Construction of Intelligent Environmental Control Laboratory for

Renewable Energy

Chunxue Gao

a

Wuhan University of Science and Technology, Wuhan, China

Keywords: Air Source Heat Pump, Central Air Conditioning System, Renewable Energy, Intelligence.

Abstract: Based on the residents' demand for central air-conditioning systems in cold winter and hot summer areas, an

air-source heat pump central air-conditioning system was built, and a renewable energy intelligent

environmental control laboratory was built to explore the comfort and energy saving of the system. At the

same time, it enriches the innovative experiment content of undergraduates majoring in the building

environment and energy application, and provides a scientific research platform for graduate students,

teachers, and the society.

1 INTRODUCTION

In the teaching of science and engineering in colleges

and universities, experimental teaching plays a vital

role. University engineering laboratories are an

important platform for cultivating engineering

students’ innovative spirit and innovative ability.

Strengthening the construction of engineering

laboratories will help deepen innovation and

entrepreneurship education development (Ge, et al.

2021). However, most of the school's professional

laboratories have outdated equipment due to tight

funding, and have not kept up with the pace of

industry development, which has seriously affected

the quality of talent training. The college is centered

on the cultivation of students' ability, facing social

needs (Zhang, et al. 2020), and Wuhan Comfort Yibai

Technology Co., Ltd. (referred to as "Comfort 100")

to jointly build a renewable energy intelligent

environmental control laboratory.

a

https://orcid.org/0000-0001-5891-4751

2 LABORATORY

CONSTRUCTION PLAN

2.1 Air Source Heat Pump Central Air

Conditioning System

How to achieve environmental comfort and energy

saving is the focus of research on household central

air conditioners. Renewable energy comes from

nature and is inexhaustible. The natural environment

such as air contains a large amount of low-grade heat

energy that cannot be directly used. After the energy

level is raised by a heat pump, it can be used as a cold

and heat source for air conditioning to form a

renewable energy utilization system (Ye 2017). Air

source heat pumps use renewable energy to transfer

the energy of outdoor air from a low-level heat source

to a high-level heat source. The evaporator absorbs

heat for cooling, and the condenser releases heat for

heat transfer. The air source heat pump unit has the

characteristics of energy saving, dual use of cold and

heat sources, no need for cooling systems and boilers,

and is particularly suitable for the hot summer and

cold winter areas in my country as the cold and heat

source of the centralized air conditioning system (Lu

2008a). Compared with other heating equipment, air

source heat pumps have more obvious advantages in

energy saving and environmental protection. This

system uses air source heat pump cold and hot water

238

Gao, C.

Construction of Intelligent Environmental Control Laboratory for Renewable Energy.

DOI: 10.5220/0011291100003444

In Proceedings of the 2nd Conference on Artificial Intelligence and Healthcare (CAIH 2021), pages 238-243

ISBN: 978-989-758-594-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

units as the cold and heat source equipment, and uses

fan coils, radiant floors, and radiators as the cooling

and heating terminals of the system respectively,

which facilitates the comparison of the heat effect and

human comfort of the terminal equipment in the later

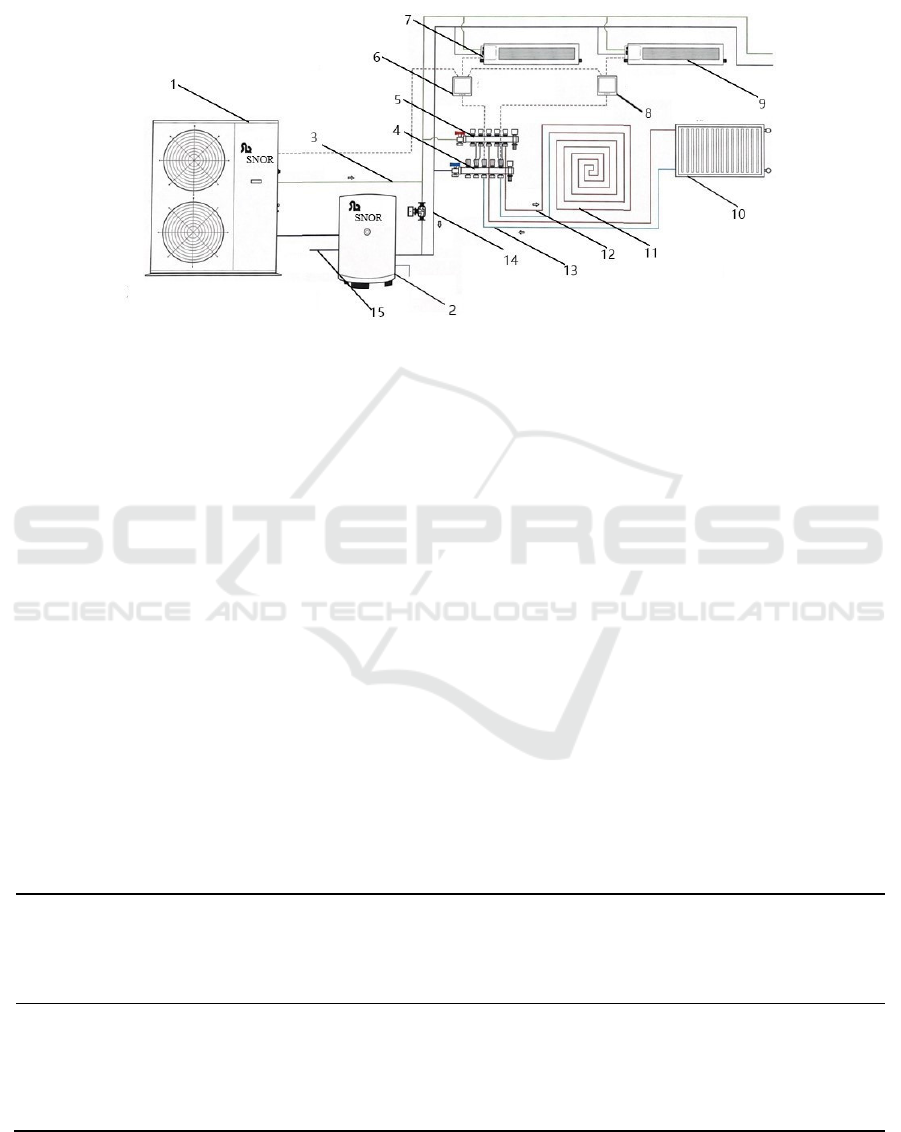

period. The schematic diagram of the intelligent floor

heating and air-conditioning integrated machine is

shown in Figure 1.

Figure 1: Schematic diagram of the intelligent floor heating and air-conditioning integrated machine system.

1-Variable-frequency air source heat pump unit 2-Buffer tank 3-Outlet pipe 4-Water trap 5-Water separator 6,8-

Intelligent temperature controller 7,9-Fan coil 10-Radiator 11-Floor heating 12-Hot water outlet pipe 13-Cold

water return pipe 14-Return pipe 15-Water supply pipe

In order to ensure indoor air quality, a fresh air

system is required. In addition, the humidity in

Wuhan is relatively high, especially during the rainy

season, requiring a dehumidification system.

Therefore, the central air-conditioning system

includes five parts: fan-coil system, floor heating

system, radiator heating system, fresh air system, and

dehumidification system, which are introduced in the

following.

2.1.1 Fan Coil System

The laboratory is located on the first floor of the

teaching building (a total of five floors). The south

faces the sun and has windows, the east and north are

aisles, and the west is adjacent to another laboratory.

There is no air conditioning system around, and the

area is 12*7.9=94.8m

2

. According to Air

Conditioning Design Manual estimates, the outdoor

unit uses SNOR inverter air-cooled heat pump unit

SHDA18.

In order to analyze and compare the actual

operating performance and noise of different fan coil

units in the later period, three fan coil units from

different manufacturers are selected for the indoor

unit (in order to keep the fan coil manufacturer secret,

the manufacturer name is replaced by "*", and the

following Same thing). The fan coil configuration of

the indoor unit is shown in Table 1.

In order to make reasonable use of the laboratory

space and facilitate teaching, the fan coil is exposed

horizontally, hung on the upper part of the room, with

its own air inlet and outlet.

Table 1: Indoor unit fan coil configuration table.

Serial

number

area

Unit

cooling

loa

d

Correction

factor

Total

cooling

loa

d

Indoor unit quantity

Indoor unit

cooling

capacit

y

Total

cooling

capacit

y

Actual

cooling

loa

d

m

2

W/m

2

W

Product

name

model tower W W W/m

2

1

94.8 220 1 20856

Shi Nuo fan

coil

FCSD07L 1 5600 5600

213

2 **fan coil FCAA12L 1 11250 11250

3 **fan coil HFCF04 1 3300 3300

total 20856 3 20150

Construction of Intelligent Environmental Control Laboratory for Renewable Energy

239

2.1.2 Floor Heating System

The floor heating system has been widely adopted by

the construction industry in recent years due to its

advantages of comfort, sanitation, energy saving, and

good thermal stability. The industry has conducted

extensive research on it: Hongwei Tang and Xiaoli

Sun (2019) studied the application of terminal design,

Yunxia Zhu (2018) analyzed the key points of floor

heating design, Zhiyong Lei (2016), Yue Wu et al.

(2016) analyzed its energy-saving effects and heat

transfer, etc. However, how to better save energy

under the condition of meeting comfort needs to be

further explored. In order to find a more energy-

efficient floor heating mode, this system adopts four

methods of laying: wet (wood floor, stone) and dry

(wood floor, stone). The pipe spacing of wet floor

heating is 50mm, and the bottom plate uses wooden

floor and floor tiles; the pipe spacing of dry floor

heating is 150mm, and the bottom plate uses wooden

floor and floor tiles.

2.1.3 Radiator Heating System

The radiator heating system is an abbreviation of a

system that heats the end with a radiator. The heat is

mainly transferred to the indoor space quickly by

means of hot air convection and radiation, so that the

indoor reaches the ideal heating temperature at the

fastest speed, and the time required is about one-fifth

of the floor heating.

Estimate the total heat load based on the

laboratory area and the standards of the Air

Conditioning Design Manual, and then select the

indoor unit-the radiator model based on the total heat

load. In order to compare the actual operating

performance of radiators from different

manufacturers in the later stage, radiators from three

manufacturers were selected. The specific

configuration is shown in Table 2.

Table 2: Radiator heating equipment configuration table.

Serial

number

area

Specific

heat

loa

d

Total

load

Indoor unit quantity

Radiator

heat

Total

calories

Actual

heat load

m2 W/m2 W

Product

name

model tower w W W/m2

1

94.8 130 12324

*** 22PKKP600*2200 1 3985 3985

116

2 *** 22PKKP600*2000 1 3622 3622

3 *** 22PKKP600*2000 1 3417 3417

total

12324

3 11024

2.1.4 Fresh Air System

In the hot summer or cold winter, people expect to be

in an air-conditioned room, which will cause various

air-conditioning diseases. The main cause of these

diseases is the poor indoor air quality. In order to

solve the problem of indoor air quality, opening

windows for ventilation is the most convenient and

effective way to improve indoor air quality, but this

will cause a great waste of energy and affect indoor

cooling and heating effects. If the central air-

conditioning and fresh air system are used at the same

time, the two complement each other and

complement each other, which can not only ensure

the appropriate indoor temperature, but also ensure

the fresh indoor air. Therefore, it is necessary to

introduce a fresh air system into the central air-

conditioning system.

The model of the fresh air blower is determined

according to the amount of fresh air required in the

room. Calculate the required fresh air volume Q in the

building, considering both the "indoor number of

people" and "indoor ventilation frequency", in order

to ensure the indoor air quality, the mechanical

ventilation host is selected with a larger value (Yu

and Xiong 2017). According to Design Standard for

Energy Efficiency of Public Buildings (GB50189-

2019) 3.0.2 and Code for Design of Heating,

Ventilation and Air Conditioning of Civil Buildings

(GB50736-2016) 3.0.6, the required fresh air volume

Q≥240m

3

/ h.

When the fresh air system is installed separately

and the air exchange rate is large, the fresh air will

have a greater impact on the heating load and air

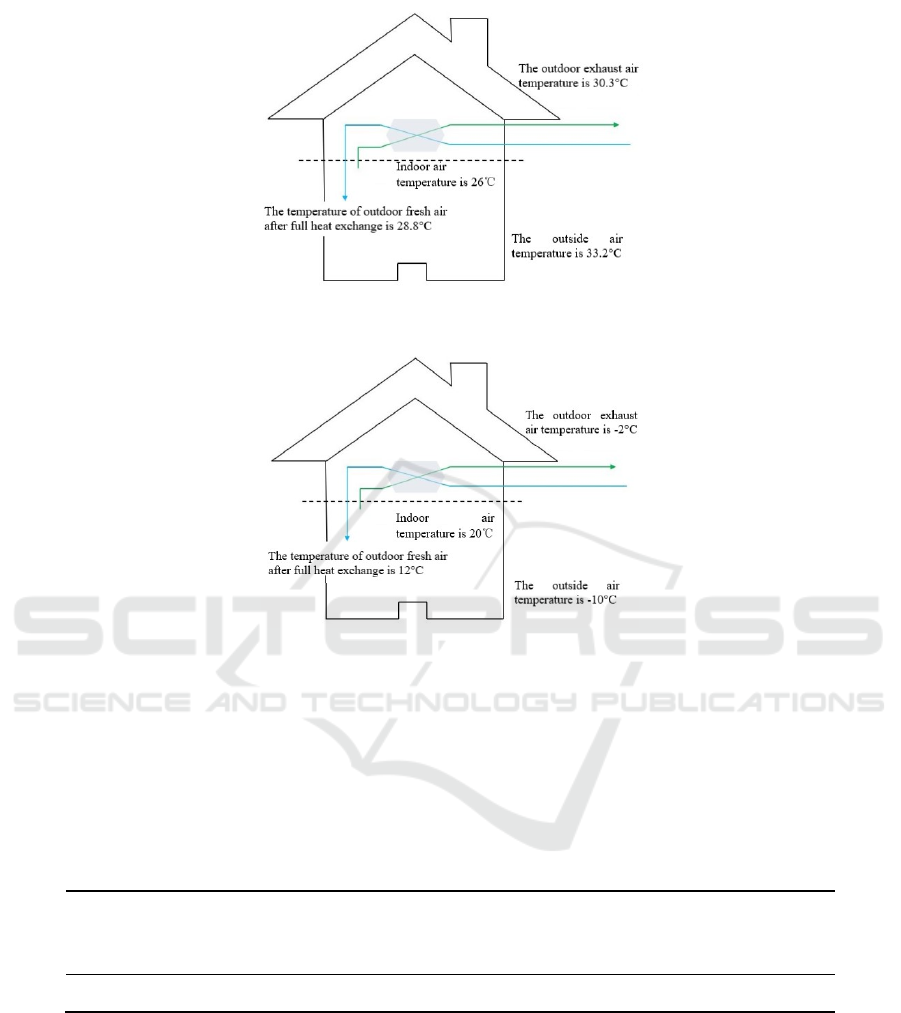

conditioning cooling load. In order to save energy, a

full heat exchange fresh air blower is used, and the

exhaust air is used for pre-cooling and fresh air

preheating to reduce the fresh air load

(Gu, et al.

2019). As shown in Figures 2 and 3.

CAIH 2021 - Conference on Artificial Intelligence and Healthcare

240

Figure 2: Schematic diagram of total heat exchange in summer.

Figure 3: Schematic diagram of total heat exchange in winter.

At the same time, the outdoor air quality is

sometimes poor, especially in autumn and winter for

a long time. When considering the delivery of

outdoor air indoors, the quality of the input outdoor

air must also be considered. The selected fresh air

system must have the function of preventing haze. It

can effectively remove PM2.5, bacteria, peculiar

smell, etc., to ensure the freshness of the indoor air.

In order to meet the above requirements, this system

uses SNOR's SFD250-EM anti-haze full heat

exchange fresh air blower, and its configuration is

shown in Table 3. In order to save energy, fresh air

operation can be realized during the transition season

(Gu, et al. 2019, Liu, et al. 2020).

Table 3: Fresh air system configuration table.

Area

Storey

hei

g

ht

Volume

Number of air

chan

g

es

Ventilation

volume

New fan model

Quantity

Remarks

m2 m m3 Times/hour m3 tower

94.8 3.8 360.2 0.6 216.1 SFD250-EM 1 250m3/h

2.1.5 Dehumidification System

Conventional air-conditioning systems generally use

heat and humidity coupling control methods in

summer to cool and dehumidify the air, and at the

same time remove the sensible heat load and latent

heat load in the building. After the condensation and

dehumidification treatment, although the moisture

content of the air can meet the requirements, the

temperature is too low. Sometimes in order to meet

the requirements of the supply air temperature, it

needs to be reheated (Wang 2019). In addition, the

indoor temperature is suitable in some seasons, but

the air humidity is relatively high, especially in the

rainy season. In order to avoid energy waste, an

independent temperature and humidity control

system is used to control the indoor temperature and

humidity separately (Lu 2008b). According to actual

Construction of Intelligent Environmental Control Laboratory for Renewable Energy

241

needs, run a fresh air system or a full

dehumidification system.

The model of the dehumidifier is determined

according to the amount of dehumidification required

for the indoor space of the building: the comfortable

humidity of the human body is 40-60%. The amount

of water that needs to be removed in a day from

90RH% to 60RH% is calculated to determine the

model of the dehumidifier. The dehumidification

system uses SDAT58/500 central dehumidifier from

SNOR. The nominal dehumidification capacity is

58L/day, the air exchange rate is 500m3/h, and the

heat recovery rate is 65-85%.

2.2 Environmental Intelligent Control

System

With the development of wireless networks, the level

of automation control of the central air-conditioning

system is gradually improving, and the requirements

for residential comfort are also increasing. The

system adopts SNOR intelligent control panel/SNOR

intelligent IOT template + SNOR intelligent energy

management to form the SNOR IOT environmental

intelligent control system, and realizes precise

temperature control of 0.5℃ through a small

program, and the operation mode of the remote

control system. The equipment operating data is

collected through the remote electronic control

system to monitor and manage energy consumption

(Yang and Han 2020). It is also possible to connect to

the remote control system of the system through the

mobile phone APP-Comfort Smart Home to monitor

the operating status and operating parameters of the

system.

The selected SNOR CBK10 thermostat can

perform big data analysis on temperature and

humidity according to seasonal weather changes and

different scene usage habits, and customize

personalized solutions and intelligent control

equipment for users to integrate people with the

building, create a beautiful feeling of being close to

nature and comfortable.

3 EXPERIMENTAL CONTENT

AND TEST EQUIPMENT

In order to enable students of this major to fully grasp

the central air-conditioning system and highlight the

characteristics of the building environment and

energy application majors, the system can be used as

a scientific and technological innovation platform for

undergraduates, and the following experiments are

set up:

(1) Test the thermal efficiency of the fresh air

ventilator.

(2) Test the dehumidification effect during the

rainy season.

(3) Test the air distribution of the fan coil.

(4) Test the distribution of the temperature field in

the radiant floor heating room.

(5) Test the temperature and humidity of floor

heating, simulate the temperature field and humidity

field respectively, and find the most energy-saving

and comfortable floor heating mode.

(6) Study the energy-saving effect of dual-supply

(fan coil + radiant floor heating) of household air

source heat pump units.

(7) Study the distribution of indoor air

distribution at different heating terminals.

(8) Study the comfort of the human body in

different heating terminals.

The testing instruments currently available are:

JTDL-80 temperature and heat flow dynamic data

acquisition system, ultrasonic flowmeter, enhanced

environmental tester, WSZY-1 temperature and

humidity automatic recording instrument, infrared

thermometer, carbon dioxide tester, PM2.5 Tester, air

particle counter, indoor air quality detector, digital

clamp multimeter, etc.

The combination of experiment and actual

engineering can not only stimulate students' interest

in experiments and mobilize students' enthusiasm,

but also enable students to grasp the frontier research

trends of the industry, improve students' scientific

research literacy, and cultivate more talents for the

development of the industry. At the same time, it also

enriches the experimental teaching content of

undergraduates and improves the traditional

experimental teaching mode.

The system can be used not only as a scientific

and technological innovation platform for

undergraduates, but also as a scientific research

platform for graduate students and teachers to realize

basic research on the application of renewable

energy, so as to better study the comfort and energy

saving of the air source heat pump central air

conditioning system;At the same time, it is open to

the society and serves as a training base for

enterprises to explore the best mode of air source heat

pump central air-conditioning system for comfort and

energy saving together with people in the same

industry.

CAIH 2021 - Conference on Artificial Intelligence and Healthcare

242

4 CONCLUDING REMARKS

In short, laboratory construction is extremely

important. The air-source heat pump central air-

conditioning system and the environmental

intelligent control system are the basis for the

construction of the laboratory. To do well in the

testing and research work of this experimental

platform, researchers need to have high standards and

strict requirements, testing instruments should be as

advanced and high-precision as possible, and the

experimental content also needs to be further

expanded and deepened. In this way, we can provide

high-quality experimental teaching and scientific

research platforms for teachers, students and the

society.

At the same time, the school makes full use of

social resources, gives full play to their respective

advantages, initiates school-enterprise cooperation,

and jointly builds an experimental platform, realizing

a new mode of industry-university-research school-

enterprise cooperation with resource sharing,

complementary advantages, and a win-win situation.

This will not only improve the school's experimental

teaching and scientific research conditions, and

organically combine teaching, scientific research and

practice, but also contribute to the development of the

industry and the energy conservation and

environmental protection of the society.

FUNDING STATEMENT

This research was funded by the Science and

Technology Program Project of the Ministry of

Housing and Urban-Rural Development "Research

on Indoor Thermal Environment Based on Zero

Energy Building Technology in Hot Summer and

Cold Winter Area" (2017-K1-014). Hubei Provincial

Natural Fund Youth Fund "Technology and

Evaluation of Multi-energy Complementary Energy

Supply for Rural Residential Buildings in Hubei"

(2017CFB311). Hubei Province Colleges and

Universities Laboratory Research Project "Research

on the Construction of Intelligent Environmental

Control Laboratory Based on Renewable Energy"

(HBSY 2019-04).

REFERENCES

Ge, T., Fu, S. C., Liu, W. M. (2021). Research on

University Laboratory Construction and Management

under the Background of Innovation and

Entrepreneurship Education. J.

[EB/OL]https://kns.cnki.net/kcms/detail/11.2034.T.20

210303.1819.003.html.

Gu, Y., Zhu, W. H., Zhao, Y. (2019). Air conditioning

system design for the new Henan Science and

Technology Museum. J. Refrigeration and Air

Conditioning. 19 (4), 50-55.

Lei, Z. Y. (2016). Analysis of the energy-saving effect of

radiant floor heating. J. Jiangxi Building Materials. 04,

59.

Liu, B. Y., Tang, C. Y., Xu, X. Y. (2020). Analysis of key

green energy-saving technologies for large-scale

exhibition buildings. J. Refrigeration and Air

Conditioning. 34(4), 493-499.

Lu, Y. Q. (2008a). Practical heating and air conditioning

design manual. M. Beijing: China Construction

Industry Press. 2, 2347.

Lu, Y. Q. (2008b). Practical heating and air conditioning

design manual. M. Beijing: China Construction

Industry Press. 2, 1794.

Tang, H. W., Sun, X. L. (2019). Research on the design

and application of low-temperature floor radiant

heating terminal in residential buildings. J. Heating and

cooling. 04, 18-20.

Wang, W. (2019). Brief introduction of temperature and

humidity independent control air-conditioning system

in a residential project. J. Clean and air-conditioning

technology. 4, 112-114.

Wu, Y., Guo, X. G., Peng, D. G., etc. (2016). Heat transfer

analysis of low-temperature floor radiant heating. J.

Building technology. 11, 970-973.

Yang, Y. Han, Y.C. (2020) Energy consumption

monitoring and management platform remote

electronic control system. P. 202020356134.8.

Ye, D. F. (2017). Talking about the green energy-saving

design of air-conditioning cold and heat sources in

public buildings. J. HVAC. 47(8), 60-65.

Yu, Y., Xiong, J. X. (2017). Talking about the application

of green design in construction engineering HVAC. J.

Architectural Design. 28, 505-505.

Zhang, J. X., Guo, L., Liu Y. N., et al. (2020).

Construction of special laboratory for measurement and

control under the background of new engineering. J.

Experimental Technology and Management. 37(12),

265-269.

Zhu, Y. X. (2018). The main points of floor heating design

in residential buildings. J. Building materials and

decoration. 26, 120.

Construction of Intelligent Environmental Control Laboratory for Renewable Energy

243