Design of Chicken Feed Mixer Machine Model to Increase Work

Productivity

I Ketut Gde Juli Suarbawa and A. A. Ngurah Bagus Mulawarman

Department of Mechanical Engineering, Bali State Polytechnic, Bukit Jimbaran, Denpasar, Indonesia

Keywords: Mixing Machine, Subjective Complaints, Workload and Work Productivity.

Abstract: Feed is the largest single variable cost in a vertically integrated industrial animal factory. U.S. Department of

Agriculture have estimated that feed costs account for 60-64 percent of the total cost of producing poultry and

eggs, 47 percent for pork, and 17 percent for beef. Feed requirements (in dry weight) for each chicken is 3-

5% of their body weight. In animal feed consumption is influenced by various factors, namely energy levels,

amino acid balance, feed fineness, animal activity, body weight, growth speed and environmental temperature.

The increasing price of animal feed in recent years has caused many farmers to mix their own feed to make

animal feed. At present the process of mixing animal feed is still stirred by hand, causing an increase in

workload and subjective complaints of pain in the back, arms and hands when stirring and the time in the

mixing process. This causes the work productivity on animal feed to be low. Efforts to overcome these

problems, carried out research with the same subject design that is designing a model of animal feed mixing

machines to help speed up the work process of mixing feed to speed up work time and increase work

productivity. The Mixer Machine model is designed according to the needs of chicken farmers and subjective

complaints data are recorded with a fatigue questionnaire, workload is measured based on work pulse and

work time is measured during work and work productivity is measured from the ratio of inputs (work pulse)

to output (Amount of kg of animal feed load stirred) multiplied by work time (hours).The results showed that

the use of the Mixing Machine Model for the stirring process of animal feed can facilitate chicken breeders

in the process of mixing animal feed so that the animal feed mixture is more evenly compared to mixing using

the previous manual method, reducing the subjective complaints of pain in the limbs when stirring decreases

by 20 %, reduce the workload of workers by 48% and increase work productivity by 84%.

1 INTRODUCTION

Feed is that the largest single variable cost during a

vertically integrated industrial animal factory. U.S.

Department of Agriculture have estimated that feed

costs account for 60-64 percent of the whole cost of

manufacturing poultry and eggs, 47 percent for pork,

and 17 percent for beef (

Dennis Olson,2006). The feed

that's given isn't only intended to beat hunger or as a

stomach filler but must be really useful for the

requirements of life, forming new cells, replacing

damaged cells and for producing (Setiawan, Tony and

Arsa Tanius,2005). the necessity for feed (in dry

weight) for every chicken is 3-5% of weight. The

consumption of animal feed is influenced by various

factors, namely energy state, aminoalkanoic acid

balance, feed fineness, livestock activity, weight, rate

of growth and ambient temperature. the extent of

difference in consumption is additionally influenced

by several factors, including: weight, age, feed

digestibility, feed quality and palatability. Palatability

is that the level of preference shown by livestock to

consume a given feed ingredient at a specific time.

Good quality food features a higher consumption

level than inferiority food in order that if the feed

quality is comparatively an equivalent, the

consumption level isn't different (Parakkasi, A,

1998). the method of blending animal feed is

currently done by hand to stir the animal feed

consisting of fifty kg of corn, 50 kg of bran, 50 kg of

concentrate and 50 kg of minerals. The animal feed

that has been placed during a large container is then

stirred by the worker with both hands stirring slowly

until the animal feed is evenly mixed. The stirring

process is administered by standing and bending for a

mean of 63 minutes to stir 200 kg of animal feed. This

work process causes the typical pulse of workers to

extend, sweating plenty, and increased pain within the

Suarbawa, I. and Mulawarman, A.

Design of Chicken Feed Mixer Machine Model to Increase Work Productivity.

DOI: 10.5220/0010967700003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1485-1490

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1485

limbs after work, like pain within the back, neck, legs,

upper arms, forearms, and hands. Increased pulse at

work and complaints after work cause work

productivity to be low (Manuaba, A, 2000). Work

posture that aren't physiological are often caused by

the characteristics of task demands, work tools, work

stations, and work Posture that are incompatible with

the skills and limitations of workers (Kroemer and

Grandjean, 2000; Manuaba, A, 2000). Non-

physiological work posture that's administered for

years can cause bone deformities in workers

(Kroemer and Grandjean, 2000).

In an attempt to beat this problem, a machine for

mixing animal feed with a gasoline motor drive was

designed with a drum capacity of 200 kg. The

working mechanism of this animal feed mixer is that

the rotation produced from the gasoline motor shaft

to rotate the stirrer shaft within the stirring drum until

the animal feed is evenly mixed. The rotation of the

driving motor is sustained with the belt rotation and

uses a pulley in order that the rotation of the stirring

shaft is smoother. the utilization of a mixing machine

for animal feed that replaces human labour within the

mixing process will increase work productivity and

reduce workloads and subjective complaints from

workers. By designing the assembly process it's ready

to save the necessity for raw materials and processes,

in order that overall costs are often saved within the

manufacturing industry Rusdiyantoro, 2011).

Ergonomic redesign of kit will reduce muscle

complaints and worker fatigue (Kroemer and

Grandjean, 2000).

2 METHODS

2.1 Research Design

This research is a one-short case study with a pre and

post test design of the design group carried out

observational to the crafters in the process of stirring

the animal feed (Suarbawa, at all, 2016). The chart

can be described as picture1.

R P0 PI

Figure 1: Research Design.

Information:

R = Random sample.

P0= the result of the pretest experimental unit.

PI = the result of the posttest experimental unit.

The research stages in the design of an animal

feed mixer is to examine the current manual stirring

process (stirring with a shovel) compared to the

stirring process with the help of a mixer on working

time, workload, skeletal muscle complaints, fatigue

and work productivity.

2.2 Research Variable

The variables to be measured during this study

include: (1) workload as measured by the heart beat

of rice before and after work; (2) complaints of

fatigue and skeletal muscles before and after work;

(3) work productivity after work by comparing work

pulse (beats per minute) with the amount of products

produced (kg) during working time (minutes). The

measurement of variables number (1) to number (3)

is that the information data of the initial condition and

therefore the final condition which is then compared

to work out the comparison before using the mixer

machine and after using the mixer machine.

2.3 Data Analysis

The design data of the mixer machine are calculated

supported the necessity for a load capacity of 100 Kg,

then an electrical motor, a shaft and a stirrer tank, and

an ergonomic machine holder construction are

planned. Test data before using mixer a machine and

after using mixer a machine include data on working

time/ a length of labour, a workload, subjective

complaints, and work productivity which can then be

analyzed descriptively to get conclusions.

3 RESULT AND DISCUSSION

3.1 Subject Characteristics

The mean age of the themes was 33.21 ± 1.56 years

and therefore the age range was 28 - 34 years. This

age range remains included within the working age

bracket. This age range still includes the workforce

consistent with the Central Statistics Agency (BPS).

The regulation for the workforce that applies in

Indonesia is 15 to 64 years old. The mean age of the

themes of this study, when viewed from muscle

strength, has decreased because the recommended

optimum muscle strength for work is between 20 and

30 years (Corlett, Nigel, 2005). The mean body mass

index (BMI) during this study was 20.21 ± 0.04

kg/m2. The meaning of this BMI value is that workers

are during a normal nutritional status. the traditional

BMI of Indonesians ranges from 18.5 - 25 kg/m2

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1486

(Almatzier, S, 2001). BMI is an indicator of body fat,

if the BMI is below 18.5 kg/m2 it's said to be very

thin (underweight) while above 25.0 kg/m2 is

claimed to be obese (overweight) because of

excessive fat accumulation. The mean work

experience of the themes during this study was 5.23 ±

1.45 years. The meaning of this experience mean is

that the topic has been skilled and ready to adapt to

his job. Work experience in formal sector jobs is

usually considered to be ready to improve one's

employability (Robbins, Stephen P and Timothy A.

Judge. 2008).

Table 1: Subject Characteristics.

Description

n Min Max Mean SD

Age (year) 4

28.00 34.00 33.21 1.56

Height (cm) 4

158.21 168.00 167.22 2.15

Weight (kg) 4

55.40 73.60 62.14 6.98

BMI (kg/m

2

) 4

20.26 21.56 20.21 0.04

Work experience

(year)

4

4.50 6.30 5.23 1.35

3.2 Manually Stirring Mixture of

Animal Feed

Previously, the process of stirring animal feed was

done manually with a working stance, standing bent

with both hands holding a shovel to stir. The length

of work in the stirring process for 200 kg of animal

feed mixture was carried out for an average of 64

minutes. A work posture that slows down repeatedly

for a long time is a non-physiological work posture.

Work posture that are not physiological can be caused

by the characteristics of task demands, work tools,

work stations, and work Posture that are incompatible

with the abilities and limitations of the workers

(Manuaba, A, 2000). Non-physiological work posture

that is carried out for years can cause bone

deformities in workers (Corlett, Nigel, 2005).

Kimberly (2011) stated that there needs to be a

change in the work system to reduce the level of

worker fatigue. Roles, et al., 2009 made a study on a

work model based on ergonomic principles, and

found that the work model was able to reduce fatigue

by 17.71% (Rolles P., Manuaba, A., Adiputra, N.,

Pangkahila, A, 2012). Torik, et al, 2009 also stated

that designing an ergonomic work system can reduce

the level of worker fatigue. The working posture and

working conditions of the craftsmen are as shown in

Figure 2.

Figure 2: Manual Stirring of Animal Feed Mixture.

3.3 Work Environment

The mean air temperature was 30.01 ± 1.11 (

0

C), the

mean ball temperature was 31.22 ± 1.03 (

0

C), the

mean ratio was 64.23 ± 1.31%, the typical WBGT

index was 29.84 ± 0.49 (0C). the edge value for the

category of heavy work with WBGT of 30.5 (

0

C) is

that the setting of working time per hour is merely

allowed to succeed in 25%, while the edge value for

the category of moderate workload with WBGT

reaches 29 (

0

C) is allowed for setting the working

time of fifty - 75% per hour. The lighting intensity is

332.21 ± 6.23 lux, this intensity value is within the

safe category consistent with the choice of the

Indonesian Minister of Health. No. 405 of 2002

concerning the wants and procedures for

implementing the health of the economic work

environment, where manual work requires a

minimum candlepower of 100 lux. Lighting that's not

enough or below the specified threshold will cause

work fatigue because the shortage of sunshine

intensity within the workplace leads to decreased eye

vision and work fatigue (Bridger, R.S, 2005). The

typical noise intensity reaches 76.43 ± 3.51 dBA.

Workplace noise remains within normal limits when

it's below 85 dBA (Tarwaka, 2010). and therefore the

air velocity is 0.85 ± 0.21 m / s. it's recommended that

indoor air movement isn't quite 0.2 m / s in order that

air movement doesn't have an adverse impact on

workers, whereas for work environments exposed to

heat a better wind speed is required (Corlett, Nigel,

2005).

Design of Chicken Feed Mixer Machine Model to Increase Work Productivity

1487

Table 2: Work Environment.

Description n Min Max Mean SD

Air Temparature

(

0

C)

10 30.10 32.90 30.01 1.11

Ball Temparature

(

0

C)

10 28.80 33.00 31.22 1.03

Humidity (

%

) 10 63.90 69.60 64.23 1.31

WBGT (

0

C) 10 27.16 28.01 27.64 2.26

Illumination

Intensity (lux)

10 380.20 3901.40 385.33 4.23

Noise Intensity

(

dBA

)

10 74.31 82.32 76.43 3.51

Air Speed (m/det) 10 0.65 0.70 0.85 0.21

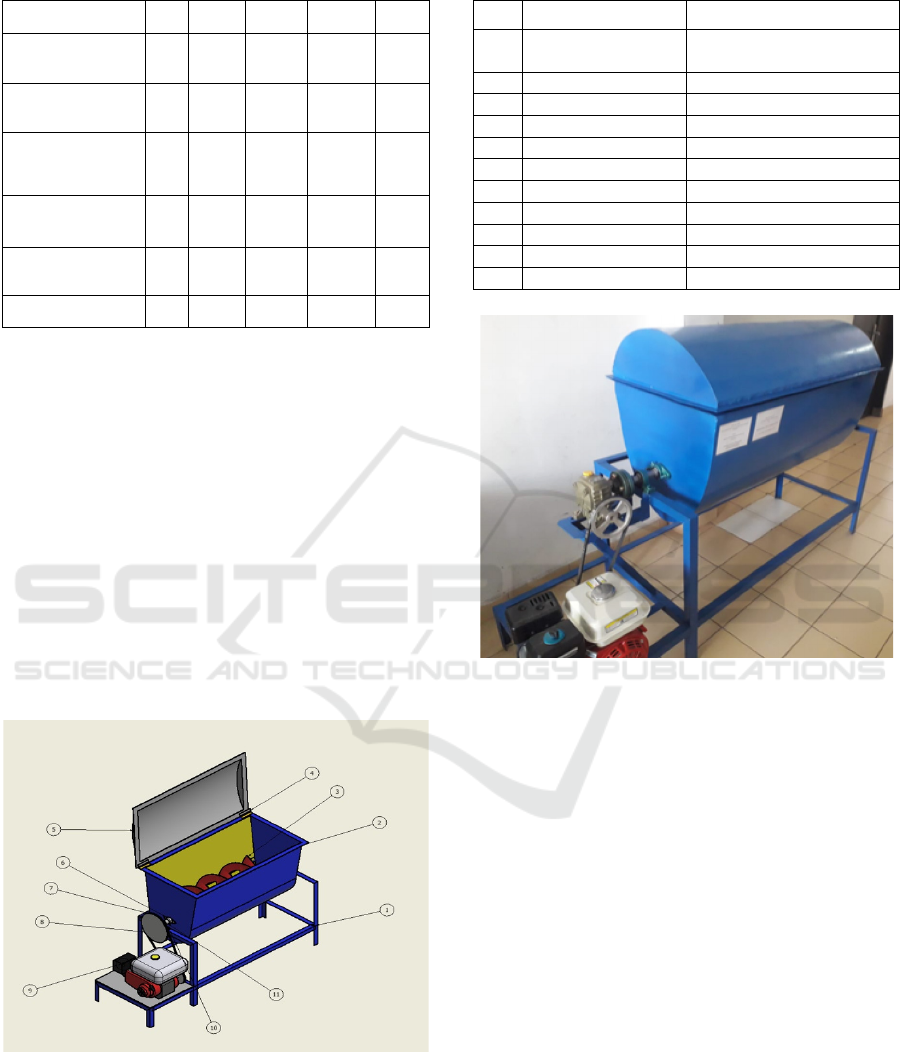

3.4 Design of Animal Feed Mixer

Machine

This animal feed mixer machine is meant with a

gasoline motor drive. the facility on the motor shaft

which is provided with a belt attached to the pulley

with a ratio of 1: 3. The rotation of the stirrer is meant

at 3600 rpm. The capacity of the mixer drum is 100

Kg. This machine is operated by one person with a

standing work posture. The way the machine works is

extremely easy, namely: 1). Put the animal feed

ingredients which will surrender into the mixer drum,

2). activate the mixer for about quarter-hour until the

animal feed is evenly mixed, 3). Remove the animal

feed mixture from the drum.

Figure 3. Design Engine Component.

Table 3: Engine Component.

No. Engine Component Caption

1 Machine frame Iron Elbow 40 mm x 40

mm x 4 mm

2 Mixing dru

m

Steel plate 1,2 mm

3 mixe

r

Iron steel

4 Hin

g

e Iron steel 12 x 3 m

m

5 Cove

r

Steel

p

late 1,2 mm

6 Bearing Holde

r

Iron steel Ø40 mm

7 Pully Ratio pully 1: 3

8 V-

b

elt 1,5 mm x 80 mm

9 Gasoline moto

r

5,5 hP

10 Pollow bloc

k

50 m

m

11 Shaft Iron steel Ø40 mm

Figure 4: The Result of Design Mixer Machine.

3.5 Workload, Musculoskeletal

Complaints, Fatigue, and

Productivity

Measurement of workload is done by measuring the

work rate per minute using the 10 pulse method.

Work pulse is measured every 60 minutes. The 10

pulse method is a method by palpation of the radial

artery of the left hand, which is calculated as the

length of time it takes from the first pulse to the

eleventh pulse, the result is in seconds (Adiputra,

2002). Workload was measured in the period I

research (P0), namely the manual stirring process

research and in the second period study (PI), the

stirring process using a mixer machine.

Musculoskeletal complaints are disorders of the

skeletal muscle system caused by work tools and

conditions of the subject, organization, environment.

The discrepancy of these factors affects the work

posture when doing work that is recorded using the

Nordic Body Map. The complaint value of the

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1488

musculoskeletal disorder system is determined based

on the difference between the mean value of

complaints before work and the mean value of

complaints after work. The assessment criteria were

not sick, slightly sick, sick and very sick.

Musculoskeletal disorder were measured in the

Period I (P0) study, namely the manual stirring

process research and in the II Period (PI) study, the

stirring process using a mixer.

Fatigue in general is a condition that is reflected

in the symptoms of psychological changes in the form

of slackness in motor and respiratory activity, a

feeling of pain, heaviness in the eyeballs, weakening

of motivation, decreased activity which will be

influenced by physical and mental activity (Bridger,

R.S, 2005). Fatigue was recorded with 30 items of

fatigue level which was modified with four Likert

scales and consisted of three categories, namely

fatigue for activity (1−10), fatigue for motivation

(11−20) and physical fatigue (21−30). Fatigue was

measured in the period I (P0) study, namely the

manual stirring process and in the second period (PI)

study, the stirring process using a stirrer machine.

Work productivity is the ratio between the amount

of output (mixture of animal feed in units of Kg) and

the input (average working pulse in units of dpm) in

a period of time (length of work in minutes),

calculated based on the following formula (Manuaba,

2000). Productivity was measured in the period I

research (P0), namely the manual stirring process

research and in the second period study (PI), the

stirring process using a mixer. The results of

measuring workload, musculoskeletal complaints,

fatigue and productivity in the first period (P0) study,

namely the manual stirring process research and the

second period research (PI), namely the stirring

process using a mixer, are presented in Table 4

.

Table 4: Measurement Results of Workload, Musculo-

skeletal Disorder, Fatigue and Productivity (Period I).

Description

Period I (P0)

Min Max Mean SD

Resting Pulse

(denyut/menit)

64,21 70,2 72,56 2,05

Work Pulse

(

den

y

ut/menit

)

18,39 23,42 20,21 2,45

Different Score

Musculoskeletal Disorder

Before and After Work

10 15 12,1 3

Different Score fatigue

Before and After Wor

k

5 10 7,2 2,1

Productions

(

K

g)

100

Times of mixer (menit) 41 48 43 1,2

Work Productivity 0,178 0,265 0,230 0,03

Table 5: Measurement Results of Workload, Musculo-

skeletal Disorder, Fatigue and Productivity (Period II).

Description

Period II (PI)

Min Max Mean SD

Resting Pulse

(

den

y

ut/menit

)

62,02 70,02 71,4 2,61

Work Pulse

(denyut/menit)

8,4 12,8 10,61 2,04

Different Score

Musculoskeletal

Disorder Before and

After Work

2,31 10,25 6,31 0,72

Different Score fatigue

Before and After Wor

k

2,33 7 4,7 0,8

Productions

(

K

g)

100

Times of mixer (menit) 12 16 13,5 0,4

Work Productivity 0,977 1,984 1,396 0,01

Table 4 and 5 shows that the use of an animal feed

mixer machine in the process of stirring the animal

feed mixture reduces the workload of workers by

48%. The average work pulse rate of workers in the

P0 study (stirring manually) was 92.58 bpm including

the light workload category (pulse 75-100), while the

average work pulse rate of workers in the P1 study

(stirring with a stirring machine) was obtained a mean

work pulse amounted to 74.25 bpm, including the

category of very light workload (pulse 65-75)

(Corlett, Nigel, 2005).

The results of measuring the musculoskeletal

complaint score showed that the use of an animal feed

mixer in the process of stirring the animal feed

mixture reduced musculoskeletal complaints by 48%.

The mean score of musculoskeletal complaints in the

P0 (Manual stirring) study was 12.1, while the mean

score of workers' musculoskeletal complaints in the

P1 study (stirring with a stirring machine) was 6.31.

The results of the measurement of the fatigue score

showed that the use of a mixer for animal feed in the

stirring process of the animal feed mixture reduced

fatigue by 35%. The mean score of fatigue in the P0

study (stirring manually) was 7.2, while the mean

score of worker fatigue in the P1 study (stirring with

a stirring machine) was 4.7. The result of productivity

measurement shows that the use of a mixer for animal

feed in the process of stirring the animal feed mixture

increases productivity by 84%. The average

productivity in the P0 study (stirring manually) was

0.230, while the average productivity of workers in

the P1 study (stirring with a stirring machine) was

1.396. A decrease in musculoskeletal complaint

scores, fatigue and an increase in work productivity

indicate that ergonomic interventions in work

systems can reduce musculoskeletal complaints

scores due to physiological work posture (Adiputra,

Design of Chicken Feed Mixer Machine Model to Increase Work Productivity

1489

N, 2002), reduce fatigue scores (Suma’mur PK,

2013), and increase productivity (Bridger, R.S, 2005).

4 CONCLUSIONS

Based on the results of the discussion of the design of

a mixture of animal feed mixer, it was found that the

use of a mixer in the process of mixing animal feed

can reduce workload by 48%, reduce the score of

musculoskeletal complaints by 48%, reduce fatigue

scores by 35% and increase work productivity by

84%. Therefore, in the process of mixing animal feed,

an ergonomic animal feed mixer can be used.

ACKNOWLEDGEMENTS

The authors would like to thank the department of

research and community service center Bali State

Polytechnic and the Ministry of Education and

Culture of Indonesia for the financing of this research.

REFERENCES

Dennis Olson, R. 2006. IATP Trade and Global

Governance Program This fact sheet draws heavily on

the Global Development and Environment Institute’s

Working Paper 05-07, “Identifying the Real Winners

from U.S. Agricultural Policies,” by Timothy A. Wise,

which was adapted for IATP by GDAE Research

Assistant Elanor Starmer. The original paper is

available at: http://www.ase.tufts.edu/gdae/policy_

research/RealWinners.htm.

Setiawan, Tony and Arsa Tanius. 2005. Raising Ettawa

Cross-breed Dairy Goats. Publisher: Swadaya. Jakarta.

Parakkasi, A. 1998. Science of Nutrition and Forage of

Ruminants. UI Press. Jakarta. (references).

Manuaba, A. 2000. Stress and Strain. Ergonomics. Vol. II.

Denpasar. Work Physiology Ergonomics Study

Program. Udayana University.

Kroemer and Grandjean, E. 2000. Fitting The Task To The

Human. A Texbook Of Occupational Ergonomics 5th.

Edition Philadelphie: Taylor and Francis (references)

Rusdiyantoro. 2011. Product Green Design Development to

Support Green Lifecycle Engineering Manufactured in

Adibuana Metalworks, Prosiding International

Conference on Creative Industry (ICCI), ISBN 978-

979-781-8

Suarbawa, JKGJ., Nyoman Adiputra, J Alek Pangkahila,

and IDP Sutjana. 2016. “Work Posture Improvement

Using Ergonomic Approach Decreases Subjective

Disorders of Perapen Workers on the Process of

Nguwad Gamelan in Bali.” International Research

Journal of Engineering, IT & Scientific Research

(IRJEIS) 2605(9): 4290–2016. http://ijcu.us/online/

journal/index.php/irjeis%5Cnhttp://dx.doi.org/10.2174

4/irjeis.v2i9.164%5Cnhttp://orcid.org/0000-0003-0948

-7858.

Corlett, Nigel. 2005. Static Muscle Loading and the

Evaluation of Posture. Evaluation of Human Work, 3rd

Edition. London: Taylor & Francis. (references).

Almatzier, S. 2001. Basic Principles of Nutrition. Jakarta:

PT. Gramedia Pustaka Utama. (references).

Robbins, Stephen P dan Timothy A. Judge. 2008.

Organizational behavior. Edition 12. Book 1. Jakarta:

Salemba Empat. (references).

Kimberly, F.K. 2011. The Effect of Shift Work on Fatigue

of Palm Oil Mill Workers at PT. X Labuhan Batu.

Journal of Industrial Engineering, Vol. 12, No. 2,

August 2011. p110–117.

Rolles P., Manuaba, A., Adiputra, N., Pangkahila, A. 2012.

Ergonomics (Apelerg) Based Field Practicum Activity

Model Improves Body Physiological Response,

Reduces Fatigue, and Increases Performance,

Compared to the Old Model (Apel), in FMIPA Unima

Students.

Torik, H., Kholil, M., Ari, S. 2009. Ergonomic Work

System Design to Reduce Fatigue Levels. Jurnal

Industrial and Systems Engineering Assessment

Journal (INASEA), Vol. 10 No.1, April 2009. p 45-58.

Indonesian Journal of Biomedical Sciences. Vol. 3, No.

1. January 2009.

Bridger, R.S. 2005. Introduction to Ergonomics. Singapore:

McGraw-Hill. (references).

Tarwaka. 2010. Industrial Ergonomics: the basics of

ergonomics knowledge and workplace applications.

First Edition. Harapan Press Solo. ISBN

9789791814416. (references).

Adiputra, N. 2002. The Pulse and Its Use In Ergonomics.

Indonesian Journal of Ergonomics. Vol. 3 No. 1, June:

22-26.

Suma’mur PK. 2013.Company Hygiene and Occupational

Health (HIPERKES). Jakarta: Agung Seto. (references).

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1490