Sustainable Development of the Metallurgical Industry based on the

Development of Waste-free Technologies and an Environmentally

Oriented Economy

Ilya Igumenov Maximovich

1

, Galina Pavlovna Gagarinskaya

2,3

,

Alexander Vladimirovich Gagarinsky

4

, Alexander Alexandrovich Khorovennikov

5

and Danila Alexandrovich Nekorysnov

1

1

Samara State University, Samara, Russia

2

Moscow State University of Technologies and Management Named After K.G. Razumovsky (PKU), Moscow, Russia

3

Volga Cossack Institute of Management and Food Technologies, Dimitrovgrad, Russia

4

Moscow State Pedagogical University Samara Branch, Samara, Russia

5

Samara State Transport University, Samara, Russia

Keywords: Environmentally-oriented economy, labor productivity, innovation, lean manufacturing, green economy.

Abstract: The article presents innovations in the organization of labor activity and personnel management of an

industrial enterprise. The topic of lean and eco-friendly production has been actively analyzed. The

unrestrained uncontrolled growth of the market economy leads to an increase in consumption and production

of goods, natural resources used for this, to an increase in harmful emissions and production waste into the

biosphere (environment). Humanity has come to an increasingly acute contradiction between its growing

needs and the inability of the biosphere to provide them with resources without collapsing. Aluminum is

called a material for the "green economy".

1 INTRODUCTION

The problem of studying the sustainability of the

development of the economy of the metallurgical

sector of industry is becoming increasingly important

today. This is due to the fact that one of the most

important problems in the organization's activities is

the insufficiently effective use of working time by

staff. The relevance of the study of this problem is

determined by the peculiarities of modern reality,

when the internal environment of the organization

becomes more complex, and the external

environment requires the organization to constantly

search for improving work efficiency.The working

time of most employees of modern organizations is

condensed to the limit, the working day is not

standardized, and yet it is often not possible to

complete all the planned tasks by the specified

deadline, and the results of the activity itself do not

always satisfy the management. Therefore, the

problem of managing the rationalization of the use of

working time by personnel as society develops,

increasing the dynamism of changes, increasing the

"information component" in the final product,

becomes a significant factor in the effectiveness of

the organization.

2 MATERIALS AND METHODS

The methodological basis of the research consists of

general scientific dialectical, systemic and situational

approaches, laws of logic, typology, basic provisions

of economic theory and entrepreneurship theory, as

well as methods of economic and mathematical

modeling, economic analysis and synthesis, empirical

generalization, etc.

The empirical basis of the study was the official

information of the Federal State Statistics Service, the

Ministry of Economic Development of the Russian

Federation, the Ministry of Energy of the Russian

Federation, open sources of petrochemical companies

and their divisions (Rosneft Oil Company, Gazprom

Neft, Sibur Holding, etc.), published materials and the

results of research by domestic and foreign scientists,

and also, the primary information of economic

research carried out with the direct participation of

the author for fourteen years (2008-2021)

300

Maximovich, I., Gagarinskaya, G., Gagarinsky, A., Khorovennikov, A. and Nekorysnov, D.

Sustainable Development of the Metallurgical Industry based on the Development of Waste-free Technologies and an Environmentally Oriented Economy.

DOI: 10.5220/0011570800003524

In Proceedings of the 1st International Conference on Methods, Models, Technologies for Sustainable Development (MMTGE 2022) - Agroclimatic Projects and Carbon Neutrality, pages

300-305

ISBN: 978-989-758-608-8

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

(Chapman,2003; Das, 2004; Marler, 2010; Stone,

2009).

In the development of industry, along with large-

scale investment projects, the following characteristic

stages can be distinguished: over the past 15-20 years

- the development and expansion of the application of

the concept of lean manufacturing; over the past 10

years, the addition to the "lean" environmental

agenda; in recent years and months, the transition to

the concept of sustainable development, including the

above and the social sphere.

The concept of lean manufacturing was developed

by Toyota, which was actively perceived and

developed by a large number of companies around the

world. With its adaptations and features, with

different names, this system of continuous

improvements, involving as many employees as

possible, has become an integral part of the

production and overall business activities of all

modern successful metallurgical companies. This

experience is reflected in a large number of book

publications, articles, studies and essays (Marler,

2010; Schmidt).

The unrestrained uncontrolled growth of the

market economy leads to an increase in consumption

and production of goods, natural resources used for

this, to an increase in harmful emissions and

production waste into the biosphere (environment).

Humanity has come to an increasingly acute

contradiction between its growing needs and the

inability of the biosphere to provide them with

resources without collapsing.

Awareness of this problem led to the idea and

strategy of sustainable development of global

civilization, states, regions, industrial companies and

enterprises.

Locally, in a number of regions of agglomerations

and single-industry towns, there is a significant

excess of emissions over absorption. The Federal

project "Clean Air" has set a goal to reduce harmful

emissions by 20% in 12 major industrial centers by

2024. In his annual message, the President proposed

to expand such quotas to all cities where the problem

of air quality is acute, and there are more than 40 of

them in the country (Das, 2004; Sapunova, 2018).

In general, over the next 30 years, i.e. by 2050, the

task has been set to ensure in the Russian Federation

a better net result on the difference between emissions

and absorption of greenhouse gases than neutral in the

European Union. This goal is quite achievable with

an active policy of decarbonization of industry and

the economy, with a significant potential for the

absorption of greenhouse gases.

Responsible industrial corporations and

companies, including metallurgical ones, create and

implement their development strategies and programs

that provide for a significant reduction in energy

consumption and harmful emissions in the regions

and places of their production locations.

Among the metallurgical companies, the

production of aluminum and metal products from

aluminum alloys is interesting. Aluminum is called a

material for the "green economy". Firstly, it is

produced in the Russian Federation mainly using

renewable sources of electricity (HPP). Secondly, the

waste from this during production or during disposal

(at the end of the life cycle of the final products) is

fully involved in production cycles. Thirdly, the use

of aluminum and its alloys due to their unique

properties provides a low mass of structures,

sufficient strength, high corrosion and cryogenic

resistance, etc., brings an improvement in the

technical characteristics of products and benefits in

their operation, both economic and environmental.

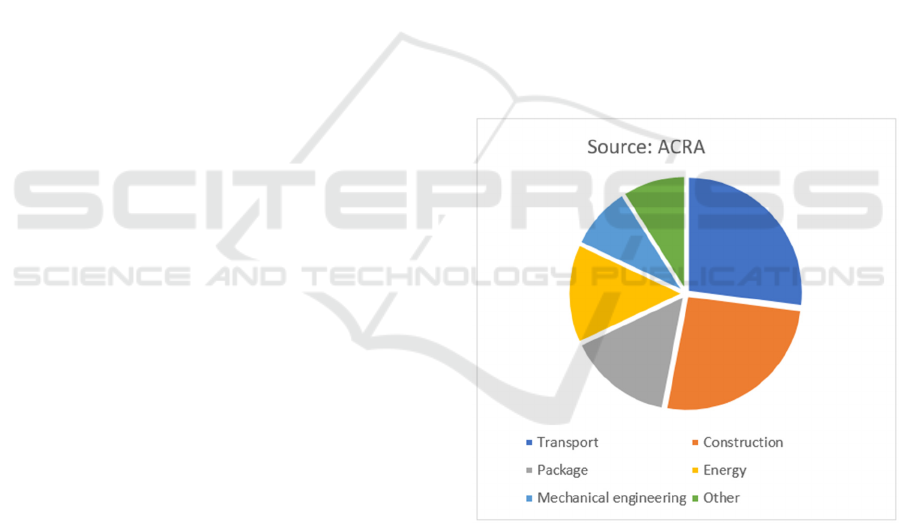

The figure 1 shows the areas of application of

aluminum.

Figure 1: Areas of aluminum consumption by industry (%).

The priorities of the aluminum industry in

developed countries include the expansion of the use

of aluminum in various consumer industries and the

development of production of products with high

added value. Russian aluminum production

enterprises have been merged into RUSAL

Corporation. At the end of last year, they produced

3.75 million tons of aluminum. The corporation

positions itself as a manufacturer of products with a

low carbon footprint, which is less than 4 tons of

CO2

Sustainable Development of the Metallurgical Industry based on the Development of Waste-free Technologies and an Environmentally

Oriented Economy

301

per ton of metal. Mainly due to the fact that the energy

of hydroelectric power plants (HPPs) is used in the

production of aluminum. The global average is 12

tons of СО

2

. In China, the largest producer of

aluminum, where coal plants form the basis of

energy, the carbon footprint reaches up to 18 tons per

ton of metal (Strohmeier, 2007; Tzafrir, 2005).

RUSAL has registered its own brand of "low-

carbon" aluminum Allow, including for its more

successful promotion with the "green brand" on the

world market. RUSAL plans to develop its

advantages, has begun a large-scale modernization of

its four largest plants in Krasnoyarsk, Bratsk,

Shelekhov (near Irkutsk) and Novokuznetsk. This

project will require 380 billion rubles and is designed

for 2022-2027. RUSAL expects that by updating

production and switching from the traditional

electrolysis technology used worldwide to the

prebaked anode electrolysis technology, it will make

its aluminum production even more productive,

environmentally friendly and economical.

Along with aluminum producers (RUSAL, etc.),

manufacturers of metal products made of aluminum

alloys (tapes, sheets, profiles, pipes, rods, stampings)

adopt and implement their strategies and programs for

the transition to "green technologies" and "green

metal products" together with increased productivity.

So, for example, Arconic Corporation (Arconic),

which includes the company Arconic SMZ JSC

(hereinafter SMZ - Samara Metallurgical Plant), due

to the "greening" of their technologies, significantly

improved environmental indicators for 2020 -

according to the corporation, greenhouse gas

emissions were reduced at plants around the world (-

14%), consumption energy (-12%) and water (-8%);

SMZ reduced the consumption of electricity (-6%),

gas (-7%) and water (-13%) (Sarukhanyan, 2016)

(Sarukhanyan, 2016;GOST R ISO 14001-2016).

In 2020, SMZ once again confirmed compliance

with the requirements of the international

environmental standard ISO 14001, and also received

professional recognition from the international

organization ASI (Aluminum Stewardship Initiative),

which develops and promotes standards for

responsible management of aluminum production

and marketing. In the annual regional competition of

the Samara region "Eco-leader – 2020", SMZ took

first place in the nomination "Industrial Giant".

Constant investments help the plant to comply with

advanced technologies and environmental standards:

since 2005, USD 0.5 billion have been allocated for

the modernization of the SMZ, including for the

improvement of environmental protection and

industrial safety systems – more than USD 40 million.

A multi-year program for the conservation of the

biodiversity of the Samara region, which is supported

by the Arconic Foundation, contributes to the

protection of the ecological well-being of the Samara

region. Over 5 years, the Fund has allocated USD 235

thousand for the implementation of environmental

projects in the Samarskaya Luka National Park and

the Zhiguli State Reserve (Amrutha, 2020; Zakharov,

2019).

Arconic and SMZ aluminum metal products can

be attributed to the leaders in environmental

friendliness – to "green semi-finished products".

Their use in subsequent technological conversion

industries (packaging, mechanical engineering,

construction, etc.), producing the final "green

products", carries not only an improvement in the

technical characteristics of products and economic

benefits, but also positive environmental effects.

3 RESEARCH RESULTS

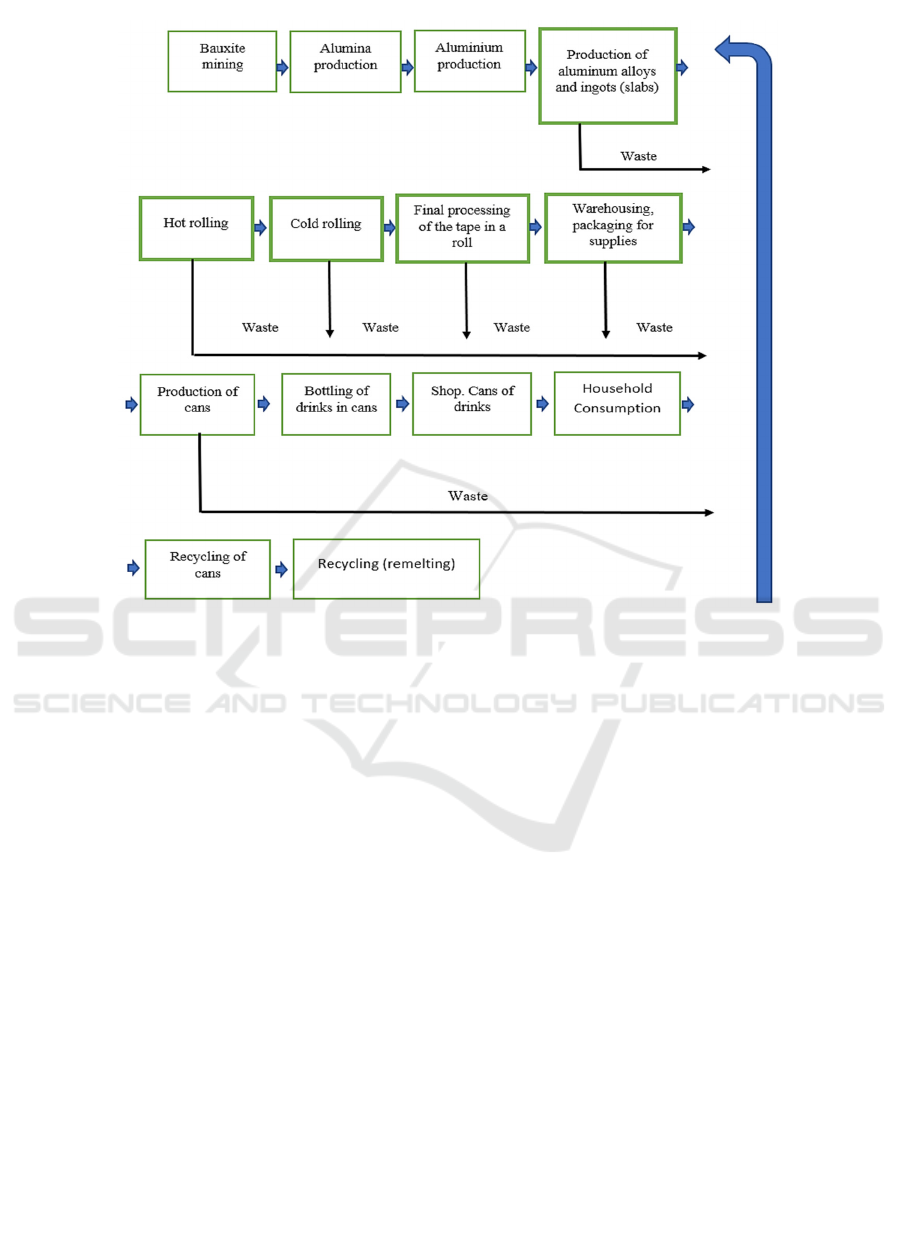

An example of a "green metal product" of SMZ is an

aluminum tape for beverage cans. Aluminum can is a

leader in recycling and environmental friendliness.

The figure 2 shows the scheme of production and

recycling of aluminum, tin tape and cans. From 4 tons

of bauxite, 2 tons of alumina are obtained, of which 1

ton of aluminum. Further along the production cycle

and recycling, all waste (there is a permanent program

to reduce them) and recycled cans are fully involved

in production. Treatment and recycling of one

aluminum can (0.5 liters – 14 grams) instead of

producing an appropriate amount of primary

aluminum by electrolysis, prevents the release of 100

grams of

CO2

. In Russia, there are factories for the

production of aluminum cans with a total output of

several billion pieces per year. Aluminum alloys, due

to their advantages, are increasingly used in transport

engineering. Arconic Corporation is actively working

in this direction. Along with the supply of metal

products for the aircraft industry, Arconic, together

with manufacturers of ground transport equipment,

participates in the creation of new types and models

of machines using aluminum parts and structures. The

corporation's enterprises master and supply the new

types and sizes of metal products necessary for this.

For example, Ford uses an all-aluminum body made

of Arconic sheets and profiles in the manufacture of

the F-150 SUV pickup truck. SMZ initiates and

participates in a number of projects for the use of its

products in special road and rail transport. Examples

of such machines are railway hoppers – for the

transportation of bulk products, tankers for the

MMTGE 2022 - I International Conference "Methods, models, technologies for sustainable development: agroclimatic projects and carbon

neutrality", Kadyrov Chechen State University Chechen Republic, Grozny, st. Sher

302

transportation of fuel, aggressive acids and cryogenic

liquid products, etc. The bodies and tanks for them

are made of aluminum metal products with special

properties. Compared with steel analogues, the load

capacity increases, energy costs and

CO2

emissions

decrease, corrosion resistance and service life

increase, intrinsic safety is guaranteed (important

when transporting fuel), etc (Teo, 2001; Ryazantsev,

2020).

The social sphere is the sphere of human capital,

its condition and development: employees of the

company and the surrounding community. For

employees, these are, first of all, conditions for safe

and comfortable work, conditions of remuneration

and social package, conditions for training and

development, conditions for equality and fairness, for

involvement in improvements in all spheres and

business processes. For the community, this is the

company's activity to improve the ecology and socio-

cultural environment, to improve the professional

level and vocational guidance of young people in

places (locations) of activity, etc. Attention is also

paid to the younger generation – through career

guidance programs at school, robotics classes, etc.

The corporation and the plant cooperate with

universities and colleges in the locations of the main

required specialties. Meetings are held with

applicants and students.

Labor productivity is one of the most important

means (factors) and methods of sustainable

development and is the subject of modern research in

the field of economic and social sciences. Systematic

work to stimulate its growth is carried out through

specialized centers of competence and labor

productivity growth created in a number of countries

(an overview of which is given in our article). At the

same time, recent research papers often emphasize

the importance of social growth factors along with

technical ones. Attention is paid to the introduction of

lean manufacturing practices and organizational

culture modernization programs (Sapunov, 2021;

Simionescu, 2020).

There are various metrics to measure

performance. Their choice for specific research is

determined by the policy vector, as well as the

availability of data. The coefficient used to evaluate

labor productivity allows you to evaluate the

efficiency of using resources for the production of

goods and services. In this case, both total

employment and the total number of hours worked

can be considered as indicators of resource

utilization.

Figure 2: Aluminum production and recycling of aluminum tape and cans.

Sustainable Development of the Metallurgical Industry based on the Development of Waste-free Technologies and an Environmentally

Oriented Economy

303

One of the most widely used approaches at the

country level is the measurement of labor

productivity as gross domestic product (GDP) per

hour of work. Productivity that takes into account

working hours is more indicative in terms of

reflecting labor costs than productivity that takes into

account the number of employees (OECD, 2019). If

you rely on the number of employees, the study will

miss the impact of the development of part-time and

overtime work (Das, 2004; Ryazanov, 2021).

The disadvantage of using the number of hours

worked in the denominator of the formula is the

complexity of obtaining statistical data and their

reliability. Even in developed countries, working

hours are most often recorded in terms of the number

of hours paid, rather than the actual hours worked.

Accordingly, such non-working hours as paid annual

leave, sick leave, maternity leave, parental leave, etc.

are not adjusted. There is a common situation when

statistics are collected only for certain categories of

workers (only for employees) or for certain categories

of enterprises (belonging to key sectors of the

economy or having a sufficiently large size) (ILO,

2015). For underdeveloped countries, these problems

are getting worse.

The models that allow the country to achieve a

high level of labor productivity are:

1) low cost of the final product with a large

volume of production and a low percentage of

employees (typical for Arab countries

specializing in oil production);

2) production of expensive products with a high

(or at least average) percentage of the

employed population (typical for the United

States and most Western European countries);

3) production of expensive products with a low

percentage of the employed population.

Labor productivity in a broad sense includes the

productivity of materialized labor (characterized by

the profitability of capital investments) and the

productivity of human labor (characterized by the

volume of production). When forming the policy of

labor productivity management, special attention is

paid to the technical side of the issue - the purchase

of new equipment, the introduction of resource-

saving technologies, modernization of production

lines, etc. All this requires additional costs, as it is

associated with investment activities. In a resource-

constrained environment, more and more companies

decide to activate their internal reserves and develop

measures aimed at increasing labor productivity

through the proper organization of the workspace,

business processes and the introduction of lean

manufacturing technologies.

The main provisions of the scientific organization

of labor are:

− improvement of labor specialization,

− improvement of workplace organization,

− improvement of working methods,

− optimization of the labor force rating,

− staff training (Krivov, 2016).

One of the modern forms of labor specialization is

outsourcing of non-core functions, standard and mass

operations using similar algorithms for different

enterprises. The obvious advantages of outsourcing

are the absence of the need for investments in

specialized equipment and training of qualified

employees, the guarantee of uninterrupted operation,

the possibility of applying the best practices and

experience, as well as the ease of control "by results".

At the SMZ, for example, vehicles used to deliver

products to customers have been outsourced.

Within the framework of personnel management

at a new level of automation, such tools for improving

the efficiency of employees' working hours as

timekeeping and photographing working hours, as

well as standardization of operations, have become

widespread.

4 CONCLUSIONS

The methods used to assess the level of labor

productivity often do not reflect the real picture. This

makes it difficult not only to conduct international

comparisons, but also to assess changes in dynamics.

Analysis of some existing methods and

performance management policies has shown that

they can be divided into two groups. The first is

focused on the use of reserves, optimization of

existing business processes, production, logistics, etc.

The second involves additional investments and is

aimed at introducing modern technologies. The latter

will be effective only if all the processes at the

enterprise are sufficiently developed and fixed, and

the organizational culture corresponds to the goals

and objectives of the company (Bikmukhametova,

2019).

Building a policy of labor productivity

management, most countries rely on small and

medium-sized businesses, form effective consulting

and methodological support for enterprises

participating in the program, and create regional and

industrial support centers.

The question of whether labor productivity is a

source of structural changes or, conversely, arises as

a result of economic restructuring remains debatable.

MMTGE 2022 - I International Conference "Methods, models, technologies for sustainable development: agroclimatic projects and carbon

neutrality", Kadyrov Chechen State University Chechen Republic, Grozny, st. Sher

304

A number of economists note in their works that the

problem of labor productivity management is not so

relevant and does not require special attention, it is

necessary to focus on managing domestic demand

and developing tools to stimulate it. In our opinion,

labor productivity management is the most important

condition for ensuring sustainable socio-economic

development. In the conditions of the demographic

trap, the growth of labor productivity will ensure a

decent level and quality of life of the population, the

restructuring of the economy to a new regime. At the

same time, labor productivity should be understood in

a broad sense, when not only technical growth factors

play an important role, but also the transformation of

social and organizational components, the

involvement of all employees in a continuous process

of improvement. Only an integrated approach can

ensure the achievement of growth targets and the

stability of the economic system.

REFERENCES

Chapman, D. S., Webster, J., 2003. The use of technology

in the processes of recruitment and selection of

candidates for work. International Journal of Selection

and Evaluation. 11. pp. 113-120.

Das, T. K., Teng, B. S., 2004. The risk-based view of trust:

a conceptual framework. J. Bus. Psychol. 19(1). pp. 85-

116.

Marler, J. H., Fisher, S. L., 2010. An evidence-based review

of e-HRM and strategic human resource management.

Stone, D. L., Lukaszewski, K., 2009. An extended model of

factors influencing the adoption and effectiveness of

electronic human resource management system.

Human Resources Management Review. 19. pp. 134-

143.

Strohmeier, S., 2007. E-HRM research: overview and

implications. Review of Human Resource Management.

17. pp. 19-37.

Teo, T. S. H., Soon, L. G., Fedric, S. A., 2001.

Implementation and impact of Human Resources

Information Systems (HRIS). Research and Practice in

the field of human resources. Management. 9. pp. 101-

117.

Tzafrir, S., 2005. The relationship between trust, HRM

practices and firm performance. Int. J. Hum. Resour.

Manag. 16(9). pp. 1600-1622.

Schmidt, A. V., The Development of Human Capital on the

Basis of Wage Efficiency. Sochi Journal of Economy,

pp. 300-307.

Schmidt, A. V. Forms of the organization's contribution to

the development of human capital, Research,

systematization, cooperation, development, analysis of

socio-economic systems in the field of management

economics: proceedings of the III All-Russian School-

Symposium of Young Scientists. pp. 236-240.

Ryazantsev, S. V., Arkhangelsky, V. N., Vorobyova, O. D.,

2020. Demographic development of Russia: trends,

forecasts, measures. National Demographic Report -

M.: LLC "United Edition", p. 156.

Sapunov, А. V., Sapunova, T. A., Bagyan, G. A., 2021.

Analysis of the current demographic situation in the

russian federation. Journal of Natural and

Humanitarian Studies. 33(1). pp. 187-189.

Sapunova, T. A., Gordeychik Yu. A., 2018. Problems of the

demographic crisis in Russia. Vector of Economy.

5(23). p. 22.

Sarukhanyan, L. A., 2016. Problems of the institution of

marriage in the Russian Federation. International

Journal of Applied and Fundamental Research. 11-4.

pp. 775-777.

Shchelakova, V. A., Negreeva V. V., Salmanov A. B.,

2019. Assessment of the demographic situation to

ensure the national security of Russia. Scientific journal

of National Research University ITMO. The series

"Economics and Environmental Management". 3. pp.

77-81.

Simionescu, M., Krivokora, E., Fursov, V., Astakhova, E.,

2020. Problems of development of the labor potential

of the regions of the russian federation, taking into

account their differentiation. Terra Economicus. 16(4).

pp. 95-101.

Ryazanov, V., 2021. The crisis is not childish. Expert. 17.

Amrutha, V. N., Geetha, S. N., 2020. A systematic review

on green human resource manage-ment: Implications

for social sustainability. Journal of Cleaner

Production. 247. pp. 119-131.

Bikmukhametova, I. S., Alyoshkina, O. V., 2019.

Definition of the category "corporate social

responsibility". Electronic scientific journal "Vector of

Economics". 12.

Zakharov, D. K., Kashtanova, E. V., 2019. Introduction of

professional standards in the personnel management

system of the organization. Personnel and intellectual

resources management in Russia. 8(6). pp. 34-37.

GOST R ISO 14001-2016. National Standard of the

Russian Federation "Environmental management

systems. Requirements and application guide"

https://docs.cntd.ru/document/1200134681.

Sustainable Development of the Metallurgical Industry based on the Development of Waste-free Technologies and an Environmentally

Oriented Economy

305