The Effect of Temperature on the Aroma of Soft Stick Oolong Black

Tea

Ling Ren

1,2 a

, Shunying Chen

1b

, Chunhua Zhang

1,* c

and Ruifang Wang

1,* d

1

Pu'er University, Pu'er, Yunnan Province, China 665000

2

Tea College of Yunnan Agricultural University, Kunming, Yunnan Province, China 650201

*

Corresponding author

Keywords: Soft Stick Oolong, Roasting, Black Tea.

Abstract: Soft stick oolong black tea using the processing technology of Yunnan Gongfu black tea is made from Taiwan

Qingxin oolong. In this study, in order to explore the effect of roasting temperature on the aroma of soft stick

oolong black tea. Soft stick oolong black tea was roast at 100°C, 110°C, 120°C, 130°C temperatures, and then

the aroma was determined by GC-MS. Our results showed that soft stick oolong black tea had the most volatile

compounds and the highest sensory evaluation score at the baking temperature 120°C.

1 INTRODUCTION

Tea (Camellia Sinensis (L.) O. Ktze.) belongs to

shrubs or small trees. China is the origin of tea (Lu

2013). Initially, it exerted its medicinal value. Legend

recored that, Shennong tasted tea. Tea has been used

to clear heat and quench thirst, diuresis and

strengthen the heart. Oolong tea is mainly distributed

in Fujian and Taiwan, which has a high aroma and

low bitterness. It is often used to make black tea and

green tea, and the produced tea has a unique aroma.

An important factor influencing the quality of oolong

tea is aroma, and processing techniques have

different effects on the aroma components of oolong

tea (Su 2019).

Gongfu black tea is named from its extremely

labor-intensive production process. And Gongfu

black tea is well-known in the world for its "high

fragrance, bright color and strong taste" (Mi 2013).

The production process is not complicated, but the

control of the production process is very important.

Withering is the process of losing some water,

volatilizing grass gas, and affecting enzyme activity.

The degree of withering can affect the quality of

black tea. The process of rolling is the result of the

coordination of chemical and physical interactions, in

which black tea has begun to ferment, and different

a

https://orcid.org/0000-0002-1796-6261

b

https://orcid.org/0000-0002-6805-019X

chemical reactions have occurred. It is also the

process of black tea shaping, rolling into a firmer

curled shape, increasing the rate of cell damage and

promoting oxidation reaction. The production

process of Yunnan Gongfu black tea is wilting →

rolling → fermentation → drying → fragrance, which

is also a way to stimulate the aroma after the black tea

has been dried (Fan et al. 2020, Feng et al. 2017).

There are baking, hot wind, far infrared, microwave,

light wave and other fragrant ways. But in Yunnan,

baking is generally used to increase fragrance,

because the boiling point of aromatic substances is

different, the temperature of baking and fragrance

will change accordingly. In recent years, consumers

have much demanding on the quality of black tea.

How to improve the aroma and taste of black tea has

always been a hot research topic for black tea (Liu et

al. 2015).

The so-called "soft branch" refers to an oolong

species introduced from Taiwan, also known as

Qingxin Oolong. It was originally introduced to

Taiwan by a century-old mother tree of dwarf oolong

from Jian'ou City, Fujian Province. It belongs to a

small-leaf species with a small tree shape. It is an

open-type dwarf variety with small leaves and dense

branches. The buds are initially purple and the leaves

are oblong. The thick mesophyll makes it extremely

rich in nutrition and aroma substances, which are

c

https:// orcid.org/0000-0001-9567-0987

d

https://orcid.org/0000-0003-4715-6240

Ren, L., Chen, S., Zhang, C. and Wang, R.

The Effect of Temperature on the Aroma of Soft Stick Oolong Black Tea.

DOI: 10.5220/0011237600003444

In Proceedings of the 2nd Conference on Artificial Intelligence and Healthcare (CAIH 2021), pages 197-202

ISBN: 978-989-758-594-4

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

197

suitable for making many different fermented teas.

Soft branch black tea is made from the fresh leaves of

soft branch oolong tea and the processing technology

of Yunnan Kungfu black tea. Because the oolong tea

has a higher aroma, making it into black tea can

improve the aroma. Therefore, soft branch black tea

is very popular nowadays.

Baking treatment is one of the important post-

treatment processes of tea, which has an important

effect on improving the quality of tea (Wen et al.

2018). In recent years, Yunnan Gongfu black tea

flavoring technology has been continuously

developed, and the commonly used baking flavoring

technology has also been continuously improved. The

market has increasingly higher requirements for the

aroma of black tea. Therefore, the related research

and improvement on the standards for black tea

fragrance enhancement are needed. Zheng Silin

(Zheng 2016) studied the processing technology of

the Qingxin Oolong variety Summer and Autumn

black tea introduced in Sichuan, showed that the

black tea made with Qingxin Oolong is of good

quality. Although it is different from the processing

technology of Yunnan Gongfu black tea, it also has a

guiding significance for Yunnan Oolong Gongfu

black tea. However, the current research results on

the aroma of soft-branch black tea are lacking, the

research on the fragrance standard needs to be

perfected, and there is no research specifically aimed

at the aroma of soft-branch oolong black tea. Shi

Daliang (Shi et al. 2018) studied the drying methods

of Qingxin Oolong Gongfu black tea. The results

proved that Qingxin Oolong Gongfu black tea had the

best quality under the conditions of 120 ℃ first firing

and 90 ℃ full firing. This study explored aromatic

substances in soft stick oolong black tea to find out

aroma-stimulating temperatures. Then through the

evaluation of the tea critics, we want to find optimal

time and temperature for soft stick oolong black tea

processing, which will have certain guiding

significance for the production of soft stick oolong

black tea.

2 MATERIALS AND METHODS

2.1 Materials and Instruments

Material: The soft stick oolong black tea purchased in

the market has uniform material quality and has not

been treated with fragrance after drying.

Instrument: American Agilent 6890-5973 Gas

Chromatography Mass Spectrometer (GC-MS).

Manual solid phase microextraction instrument PC-

420D, Supelco, USA; Extraction head 65μm,

PDMS/DVB, Supelco, USA.

2.2 Sample Preparation

Divide the material into 4 groups, each group is 500g

and set 3 repetitions for 60 minutes. The temperature

of control group was set at 100°C; the temperature of

other three groups were set at 110°C (Ⅰ),120°C (Ⅱ)

and 130°(Ⅲ). Spread the fragrance and cool it in the

same room. The indoor temperature is 20-23℃, and

the relative humidity of the air is 70%-80%. After

spreading to room temperature, put it in a No. 10

ziplock bag for sealing, and the air is full of self-

sealing. After the bag is sealed, the fragrance is

prevented from being lost after the gas exchange with

the outside (Luo et al. 2016).

2.3 GC-MS Conditions

The solid phase microextraction (SPME) method is

used to collect volatile substances. Use a clean

dissecting needle to poke a small hole about 5cm

below the top of the ziplock bag, insert a 0.5mm

length of 65μm PDMS/DVB solid phase

microextraction head manual SPME sampler into the

ziplock bag, headspace extraction and adsorption for

1 hour, sampling After the end, it was transferred to

the gas chromatograph mass spectrometer for

injection (Zhang et al. 2020).

An Agilent 7890A-5975C gas chromatography-

mass spectrometer was used to analyze plant

volatiles. Capillary column HP-5MS (30m×0.25mm,

0.25μm), the carrier gas is high-purity helium, and the

flow rate: 1.0mL·min-1. Heating program: the initial

temperature is 50°C, the temperature is raised to

280°C in 10 minutes, and after waiting 5 minutes, the

temperature is lowered to 50°C, and the instrument

runs for 52 minutes after sample injection. The

solvent is delayed by 2 min. The ion source

temperature is 230°C, and the quadrupole

temperature is 150°C. The detector temperature is

280°C, and the inlet temperature is 220°C (Zhang et

al. 2020, Ma et al. 2019, Chen et al. 2021, Xie et al.

2019).

2.4 Materials and Instruments

After completing the GC-MS test, take the sample to

the tea review room for sensory review and scoring.

The sensory review of black tea is carried out with

reference to GB/T23776-2018 "Tea Sensory

Evaluation Method" (GB/T23776-2018), and the

determination of sensory attributes refers to GB/T

CAIH 2021 - Conference on Artificial Intelligence and Healthcare

198

14487-2017 "Tea Sensory Evaluation Terminology"

(GB/T14487-2017), which was reviewed by 5

professionals Sensory evaluation of tea leaves is

conducted, and the scores are based on the average of

the tea judges to find the group with the best taste.

2.5 Data Analysis

Delete all compounds with matching degree <80 and

silicon-containing oxides. Query, identify and

analyze the compound components in the samples by

CAS number, and use Microsoft Excel 2019 software

to carry out the data statistical analysis of aroma

components (Zhang et al. 2020, Ma et al. 2019, Liu et

al. 2021, Zhou et al. 2011).

3 RESULTS AND ANALYSIS

3.1 Analysis of Aroma Components of

Soft-Branch Oolong Black Tea

A total of 113 volatile compounds were identified in

the 4 treatments by GC-MS. The control group

identified 56 volatile substances, including 12

olefins, 10 alcohols, 8 alkanes, 7 aldehydes, and 6

aromatic hydrocarbons. The contents of various

volatiles were 21.4%, 17.9%, 14.3%, 12.5%, and

10.7% respectively. Group A has identified 55

volatile substances, including 17 olefins, 11 alkanes,

8 aromatic hydrocarbons, and 4 alcohols. The

contents of various volatiles were 30.9%, 20.0%,

14.6%, and 7.3%, respectively. Group B has

identified 66 volatile substances, including 21

olefins, 18 alkanes, 10 aromatic hydrocarbons, and 4

alcohols. The contents of various volatiles were

31.8%, 27.3%, 15.2%, and 6.1%, respectively. Group

C has identified 46 volatile substances, including 18

olefins, 11 alkanes, 9 aromatic hydrocarbons, and 2

alcohols. The contents of various volatiles were

39.1%, 23.9%, 19.6%, and 4.3% respectively. The 4

treatments mainly include 23 kinds of alkanes, 31

kinds of olefins, 13 kinds of aromatic hydrocarbons,

12 kinds of alcohols, 10 kinds of aldehydes, 5 kinds

of ketones, 3 kinds of esters, 4 kinds of acids, and 2

kinds of oxygen heterocycles, 3 kinds of nitrogen

heterocycles, 3 kinds of ethers, 2 kinds of sulfides and

2 kinds of other substances (Table 1,2,3).

With the increase of flavoring temperature, the

proportion of olefins and aromatic hydrocarbons

gradually increases, and the proportion of alcohols

gradually decreases. It shows that with the increase of

the flavoring temperature, most of the volatile

substances in soft stick oolong black tea are

converted into olefins, and alcohols are decomposed

into other volatile substances.

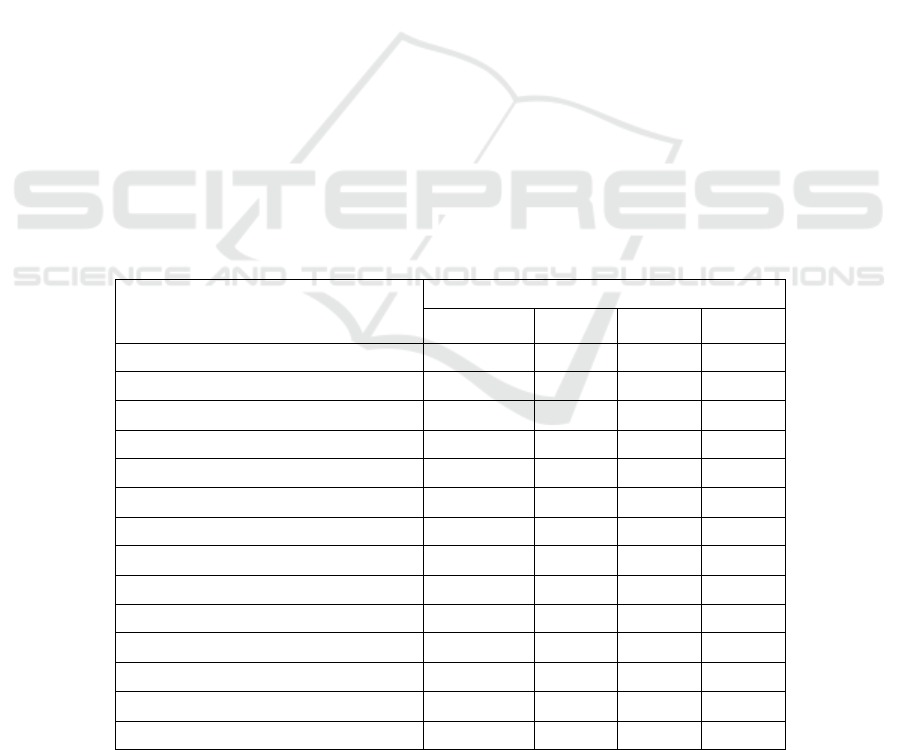

Table 1: The total fraction of aroma substance in soft stick oolong black tea

Varieties

Total fraction

control Ⅰ Ⅱ Ⅲ

Alkanes 8 11 18 11

Olefins 12 17 21 18

Aromatic hydrocarbons 6 8 10 9

Alcohols 10 4 4 2

Aldehydes 7 4 6 3

Ketones 3 3 1 1

Esters 3 0 1 0

Acids 2 2 0 0

Oxygen heterocycles 1 1 1 0

Nitrogen heterocycles 2 0 1 1

Ethers 0 2 1 0

Sulfide 1 2 1 1

Other 1 1 1 0

Total 56 55 66 46

The relative content of alkanes with more than 10

carbon atoms (Dodecane, Tetradecane, Undecane,

Tridecane, 3-methyl-) decreases with the increase of

the flavoring temperature, while those with less than

The Effect of Temperature on the Aroma of Soft Stick Oolong Black Tea

199

10 carbon atoms The relative content of alkanes

(Nonane, Decane) increases with the temperature,

indicating that long-chain alkanes are decomposed

into short-chain alkanes at high temperature.

Myrcene is made from linalool as the raw material.

The relative content of myrcene gradually increases

with the fragrance temperature, while the relative

content of linalool has a downward trend with the

increase of the fragrance temperature. It shows that

with the increase of fragrance temperature, a large

amount of linalool is converted into myrcene. beta-

Pinene and (1S)-L-β-Pinene are both intermediates in

the manufacture of flavors and fragrances. As the

flavoring temperature increases, their relative content

tends to increase, indicating that as the flavoring

temperature increases Some of the elevated

substances are converted into beta-Pinene and (1S)-

L-β-pinene (Table 2).

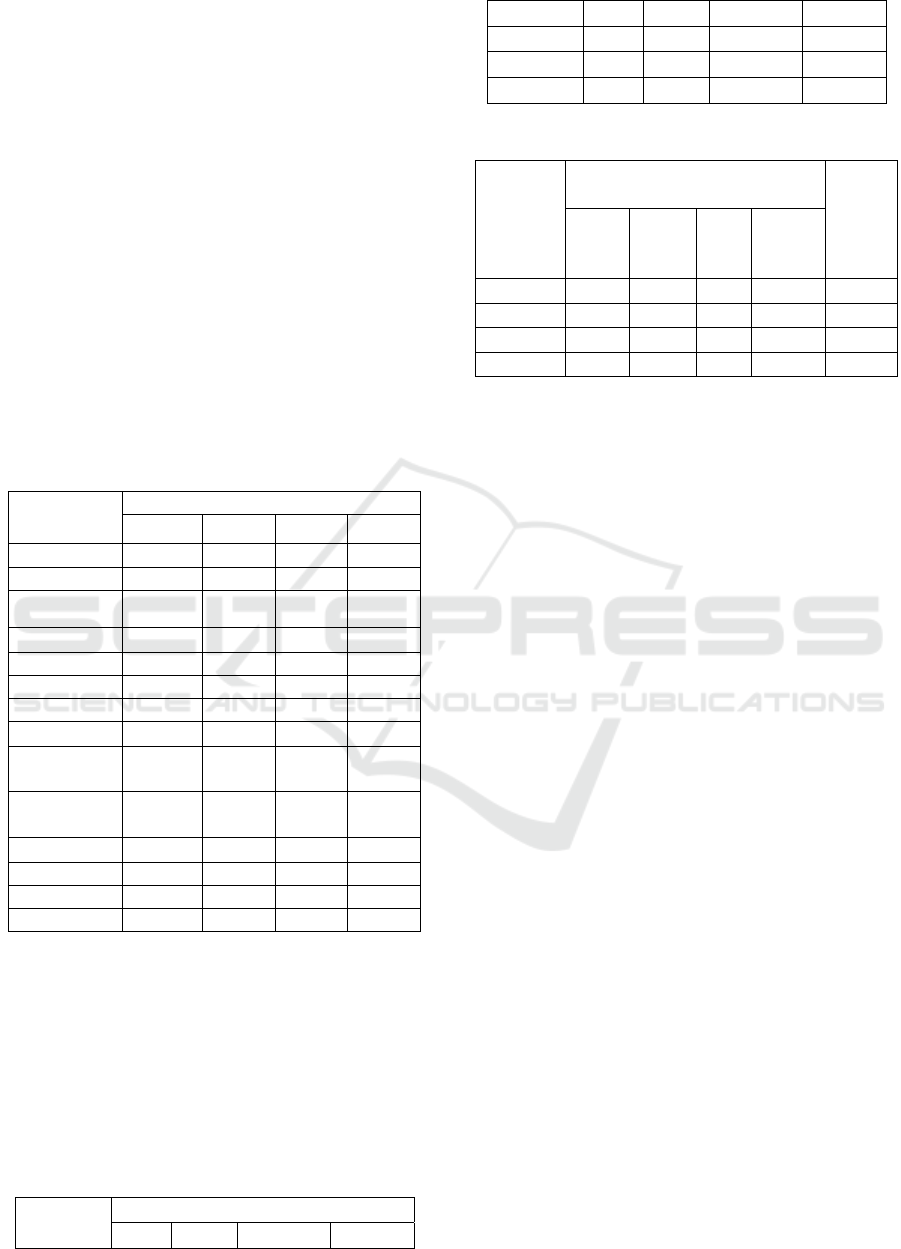

Table 2: Percentage of aroma substances in soft stick

oolong black tea.

Varieties

Precentage (%)

control Ⅰ Ⅱ Ⅲ

Alkanes 14.3% 20.0% 27.3% 23.9%

Olefins 21.4% 30.9% 31.8% 39.1%

Aromatic

hydrocarbons

10.7% 14.6% 15.2% 19.6%

Alcohols 17.9% 7.3% 6.1% 4.3%

Aldehydes 12.5% 7.3% 9.1% 6.5%

Ketones 5.4% 5.5% 1.5% 2.2%

Esters 5.4% 0 1.5% 0

Acids 3.5% 3.6% 0 0

Oxygen

heterocycles

1.8% 1.8% 1.5% 0

Nitrogen

heterocycles

3.5% 0 1.5% 2.2%

Ethers 0 3.6% 1.5% 0

Sulfide 1.8% 3.6% 1.5% 2.2%

Other 1.8% 1.8% 1.5% 0

Total 100% 100% 100% 100%

3.2 Sensory Review

Compared with the control group, different

temperatures had no effect on the cord and clarity, but

slightly affected the color, evenness, tea liquor color,

tea taste and infused leaves of the dry tea, and had a

greater impact on the flavor and height of the tea

aroma (Table 3-4).

Table 3: Sensory evaluation of shape

Titian

treatment

Shape- Sensory evaluation (score)

Cord Color Evenness clarity

control 82.8 85.4 86.2 86.0

Ⅰ 82.8 85.4 86.2 86.0

Ⅱ 82.8 85.4 86.2 86.0

Ⅲ 82.8 84.8 83.6 86.0

Table 4: Sensory evaluation of quality.

Titian

treatment

Quality - Sensory evaluation

(score)

overall

ratings

Tea

liquor

color

Tea

aroma

Tea

taste

infused

leaves

control 85.2 83.0 83.6 85.0 84.65

Ⅰ 85.8 84.8 83.0 85.0 84.88

Ⅱ 85.6 89.4 82.6 85.0 85.38

Ⅲ 84.0 84.0 80.8 82.6 83.58

Proper high-temperature fragrant treatment will

make the black tea liquor color red slightly, and the

tea liquor color will become turbid after over-baking.

The unflavored black tea tastes mellow, and the

flavored black tea has different degrees of high fire

flavor. Over-baked black tea will cause throat

discomfort. In the sensory evaluation, the aroma

gradually changed from rock and flower aromas to

sweet and sugary aromas. After the caramel aroma, a

burnt smell would appear.

In summary, with the increase of temperature, soft

stick oolong black tea has the most volatile

substances and compounds at 120°C, and the sensory

evaluation score is the highest.

4 DISCUSSION AND

CONCLUSIONS

The aromatic substances in tea are organic

compounds. So far, more than seven hundred aroma

substances have been separated from tea (Zhang et al.

2008). To date, more than 400 aroma components

have been detected in black tea (Zhang et al. 2019,

Shi 2010, Wan 2003).

Alcohols, esters, aldehydes,

ketones, alkenes, alkanes, etc. are the main aroma

substances in black tea, among which linalool, nerol,

methyl salicylate, nonanal and phenylacetaldehyde

are among the aroma components. The content of

black tea is higher (Wang et al. 2013, Li et al. 2021).

According to the source of aroma, it can be

divided into tea aroma and aroma produced during

production; most aromas contain unsaturated double

bonds, which are chemically active and volatile.

Aroma is not only an important factor in determining

the quality of tea, but also an important indicator for

CAIH 2021 - Conference on Artificial Intelligence and Healthcare

200

distinguishing the quality of different tea leaves (Ye

et al. 2018).

With the increase of fragrance temperature,

alcohols such as linalool show a downward trend.

Some previous studies have shown that alcohols are

the key aroma substances for the aroma of black tea.

For example, Li Jun (Li et al. 2021) found that 2,6-

Octadien-1-ol, 3,7-dimethyl-, (E)-, 1,6-Octadien-3-

ol, 3,7-dimethyl-, Benzyl Alcohol, Benzaldehyde,

and Acetic acid are the key aromas compound of

Guizhou black tea. Liu Yang (Liu et al. 2021) found

that alcohols and aldehydes are the most important

aroma components in tribute eyebrows. Peng Yun

(Peng et al. 2021) showed that 1,6-Octadien-3-ol, 3,7-

dimethyl- and its oxides are characteristic aroma

components in Yunnan black tea.

In order to explore

the reasons for the formation of the special aroma and

flavor of Sichuan Qingxin Oolong black tea, Luo

Xueping used SPME-GC-MS combined technology

and found that the main aroma-contributing

components of Sichuan Qingxin Oolong black tea

were alcohol compounds, with a content of 58.20%

(Luo et al. 2021).

Lin Yanping (Lin et al.2021) found

that the aroma components of Wuyi black tea

"Jinjunmei" were mainly alcohols, hydrocarbons,

esters, aldehydes and ketones.

Zhou Senjie (Zhou et

al. 2021) research found that the aroma components

among the tender, fresh and high-grade Longjing tea

types are alcohols, aldehydes, terpenes, ketones,

alkanes, alkenes, heterocycles and esters and other

compounds. There are differences in species and

relative content.

3-methylpentane, 3-ethylpentane,

myrcene, linalool, nerol, trans-2-hexene and α-

terpinene are the key aroma compounds of Dianhong

(Shu et al. 2022).

Xu Yuanjun (Ge et al. 2015)

research shows that the content of alcohols, alkanes,

lipids and ketones in floral black tea is higher

In summary, with the increase of the flavoring

temperature, alcohols will be decomposed and

converted into other substances. It is not that the

higher the flavoring temperature, the better quality of

tea. The soft stick oolong black tea has an extremely

rich aroma and overall best quality after 60 minutes

flavoring at 120°C. The aroma substances of tea have

a great relationship with the production process.

Consumers’ demand for the aroma of tea is still

increasing. Detecting the aroma of different

production processes is conducive to the

standardization and improvement of the tea

production process. Soft branch oolong is made into

black tea. It is an innovation. Different Titians will

produce different aromas or different aroma ratios.

There is still a lot of research space for the aroma of

soft branch oolong black tea.

ACKNOWLEDGEMENTS

This work was supported by the Outstanding Young

Teacher program (2020GGJS006).

REFERENCES

Can Chen, Xiaoli Zhang, Bailong Liu, et al. Analysis of rice

volatiles induced by rice planthopper[J]. Southern

Agricultural News, (2021)52: 37-44.

Chen Li, Cuinan Yue, Puxiang Yang, et al. Research

progress on characteristic aroma of Gongfu black

tea[J]. Journal of Food Safety and Quality Inspection.

(2021),12(22):8834-8842.

Daliang Shi, Jizhong Yu, Minming Guo, et al. The effect of

drying methods on the quality of Qingxin Oolong

Gongfu black tea[J]. Hangzhou Agriculture and

Technology. (2018)06: 32-34.

Fan Zhang, Changqing Xu, Jun Chen, et al.

Electrophysiological and behavioral responses of Red

Gall Midge from Lycium barbarum to host plant

volatiles[J]. Chinese Journal of Applied Ecology,

(2020)31: 2299-2306.

Fei Lu. Research on the origin theory of Chinese tea [J].

Tokyo Gakugei University. (2013) 06: 131-134.

General Administration of Quality Supervision, Inspection

and Quarantine of the People's Republic of China,

National Standardization Administration of China. Tea

sensory evaluation method: GB/T23776-2018[S].

Beijing: China Standards Press, (2018): 1-24.

General Administration of Quality Supervision, Inspection

and Quarantine of the People's Republic of China,

National Standardization Administration of China. Tea

sensory terminology: GB/T14487-2017[S]. Beijing:

China Standards Press, (2017): 27-29

Jie Fan, Qiushuang Wang, Dandan Qin, et al. Research

progress on the quality of black tea and its related

biochemical factors [J]. Food Science.

(2020),41(03):246-253.

Jun Li, Yuan Zhu, Shuting Fang, et al. Study on the aroma

components of Guizhou black tea based on solid phase

microextraction and GC/MS[J]. Food Industrial

Technology. (2021),42:304-316.

Lan Feng, Xiaoyan Mo, Guangzhi Liang, et al. Effects of

Different Processes on the Quality of Black Tea[J].

Chinese tropical agriculture. (2017):58-59+73.

Lixiang Wen, Fen Zhang, Chaomin Xie, et al. The effect of

different flavoring treatments on the quality of Jinxiu

wild black tea[J]. Agricultural Research and

Application. (2018)31: 30-33.

Qiushuang Wang, Dong Chen, Yongquan Xu, et al. Study

on the Aroma Components in Chinese Famous Black

Tea[J]. Journal of Chinese Institute of Food Science

and Technology, (2013),13(1): 195-200.

Senjie Zhou, Chuangsheng Huang, Chunlin Li, et al.

Comparison of Aroma Composition and Related

Components of Longjing Tea with Different Aroma

The Effect of Temperature on the Aroma of Soft Stick Oolong Black Tea

201

Types[J]. Journal of Zhejiang University (Agriculture

and Life Sciences Edition). (2021),47(02):203-211.

Silin Zheng. Research on the processing technology of

summer and autumn black tea introduced from Sichuan

Qingxin Oolong variety [D]. Sichuan: Sichuan

Agricultural University. (2016):10-14.

Suqiang Liu, Juan Yang, Linying Yuan, et al. The effects

of baking and flavoring conditions on the sensory

quality and main biochemical components of black

tea[J]. Journal of Food Safety and Quality Inspection.

(2015)04: 1301-1306.

Weisheng Ye, Jianliang Hu. Research progress of tea aroma

components and detection technology[J]. Agriculture

and Technology. (2018): 34-35.

Wengang Xie, Shisheng Fan, Yan Liu, et al. Analysis of

aroma components of Guizhou high-quality

“Wuniuzao” green tea byHS-SPME/GC-MS[J]. Tea

Communication, (2019),46(4): 448-454.

Xiaochun Wan. Tea biochemistry [M]. Beijing: China

Agricultural Press. (2003): 39

Xin Shu, Yanxiang Gao. Research progress on extraction

of volatile components from tea and analysis of aroma

characteristics[J/OL]. Food Industry Technology: 1-

19[2022-02-14] DOI:10.13386/j.issn1002-

0306.2021080311.

Xuan Mi. Research on the processing technology and

quality characteristics of Anyuan Gongfu black tea [D].

Beijing: Chinese Academy of Agricultural Sciences:

(2013): 17-20.

Xuefang Zhou, Hong Tang, Qian Lei, et al. Analysis of

Aroma Components in Sichuan Gongfu Black Tea[J].

Journal of Southwest Normal University (Natural

Science Edition). (2011)36(3): 178-182.

Xueping Luo, Lixia Li, Chaolong Ma, et al. SPME-GC-MS

Analysis of Aroma Components in Black Tea from

Mainly Planted Tea Plants in Sichuan[J]. Food Science.

(2016)37(16):173-178.

Xueping Luo, Lixia Li, Xueyan Lian, et al. Analysis of

Aroma Components in Sichuan Qingxin Oolong Black

Tea by SPME-GC-MS[J]. Southern Agriculture.

(2021),15(16):7-11.

Yan Ma, Liyang Shi, Yi Zhao, et al. Antennae potential and

behavioral responses of L-onghorn beetle to the volatile

components of hickory under different conditions[J].

Journal of Zhejiang Agriculture and Forestry

University, (2019)36: 437- 443.

Yan Ma, Liyang Shi, Yi Zhao, et al. GC-EAD and

behavioral responses of volatile com-ponents of

hickory nut under different infestation states of A.

longiflora[J]. Acta Applied Entomology, (2019)56:

530-538.

Yanan Zhang, Yiling Ou, Li Qin, et al. Research progress

on the formation of aroma substances and its influence

of processes in black tea[J]. Science and Technology of

Food Industry, (2019),40(11): 351-357.

Yang Liu, Yafang Liu, Zhi Lin, et al. Analysis of aroma

composition and key aroma components of white tea

tribute eyebrow[J]. Food Science. (2021),42:183-190.

Yanping Lin, Bo Zhang, Jianming Zhang et al. Effects of

different withering methods on the quality of Wuyi

black tea "Jinjunmei" [J]. Food Research and

Development. (2021),42(19):78-85.

Yuanjun Xu, Liang He, Lingyan Jia, et al. Differentiation

of aroma compositions in different regions and special

varieties of black tea[J]. Journal of Zhejiang University

(Agriculture & Life Sciences), (2015),41(3): 323-330.

Yun Peng, Guo Li, Xueyan Liu, et al. SPME/GC-MS

analysis of aroma quality of black tea from different

origins[J]. Food Industry Science and Technology,

(2021)42: 237-244.

Zhaopeng Shi. Tea review and inspection [M]. Beijing:

China Agricultural Press.

(2010): 6-57.

Zhenxian Zhang. The effect of UV-B on the formation of

volatile compounds in tea [D]. Zhejiang: Zhejiang

University. (2008) 05: 19-20.

Zhongping Su. The influence of different processing

techniques on the aroma components of Oolong tea[J].

Quanzhou Manyi Tea Industry., Fujian Province.

(2019): 254-255.

CAIH 2021 - Conference on Artificial Intelligence and Healthcare

202