Prototyping and Early Validation of an Integrated, Electrochemical

and Mass Three-sensor Array for Dengue Detection

Ahmad Anwar Zainuddin

1,2

, Mohd Afiq Mohd Asri

1

, Cyril Guines

3

, Muhammad Zahid Zabedi

4

,

Khin Maung Htay

1

, Abdul Hakim Ab Rahim

1

, Matthieu Chatras

4

, Arnaud Pothier

4

,

Wing Cheung Mak

5

and Anis Nurashikin Nordin

1

1

Kulliyyah of Engineering, International Islamic University Malaysia, 53100 Gombak, Kuala Lumpur, Malaysia

2

Department of Computer Science and Engineering, School of Engineering, Manipal International University,

71800 Nilai, Negeri Sembilan, Malaysia

3

XLIM-UMR 7252, University of Limoges/CNRS, 87060 Limoges, France

4

3D Synapsis, 44a, Jalan Keluli AK7/AK, Taman Perindustrian Bukit Raja Selatan, 40000 Shah Alam, Selangor, Malaysia

5

Biosensors and Bioelectronics Centre, Department of Physics, Chemistry and Biology (IFM), Linkoping University,

58183 Linkoping, Sweden

Keywords: Dengue, Biosensor, Sensor Arrays, Integrated Electrochemical-Quartz Crystal Microbalance, Point-of-Care

Diagnostics.

Abstract: This paper presents the current progress towards a lab-on-chip biosensor for early dengue detection, consisting

of an integrated sensor with dual-function working electrode that enables in-situ measurements of both

electrochemical impedance spectroscopy (EIS) and quartz crystal microbalance (QCM) enclosed in a

miniaturized 3D-printed package equipped with electrical contacts and sample fluid delivery to the quartz

biosensor array. The sensors consist of an array of three 10 MHz IEQCM biosensors on a single quartz

substrate. Early validation is performed for future dengue sensing application. We report the design,

optimisation, and fabrication of the sensors, as well as early optimisation and validation of surface

bioconjugation of antibodies. This lab-on-chip has the potential to provide accurate dengue detection due to

its high sensitivity and dynamic range, as well as providing rapid and early dengue detection in point-of-care

settings.

1 INTRODUCTION

Biosensors are analytical devices that integrate

molecular recognition platforms with a

physicochemical transducer to produce a single

detection processing unit (Hong et al., 2012; Miserere

& Merkoçi, 2015). Rapid point-of-care (PoC)

biosensors are advantageous as they allow analyses to

be performed in the field (Hu et al., 2016; Lisowski

& Zarzycki, 2013; St John & Price, 2014).

Commercial screen printed electrodes have been

commonly employed by researchers for

electrochemical dengue detection due to their

simplicity, biocompatibility, cost-effectiveness,

disposability, and flexibility of integration (Cecchetto

et al., 2015; Parkash et al., 2014; Sinawang et al.,

2016). Apart from SPGE, quartz crystal microbalance

(QCM) has been used as a simple PoC device, which

offers shorter analysis time, real-time monitoring and

label-free detection (Omar & Fen, 2018). A 2017

study reported the detection of dengue NS1 antigens

using modified bacterial cellulose nanocrystals (CN)-

QCM (Pirich et al., 2017). Based on literature, while

QCM devices excel in sensitivity, electrochemical

sensors provide better selectivity.

Integration of these two mechanisms on a single

device have also been done in the form of an

electrochemical quartz crystal microbalance

(EQCM). These devices produce high accuracy of

measurements in biological and chemical systems

(Yang et al., 2015; Yu et al., 2009). Basic EQCM

sensors comprise of a quartz crystal microbalance

sensor (QCM), a counter electrode and a reference

electrode, integrated into a single measurement

platform. The advantage of these integrated sensors is

that it can measure both resonance frequency changes

and electrochemical reactions in a single platform.

204

Zainuddin, A., Asri, M., Guines, C., Zabedi, M., Htay, K., Rahim, A., Chatras, M., Pothier, A., Mak, W. and Nordin, A.

Prototyping and Early Validation of an Integrated, Electrochemical and Mass Three-sensor Array for Dengue Detection.

DOI: 10.5220/0010961500003123

In Proceedings of the 15th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2022) - Volume 1: BIODEVICES, pages 204-211

ISBN: 978-989-758-552-4; ISSN: 2184-4305

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

This is done by using the top electrode as both the

electrochemical working electrode and QCM

terminal. An early demonstration of combined

electrochemical and QCM sensors observed that the

an integrated sensor enabled cross-validation of the

measurement, increased the accuracy of detection,

and reduced false positives and false negatives (Yu et

al., 2009). However, existing EQCM systems are

limited to laboratory-only settings due to the

instruments’ large footprint and handling

complexities (Ashton, 2012; Srivastava et al., 2018).

We previously hypothesized that using dual-

function sensors could increase sensor sensitivity to

very low limits of detection, increase dynamic range

of disease quantification, and provide higher

diagnostic accuracy through cross-validation of

parallel measurement techniques (A. Zainuddin et al.,

2019). In this paper, we present our current progress

towards a rapid point-of-care (PoC) device for early

detection of dengue, based on integrated

electrochemical and mass biosensor. This PoC device

has an array of three identical sensors on a single

quartz substrate. Each sensor is a three-electrode

system which can perform in-situ measurements of

the electrode’s surface changes based on piezoelectric

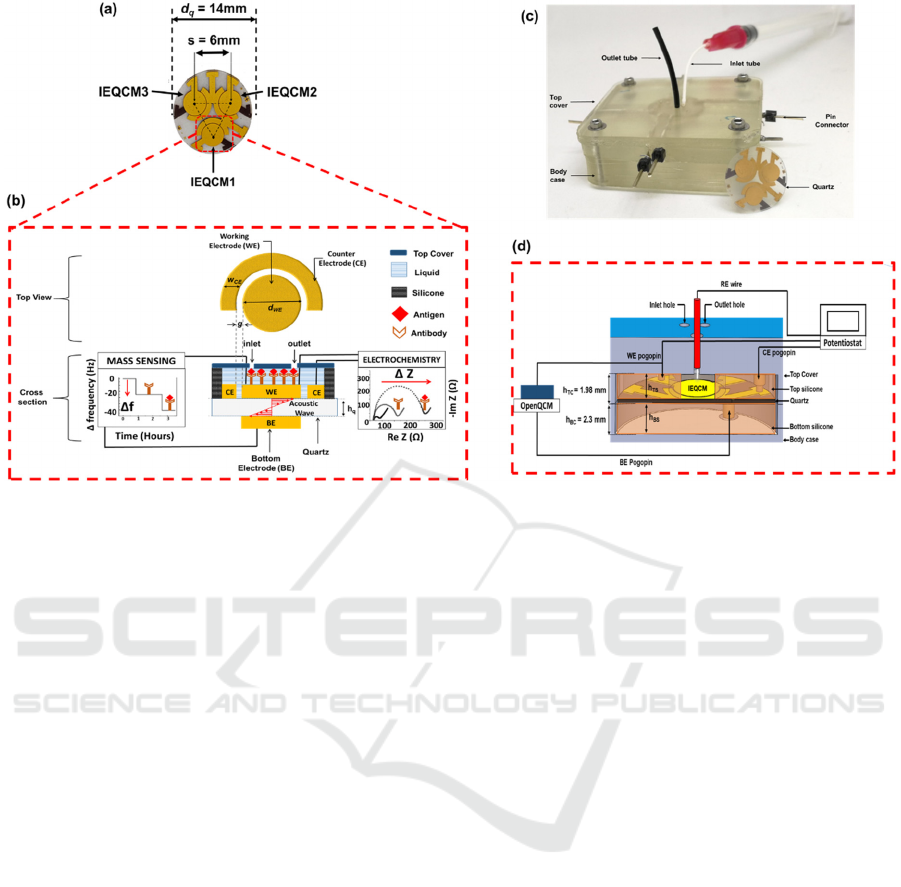

and electrochemical transductions (Figure 1(a, b)).

This system is packaged in a portable unit for

deployment at patient-side or in the field (Figure 1(c,

d)). We envision this sensor to achieve ultralow limit

of detection, dual-sensing cross-validation capability,

portable size, short sample-to-analysis time, and

parallelization of multiple assays.

2 DEVICE DESIGN,

FABRICATION AND

VA L I D AT I O N

2.1 Device Concept and Operation

The biosensor has two measurement mechanisms,

namely mass and electrochemical sensing. The mass

sensor, which is known as quartz crystal

microbalance (QCM) are widely used as a non-

destructive method to measure the changes in surface

mass due to adsorption process, based on changes in

the resonance frequency (Deng et al., 2018). The

QCM consists of electrodes on the top and bottom

(BE) sides of thin AT-cut quartz substrate. The

electrochemical biosensor consists of a three-

electrode system, which are working electrode (WE),

counter electrode (CE) and reference electrode (CE).

These electrodes are implemented as a planar device

on top of thin AT-cut quartz substrate. This leads to

the working electrode (top) having dual functions as

electrochemical and QCM sensor in a single chip

device. The quartz crystal substrate (diameter, d

q

=

14 mm) consisted of an array of three 10 MHz

integrated electrochemical quartz crystal

microbalance (IEQCM) sensors as shown in Figure

1(a). The centre-to-centre distance of QCM

electrodes was set to s = 6 mm to minimize frequency

interference (A. Zainuddin et al., 2019). Figure 1(b)

illustrates a two-electrode system consisting of WE

and CE for both the cross-section and top view of the

integrated electrochemical and QCM biosensor. The

electrochemical sensor is placed within a well, which

is made by silicone gasket to contain the liquid. Gold

(Au) was selected for the working and counter

electrodes as it is an inert (noble) electrode that has

high resistance to oxidation (Pereira et al., 2011;

Serafín et al., 2011) and has unique covalent bonding

characteristics with thiol-based self-assembly

monolayers (SAM) (A. A. Zainuddin et al., 2016) that

enables simple antibody immobilization. The

variables d

WE

, w

CE

, g and h

q

indicate the diameter of

working electrode, width of counter electrode, gap

between electrodes and quartz thickness,

respectively. To minimize the interference of electric

field during electrochemical measurements and

higher current density across electrodes, the w

CE

and

g were set to 1000 µm and 70 µm, respectively. The

device is then interfaced with measuring

instrumentation with a 3D-printed custom enclosed

sensor packaging (Figure 1(c)). This 3D-printed

packaging was developed for a single quartz crystal

substrate with diameter of 14 mm.

2.2 IEQCM Sensor Fabrication

Sensor fabrication was performed at the XLIM

Circuits Technology Center cleanroom in XLIM

Research Institute, Université de Limoges. IEQCM

sensors consists of 3 top/working electrodes (WE), a

common counter electrode (CE), and 3 bottom

electrodes (BE). The sensors were fabricated on a 14

mm (Ø) 168 µm thick AT-cut quartz crystal

piezoelectric substrate (Great Microtama Industries,

Indonesia) using standard lift-off lithography.

Fabrication begins with WE and CE on the top

side of quartz, followed by the fabrication of BE at

the bottom side of quartz. First, the substrate was

cleaned with piranha solution, 30% H

2

SO

4

, 5%

H

2

O

2

). Then, it was rinsed in ethanol and deionized

water (DI) and dried in N

2

stream. Subsequently, the

substrate was pre-baked at 120 °C for 300 s. The

image reversal photoresist (Merck AZ5214E,

Prototyping and Early Validation of an Integrated, Electrochemical and Mass Three-sensor Array for Dengue Detection

205

Figure 1: (a) Top view of the fabricated IEQCM sensor. (b) Conceptual illustration of the functional units of the integrated

electrochemical and mass biosensor. (c) Custom 3D-printed enclosed sensor interfacing device. (d) Cross-sectional view of

biosensor packaging. The height of top silicone area, h

tc

was optimally set to 1.98 mm to prevent leakage. Pogo pins are used

to form electrical contacts to the IEQCM quartz wafer. Laser-cut silicone (top and bottom) is used as hermetic gaskets and

wells. Each unit of IEQCM has three holes with radius of 400 µm corresponding to the sample inlet and outlet, and a port for

an external reference electrode (RE). The QCM measurements were done using a portable openQCM (Novatech, Italy) which

displayed measurement of frequency versus time. The electrochemical measurements were done using three electrodes (WE,

CE and RE), which were carried out using a potentiostat (Autolab PGSTAT128N).

MicroChemicals GmbH, Germany) was applied by

spin-coating to a resulting thickness of 1.5 µm and

baked at 105 °C for 60 s. Pattern was transferred onto

the resist (exposure time: 3.5 s) using a Karl Suss

MJB-3 or MJB-4 mask aligner. Prior to full exposure,

the substrate was baked at 120 °C for 60 s, followed

by the full exposure photolithography about 20 s.

After the photoresist removal process with MF-26,

Ti/Au electrode (20 nm/200 nm thick) was deposited

using E-Beam evaporator (PLASSYS MEB 300).

Finally, the release process (lift-off) was done with

acetone to strip the remaining photoresist and define

the electrodes. The same procedures were repeated to

realize the BE at the bottom side of quartz substrate.

The position of the BE relative to the WE are aligned

with assistance of alignment markers on the top side

of the quartz.

The disposable silver/silver chloride (Ag/AgCl)

RE was fabricated through bleach immersion. Silver

wire with diameter of 100 µm and minimum length

of 3 cm was chosen so that it can be fitted into the

reference electrode inlet port in the packaging

module. The silver wire is first soldered to copper

wired cables. The pure silver wire (99% Ag) is then

immersed into undiluted household bleach (NaClO,

40 mg mL

−1

) for up to 5 min (da Silva et al., 2014).

All the wire interconnects will be described in the

next section.

2.3 Sensor Packaging

A 3D-printed custom enclosure for the IEQCM

biosensor was fabricated in this work. This sensor

packaging would enable integration of electrical

contacts and sample fluid delivery to the IEQCM

sensor array. The packaging unit weighed 50 g,

measured 80 mm × 32 mm × 12.4 mm (l × w × h),

and was fabricated from a rapid 3D clear resin

(Monocure 3D, New South Wales, Australia) formed

using using a WDi7 DLP stereolithographic 3D

printer (3D Synapsis, Malaysia). Print setting for the

biosensor packaging is 50 microns per layer, with

cure time of 22.4 s per layer. Printed units were rinsed

using isopropyl alcohol and cleaned in an ultrasonic

bath (Crest Ultrasonics Corp., NJ) to remove resin

residuals, and post-processed under commercial nail

UV lamp to cure underexposed coatings.

This packaging consists of two parts (top cover

and body case). In the top cover, there are three

different regions which correspond to three IEQCM

BIODEVICES 2022 - 15th International Conference on Biomedical Electronics and Devices

206

sensors in this system. Each region has three holes

with radius of 400 µm corresponding to sample inlet

and outlet, and a port for the external reference

electrode. The top cover contains a slot with height

h

TC

= 1.98 mm to contain the silicone gasket. A

circular silicone gasket (thickness h

TS

= 2 mm,

diameter 14 mm) is laser cut with three holes of

diameter 5.5 mm as wells to contain liquid samples

under test, which corresponds to the three IEQCM

sensors in this system. This matching of h

TC

and h

TS

was optimized over several iterations to prevent

sample leakages across the silicone gasket-top cover

interface (see Figure 1(d)). Silicone was selected to

ensure hermetic sealing and prevent mechanical

stress on the quartz crystal.

For the (lower) body case, a circular silicone

(thickness h

BS

= 2 mm, diameter 14 mm) was used to

support the quartz substrate, placed inside a slot with

height h

BC

= 2.3 mm. For electrical contact to the

sensors, gold coated pogo pins (2.80 mm; Harwin

Asia Pte Ltd, Singapore) were used due to its spring-

loaded contacts that produced low mechanical stress

on the quartz crystal surface. The pogo pins are

distributed in radial symmetry (9 for top unit, 3 for

bottom unit) to reduce mechanical stress over the

quartz wafer. The top and bottom silicone gaskets are

laser cut with holes that align with the pogo pins. The

pogo pins are wired through the case by fine copper

wires (100 µm diameters) and soldered to pin headers

outside the case, for connections to external

instrumentation. The top cover and the body case are

then clamped together with bolts and nuts.

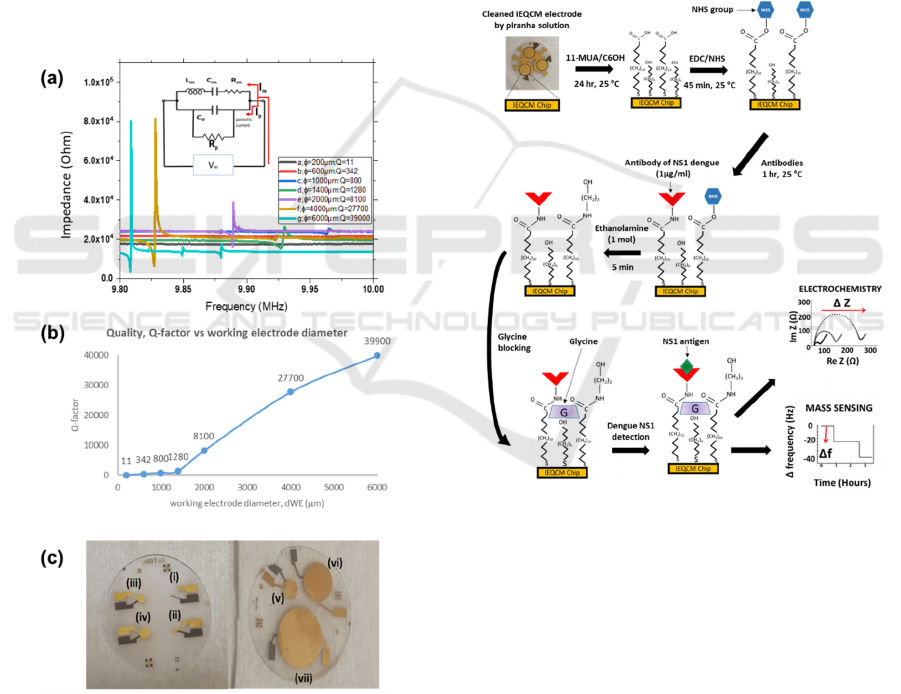

2.4 Surface Modification on IEQCM

Figure 3 shows the surface modification and

immobilization process for the NS1 immunosensors.

Bio-functionalization of mixed self-assembled

monolayers (mix-SAMs) on gold working electrode

surface was performed to immobilize the anti-NS1

IgG antibodies (ab138696, Abcam, Cambridge, UK).

Before the mix-SAMs process, the bare IEQCM

electrodes were cleaned with piranha solution, rinsed

with a large amount of deionised water and dried with

air blower pump. Polydimethylsiloxane (PDMS, 10:1

precursor-curing agent ratio; Sylgard 184, Dow

Corning) slabs with punched liquid wells was used as

a reversible mask to limit bio-functionalization

reactions (SAM, EDC/NHS, Glycine) specifically to

the working electrode.

The alkanethiols mix-SAMs was formed on the

electrodes by immersing these electrodes for 24 h at

25°C in a mixed solution containing 1 mM

11-

mercaptoundecanoic acid (for covalent anti-NS1

attachment) and 1 mM 6-mercaptohexanol (6COH) in

ethanol. Alkanethiol SAM is formed on the WE due

to formation of gold-thiol bonds. After the mix-SAMs

preparation, the electrodes were washed with excess

anhydrous ethanol and deionized water to remove any

unbound molecules. It was followed by immersion of

the WE in an aqueous solution containing 0.4 M N-

(3-dimethylaminopropyl)-N-ethylcarbodiimide

(EDC) and 0.1 M N-hydroxysuccinimide (NHS) for

40 min, to activate the carboxylic acid terminated-

group on the modified electrodes for NS1 antibody

attachment. The electrodes were then washed with

excess amounts of phosphate-buffered saline (PBS,

pH 7.4) and dried with air blower pump. It was

followed by the incubation of 50 µL of anti-NS1

solution (1 µg mL

−1

in PBS) onto the electrodes

surface. Following this incubation for 1 h, the

remaining NHS esters were deactivated by addition

of a 1 M ethanolamine solution for 5 min and the

surface was thoroughly rinsed with deionized water.

Finally, the modified mix-SAMs-NHS/EDC-anti-

NS1 electrodes were immersed in 5 mM glycine

solution (in PBS) for 30 min to block non-specific

binding sites.

2.5 QCM and EIS Validation

Early validation was performed with endpoint

measurements (i.e., not in continuous time) at each

surface modification step. The measurement setup for

the lab-on-chip biosensor is shown in Figure 1(d).

Initially, the QCM measurements were done using a

portable openQCM (Novatech, Italy) which

displayed measurement of frequency versus time. The

frequency changes were monitored by injecting 100

µL of phosphate-buffered saline (PBS) to the inlet

and outlet of the packaging biosensor. Following

injection of PBS into the chamber, the measurement

is left to stabilize, and the last 200 s of the

measurements is averaged to obtain frequency change

values corresponding to the surface modification step.

The electrochemical measurements were

performed on an Autolab PGSTAT128N potentiostat

(Metrohm AG, Switzerland). In this work, 40 µl of 5

mM ferri-ferrocyanide ([Fe(CN)

6

]

3-/4−

) in PBS were

used as redox probe (K

3

[Fe(CN)

6

], Sigma Aldrich, St.

Louis, MO). EIS measurements were recorded via

AC potential of 5 mV amplitude in the frequency

range from 1 MHz to 0.01 Hz at the optimized

oxidation peak potential of 0.2 V and plotted over a

Nyquist plot.

Prototyping and Early Validation of an Integrated, Electrochemical and Mass Three-sensor Array for Dengue Detection

207

3 RESULTS AND DISCUSSIONS

3.1 Optimization of QCM Sensors

It was previously observed that quartz thickness of

168 µm with resonance frequencies of 10 MHz was

used for biosensing (Pirich et al., 2017), and was also

chosen for this work. The working (WE) and bottom

(BE) electrodes’ diameter were selected based on an

optimal Q-factor resolution. This Q-factor

corresponds to a greater mechanical energy stored by

the resonator. Figure 2(a) indicates the measurements

of resonance frequency for the working electrode of

7 varying diameters ranging from 200 μm to 6000

μm. Figure 2(c) shows the corresponding fabricated

QCM sensors. From the results, all diameters of

QCM, d

we

showed a fundamental resonance

frequency peak close to f

o

= 10 MHz.

Figure 2: (a) Measurement of resonance frequency and Q-

factor value at different diameter of QCM sensors. (Inset)

A modified BVD equivalent circuit, where Rp was to

represent an additional value for compensating parasitic

capacitance. (b) Plot of Q-factor versus working electrode

diameter, d

WE

. (c) Fabricated QCM sensors for WE

diameters (i) 200 µm, (ii) 600 µm, (iii) 1000 µm, (iv) 1400

µm, (v) 2000 µm, (vi) 4000 µm, (vii) 6000 µm.

According to the classical Butterworth-van-Dyke

(BVD) circuit, the RLC parameters of the QCM

equivalent circuit can be divided into motional

components, R

m

, L

m

and C

m

, as shown in Figure 2(a)

(inset). These motional components are derived from

the resonance operation of the QCM and an additional

parallel static capacitor (C

0

). The motional resistance

(R

m

)

represents energy loss at resonance frequency.

The motional impedance (L

m

) and motional

capacitance (C

m

) represent the vibrating mass and

coupling coefficient, respectively. C

0

contributes to

the dielectric energy storage because the oscillation

crystal is established in between the two electrodes

(A. A. Zainuddin et al., 2018). R

p

was added to

represent an additional value for compensating

parasitic capacitance. Taking these factors into

Figure 3: The modification and immobilization process for

the NS1 immunosensor design. The mixed thiol-SAM

structures, in which 11-mercaptoundecanoic acid serves as

a linker layer for anti-NS1 antibodies attachment, and

6-mercaptohexanol functioned as spacers, is constructed

onto a gold electrode surface. It is followed by the standard

EDC/NHS amine conjugation which enables Anti-NS1

immobilization on this gold electrode. Glycine is used to

block nonspecific sites. Samples containing dengue NS1

antigen is then introduced on the sensor interface. The

faradaic impedance measurements are carried out using a

redox probe in solution [Fe(CN)

6

]

3−/4−

. When NS1 antigens

are bound to anti-NS1 antibodies, the change of impedance

is measured by EIS through approximation of the diameter

of the semi-circle of Re (Z), R

ct

. The change of frequency

is also evaluated from the reduction in resonance frequency

of the propagated acoustic wave through the surface of the

quartz using QCM.

BIODEVICES 2022 - 15th International Conference on Biomedical Electronics and Devices

208

account, widening the diameter of working electrode

may enhance the Q-factor value. This is due a high

resistance R

m

, which caused significant reduction of

current, I

m

flowing through the RLC equivalent

circuit of the QCM sensor. Therefore, a weak

resonance frequency was observed due to the

existence of a high parasitic current, I

p

. This I

p

was

forced by the electric actuation signal flowing

through the QCM parasitic capacitance C

0

. Thus, this

I

p

caused small I

m

flowing through the RLC

equivalent circuit of the QCM (Waszczuk et al.,

2011). Consequently, these smaller diameters (200

µm to 1400 µm) are not suitable to be used in the

QCM in liquid sensing due to low Q factor.

The QCM diameters of 2000 µm, 4000 µm and

6000 µm corresponds to motional resistances

R

m

= 1.51 kΩ, R

m

= 315 Ω and R

m

= 76.10 Ω

respectively. These R

m

values correspond to higher

Q-factors (Figure 2(b)), which is necessary for

sensing application in fluids. The highest Q-

factorvalue (39000) with the resonance frequency of

9.83 MHz is produced at diameter of 6000 μm.

However, d

WE

= 4000 µm was selected for our

biosensor since it showed an optimal size with

adequate Q-factor value (27700) while also allowing

geometric fit into a radial array of 3 identical sensors

on a single 14 mm quartz crystal substrate.

3.2 Electrochemical and Mass

Detection for Validation of Surface

Bio-Functionalization

Dengue is a mosquito-borne viral disease caused by

the dengue virus, which is prevalent in most tropical

and subtropical regions. Dengue disease is endemic

in more than 100 countries from South East Asia,

Western Pacific, Eastern Mediterranean, Africa to

America (Cheah et al., 2014). About 400 million

people are infected per year, of which 25% are

symptomatic (febrile illness) and 75% are

asymptomatic (Flores & O’Neill, 2018; Messina et

al., 2015), resulting in an estimated 500,000 recorded

cases of Dengue Hemorrhagic Fever (DHF) and

25,000 deaths occur per annum (Low et al., 2017).

Early detection of dengue infection is very important

for epidemiological strategies, clinical management

and administering appropriate treatment to the

patients. The urgency for early dengue detection

presents a suitable test case for our biosensor.

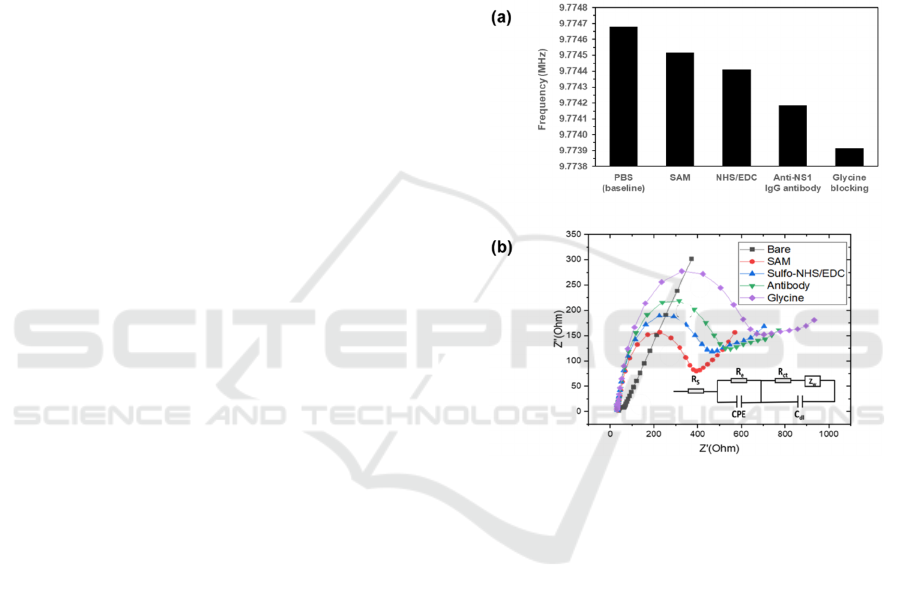

Electrochemical impedance spectroscopy (EIS) is

an electrochemical detection method that estimates

impedance or current changes in electrode surface

owing to surface reactions (Prakash et al., 2012).

Deposition of antigens and antibodies on working

electrode impede current flow to the electrode and

electrolyte system. The use of Randles circuit can be

implemented as a simple model to portray a solution

resistance (R

S

), a double layer capacitor or constant

phase element (CPE) and a charge transfer resistance

(R

CT

). The value of CPE and R

CT

are measured to

show the changes in capacitance of electrode surface

(Berggren et al., 1999). Warburg impedance (W)

contribution to the overall impedance is negligible in

our system, and thus excluded from the Randles

circuit model used in our data acquisition (Figure

4(b)).

Figure 4: Change of frequency (a) and Nyquist impedance

diagrams (b) of a surface functionalized IEQCM, layer-by-

layer: bare electrode, SAM, NHS/EDC, dengue anti-NS1

capture antibody, and blocking agent glycine. Surface

modification experiments were performed with n = 1.

The step-by-step monitoring of the surface

functionalization of the WE are performed by EIS and

QCM. Figure 4(a, b) shows the frequency change of

the QCM measurement and Nyquist diagrams of EIS

measurement following surface functionalization

steps of the IEQCM: bare electrode (Au), SAM,

SAM-EDC/NHS, SAM-EDC/NHS-antibody, SAM-

EDC/NHS-antibody-glycine. In Figure 4(a), it can be

observed that the resonant frequency is reduced for

every phase of the functionalization steps, which

corresponds to the added mass onto the surface of the

bare gold electrode. The stepwise reduction of

resonant frequency during each phase confirms the

completion of each immobilization step. This is also

confirmed by the increasing impedance (denoted by

R

CT

i.e., the diameter of the half circle) as indicated

Prototyping and Early Validation of an Integrated, Electrochemical and Mass Three-sensor Array for Dengue Detection

209

by the Nyquist plot from the EIS measurement in

Figure 4(b). The bare IEQCM exhibited a low

resistance, suggesting a fast electron process of

potassium ferrocyanide in PBS to the electrode

surface.

4 CONCLUSIONS AND FUTURE

WORKS

We report our progress in the development and

validation of an integrated electrochemical quartz

crystal microbalance (IEQCM) sensor arrays with

mixed-SAM bio-recognition layer developed for

point-of-care dengue detection. We demonstrated that

this sensor could perform both as an electrochemical

sensor and as a QCM sensor, enabling future

developments for diagnostic cross-validation on a

single platform. The biosensor is very promising with

regards to its potential use at the point-of-care. The

small footprint of the device, coupled with the

portable openQCM instrumentation, allows a high

degree of portability. While it is currently used with

an AutoLab PGSTAT128N potentiostat which is too

bulky for use in point-of-care settings, open-source

portable potentiostats (Hoilett et al., 2020) may allow

integration and development of portable and fully-

automated IEQCM dual sensing devices in the near

future. The sensor also allows to some degree of

parallelized analysis due to its triple arrayed

electrodes, further improving its capabilities for

point-of-care use. Ongoing works on this project

include development of miniaturized potentiostat for

a portable integrated instrument, improved sensor

fabrication process for integrated reference electrode

and larger scale manufacturing, and validation works

using real dengue patient samples.

ACKNOWLEDGEMENTS

This project is funded by the Swedish Research

Council (2014-4254), the Malaysian Ministry of

Higher Education under Fundamental Research Grant

Scheme (FRGS15-217-0458), and the French

National Research Agency under the Investments for

the Future program (ANR-10-LABX-0074-01

Sigma-LIM). Dr Sheroz Khan (IIUM) facilitated the

international collaborative effort. Dr Rosminazuin Ab

Rahim (IIUM) facilitated the logistics for funding.

We thank Dr Raihan Othman and Dr Shahrul Razi

Meskon (IIUM) for access to and training for the

AutoLab potentiostat.

REFERENCES

Ashton, S. J. (2012). Differential Electrochemical Mass

Spectrometry. In Design, Construction and Research

Application of a Differential Electrochemical Mass

Spectrometer (DEMS) (pp. 9–27). Springer, Berlin,

Heidelberg. https://doi.org/10.1007/978-3-642-30550-

4_2

Berggren, C., St\a alhandske, P., Brundell, J., & Johansson,

G. (1999). A feasibility study of a capacitive biosensor

for direct detection of DNA hybridization.

Electroanalysis, 11(3), 156–160.

Cecchetto, J., Carvalho, F. C., Santos, A., Fernandes, F. C.

B., & Bueno, P. R. (2015). An impedimetric biosensor

to test neat serum for dengue diagnosis. Sensors and

Actuators B: Chemical, 213, 150–154. https://doi.org/

10.1016/j.snb.2015.02.068

Cheah, W. K., Ng, K. S., Marzilawati, A. R., & Lum, L. C.

(2014). A review of dengue research in malaysia. The

Medical Journal of Malaysia, 69, 59–67.

da Silva, E. T. S. G., Miserere, S., Kubota, L. T., &

Merkoçi, A. (2014). Simple On-Plastic/Paper Inkjet-

Printed Solid-State Ag/AgCl Pseudoreference

Electrode. Analytical Chemistry, 86(21), 10531–10534.

https://doi.org/10.1021/ac503029q

Deng, F., Chen, W., Wang, J., & Wei, Z. (2018).

Fabrication of a sensor array based on quartz crystal

microbalance and the application in egg shelf life

evaluation. Sensors and Actuators B: Chemical, 265,

394–402. https://doi.org/10.1016/j.snb.2018.03.010

Flores, H. A., & O’Neill, S. L. (2018). Controlling vector-

borne diseases by releasing modified mosquitoes.

Nature Reviews Microbiology, 16(8), 508–518.

https://doi.org/10.1038/s41579-018-0025-0

Hoilett, O. S., Walker, J. F., Balash, B. M., Jaras, N. J.,

Boppana, S., & Linnes, J. C. (2020). KickStat: A Coin-

Sized Potentiostat for High-Resolution Electrochemical

Analysis. Sensors, 20(8), 2407. https://doi.org/10.3390/

s20082407

Hong, P., Li, W., & Li, J. (2012). Applications of

aptasensors in clinical diagnostics. Sensors, 12(2),

1181–1193.

Hu, J., Cui, X., Gong, Y., Xu, X., Gao, B., Wen, T., Lu, T.

J., & Xu, F. (2016). Portable microfluidic and

smartphone-based devices for monitoring of

cardiovascular diseases at the point of care.

Biotechnology Advances, 34(3), 305–320.

Lisowski, P., & Zarzycki, P. K. (2013). Microfluidic paper-

based analytical devices (μPADs) and micro total

analysis systems (μTAS): Development, applications

and future trends. Chromatographia, 76(19–20), 1201–

1214.

Low, J. G. H., Ooi, E. E., & Vasudevan, S. G. (2017).

Current Status of Dengue Therapeutics Research and

Development. The Journal of Infectious Diseases

,

215(suppl_2), S96–S102. https://doi.org/10.1093/

infdis/jiw423

Messina, J. P., Brady, O. J., Pigott, D. M., Golding, N.,

Kraemer, M. U. G., Scott, T. W., Wint, G. R. W., Smith,

D. L., & Hay, S. I. (2015). The many projected futures

BIODEVICES 2022 - 15th International Conference on Biomedical Electronics and Devices

210

of dengue. Nature Reviews Microbiology, 13(4), 230–

239. https://doi.org/10.1038/nrmicro3430

Miserere, S., & Merkoçi, A. (2015). Microfluidic

Electrochemical Biosensors: Fabrication and

Applications. In Lab-on-a-Chip Devices and Micro-

Total Analysis Systems (pp. 141–160). Springer.

http://link.springer.com/chapter/10.1007/978-3-319-

08687-3_6

Omar, N. A. S., & Fen, Y. W. (2018). Recent development

of SPR spectroscopy as potential method for diagnosis

of dengue virus E-protein. Sensor Review, 38(1), 106–

116.

Parkash, O., Yean, C., & Shueb, R. (2014). Screen Printed

Carbon Electrode Based Electrochemical

Immunosensor for the Detection of Dengue NS1

Antigen. Diagnostics, 4(4), 165–180. https://doi.org/

10.3390/diagnostics4040165

Pereira, S. V., Bertolino, F. A., Fernández-Baldo, M. A.,

Messina, G. A., Salinas, E., Sanz, M. I., & Raba, J.

(2011). A microfluidic device based on a screen-printed

carbon electrode with electrodeposited gold

nanoparticles for the detection of IgG anti-

Trypanosoma cruzi antibodies. Analyst, 136(22), 4745–

4751.

Pirich, C. L., de Freitas, R. A., Torresi, R. M., Picheth, G.

F., & Sierakowski, M. R. (2017). Piezoelectric

immunochip coated with thin films of bacterial

cellulose nanocrystals for dengue detection. Biosensors

and Bioelectronics, 92, 47–53.

Prakash, S., Pinti, M., & Bhushan, B. (2012). Theory,

fabrication and applications of microfluidic and

nanofluidic biosensors. Phil. Trans. R. Soc. A,

370(1967), 2269–2303.

Serafín, V., Agüí, L., Yáñez-Sedeño, P., & Pingarrón, J. M.

(2011). A novel hybrid platform for the preparation of

disposable enzyme biosensors based on poly (3, 4-

ethylenedioxythiophene) electrodeposition in an ionic

liquid medium onto gold nanoparticles-modified

screen-printed electrodes. Journal of Electroanalytical

Chemistry, 656(1), 152–158.

Sinawang, P. D., Rai, V., Ionescu, R. E., & Marks, R. S.

(2016). Electrochemical lateral flow immunosensor for

detection and quantification of dengue NS1 protein.

Biosensors and Bioelectronics, 77, 400–408.

https://doi.org/10.1016/j.bios.2015.09.048

Srivastava, J., Kushwaha, A., & Singh, M. (2018).

Imprinted Graphene-Starch Nanocomposite Matrix-

Anchored EQCM Platform for Highly Selective

Sensing of Epinephrine. Nano, 13(11), 1850131.

https://doi.org/10.1142/S179329201850131X

St John, A., & Price, C. P. (2014). Existing and emerging

technologies for point-of-care testing. The Clinical

Biochemist Reviews, 35(3), 155.

Waszczuk, K., Piasecki, T., Nitsch, K., & Gotszalk, T.

(2011). Application of piezoelectric tuning forks in

liquid viscosity and density measurements. Sensors and

Actuators B: Chemical,

160(1), 517–523.

Yang, Y., Tu, Y., Wang, X., Pan, J., & Ding, Y. (2015). A

label-free immunosensor for ultrasensitive detection of

ketamine based on quartz crystal microbalance.

Sensors, 15(4), 8540–8549.

Yu, L., Huang, Y., Jin, X., Mason, A. J., & Zeng, X. (2009).

Ionic liquid thin layer EQCM explosives sensor.

Sensors and Actuators B: Chemical, 140(2), 363–370.

Zainuddin, A. A., Nordin, A. N., Ab Rahim, R., & Mak, W.

C. (2016). Modeling of a novel biosensor with

integrated mass and electrochemical sensing

capabilities. Biomedical Engineering and Sciences

(IECBES), 2016 IEEE EMBS Conference On, 420–425.

http://ieeexplore.ieee.org/abstract/document/7843485/

Zainuddin, A. A., Nordin, A. N., Rahim, R. A., Ralib, A. A.

M., Khan, S., Guines, C., Chatras, M., & Pothier, A.

(2018). Verification of Quartz Crystal Microbalance

Array using Vector Network Analyzer and OpenQCM.

Indonesian Journal of Electrical Engineering and

Computer Science, 10(1), 84–93. https://doi.org/

10.11591/ijeecs.v10.i1.pp%p

Zainuddin, A., Nordin, A., Asri, M., Rahim, R., Guines, C.,

Chatras, M., Pothier, A., & Mak, W. (2019).

Development of Integrated Electrochemical–

QuartzCrystal Microbalance Biosensor Arrays:

Towards Ultrasensitive, Multiplexed and Rapid Point-

of-Care Dengue Detection: Proceedings of the 12th

International Joint Conference on Biomedical

Engineering Systems and Technologies, 220–227.

https://doi.org/10.5220/0007523802200227

Prototyping and Early Validation of an Integrated, Electrochemical and Mass Three-sensor Array for Dengue Detection

211