; MnSO

4

× H2O - 0.02;

FeSO

4

× 7H

2

O - 0.015; NaCl - 0.01; ammonium

acetate - 3.0; yeast extract - 1.0; peptone - 1.0;

cysteine - 0.5; glucose - 20.0. To preserve the culture

and maintain anaerobic conditions, a small amount of

sterile vaseline oil was added to the test tubes on the

surface of the nutrient medium inoculated with

microorganisms. Incubation was carried out at a

temperature of 35-37°C. A 5-day culture of Cl.

acetobutylicum VKPM-4786 was used to add to the

MFC. 3 ml of culture liquid were added to the MFC

anolyte.

2.3 Generation of Electricity in MFC

Before starting operation, the MFC chambers were

sterilized with a 3% hydrogen peroxide solution.

Then they were washed with distilled water and kept

under an ultraviolet lamp for 15 min. The anode

compartment of the MFC was filled with pre-

sterilized model waste water. The test substrate was

also placed here. Model waste water was also poured

into the cathode chamber, but without the addition of

an organic substrate. At the same time, the anode

chamber was completely filled to expel air from the

chamber, and the liquid level in the cathode chamber

was left 1.5–2.0 cm below the chamber cover to

aerate the catholyte. Working electrodes made of

URAL T-22R A carbon cloth were placed in both

compartments of the MFC. The introduction of

microorganisms into the anolyte was carried out with

Sludge-lignin of the Baikal Pulp and Paper Mill as a Substrate for Generating Electric Energy in MFC

317

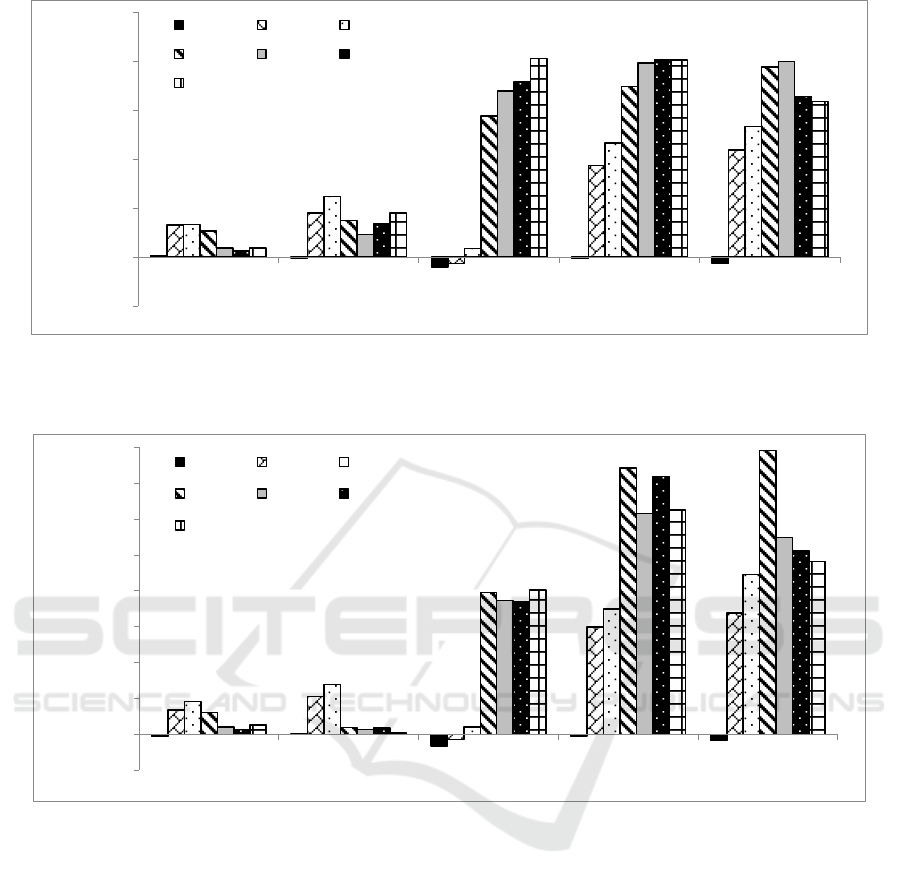

Figure 2: Dynamics of voltage (measured in open circuit mode), generated in the MFC by strain Cl. acetobutylicum VKPM-

4786 (medium - model wastewater, substrate - sludge-lignin from the Baikal Pulp and Paper Mill (0.1; 1.0; 2.0; 5.0 g/l),

electrodes – carbon cloth).

Figure 3: Dynamics of the current strength (measured in the short circuit mode), generated in the MFC by strain Cl.

acetobutylicum VKPM-4786 (medium – model waste water, substrate – sludge-lignin from the Baikal Pulp and Paper Mill

(0.1; 1.0; 2.0; 5.0 g/l), electrodes – carbon cloth).

a sterile syringe through a special rubber plug in the

side of the chamber. The ability of microorganisms to

generate an electric current in the MFC when using

the tested substrates was evaluated by increasing the

electrical parameters of the MFC. Voltage was

measured in open circuit mode, current strength was

measured in short circuit mode, using a Fluke 17B

digital multimeter. The duration of the experiments

was up to 120 h, depending on the kinetics of the

MFC readings.

2.4 Statistical Processing of Results

All experiments were carried out in at least 3

independent experiments with 3-5 parallel

measurements in each. For statistical processing of

the obtained data, the Microsoft Excel software

package was used. Conclusions are made with the

probability of an error-free forecast P ≥ 0.95.

Significance of differences was determined using

Student's t-test.

3 RESULTS AND DISCUSSION

The experiments revealed a fairly good electrogenic

activity of Cl. acetobutylicum VKPM - 4786 when

using lignin sludge from the Baikal PPM as a

substrate. At the same time, the values of electrical

parameters

increased with an increase in the

-100

0

100

200

300

400

500

control 0,1 1 2 5

Voltage, mV

Sludge-lignin concentration, g/l

0 h 18 h 24 h

48 h 68 h 75 h

123 h

-100

0

100

200

300

400

500

600

700

800

control 0,1 1 2 5

Current strength, µA

Sludge-lignin concentration, g/l

0 h 18 h 24 h

48 h 68 h 75 h

123 h

MMTGE 2022 - I International Conference "Methods, models, technologies for sustainable development: agroclimatic projects and carbon

neutrality", Kadyrov Chechen State University Chechen Republic, Grozny, st. Sher

318

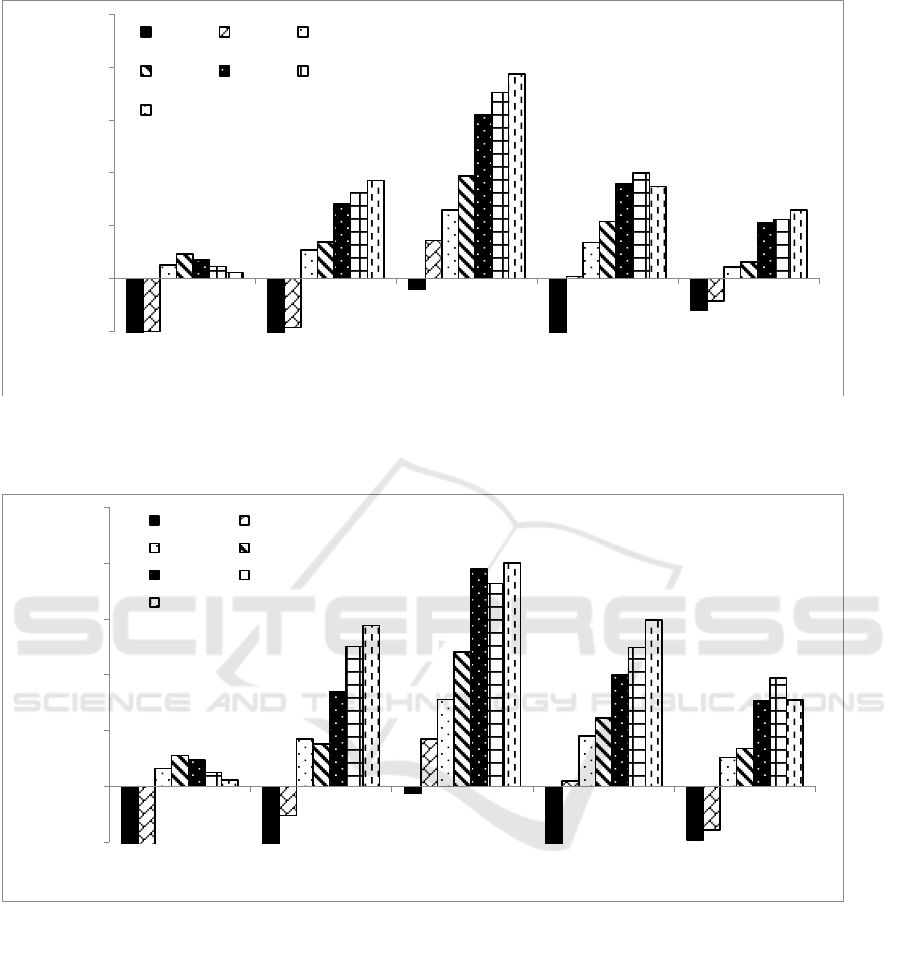

Figure 4: Dynamics of voltage (measured in open circuit mode) generated in the MFC by the biological product "Doctor

Robik 109K" (environment – model wastewater, substrate – lignin sludge from the Baikal Pulp and Paper Mill (0.1; 1.0; 2.0;

5.0 g/l), electrodes – carbon cloth.

Figure 5: Dynamics of the current strength (measured in the short circuit mode) generated in the MFC by the biological

product "Doctor Robik 109K" (medium – model wastewater, substrate – lignin sludge from the Baikal Pulp and Paper Mill

(0.1; 1.0; 2.0; 5.0 g/l), electrodes – carbon cloth).

concentration of this waste in the anolyte. So, in the

MFC with the addition of 0.1 g/l of sludge-lignin, for

123 hours of the experiment, the values of voltage and

current only slightly exceeded the control ones (in the

experiment – up to 124 mV and 139 μA, in the control

– up to 67 mV and 92 μA, respectively). But an

increase in the content of the substrate to 1 g/l led to

a significant increase in indicators. In this case, the

voltage generated by Clostridium increased to 405

mV, and the current increased to 403 μA. When 2.0

g/l of the tested waste was added to the MFC, these

indicators reached 402 mV and 742 µA, in the

presence of 5.0 g/l - 400 mV and 791 µA, respectively

(Fig. 2, 3).

The ability to generate current in MFCs, in which

the lignin sludge from the Baikal Pulp and Paper Mill

acted as a substrate, was also noted in the commercial

microbiological complex biological preparation

“Doctor Robik 109K. However, the efficiency of

these bioagents was significantly lower than that of

Cl. acetobutylicum.

-100

0

100

200

300

400

500

control 0,1 1 2 5

Voltage, mV

Sludge-lignin concentration, g/l

0 h 4 h 22 h

28 h 46 h 96 h

117 h

-100

0

100

200

300

400

500

control 0,1 1 2 5

Current strength, µA

Sludge-lignin concentration, g/l

0 h 4 h

22 h 28 h

46 h 96 h

117 h

Sludge-lignin of the Baikal Pulp and Paper Mill as a Substrate for Generating Electric Energy in MFC

319

Thus, the microbiological preparation "Doctor

Robik 109K" in MFC with the addition of 1 g/l of

sludge-lignin during 117 hours of the experiment

generated a voltage of up to 387 mV, a current of 400

μA. When lower (0.1 g/l) and higher concentrations

of lignin sludge (2 and 5 g/l) were introduced into the

MFC, the generated indicators were significantly

lower (Fig. 4, 5).

Waste incineration is used in the world to dispose

of waste from the pulp and paper industry; pyrolysis;

direct liquefaction; oxidation with moist air;

gasification, including plasma; composting (Zainith

et al. 2019); production of ethyl alcohol, lactic acid;

animal feed production; sludge granulation;

anaerobic digestion (Mandeep et al. 2020; Bakraoui

et al. 2019). Waste can also become a raw material

for the production of coal, fibreboard, cement and

cement products, concrete, ceramic material, drywall,

sorbents, fillers, as well as nanocomposites and

additives in the road surface (Larionova 2017; Jaria et

al. 2017; Simão et al. 2018).

This retreat presents a big problem in the Baikal

region (Tkachev, Dagaev 2021). The negative

features of the Baikal pulp and paper mill lignin

sludge are the formation in its deeper layers of a large

amount of toxic and foul-smelling gases: hydrogen

sulfide and methyl mercaptan, the presence of

organochlorine compounds, as well as the formation

of explosive methane gas (Solovyanov 2017). A

number of different physicochemical and

biotechnological approaches have been proposed for

the disposal of lignin sludge from the Baikal Pulp and

Paper Mill: drying in centrifuges and filter presses

followed by incineration (Fedyaeva et al. 2020),

backfilling of maps with lignin sludge with

construction debris, dehydration by layer-by-layer

freezing (Stom et al. 2018), use in the manufacture of

building materials (Bogdanov et al. 2017),

composting (Patent No. 2159756 RU), as a coagulant

in wastewater treatment (Patent No. 2136599 RF), for

obtaining organomineral fertilizers (Patent No.

2086521 RU) and soils (Bogdanov et al. 2021; patent

No. 2086521 RU), filling cards with ash pulp from

thermal power plants (Patent 2 526 983 RU), filling

and monolithic sludge (Samarin et al. 2020;

Kondratiev et al. 2017). However, despite the large

number of proposed approaches, the problem of

eliminating waste from the Baikal Pulp and Paper

Mill is still not resolved.

The data obtained in this work demonstrate the

possibility of utilizing lignin sludge from the Baikal

Pulp and Paper Mill in MFC with simultaneous

generation of electric current. The generation of

electricity in an MFC by adding pulp and paper waste

has been previously demonstrated by other authors

(Takeuchi et al. 2017; Cheng et al. 2012; Sugano et

al. 2010; Javed et al. 2017). This approach can be

promising both as one of the stages of processing

lignin sludge from the Baikal Pulp and Paper Mill,

and as an independent technological solution.

4 CONCLUSIONS

The possibility of using lignin sludge from the Baikal

Pulp and Paper Mill as a substrate in microbial

processes for generating electrical energy, on which

the MFC technology is based, has been demonstrated.

The scale of accumulation of this waste in the maps

of the sludge collectors of the now defunct enterprise,

their danger to the environment, especially in

connection with the territorial proximity to the unique

protected natural object - Lake Baikal, force us to

look for ways to effectively dispose of these wastes.

Great prospects for these purposes are seen in

biological technologies, which can make it possible

to convert waste into useful products - fertilizers,

fertile soil, etc. MFC can also act as one of the stages

of such a biotechnology for processing waste from the

Baikal Pulp and Paper Mill.

Of the tested strains and consortiums of

microorganisms, the Cl. acetobutylicum VKPM-

4786. Positive results were also obtained when using

the complex commercial biopreparation for cesspools

and septic tanks "Doctor Robik 109" as a bioagent,

however, the current generation processes by this

microbial consortium were less effective than when

using Cl. acetobutylicum.

ACKNOWLEDGEMENTS

The work was financially supported by the Ministry

of Science and Higher Education of the Russian

Federation within the framework of the state task in

the field of scientific activity (project no. FEWG-

2021-0013).

REFERENCES

Gromova, N. Yu., 2012. Theoretical aspects of the

bioconversion of cellulose-containing waste.

Proceedings of the International Academy of

Agricultural Education. 15(1). pp. 8-12.

Nikonorov, A. M., Matveev, A. A., Reznikov, S. A. et al.,

2012. Results of multiyear studies on the dynamics of

pollution of lake Baikal by polycyclic aromatic

MMTGE 2022 - I International Conference "Methods, models, technologies for sustainable development: agroclimatic projects and carbon

neutrality", Kadyrov Chechen State University Chechen Republic, Grozny, st. Sher

320

hydrocarbons in the area waste water discharge from

the Baikal Pulp and Paper. Plant Dokl. Earth Sc. 443.

pp. 361–364.

Varanasi, J. L., et al., 2015. Improvement of energy

recovery from cellobiose by thermophillic dark

fermentative hydrogen production followed by

microbial fuel cell. International journal of hydrogen

energy. I(II). pp. 1–11.

Stom, D. I., Zhdanova, G. O., Kashevskii, A. V., 2017. New

designs of biofuel cells and testing of their work. IOP

Conference Series: Materials Science and Engineering.

262. 012219.

Zainith, S., Chowdhary, P., Bharagava, R. N., 2019. Recent

Advances in Physico-chemical and Biological

Techniques for the Management of Pulp and Paper Mill

Waste. Bharagava R., Chowdhary P. (eds). Emerging

and Eco-Friendly Approaches for Waste Management.

Springer, Singapore.

Mandeep, G. K. G., Pratyoosh, Sh., 2020. Insights into the

resources generation from pulp and paper industry

wastes: Challenges, perspectives and innovations.

Bioresource Technology. 297. 122496.

Bakraoui, M., Karouach, F., Ouhammou, B. et al., 2019.

Kinetics study of the methane production from

experimental recycled pulp and paper sludge by CSTR

technology. J Mater Cycles Waste Manag. 21, pp.

1426–1436.

Larionova, N. A., 2017. The Use of Industrial Waste as a

Secondary Mineral Raw Materials for the Production

of Building Materials with Desired Properties.

Moscow: GeoInfo.

Jaria, G., Silva, C. P., Ferreira, C. I. A., Otero, M., Calisto,

V., 2017. Sludge from paper mill effluent treatment as

raw material to produce carbon adsorbents: An

alternative waste management strategy. Journal of

Environmental Management. 188. pp. 203–211.

Simão, L., Hotza, D., Raupp-Pereira, F., Labrincha, J. A.,

Montedo, O. R. K., 2018. Wastes from pulp and paper

mills - a review of generation and recycling

alternatives. Cerâmica, 64 (371).

Tkachev, V., Dagaev, Y., 2021. Requiem for Baikal as a

warning. E3S Web Conf., 284, 01012.

Solov'yanov, A. A., 2017. Past (accumulated)

environmental damage: problems and solutions, 10.

Waste of the Baikal Pulp and Paper Mill. Ecological

Bulletin of Russia, Publisher: Bulletin "Ekologicheskiy

Vestnik Rossii". 2. pp. 19–27.

Fedyaeva., O. N., Vostrikov, A. A., Artamonov, D. O. et

al., 2020. Combustion of Sludge-Lignin in Water-

Oxygen Mixture. J. Engin. Thermophys. 29. pp. 26–41.

Stom, D. I., Zhdanova, G. O., Potekhin, S. A., Balayan, A.

E., Saksonov, M. N., Butyrin, M. V., Kondratiev, V. V.,

Ivanov, N. A., Spirin, V. I., Kizeev, D. A., 2018.

Assessment of the possibility of using the method of

sludge-lignin dehydration of the Baikal Pulp and Paper

Mill by the freeze-thaw method. International Journal

of Engineering & Technology. 7 (2.23). pp. 114–118.

Bogdanov, A., Shatrova, A., Kachor, O., 2017. Use of the

Accumulated Waste of the Pulp and Paper Industry as a

Component Raw Material for the Production of

Cements. Ecology and Industry of Russia. 21(11). pp.

15-19.

Grishin, V. K., Method for composting sewage sludge

Patent No. 2159756 RU Publ. 11/27/2000.

Leonov, S. B. et al., Wastewater treatment method Patent

No. 2136599 RU Publ. 09/10/1999.

Suturin, A. N. et al., Method for obtaining organomineral

fertilizer Patent No. 2086521 RU, Publ. 08/10/1997.

Bogdanov, A. V., Shatrova, A. S., Darmaeva, L. B.,

Shkrabo, A. I., 2021. The use of pulp and paper industry

waste as soil for recultivation of disturbed lands. IOP

Conf. Ser.: Earth Environ. Sci. 677. 052005.

Suturin, A. N., Goncharov, A. I., Minaev, V. V., Kulikova,

N. N., Dambinov, Yu., A Method for reclamation of

sludge accumulators of enterprises for the production of

bleached sulfate pulp Patent 2 526 983 RU dated

11/14/2012.

Samarin, E., Kravchenko, N., Zerkal, O., Chernov, M. and

Rodkina, I., 2020. Grouting of Waste of the Baikal Pulp

and Paper Mill to Reduce the Technogenic Impact to

the Baikal Lake Ecosystem. Journal of Geoscience and

Environment Protection. 8. pp. 112–118.

Kondratyev, V. V., Gorovoy, V. O., Stom, D. I., Ivanov, N.

A., Balayan, A. E., 2017. Development of technology

of neutralization and binding sludge-lignin in cards

sludge collectors of the Baikal pulp and paper mill. 17th

International Multidisciplinary Scientific

Geoconference SGEM 2017 (conference proceedings).

17(52). pp. 257–264.

Takeuchi, Y., Khawdas, W., Aso, Y., Ohara, H., 2017.

Microbial fuel cells using Cellulomonas spp. with

cellulose as fuel. Journal of Bioscience and

Bioengineering. 123(3). pp. 358-363.

Cheng, H., Qian, Q., Wang, X., Yu, P., Mao, L., 2012.

Electricity generation from carboxymethyl cellulose

biomass: A new application of enzymatic biofuel cells,

Electrochimica Acta, 82, pp. 203-207.

Sugano, Y., Vestergaard, M., Yoshikawa, H., Saito, M. and

Tamiya, E., 2010. Direct Electrochemical Oxidation of

Cellulose: A Cellulose-Based Fuel Cell System.

Electroanalysis. 22. pp. 1688-1694.

Javed, M. M., Nisar, M. A., Muneer, B. and Ahmad, M. U.,

2017. Bioelectricity from Vegetable Waste Extract by

Designing a U-shaped Microbial Fuel Cell. Pakistan J.

Zool. 49(2). pp. 711–716.

Sludge-lignin of the Baikal Pulp and Paper Mill as a Substrate for Generating Electric Energy in MFC

321