Innovative Technologies for Detecting Methane in the Atmosphere

R. F. Mustafin

1,2

, M. R. Bogdanov

3

and R. R. Khisamov

1

1

Bashkir State Agrarian University, Ufa, Russia

2

Ufa State Petroleum Technical University, Ufa, Russia

3

Bashkir State Pedagogical University Named After M. Akmulla, Ufa, Russia

Keywords: Extreme environmental conditions, habitat, sustainable architecture, physical and climatic parameters.

Abstract: The article is devoted to the actual problem of the formation of sustainable architectural objects for extreme

living conditions, caused by physical and climatic parameters. It has been established that globalization, the

acceleration of the pace of scientific and technological progress, the growth of the global population and the

increasing pressure on the environment caused by these factors lead architects, engineers and researchers to

the need to quickly respond to changing conditions and form a favorable artificial environment in extreme

environments, which are determined by physico-climatic, anthropogenic physical and socio-economic param-

eters. The purpose of the study is to identify the principles of the formation of architectural objects in extreme

conditions in the context of international architectural and engineering trends. The methodological approach

to the study of this issue is based on system analysis and is based on the materials of implemented and de-

signed buildings and structures, as well as the study of open scientific research. The materials of the article

can be used for the theory and practice of the formation of an artificial environment for extreme living condi-

tions.

1 INTRODUCTION

It is impossible to imagine the life of modern society

without achievements in the field of analytical

chemistry. Accurate and timely analysis of various

compounds is required in the fuel industry,

agriculture, pharmaceuticals, food industry and many

other industries. Chemical analysis of gaseous

substances acquires a special role and importance. In

the gas industry enterprises, air cleanliness and gas

leaks in pipelines are constantly monitored, engineers

talk about “hydrogen energy”, experts in the field of

transport are developing environmentally friendly

fuel for rockets, airplanes and cars based on methane.

2 SCIENTIFIC AND LITERARY

REVIEW

The problem of determining the composition of the

gas mixture becomes particularly relevant in the light

of testing hypotheses about climate change and

natural gas leaks during production and

transportation.

Climate change research

Questions about global warming have been the

subject of scientific discussions for a number of years.

According to some estimates (Lal, 2008; Schrader,

1995; Degler, 2015; Elger, 2019; Kohl, 1989; Stuart,

2005; Mizaikoff, 2013; Wilk, 2012; Glöckler, 2020),

global surface temperatures have increased by about

0.88°C since the end of the 19th century.

Terrestrial ecosystems have been a source of

atmospheric carbon dioxide since the dawn of

agriculture, and methane since the domestication of

cattle and the cultivation of rice fields. Increasing the

concentration of carbon dioxide in the atmosphere

enhances the effect of fertilizer. The restoration of

degraded ecosystems and the combination of carbon

cycles with nitrogen and phosphorus increases the

carbon stock in terrestrial ecosystems.

Based on the above, it can be concluded that the

validity of climate forecasts depends on the accuracy

of measuring the concentration of carbon dioxide and

methane.

Natural gas leaks

Methane is the main component of natural gas.

Methane emissions can be the result of equipment

malfunctions such as pipe cracking or leaky pipe

Mustafin, R., Bogdanov, M. and Khisamov, R.

Innovative Technologies for Detecting Methane in the Atmosphere.

DOI: 10.5220/0011569000003524

In Proceedings of the 1st International Conference on Methods, Models, Technologies for Sustainable Development (MMTGE 2022) - Agroclimatic Projects and Carbon Neutrality, pages

227-233

ISBN: 978-989-758-608-8

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

227

connections, emission methods such as flaring, or

accidental emissions during normal transportation,

storage and distribution operations (Glöckler, 2020).

In addition, methane emissions from wells can be

caused by loss of integrity of natural gas due to

defective sealed casing pipes, cement wear in

boreholes or transverse migration along neighboring

geological formations (Fortes, 2014). Methane

released as a result of leakage through wells and

equipment accounts for 8.5% of greenhouse gas

emissions in Canada (Fortes, 2014; Dosi, 2019).

Methane emissions from the global transportation of

liquefied natural gas account for more than 5% of the

total 932 million tons of CO

2

equivalent. Average

methane emissions from oil and gas wells in

Pennsylvania reach 55,600 tons per year. In

northeastern British Columbia, where shale gas

basins are located, 75,000 metric tons of methane

were released per year.

3 MATERIALS AND METHODS

Methane (CH

4

), a combustible gas that has neither

smell nor color, is the main component of natural gas

(Aldhafeeri, 2020). It is used as a fuel worldwide as a

source for electricity generation and heating and plays

a significant role in climate change. Methane is a

powerful greenhouse gas (GHG) with a global

warming potential 28 times higher than that of carbon

dioxide (CO

2

) over a 100-year period (Aldhafeeri,

2020). Since the beginning of the industrial

revolution, the concentration of methane in the

atmosphere has increased dramatically from about

800 parts per billion (ppb) in the early 1900s to more

than 1800 parts per billion in 2016. This increase can

be explained, first of all, by the following

anthropogenic sources of emissions: landfills,

livestock waste, coal mining, petrochemical

production, as well as oil and gas distribution and

production facilities (Aldhafeeri, 2020). In addition,

methane ignites and can be explosive if its

concentration reaches 5-15% indoors (Aldhafeeri,

2020). Despite its negative impact on the

environment, natural gas is valued for its abundance

and clean combustion process, and therefore it will be

widely used in the future (Aldhafeeri, 2020). It

replaces coal due to lower CO

2

emissions in the

process of combustion and lower production cost

(Stuart, 2005). Moreover, it is predicted that in the

future natural gas will become the second most used

source of energy (Aldhafeeri, 2020).

Since the use of natural gas in the future is

inevitable, it is necessary to develop solutions to

reduce methane emissions.

To detect leaks in the natural gas infrastructure, it

is necessary to develop reliable and cost-effective

methane detector sensors. This will allow pollutants

and law enforcement agencies to detect and eliminate

leaks in a timely manner. Therefore, many methane

sensors have been developed, each of which has its

own technology. Sensors based on different physical

principles are used to detect methane, for example:

optical sensors, capacitive sensors, calorimetric

sensors, resonance sensors, acoustic sensors,

pyroelectric sensors, semiconductor sensors based on

metal oxide (MOx), electrochemical sensors.

The purpose of the proposed work is to describe

some new approaches in the field of methane

detection. The advantages and disadvantages of these

approaches, as well as various scenarios for their

application, will be considered.

4 OPTICAL SENSORS

Optical gas sensors detect changes in electromagnetic

waves resulting from the interaction of the analyte

with the receptor (Aldhafeeri, 2020). The most

common instrument for determining methane is

infrared (IR) absorption spectroscopy, based on the

fact that methane gas has two strong absorption lines

- 2.3 and 3.26 micrometers (mid-IR range) and two

weak absorption lines – 1.33 and 1.6 micrometers

(near-IR range).

There are several approaches aimed at improving

optical methods for detecting methane. Yang et al.

(Aldhafeeri, 2020) increased the sensitivity of an

optical methane sensor with a long-period fiber

grating (LPFG) using a polycarbonate/cryptophane

overlay with a high refractive index. The change in

the thickness of the overlay led to a shift in the

resonant wavelength, and at the optimal thickness, a

significant increase in the sensitivity of the sensor

was observed. Dong et al. improved the sensor based

on the Fabry-Perot cavity (FPC) resonator to improve

the accuracy of gas measurement. The technique

consisted in recording the transmission maxima of the

resonator modes by scanning the resonator

wavelengths at each laser frequency. It was found that

the FPC sensor with integrated new technology was

able to achieve a methane detection sensitivity of 0.7–

2.9 parts per million by mass (ppm-m). Zhang et al.

developed a fiber-optic methane sensor based on

graphene-doped tin oxide. The sensor was

manufactured by coating optical fibers with lateral

MMTGE 2022 - I International Conference "Methods, models, technologies for sustainable development: agroclimatic projects and carbon

neutrality", Kadyrov Chechen State University Chechen Republic, Grozny, st. Sher

228

polishing with thin films of tin oxide doped with

graphene, while the light source operating in the

visible region was tuned to a wavelength of 1550 nm.

An interesting implementation of the optical

method of methane detection is the combination of IR

spectroscopy and remote chemical sensing. Yutaka

and his collaborators (Matsumi, 2016) have

developed a method for measuring methane by the

open optical path method by detecting the second

harmonic, using a near-IR diode laser for IR

absorption spectroscopy. During field measurements

in rice fields in India, the laser beam is returned by a

reflector located tens of meters from the device and

detected by a photodetector in the device (Figure 1).

The measurement error at a distance of 50 m was 2%.

Figure 1: A field system for measuring methane

concentration (CH

4

) using a LaserMethane miniG detector

(LMm) and a solar power source (Matsumi, 2016).

5 CALORIMETRIC SENSORS

Calorimetric sensors are used to detect methane and

other combustible gases in coal mines, drilling rigs,

oil refineries, and landfills (Aldhafeeri, 2020). There

are three types of calorimetric sensors: a catalytic gas

sensor, an adsorbent-based gas sensor, and a gas

thermal conductivity sensor. A calorimetric gas

sensor often consists of a temperature meter, a

catalytic combustion chamber and a heating element.

The principle of operation of a calorimetric sensor is

based on the fact that a chemical reaction or a physical

adsorption process absorbs or releases heat. The most

important part of the calorimetric sensor is the

material that interacts with the gas. The surface layer

is often used as a combustion reaction catalyst to

reduce the combustion temperature. Platinum (Pt),

palladium (Pd) and rhodium (Rh) are the most

commonly used catalysts in calorimetric gas sensors.

Conventional calorimetric sensors use a catalytic coil

made of platinum or palladium, also known as a

pellistor. For methane, gas oxidation in contact with a

catalyst is an exothermic reaction with the release of

heat. This leads to a change in the temperature of the

catalytic surface due to a chemical reaction, which is

used by calorimetric sensors to obtain a useful signal.

Calorimetric gas sensors are simple, cheap and

convenient to use. These sensors are affected by

temperature, pressure and humidity, however, they

are sensitive to methane and other hydrocarbons.

Purely calorimetric methane sensors have a

measurement error of 5%. Calibration using gas with

a known concentration is proposed to increase

accuracy.

6 PYROELECTRIC SENSORS

Pyroelectric sensors register electromagnetic

radiation at a certain wavelength range. They convert

electromagnetic or thermal energy into electricity.

They are non-contact thermometers operating at room

temperature. In the sensor, the dielectric is located

between two electrodes. The advantages of the

pyroelectric methane sensor include its ability to

work without oxygen, good sensitivity and a wide

operating range. These sensors can operate at room

temperature. In addition, the pyroelectric effect is a

thermal process in which no chemical reactions are

involved, so the risk of degradation of the sensor is

reduced. However, pyroelectric sensors are expensive

and require a high-energy power source and a

constant source of heat or infrared radiation, which

makes them unsuitable for many applications. In

addition, they are difficult to manufacture, since a thin

pyroelectric element must be fixed on a supporting

base.

Dong et al. have developed a multi-gas sensor

system that uses one broadband light source and

several pyroelectric sensors for carbon monoxide,

carbon dioxide and methane using time-division

multiplexing (TDM) technology. A rotating system

based on a stepper motor and a spherical optical

Innovative Technologies for Detecting Methane in the Atmosphere

229

mirror with a single reflection have been developed

and integrated to improve the detection of multiple

gases. Experimentally, it was determined that the

detection limit of methane is 2.84 ppm.

7 SENSORS BASED ON METAL

OXIDES MOX

Sensors based on metal oxides are attracting more and

more attention of analytical specialists (Glöckler,

2020). The principle of operation of such devices is

based on the reactions of transformation of target

molecules on their semiconductor surface. Johannes

and his collaborators (Glöckler, 2020) combined two

optical sensing methods - luminescence quenching

for molecular oxygen and infrared spectroscopy for

carbon dioxide and methane to study the behavior of

a sample of a semiconductor MOx sensor of methane

integrated into a small volume gas cell. As a result of

the experiments, it became possible to quantitatively

control oxygen consumption, as well as the formation

of carbon dioxide as a result of the methane

conversion reaction during the operation of the MOx

sensor. The latter was analyzed using a gas analyzer

in the mid-infrared range, based on the technology of

a hollow waveguide integrated into the substrate

(substrate-integrated hollow waveguide, iHWG), in

combination with a portable infrared spectrometer

with Fourier transform, which can not only determine

the amount of carbon dioxide released, but also the

consumption of methane during the operation of a

MOx sensor. This approach made it possible to

quantify organic compounds (CH

4

) in real time in

traces. The use of chemical-resistant gas sensors

based on semiconductor metal oxides makes it

possible to detect explosive gases such as propane

and toxic gases such as carbon monoxide or nitrogen

dioxide, to detect gas leaks in atmospheric conditions

and identify volatile organic compounds. This

approach can be used in agriculture, automotive

industry, indoor air quality control and monitoring of

gases in the environment. The disadvantages of MOx

sensors include limited selectivity, the advantages are

small area, fast response and cost-effectiveness

compared to traditional analytical methods, such as

gas chromatography combined with mass

spectrometry (GC-MS) and infrared Fourier

transform spectroscopy (FTIR) using bulky multi-

pass gas cells.

MOx sensors consist of a substrate equipped with

electrodes (for example, ceramic Al

2

O

3

), which is

covered with a sensitive layer. The electrodes allow

analyzing changes in the conductivity of the sensitive

layer. In addition, resistive heaters are integrated into

the sensors, which are electrically separated by an

insulating shield from the sensor, which later allows

heating the measuring electrode in the range of 200-

400 °C. Heating of the sensor layer increases the

sensitivity of MOx sensors due to the higher

conductivity of the semiconductor and faster

adsorption/desorption of target particles on/off the

surface.

Studies of SnO

2

surfaces have shown that

methane oxidation occurs during several intermediate

stages compared to acetate before complete oxidation

to water and carbon dioxide. Acetaldehyde could be

detected both on the surface and in the gas phase.

However, these reactions do not proceed in the same

way on all SnO

2

surfaces.

The surface structure and alloying impurities

along with the layer thickness play an important role

in surface processes. Temperature probably has a big

influence on the type of absorption and other surface

reactions that occur. The initial oxygen adsorption is

largely determined by the surface temperature of the

MOx sensor. In addition, humidity plays a significant

role and worsens the characteristics of the device. For

example, deoxidization of SnO

2

in a humid

environment directly correlates with the formation of

surface hydroxyl groups. The target molecules also

react with the oxygen of the crystal lattice, which

makes it difficult to study the change in resistance

depending on the oxygen concentration.

The registered MOx sensor signal indicates a

change in the resistance of the sensitive layer, which

is caused by the oxidation of methane by previous

adsorbed oxygen forms on the surface by a rather

complex mechanism, eventually with the formation

of carbon dioxide (CO

2

) and water (H

2

O). The

resulting carbon dioxide, together with the remaining

methane, can be detected using infrared spectroscopy.

As a detector, the TGS2611-C00 sensor is often

used - a semiconductor thick-film sensor consisting

of tin oxide SnO

2

, designed to detect flammable

gases in the air. According to the manufacturer's

passport, the TGS2611 sensor has a high sensitivity

to methane, propane and butane with a similar

sensitivity. These properties are determined by the

characteristics of the SnO

2

surface and the presence

of impurities acting as catalysts. The thermistor was

made of RuO

2

, the lead wires were made of Pt - W

alloy, and the connections to the sensor substrate were

Ni - Fe contacts (50%). SnO

2

is an n-type wide-band

semiconductor. The advantages of SnO

2

include high

sensitivity and resistance to a reducing atmosphere,

MMTGE 2022 - I International Conference "Methods, models, technologies for sustainable development: agroclimatic projects and carbon

neutrality", Kadyrov Chechen State University Chechen Republic, Grozny, st. Sher

230

and its disadvantages are low selectivity and

dependence on humidity.

Figure 2 shows a sensor circuit based on SnO

2

.

The MOx sensor allows simultaneous real-time

measurements of methane, carbon dioxide and

oxygen using the principles of orthogonal direct

optical sensing - infrared radiation and luminescence.

The detection limit of methane is 41 ppm (parts per

million).

8 ELECTROCHEMICAL

METHANE SENSORS BASED

ON LASER-INDUCED

GRAPHENE WITH A SOLID

POLYMER ELECTROLYTE

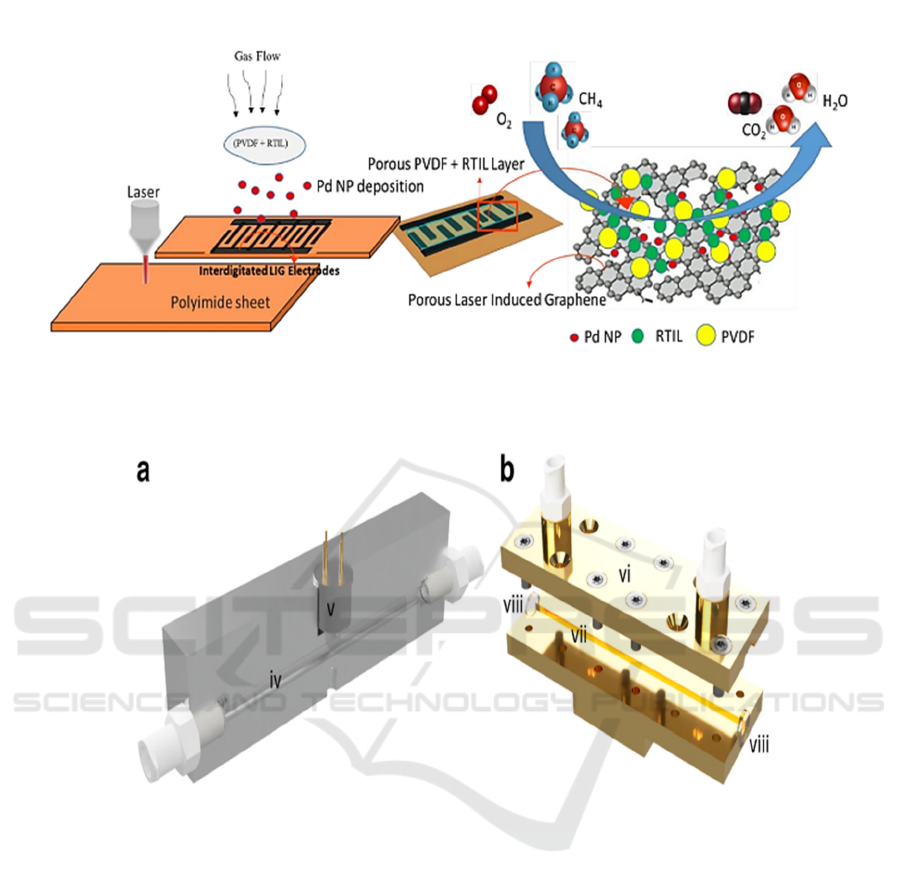

Manan Dosi and his collaborators (Dosi, 2019) have

developed an electrochemical gas sensor that allows

detecting methane at room temperature for 40

seconds in concentrations of less than one part per

million. The sensor was manufactured as follows.

Porous electrodes made of laser-induced graphene

(LIG) form a pattern in polymer films and are

impregnated with a dispersion of palladium

Figure 2: MOx sensor gas cell. a - an aluminum block with a gas channel (iv) and a MOx sensor (v), b - an open

iHWG with an upper substrate (vi), a base substrate (vii), windows from BaF

2

(viii) (Glöckler, 2020).

Fi

g

ure 3. Dia

g

ram of the manufacturin

g

p

rocess of an electrochemical methane sensor.

Innovative Technologies for Detecting Methane in the Atmosphere

231

nanoparticles to distribute the electrocatalyst inside a

carrier with a large surface area. An ionic liquid in a

pseudo-solid state / polyvinylidene fluoride

electrolyte is applied to a flexible element to form a

porous electrolyte inside a porous electrode made of

laser-induced graphene, which simultaneously

promotes rapid gas transfer and electrooxidation of

methane at room temperature (Figure 3). The gas

analyzer thus obtained is an amperometric sensor. Its

ability to detect methane is tested in the presence of

moisture and interfering gases.

A CO

2

laser is used to transform a polyamide

sheet into a patterned graphene structure. Pd

nanoparticles are absorbed into the structure of laser-

induced graphene (LIG) with a large surface area,

after which a porous layer of polyvinylidene fluoride

(PVDF) / ionic liquids operating at room temperature

(room temperature ionic liquids, RTIL) is applied to

the electrodes. This provides a large number of three-

phase contacts between gas, Pd and RTIL, which

ensures high sensitivity and fast response (Dosi,

2019).

The described device is a flexible flat device of a

small area (~ 2 cm

2

), the voltage consumed is 0.6 V,

the current consumed is 1.1 µA, the methane

detection limit is ~ 9 ppm.

For a long time, most analytical instruments were

cumbersome, expensive and time-consuming to

maintain. However, recent advances in materials

science, microelectronics, communications and data

analysis make it possible to implement several very

interesting scenarios. Let's look at some of them.

Wireless electrochemical platform based on RFID

technology. Radislav Poteryailo from General

Electric has proposed an interesting solution designed

for the analysis of multicomponent mixtures, having

a small size, low price, high selectivity, sensitivity at

the level of ppm units and does not require energy

(Potyrailo, 2012). The device works as follows. As

you know, passive tags with radio frequency

identification consist of an antenna, a microprocessor,

a transmitter and a memory on which service

information is recorded. Separately, I would like to

note the fact that such devices do not need power

supply. For the first time, this concept was

implemented by Lev Semenovich Termen, who

developed radio microphones for the NKVD in the

30s. The energy is taken from an external source of

electromagnetic radiation, which induces induction

EMF on the antenna. At the same time, the capacitor

is charged. Its charge is enough to operate the

transmitter. Radislav Poteryailo opened the passive

RFID tag (Figure 4) and placed the nafion material on

the antenna surface.

Figure 4: The multi-gas sensor is located on an American

one-penny coin.

https://www.ge.com/research/newsroom/ge-researchers-

demonstrate-grain-size-gas-sensor-bloodhound-sensing-

capabilities-ideal

9 RESULTS AND DISCUSSION

The development of materials science,

communications, nanotechnology, and data analysis

makes it possible to implement very interesting

scenarios in the development and application of

chemical sensors for detecting methane in the

atmosphere. The wireless electrochemical platform

has already been mentioned above. To control the

ecological environment, a wireless sensor network

can be deployed. A number of companies are

developing chemical sensors that can be embedded in

cell phones, flexible and stretchable sensors are being

developed, work is underway in the field of "sensitive

skin" for cyborgs, advances in

micro/nanoelectromechanics are designed to create

an "electronic nose".

10 CONCLUSIONS

Methane plays a very important role in the life of

society. First of all, this concerns the fuel and energy

complex. Thermal power plants running on natural

gas are much more environmentally friendly than

thermal power plants running on fuel oil or coal. In

Russia, the transition of trucks and commercial

vehicles to methane is a reasonable alternative to

electric vehicles. Methane is the most important

greenhouse gas, which makes it relevant to research

in the field of anthropogenic impact of methane.

Timely and accurate detection of methane

emissions into the atmosphere is an urgent problem.

MMTGE 2022 - I International Conference "Methods, models, technologies for sustainable development: agroclimatic projects and carbon

neutrality", Kadyrov Chechen State University Chechen Republic, Grozny, st. Sher

232

This is important both for fire safety and for reducing

losses in the fuel and oil and gas industry, protecting

the environment and preserving the climate balance.

There are classical methods for detecting

methane, such as gas chromatography or mass

spectrometry. Recently, optical, colorimetric, and

pyroelectric methods for detecting methane have also

become widespread. Sensors based on metal oxides

and electrochemical methane sensors based on laser-

induced graphene with a solid polymer electrolyte are

being developed (Blair, 1991). Such methods will

make it possible in the future to create fairly compact,

inexpensive and sensitive methane sensors. There are

new scenarios for detecting methane, for example,

remotely. The team of authors, together with

colleagues from related industries, is ready to conduct

scientific research with the above-mentioned high-

tech equipment and devices.

REFERENCES

Lal, R., 2008. Carbon sequestration. Phil. Trans. R. Soc. B.

363. pp. 815-830.

Schrader, B., Bougeard, D., 1995. Infrared and Raman

spectroscopy: methods and applications. VCH.

Degler, D., Wicker, S., Weimar, U., Barsan, N., 2015.

Identifying the active oxygen species in SnO2 based

gas sensing materials: an operando IR spectrsocopy

study. J Phys Chem C. 119. pp. 11792-11799.

Elger, A. K., Hess, C., 2019. Elucidating the mechanism of

working SnO2 gas sensors using combined operando

UV/Vis, Raman, and IR spectroscopy. Angew Chem Int

Ed. 58. pp. 15057-15061.

Kohl, D., 1989. Surface processes in the detection of

reducing gases with SnO2-based devices. Sensors

Actuators. 18. pp. 71-113.

Stuart, B. H, 2005. Infrared spectroscopy: fundamentals

and applications.

Mizaikoff, B., 2013. Waveguide-enhanced mid-infrared

chem/bio sensors. Chem Soc Rev. 42. p. 8683.

Wilk, A., Seichter, F., Kim, S. S., Tütüncü, E., Mizaikoff,

B., Vogt J. A. et al., 2012. Toward the quantification of

the 13CO2/12CO2 ratio in exhaled mouse breath with

mid-infrared hollow waveguide gas sensors. Anal

Bioanal Chem. 402. pp. 397-404.

Glöckler, J., Jaeschke, C., Tütüncü, E., Kokoric, V.,

Kocaöz, Y., Mizaikoff, B., 2020. Characterization of

metal oxide gas sensors via optical techniques.

Analytical and Bioanalytical Chemistry. 412, pp. 4575-

4584.

Fortes, P. R., da Silveira Petruci, J. F., Wilk, A., Cardoso, A.

A., Raimundo, I. M. Jr., Mizaikoff, B., 2014. Optimized

design of substrate-integrated hollow waveguides for

mid-infrared gas analyzers. J Opt. 16, pp. 1-6.

Dosi, M., Lau, I., Zhuang, Y., Simakov, D. S. A., Fowler,

M. W., Pope, M. A., 2019. Ultra-Sensitive

Electrochemical Methane Sensors based on Solid

Polymer Electrolyte-Infused Laser-Induced Graphene.

ACS Appl. Mater. Interfaces, Just Accepted Manuscript.

Aldhafeeri, T., Tran, M.-K., Vrolyk, R., Pope, M., Fowler,

M., 2020. A Review of Methane Gas Detection Sensors:

Recent Developments and Future Perspectives.

Inventions. 5. 28.

Matsumi, Y., Hidemori, T., Nakayama, T., Imasu, R.,

Dhaka, S. K., 2016. Measuring methane with a simple

open-path gas sensor A near-IR laser spectroscopic

technique enables continuous in situ measurements of

methane emissions in rural northern India.

https://spie.org/news/6283-measuring-methane-with-a-

simple-open-path-gas-sensor.

Potyrailo, R. A., Surman, C., Lai, H., Kelley-Loughnane,

N., Naik, R. R., 2012. Wireless sensors and sensor

networks for homeland security applications. Trends

Analyt Chem. 40. pp. 133-145.

Potyrailo, R. A., Bonam, R. K., Hartley, J. G., Starkey, T.

A., Vukusic, P., Vasudev, M., Bunning, T., Naik, R. R.,

Tang, Z., Palacios, M. A., Larsen, M., Le Tarte, L. A.,

Grande, J. C., Zhong S., Deng, T., Towards

outperforming conventional sensor arrays with

fabricated individual photonic vapour sensors inspired

by Morpho butterflies.

Joshi, G. P., Nam, S. Y., Kim, S. W., 2013. Cognitive Radio

Wireless Sensor Networks: Applications, Challenges

and Research Trends. Sensors, 13, pp. 11196-11228.

Blair, J. M., Crossley, D. A., Callaham, L. C., 1991. A

litterbasket technique for measurement of nutrient

dynamics in forest floors. Agriculture, Ecosystems and

Environment, 34. pp. 465-471.

Innovative Technologies for Detecting Methane in the Atmosphere

233