Signal Detection for Tracer-Based-Sorting using Deep Learning and

Synthetic Data

Christian Linder

a

, Frank Gaibler, Andreas Margraf

b

and Steffen Geinitz

c

Fraunhofer Institute for Casting, Composite and Processing Technology IGCV,

Am Technologiezentrum 2, 86159 Augsburg, Germany

Keywords:

Signal Processing, Deep Learning, Tracer-Based-Sorting, Synthetic Data, Convolutional Neural Network

(CNN), Fluorescent Tracers, Data Augmentation, Recycling, Plastics Sorting.

Abstract:

Increasing environmental awareness and new regulations require an improvement of the waste cycle of plastic

packaging. Tracer-Based-Sorting (TBS) technology can meet these challenges. Previous studies show the

market potential of the technology. This work improves on the solution approach using artificial intelligence to

maximize the number of tracers that can be detected accurately. A convolutional neural network and random

forest classifier are compared for classification of each tracer based on signal intensities. The approach is

validated on different settings using synthetic data to counter the low amount of available data. The results

show that theoretically up to 120 tracers can be classified simultaneously under near-optimal conditions. Under

more difficult conditions, the maximum number of tracers is reduced to 45. Thus, the approach can increase

the diversity of TBS by increasing the maximum tracer count and enable a broader range of applications. This

helps to establish the technology in the field of recycling.

1 INTRODUCTION

Modern societies rely on mass production of all dif-

ferent kinds. One type of material in particular stands

out from the crowd: plastic has proven to be ex-

tremely useful because it is so easily moldable and

versatile which is why it is used almost everywhere.

This comes with a prize: production and disposal

of plastic generates greenhouse gases and hazardous

waste. At 3.22 million tons (2019), plastic sales pack-

aging is one of the most relevant plastic waste streams

in Germany alone. They take up over a quarter of

all plastic waste and are still mostly thermally recy-

cled. Since the share of plastic recyclate accounts for

a total of 13.7% of the processing volume, increasing

reuse is a major challenge (Conversio GmbH, 2020).

Increasingly, it is precisely the packaging properties

that pose barriers to high-quality recycling: packag-

ing is becoming smaller (pre-portioned units), more

wide-spread (“to-go” products) and is predominantly

equipped with portioning and handling functions as

e.g., pump dispensers. Unfortunately, design or dura-

bility reasons induce packaging units to be harmful to

a

https://orcid.org/0000-0002-2967-4581

b

https://orcid.org/0000-0002-2144-0262

c

https://orcid.org/0000-0001-9835-7937

the circulation (multilayer or black polymers). Pack-

aging waste can be sorted with state-of-the-art ma-

chinery (e.g., near infrared (NIR) sorter) only by main

polymers and colors and thus can no longer be re-

cycled on an equal basis by its plastic specification

(Woidasky et al., 2017). The state of Germany and

the European Union address this challenge with the

German Circular Economy Act 2012 (Bundesminis-

terium der Justiz, 2012) and the European Circular

Economy Action Plan (European Comission, 2018;

European Comission, 2020). They aim to establish a

sustainable circular economy, which is seen as a so-

lution to reduce raw materials and plastics. A more

comprehensible material flow is important to recycle

more efficiently. This work helps to establish new

ways to more reliably detect material flows, espe-

cially plastic materials. To achieve this, a new tech-

nology which was developed by Polysecure GmbH

called Tracer-Based-Sorting is used in combination

with artificial intelligence. This combination enables

the detection of many types of materials while main-

taining high accuracy.

Linder, C., Gaibler, F., Margraf, A. and Geinitz, S.

Signal Detection for Tracer-Based-Sorting using Deep Learning and Synthetic Data.

DOI: 10.5220/0011337000003332

In Proceedings of the 14th International Joint Conference on Computational Intelligence (IJCCI 2022), pages 323-330

ISBN: 978-989-758-611-8; ISSN: 2184-3236

Copyright © 2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

323

Figure 1: Illustration of the general tracer-based-sorting workflow for plastic waste (source: Polysecure GmbH; based on

(Treick, 2019; Gasde et al., 2020)).

1.1 Incentive

Comprehensive recycling is still a major challenge

(Conversio GmbH, 2020). The project MaReK

(Lang-Koetz and Woidasky, 2021) showed that the

establishment of a circular plastic economy can be

implemented with Tracer-Based-Sorting (TBS) tech-

nology, but not with a state-of-the-art NIR sorter

(Schmidt et al., 2021). At the same time, further

development needs for innovative approaches were

identified for market entry (Schmidt et al., 2022).

TBS can help plastics recycling to be more qualita-

tive and economical, enabling more circular economy

and environmental protection in terms of global mar-

ket economy. However, previous studies revealed the

importance of optimizing excitation, quantum yield,

and differentiability of fluorescence sorting codes

(Woidasky et al., 2020a).

The overarching goal of the project is to increase

the economic efficiency of TBS technology. This in-

novative sorting process is a central building block on

the way to a circular economy, as it allows for sub-

stantially higher material flow differentiation to be

achieved compared to current processes. The paper

aims to improve TBS for usage in a circular economy

and in addition widens its use to other fields of ap-

plication. Further extending the differentiable tracer

variants is one way to approach this. For that matter,

the goal is to develop a signal recognition approach

that classifies as many different tracers as possible

with as high an accuracy as possible.

1.2 Groundwork

TBS was developed by Polysecure GmbH and is an

innovative approach to detection and sorting steps in

waste management that enables sorting of materials or

products regardless of their physical properties. The

technology uses inorganic fluorescent tracers in ppm

concentrations. The tracers can be applied in the ma-

terial or on the surface by printing or using printed la-

bels. They emit bright emission lines in green, red and

near-infrared after stimulation with a laser. This sig-

nature emission differs depending on the used tracer

mixtures. The detection process is done by upconver-

sion. Upconversion is a multiphoton process. Lower

energy photons are absorbed and higher energy pho-

tons are emitted (Woidasky et al., 2020a). This pro-

cess practically does not occur in nature, so the mea-

surement is free from background noise.

Previous work showed that 11 out of 15 tested

variants could be detected (Woidasky et al., 2020b).

The waste sorting consists of a three stage ap-

proach, as sketched in Figure 1: The material waste is

collected and transported to the sorting facility, where

it is emptied in a waste bunker. During the singu-

lation stage, the objects are separated and placed in-

dividually on a conveyor belt, tray sorter or similar.

This is to ensure that only one item will be scanned

at a time during the following stage, in which the

fluorescent behavior of the inorganic tracers is trig-

gered by an electromagnetic stimulus. The emitted

light is captured by a sensitive sensor. The signal is

then further processed by a classification model dur-

ing the detection stage as can be seen in the cen-

tered excitation / detection label in Figure 1. The re-

sulting values are used to distinguish material types

in the sorting process and thus enable targeted pre-

sorting and subsequent processing into high-quality

recyclates (Woidasky et al., 2021).

1.3 Related Work

The following section will give an overview on the

research fields and previous work that inspired this

paper:

The field of time series classification has been ex-

amined in a comparative study by Bagnall et al. (Bag-

nall et al., 2016) who listed the most commonly used

algorithms based on series similarity, phase depen-

dent intervals, phase independent shapelets and dic-

tionaries. Further studies proposed deep learning for

time series classification (Ismail Fawaz et al., 2019),

analysis of EEG signals (Craik et al., 2019) and fea-

ture extraction using convolution and pooling opera-

tions (Zhao et al., 2017). Mertes et al. (Mertes. et al.,

2020; Mertes et al., 2022) demonstrated data augmen-

tation in an industrial application for images of tex-

tile defects. Also, fluorescence imaging was used for

plastic waste classification by Gruber et al. (Gruber

NCTA 2022 - 14th International Conference on Neural Computation Theory and Applications

324

et al., 2019).

As for garbage detection, Liu et al. (Liu et al.,

2021) designed a robot vision system to collect

and detect plastic waste and estimate poses using a

YOLACT FCN. A related machine vision approach

based on hyperspectral imaging for waste identifi-

cation was introduced by Krasniewski et al. (Kras-

niewski et al., 2021). Studies addressing signal pro-

cessing as bearing fault detection was published by

Zhang et al. (Zhang et al., 2020).

The authors of this paper confirm that to the best

of their knowledge this is the first publication that

presents a signal filter augmentation using a convo-

lutional neural network for TBS and packaging waste

identification.

1.4 Structure

The remainder of this paper is organized as follows:

Section 2 describes the algorithm design and config-

uration. Furthermore, section 3 elaborates the exper-

imental setup. Section 4 discusses the results accom-

panied by a critical reflection, before we conclude

with an overview of future applications and research

goals in section 5.

2 APPROACH

The following section proposes an approach to maxi-

mize the tracer count and accuracy for TBS. The ap-

proach uses the excited signals from the excitation /

detection step illustrated in Figure 1 to classify the

tracer variant. For that matter, each signal is prepro-

cessed. The classification method is based on a con-

volutional neural network (CNN) consisting of 1D-

filter operations due to its good performance for time

series classification (Ismail Fawaz et al., 2019). For

comparison, we use a state-of-the-art machine learn-

ing model from the random forest (RF) classifier fam-

ily. Due to the limited size of available data, we gen-

erate synthetic mixtures from real data to enlarge the

test and training dataset and to validate different tracer

mixture scenarios.

2.1 Preprocessing

For each classifier, we apply an appropriate prepro-

cessing method to prepare data to fit the input spec-

ification. The data consist of pulses for three chan-

nels in the time domain. As for the CNN, the data

is normalized to be in the range of 0 to 1. Further-

more, a down-sampling operation is applied so that

0.0

0.5

1.0

1.5

0 1000 2000 3000

Intensity

0.0

0.1

0.2

0.3

0 50 100

Time step

Intensity

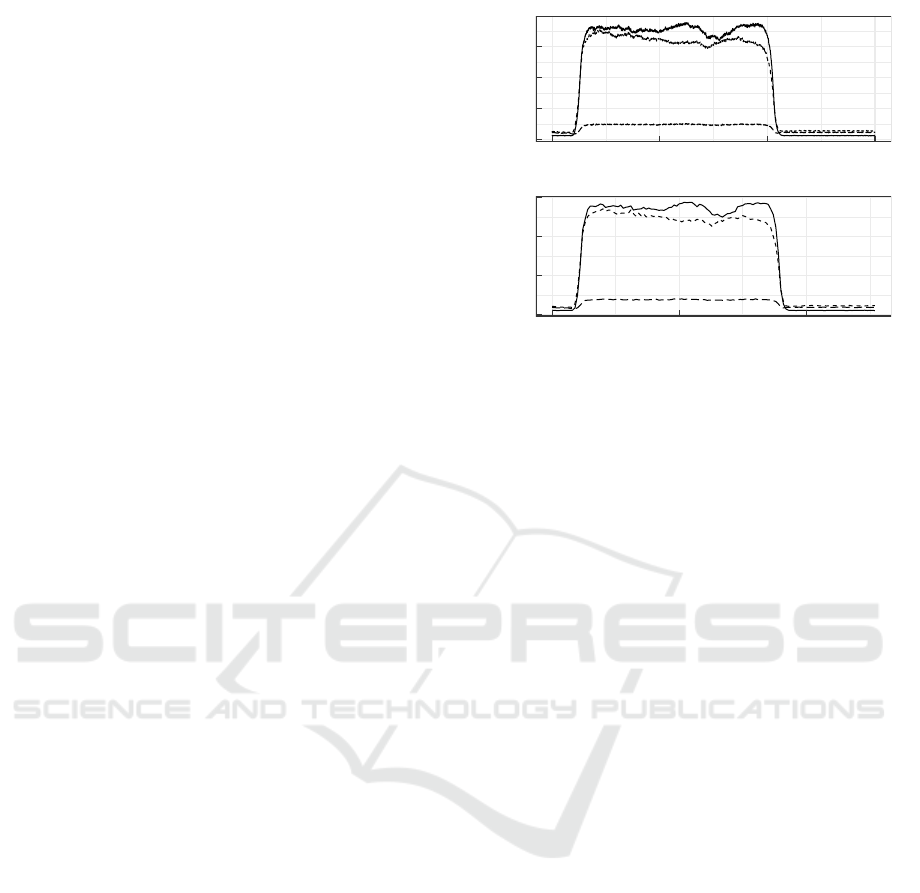

Figure 2: Preprocessing example of the CNN approach: the

top chart shows the original signal with three channels, the

bottom chart contains the time series after normalization

and compression.

each channel is reduced to 128 data points. The com-

pression lowers the complexity by removing redun-

dant information which in turn allows the model to

generalize better. Figure 2 presents an example of the

signal before preprocessing (top) and after normaliza-

tion and reduction; as can be seen, the number of time

steps is reduced from 3000 to 128. Likewise, the

maximum intensity decreases from 1.7 to less than

0.3 due to normalization. However, Figure 2 clearly

suggests that the main curve characteristics are pre-

served.

We then apply preprocessing and feature extrac-

tion to prepare data for the RF. Six features are ex-

tracted based on process-specific expert knowledge:

the channel ratio and peak value for each channel.

The channel ratios characterize a tracer mixture and

are derived from the maximum value of a channel.

The peak values are needed because the tracer ratios

can slightly vary due to the scan object’s conditions

like deformations and soiling on the packaging. Each

feature is subsequently normalized for the range from

0 to 1.

2.2 Generation of Synthetic Data

For this study, synthetic data is created in order to

counteract the small amount of mixture data available.

The synthetic data helps to validate the approach for

more different scenarios and can increase the gener-

alization of the model. Synthetic data is created by

scaling the primary (100%) tracer samples from each

category linearly and summing up the individual trac-

ers. During this process, each channel of each tracer

is augmented randomly by a factor of 0.02 to increase

Signal Detection for Tracer-Based-Sorting using Deep Learning and Synthetic Data

325

0.0

0.1

0.2

0.3

0 50 100

Time step

Intensity

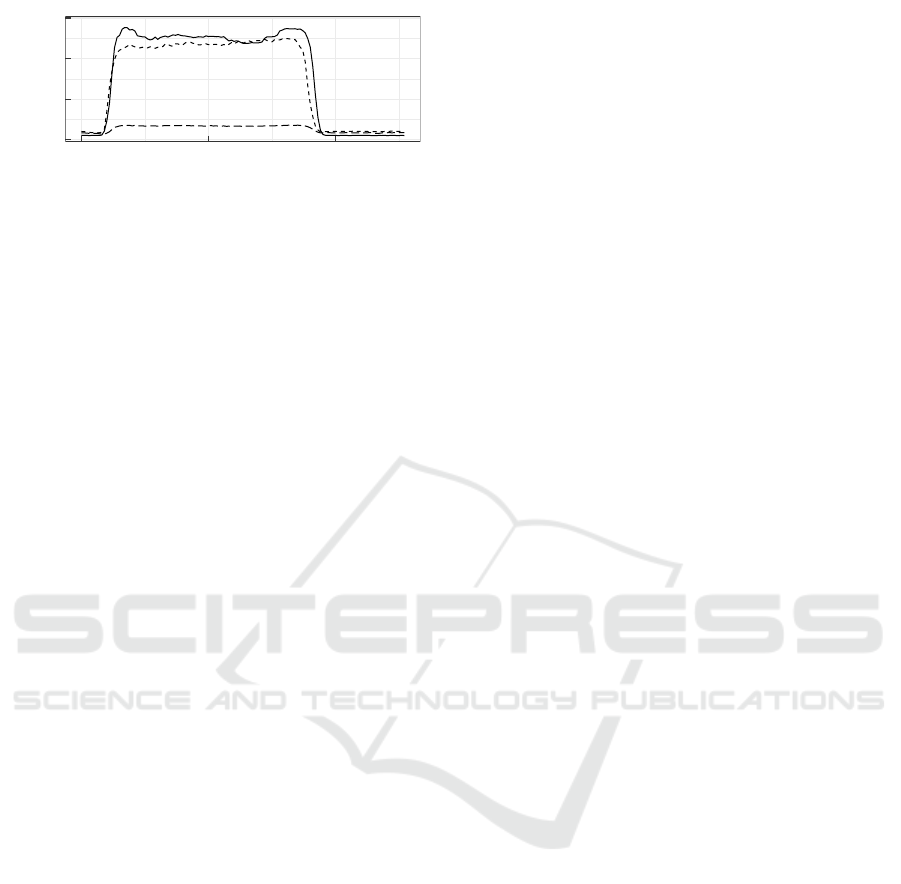

Figure 3: Example of synthetically mixed tracers represent-

ing a mix rate of 50% of tracer 1 and 2 and 0% for tracer

3.

the variety of data. For example, a 50% mixture of

channel 1 and 2 with no augmentation is calculated

by taking 50% of tracer 1, 50% of tracer 2 and 0% of

tracer 3. Figure 3 exhibits the output of a synthetic

50% mix rate. This mix rate is equally applied to the

signal as for the example presented in Figure 2.

2.3 Convolutional Neural Network

In our approach we apply a CNN based on the residual

network (ResNet) kernel for classification (He et al.,

2016). The selection of the exact architecture is based

on multiple test runs and consists of 5 residual blocks.

Each residual block consists of two 1D convolutional

layers and one 1D max pooling layer. The architec-

ture is followed by two fully connected layers with

256 and 128 neurons subsequently where each layer

is combined with a dropout layer with a probability of

0.4. The last layer is a softmax layer.

The model is trained using the Adam optimizer

(Kingma and Ba, 2014) and a learning rate of 0.0001.

The batch size is set to 64. Furthermore, the model is

trained for 100 epochs where each epoch consists of

3456 synthetic samples.

2.4 Random Forest

A RF ensemble classifier with 100 decision trees is

trained for comparison due to its high generalization

ability and flexibility (H

¨

ansch and Hellwich, 2016).

The number of features to consider when looking for

the best split is set to 2 and the Gini criterion is used

for the evaluation of splits. The hyperparameter set-

ting is based on default values from scikit-learn (Pe-

dregosa et al., 2011).

3 EXPERIMENTAL SETUP

The following section describes the available data that

is used for the experiments. Furthermore, different

scenarios are proposed to validate our approach.

3.1 Data Acquisition and Preparation

The data was collected at Polysecure GmbH based on

several test runs with different tracers. Two individual

test runs are analyzed in detail. The test runs have to

be examined separately as individual datasets due to

different recording conditions.

The first dataset contains samples for the three pri-

mary tracers and samples for the 50 % mixtures of

these primary tracers. In total there are 11793 real

samples. In order to synthetically increase the vari-

ance in the dataset, the laser intensities for stimulat-

ing the tracers for individual recordings are varied.

This allows to emulate different conditions like soil-

ing on the packaging and therefore increased absorp-

tion which may occur in the real-world environment.

The second dataset consists of recordings of trac-

ers applied to printed white labels placed on black

panels. Dataset 2 contains samples for the primary

tracers and 50 % mixtures which is analogue to

dataset 1. In contrast, however, dataset 2 addition-

ally contains mixtures for 25 % step size. In total the

datasets comprise 1660 samples.

3.2 Evaluation Scenarios

To evaluate our approach, we define the following

three scenarios:

1. Incremental augmentation

2. Tracer count maximization

3. Synthetic mixture validation

In scenario 1, CNN and RF are compared by in-

crementally increasing the augmentation on the test

data. This becomes necessary because training and

testing is performed only on synthetic mixtures due to

limited availability of real mixtures. By augmenting

the data, the generalization to unknown scenarios can

be validated. Three different types of augmentation

are tested. In the first one, the noise level is gradu-

ally increased. The second augmentation deals with

the stepwise shifting of the curve in the time domain.

The last augmentation approaches an offset shift of

the curve intensity. The experiments are run five times

each due to the stochastic nature of the training meth-

ods while mean and standard deviation of the accu-

racy results are recorded.

The second scenario is designed to maximize the

tracer count. Hereby, the tracer count is incremented

stepwise, while the mean and standard deviation of

the related model’s accuracy are recorded over five

consecutive runs. As before, the training and valida-

tion is only applied to synthetic data. A stepwise noise

NCTA 2022 - 14th International Conference on Neural Computation Theory and Applications

326

augmentation is utilized on the test data to counterbal-

ance the usage of only synthetic data.

In scenario 3, the synthetic mixtures are validated

by training the model only on synthetic mixtures and

then validating on real samples. If the synthetic data is

similar to real data, then the model should generalize

well and achieve high accuracy values on the valida-

tion set. The training step is repeated five times.

4 RESULTS AND DISCUSSION

The following section describes the results for the

aforementioned experiment in details. At first, RF and

CNN are compared to each other. Then, the tracer

count is maximized by analyzing different tracer

count scenarios and lastly, the quality of the synthetic

data is investigated.

4.1 Model Comparison and Evaluation

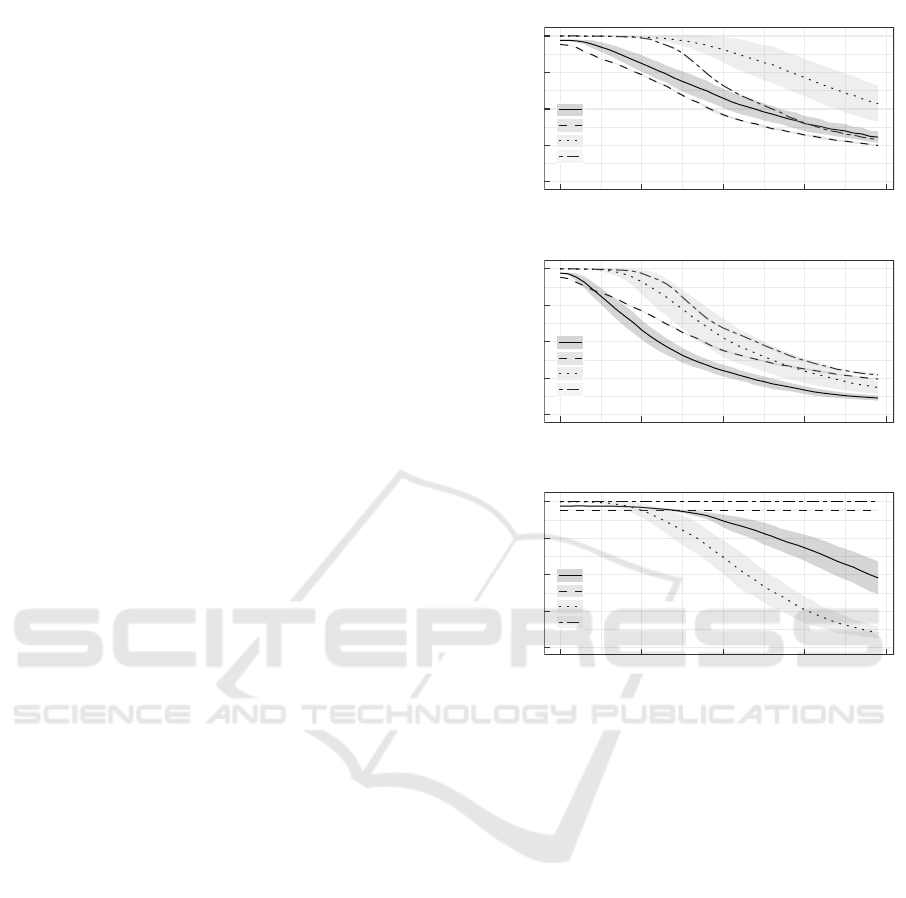

CNN and RF are compared for a scenario with 45

tracer mixtures and incremental data augmentation.

Figure 4 visualizes the results for noise, offset and

shift augmentation where the bars show the standard

deviation of five test runs. CNN-1 and RF-1 de-

scribe the results for dataset 1 and CNN-2 and RF-2

for dataset 2 respectively. The results appear simi-

lar but especially for noise augmentation, the CNN

exhibits slightly better accuracy values. Neverthe-

less, the CNN’s performance seems to significantly

decrease for high shift values. In contrast, high shift

values do not affect the RF approach because only

the maximum peak values are used for calculating the

features and the 40 time steps considered at maximum

are not enough to shift the peak of the curve out of the

time window.

It should be noted that the results for RF can prob-

ably be improved by more detailed hyperparameter

tuning and feature engineering. Nevertheless, the key

advantage of a CNN is that it automatically extracts

features and the model adapts for very complex sce-

narios if enough data is provided. Further studies are

expected to show, that more real data can be collected

once the demonstrator is ready for experimentation.

Furthermore, problems like shift can be alleviated by

using augmentation during training. Therefore, the

CNN approach will be further pursued for the previ-

ously mentioned tracer maximization scenario No. 2.

4.2 Maximizing Tracer Count

Next, we tested the model’s limitation on an increas-

ing number of tracers. Therefore, we applied the

0.00

0.25

0.50

0.75

1.00

0 1 2 3 4

Noise [%]

Accuracy

cnn-1

rf-1

cnn-2

rf-2

0.00

0.25

0.50

0.75

1.00

0 1 2 3 4

Offset [%]

Accuracy

cnn-1

rf-1

cnn-2

rf-2

0.00

0.25

0.50

0.75

1.00

0 10 20 30 40

Shift [time step]

Accuracy

cnn-1

rf-1

cnn-2

rf-2

Figure 4: Comparison of CNN and RF model configu-

rations: accuracies are measured for scenarios of varying

noise, offset and shift with 45 tracer mixtures.

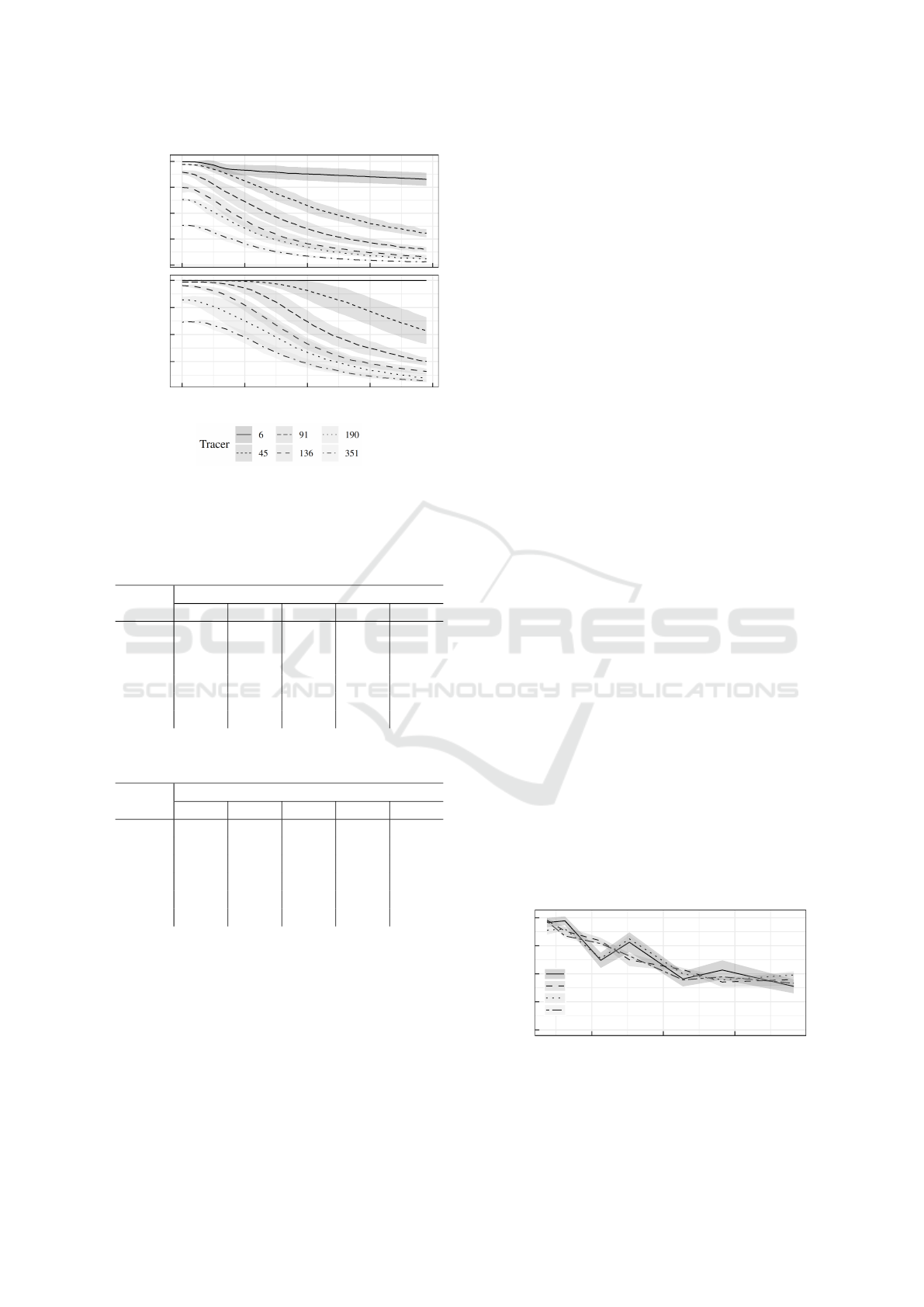

CNN to different tracer counts by reducing the scal-

ing step width. Figure 5 shows the results, where the

top chart shows the results for dataset 1 and the bot-

tom accuracy values for dataset 2. Due to limited

space, the figures only display the values for noise

augmentation. Nevertheless, the results for offset and

shift are similar. As can be seen, the accuracy clearly

decreases for an increasing number of tracers. The

degradation of accuracy values between both datasets

derive from the use of different laser intensities during

data acquisition of dataset 1 which synthetically in-

creased the complexity in order to simulate real-world

conditions. Further results are shown in Table 1 for

dataset 1 and in Table 2 for dataset 2. In the tables,

more detailed results are illustrated for smaller tracer

numbers, whereas the previous plot had higher spac-

ing between tracer numbers to highlight the general

trend. Up to 45 tracers in dataset 1 and 120 tracers

in dataset 2 can be classified with high accuracy. For

these cases, the accuracy is greater than 97%. Nev-

Signal Detection for Tracer-Based-Sorting using Deep Learning and Synthetic Data

327

0.00

0.25

0.50

0.75

1.00

Accuracy

0.25

0.50

0.75

1.00

0 1 2 3 4

Noise [%]

Accuracy

Figure 5: CNN packaging material classification accuracy

for different numbers of tracer mixtures; Top: classification

accuracy for dataset 1. Bottom: classification accuracy for

dataset 2.

Table 1: CNN packaging material classification accuracy

for dataset 1.

Tracer

count

Noise

0 % 1 % 2 % 3 % 4 %

6 0.997 0.915 0.879 0.851 0.827

21 0.992 0.943 0.816 0.696 0.586

45 0.970 0.811 0.573 0.399 0.307

78 0.907 0.658 0.395 0.236 0.159

120 0.817 0.522 0.284 0.177 0.119

171 0.652 0.331 0.171 0.105 0.073

Table 2: CNN packaging material classification accuracy

for dataset 2.

Tracer

count

Noise

0 % 1 % 2 % 3 % 4 %

6 1.000 1.000 1.000 1.000 1.000

21 1.000 1.000 0.994 0.959 0.895

45 1.000 0.992 0.908 0.714 0.536

78 0.976 0.867 0.621 0.379 0.252

120 0.972 0.839 0.517 0.285 0.178

171 0.906 0.697 0.351 0.186 0.111

ertheless, the accuracy values decrease sharply with

increasing noise values. For dataset 1 and 45 trac-

ers the accuracy drops to 81% and for dataset 2 and

120 to 84% for a noise level of 1%. These results

suggest that considering both datasets, a maximum

of 120 tracers is possible under near-optimal condi-

tions. Whereas under more difficult conditions 45

tracers are accurately classifiable. Detailed results for

45 tracer are in the aforementioned Figure 4.

Nevertheless, the results have to be viewed with

some caution. The reason for this is that only syn-

thetic data is used for validation. The incremental

augmentation can only counter this problem to some

degree and further studies have to confirm these re-

sults with more real data.

4.3 Validation of Synthetic Mixtures

As for the last scenario, a training is applied only to

the synthetic mixtures and the validation on the real

mixture samples to validate how well the synthetic

data represents the real-world data. Figure 6 shows

the results for this scenario. CNN-1 and RF-1 exhibit

the results for dataset 1 validated on the according

model while CNN-2 and RF-2 show the related result

for dataset 2. In summary, the outcome suggests that

real mixtures can be mapped well for small numbers

of tracers. But as the number of tracers increase, the

accuracy significantly decreases.

This effect can be explained as follows: even

though we perform the experiments on augmented

data, we use the same overall dataset and partition

it in smaller subsets. Therefore, the tolerance range

becomes smaller with each additional mixture setting

which results in a potentially higher error rate. In

the previous validation scenario, this effect was not

as strong, but was already present. The small devi-

ation to the previous validation scenario shows that

synthetic and real data are not identical, but especially

the high accuracy values at low tracer counts indicate

that the synthetic and real data have similar proper-

ties. We consider this relation sufficient for initial the-

oretical analysis.

5 CONCLUSION AND OUTLOOK

The recycling of plastic waste is a ubiquitous chal-

lenge due to the incredible mass deployed around the

world each day. In this paper, we propose a technique

0.00

0.25

0.50

0.75

1.00

40 80 120

Tracer count

Accuracy

cnn-1

cnn-2

rf-1

rf-2

Figure 6: Validation of models trained exclusively on syn-

thetic data and validated on real data.

NCTA 2022 - 14th International Conference on Neural Computation Theory and Applications

328

for improving the efficiency of packaging waste recy-

cling by means of TBS. Our approach builds upon sig-

nal data from fluorescent emitting tracers which can

be combined in any way to indicate the type of plas-

tic. We applied two different classification models, a

RF and CNN to distinguish between the tracer com-

binations by signal intensity per channel. Due to the

limited size of the training and test data, we used syn-

thetic data which we generated by artificially varying

the tracer channels and their mixture. We then com-

pared the RF and CNN in different evaluation scenar-

ios in order to compare and assess the models.

The results show that although model perfor-

mance decreases for theoretically high numbers of

tracers, their accuracy still remains high enough for

classification decisions up to a tracer count of 120 un-

der near-optimal conditions. In more difficult condi-

tions, the maximum number of tracers is reduced to

45.

Furthermore, RF and CNN seem to provide simi-

lar results at first sight; however, the experimentation

suggests that the performance of the CNN is likely

limited due to the low variation in the dataset and the

small amount of available data. It should be men-

tioned that this problem could be alleviated by at-

taining more training data and using further data aug-

mentation methods while training. The experiments

suggest that synthesized data from tracer data repre-

sent the real-world data well enough for first insights.

Nevertheless, further studies with more real data are

needed to confirm our results. Especially the effects

of contamination on the surface need to be studied

more in detail on real data.

In view of the dataset size and tracer quality, this

study reveals the potential of future TBS applications.

In addition, the use of computer vision algorithms

in combination with our signal processing approach

would increase the search space and add to the avail-

able features which would certainly allow to better

distinguish between different tracers. The authors

plan to continue the work presented in this paper and

improve the field of TBS. Further studies are intended

to increase the economic efficiency of a circular econ-

omy of plastic packaging by means of AI innovation.

ACKNOWLEDGEMENTS

The authors would like to thank the German Federal

Ministry of Education and Research for supporting

the project Tracer Based Sorting – Effizient und Flex-

ibel (Tasteful). The authors would also like to express

their thanks to Polysecure GmbH for providing mea-

surement data and helpful support.

REFERENCES

Bagnall, A., Lines, J., Bostrom, A., Large, J., and Keogh,

E. (2016). The great time series classification bake

off: a review and experimental evaluation of recent

algorithmic advances. Data Mining and Knowledge

Discovery, 31(3):606–660.

Bundesministerium der Justiz (2012). Kreislaufwirtschafts-

gesetz. https://www.bkv-gmbh.de/studien/. Viewed

on 01.02.2022.

Conversio GmbH (2020). Studie: Stoffstrombild kunst-

stoffe in deutschland 2019. https://www.bkv-gmbh.

de/studien/. Viewed on 01.02.2022.

Craik, A., He, Y., and Contreras-Vidal, J. L. (2019). Deep

learning for electroencephalogram (EEG) classifica-

tion tasks: a review. Journal of Neural Engineering,

16(3):031001.

European Comission (2018). A european strat-

egy for plastics in a circular economy.

https://eur-lex.europa.eu/legal-content/EN/TXT/

?qid=1516265440535&uri=COM:2018:28:FIN.

Viewed on 01.02.2022.

European Comission (2020). A new circular economy ac-

tion plan. https://eur-lex.europa.eu/legal-content/EN/

TXT/?qid=1583933814386&uri=COM:2020:98:FIN.

Viewed on 01.02.2022.

Gasde, J., Woidasky, J., Moesslein, J., and Lang-Koetz, C.

(2020). Plastics recycling with tracer-based-sorting:

challenges of a potential radical technology. Sustain-

ability, 13(1):258.

Gruber, F., Gr

¨

ahlert, W., Wollmann, P., and Kaskel, S.

(2019). Classification of black plastics waste using

fluorescence imaging and machine learning. Recy-

cling, 4(4):40–0.

H

¨

ansch, R. and Hellwich, O. (2016). Random Forests,

pages 1–42. Springer Berlin Heidelberg, Berlin, Hei-

delberg.

He, K., Zhang, X., Ren, S., and Sun, J. (2016). Deep resid-

ual learning for image recognition. In Proceedings of

the IEEE conference on computer vision and pattern

recognition, pages 770–778.

Ismail Fawaz, H., Forestier, G., Weber, J., Idoumghar, L.,

and Muller, P.-A. (2019). Deep learning for time series

classification: a review. Data mining and knowledge

discovery, 33(4):917–963.

Kingma, D. P. and Ba, J. (2014). Adam: A

method for stochastic optimization. arXiv preprint

arXiv:1412.6980.

Krasniewski, J., Dabala, L., and Lewandowski, M. (2021).

Hyperspectral imaging for analysis and classification

of plastic waste. In 2020 25th International Confer-

ence on Pattern Recognition (ICPR). IEEE.

Lang-Koetz, C. and Woidasky, J. (2021). Markerbasiertes

sortier- und recyclingsystem f

¨

ur kunststoffverpackun-

gen.

Liu, J., Balatti, P., Ellis, K., Hadjivelichkov, D., Stoy-

anov, D., Ajoudani, A., and Kanoulas, D. (2021).

Garbage collection and sorting with a mobile manip-

ulator using deep learning and whole-body control.

Signal Detection for Tracer-Based-Sorting using Deep Learning and Synthetic Data

329

In 2020 IEEE-RAS 20th International Conference on

Humanoid Robots (Humanoids). IEEE.

Mertes, S., Margraf, A., Geinitz, S., and Andr

´

e, E. (2022).

Alternative data augmentation for industrial moni-

toring using adversarial learning. arXiv preprint

arXiv:2205.04222.

Mertes., S., Margraf., A., Kommer., C., Geinitz., S., and

Andr

´

e., E. (2020). Data augmentation for semantic

segmentation in the context of carbon fiber defect de-

tection using adversarial learning. In Proceedings of

the 1st International Conference on Deep Learning

Theory and Applications - Volume 1: DeLTA,, pages

59–67. INSTICC, SciTePress.

Pedregosa, F., Varoquaux, G., Gramfort, A., Michel, V.,

Thirion, B., Grisel, O., Blondel, M., Prettenhofer,

P., Weiss, R., Dubourg, V., Vanderplas, J., Passos,

A., Cournapeau, D., Brucher, M., Perrot, M., and

Duchesnay, E. (2011). Scikit-learn: Machine learning

in Python. Journal of Machine Learning Research,

12:2825–2830.

Schmidt, J., Auer, M., Moesslein, J., Wendler, P., Wiethoff,

S., Lang-Koetz, C., and Woidasky, J. (2021). Chal-

lenges and solutions for plastic packaging in a circular

economy. Chemie Ingenieur Technik, 93(11):1751–

1762.

Schmidt, J., Grau, L., Auer, M., Maletz, R., and Woidasky,

J. (2022). Multilayer packaging in a circular economy.

Polymers, 14(9):1825.

Treick, A. C. H. (2019). Evaluation der ablagetech-

nologie identifizierter artikel in fraktionen: Entwick-

lung von innovationsans

¨

atzen f

¨

ur das markerbasierte

sortieren von kunststoffverpackungen: zum erlangen

des akademischen grades bachelor of science.

Woidasky, J., Auer, M., Schmidt, J., Kusch, A., Gasde, J.,

Lang-Koetz, C., Wiethoff, S., Sander, I., Schau, A.,

Richards, B. S., Turshatov, A., Busko, D., Treick, A.,

Wendler, P., Kirchenbauer, D., Wacker, D., Fuchs, F.,

and Moesslein, J. (2021). Tracer-based-sorting in der

verpackungs-abfallwirtschaft. M

¨

ull und Abfall, (7):5–

13. 38.01.05; LK 01.

Woidasky, J., Heyde, M., Sander, I., Moesslein, J., Fahr,

M., Richards, B., Turshatov, A., and Lang-Koetz, C.

(2017). Hochwertiges recycling durch tracer-nutzung.

ReSource, 30(4):24–8.

Woidasky, J., Sander, I., Schau, A., Moesslein, J., Wendler,

P., Wacker, D., Gao, G., Kirchenbauer, D., Kumar, V.,

Busko, D., et al. (2020a). Inorganic fluorescent marker

materials for identification of post-consumer plastic

packaging. Resources, Conservation and Recycling,

161:104976.

Woidasky, J., Schmidt, J., Auer, M., Sander, I., Schau,

A., Moesslein, J., Wendler, P., Kirchenbauer, D.,

Wacker, D., Gao, G., et al. (2020b). Photoluminescent

tracer effects on thermoplastic polymer recycling. In

Advances in Polymer Processing 2020, pages 1–13.

Springer.

Zhang, S., Zhang, S., Wang, B., and Habetler, T. G.

(2020). Deep learning algorithms for bearing fault

diagnostics—a comprehensive review. IEEE Access,

8:29857–29881.

Zhao, B., Lu, H., Chen, S., Liu, J., and Wu, D. (2017). Con-

volutional neural networks for time series classifica-

tion. Journal of Systems Engineering and Electronics,

28(1):162–169.

NCTA 2022 - 14th International Conference on Neural Computation Theory and Applications

330