Design of Tracker based PV System for Health Care Facilities in

Remote Islanded

Syafii

1

, Lovely Son

1

and Rahmad Fahreza

2

1

Electrical Engineering Department Engineering Faculty, Universitas Andalas, Padang, Indonesia

2

Mechanical Engineering Department Engineering Faculty, Universitas Andalas, Padang, Indonesia

Keywords: Tracker based PV System, Heath Care Facilities, Optimum Design.

Abstract: In this paper, the solar based electrical power system for health care facilities in the Mentawai island has

been presented with different tracking mechanisms. First, the health center's electrical system was designed

for a photovoltaic (PV) system with fixed installations combined with diesel generators as backup systems.

The optimal results with the lowest cost of energy (CoE) values are obtained with the PV/Diesel

configuration and storage system in operation. Furthermore, the electrical system was tested using three

different PV structure installations - fixed structures, single-axis tracking, and dual-axis tracking

mechanisms. Among the three tracking configurations, the two-axis tracking system was found to be the

most profitable in terms of PV electricity production 3,931 kWh in a year and had the lowest CoE of 0,307

$/kWh. The payback period for a flat PV system longer than the two-axis tracker PV system. Apart from the

increase in power generation, PV systems with two-axis solar tracking will need fewer PV modules to

supply the same load, hence requiring less space.

1 INTRODUCTION

Community health centers for remote areas in the

Indonesian archipelago need to be considered during

the current Covid-19 pandemic. Lack of facilities

and electricity resources is an important issue that

needs attention. Based on the the Indonesian state-

owned power utility firm, PT PLN (Persero)

planning document in Electricity Supply Business

Plan 2018-2027, there are still some areas in

Indonesia that have an electrification ratio below

80%, mainly in the islands area. The availability of

electricity resources for the region is a priority, but

the quality is less noticeable.

Generally, the supply of electricity in the islands

relies on diesel generators. Diesel generators are

known consume expensive fuels and are not very

environmentally friendly. Therefore, the presence of

the assembler from an easily installed and

environmentally friendly solar energy source

becomes the right choice as an electric power source

in rural health clinics for the islands. This is also in

line with the Nawacita vision as part of the

Indonesia government's policies, which is intended

to build a political, economic, and Indonesia cultural

sovereign. This policy has nine work programs, one

of which is to develop Indonesia from the periphery

by strengthening regions and villages.

Several previous studies have been carried out

by utilizing solar energy with low operational costs

and environmentally friendly. The 6,709 kWh

energy per day during clear sky can be produced by

using 5@250 Wp PV panel in West Sumatera. In the

literature, a study on the design of hybrid PV power

plants with battery storage has been carried out for

health care clinics in remote areas in the Gema sub-

district of Kampar Regency. Several studies on the

optimization and feasibility of PV have also been

carried out for rural villages in Nigeria , Masirah

Island, and rural desert areas in Oman. The optimal

design and feasibility analysis carried out using

Homer software. The result obtained revealed a

hybrid PV/wind/diesel/battery system as the most

cost-effective. However, the load of health care

center studied used general health clinic facilities

and not support Covid-19 patients and used flat solar

panel installation.

The feasibility study of the PV system in a

public health center in the midst of the covid-19

pandemic must pay attention to some Covid service

equipment. The lack of weather data will affect the

calculation of economic viability, especially on PV

Syafii, ., Son, L. and Fahreza, R.

Design of Tracker based PV System for Health Care Facilities in Remote Islanded.

DOI: 10.5220/0010966400003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1415-1419

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1415

systems installed in the tropical area. Economic

feasibility studies have also been carried out in

previous studies taking into account the cycling cost

of each component. The economic feasibility study

also functions to determine the optimal NPC (Net

Present Cost) of all the system options designed.

Details of the PV system design for the Community

Health Center (Puskesmas) in the Siberut Island, one

of the islands in the Mentawai Islands as a case

study will be explained in the following section.

2 DESIGN OF PV POWERED

HEALTH CARE FACILITIES

2.1 Health Care Clinic Facilities

In rural communities, the health care facilities are

not in a well-developed state. In some cases, rural

individuals do not have access to these facilities and

are required to travel to distant places or urban areas.

Considering the current pandemic condition, health

facilities in remote island health centers need to be

equipped with Covid patient handling equipment

and sufficient availability of electrical energy. The

Covid-19 patient handling equipment at least as

default data given by Hybrid Optimization of

Multiple Energy Resources (HOMER) Powering

Health Tool (NREL, 2020):

Covid Isolation Ward

Exhaust fan (per Covid isolation cubicle)

Exhaust fan (staff change area)

Basic Care Ward

Exhaust fan (per Covid isolation cubicle)

Oxygen Concentrator (50% of beds)

BiPAP respirator (50% of beds)

CPAP respirator (50% of beds)

Infusion pump

Exhaust fan (staff change area)

The daily electrical demand of health care facilities

is as shown in Figure 1. The average power of health

care facilities load is 0,24 kW with peak load is

1,49kW. The energy average of 5,68 kWh/day with

load factor is 16.

The monthly average load profile with a peak

demand in April and November in November is

illustrated in Figure 2.

Figure 1: Daily electrical demand of health care Facilities.

Figure 2: Annual electrical demand of health care

Facilities.

2.2 Homer based PV System Design

The HOMER Powering Health Tool uses the

proprietary optimization algorithm of the HOMER

(Hybrid Optimization Model for Multiple Energy

Resources). The tool can be used through link:

https://poweringhealth.homerenergy.com/ developed

by the National Renewable Energy Laboratory

(NREL) (NREL, 2020). The economic feasibility

study of the generation installation commonly uses

general business feasibility study criteria such as

CoE and net present cost (NPC) (Haghighat et al.,

2016). These criteria can be used to determine the

profitability of a project as an initial consideration

PV system installation.

The cost of energy can be calculated by using the

following equation (2):

Total

OutF

kWh

TInvest

CoE

×

=

(1)

where:

Invest = initial investment cost ($)

TOutF = Total Out Flow ($)

kWhTotal = Total PV energy generated (kWh)

The net present cost or life-cycle cost of a

component to be evaluated is the present value of all

the costs of installing and operating the component

during the life of the project, minus the present value

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1416

of all revenue generated during the life of the

project. Homer calculates the net present cost of

each component in the system and the overall

system. The formula for determining NPV is as

follows (O. dan C. H. Thum, 2013).

=

−

+

=

m

t

t

t

Invest

k

CIF

NPV

0

)1(

(2)

where:

m = lifespan of the PV system in year

CIF = cash in flow ($)

k = Discount rate

The payback period can be calculated by using the

following equation (3):

)(12*)(

1

month

F

F

yearyPP

D

i

i

+=

−

(3)

where:

PP = payback period

yi = year at full recovery or net cash flow equal to

zero

Fi-1 = unrecovered cost at the beginning of last

year

FD = cash flow during the year

The annual maintenance and operational costs

for the PV system generally accounted as 1 - 2% of

the total initial investment cost (R. G. J.Lee, B.

Chang, 2016). The large percentage of annual

maintenance and operational expenses in the PV

power plant covering costs for solar panel cleaning

work, maintenance and inspection costs of

equipment and installations will be set at 1% of the

initial total investment because Indonesia only has

two seasons, i.e., the rainy season and the dry season

so that the cost of cleaning and maintaining the solar

panel is not as high as the country that has four

seasons in one year. Besides, the determination of

this percentage is also based on the level of wage

labor in Indonesia, which is cheaper than the wage

rate of labor in other countries.

3 DESCRIPTION OF TEST

SYSTEM STUDY

The feasibility study carries out for health care

facilities in Simatalu, West Siberut, Kepulauan

Mentawai, West Sumatra, Indonesia. The location

coordinate is 1 degree 25.56 minutes South for

latitude and 98 degrees 55.47 minutes East for

longitude.

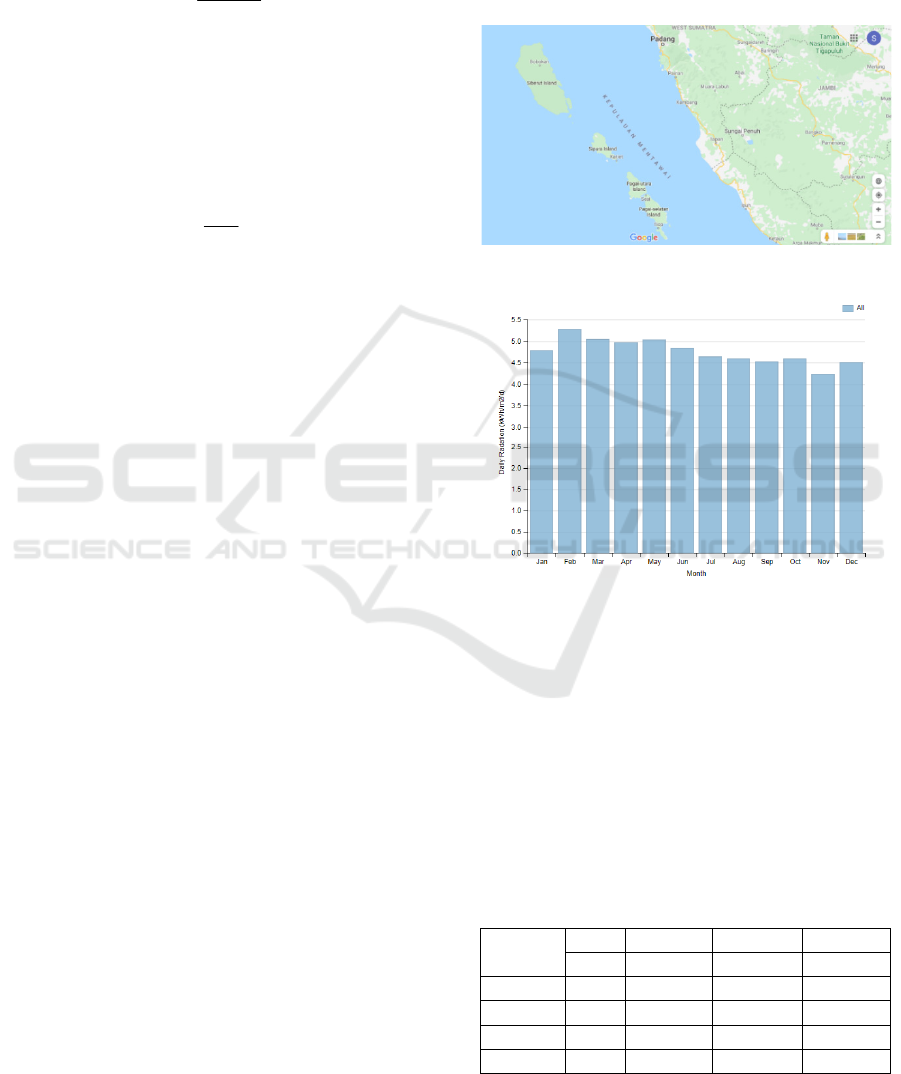

The average solar radiation in kWh/m

2

/day is as

Figure 4 with the highest radiation in February.

The optimum design of a hybrid power system

for a small health clinic in Mentawai Island was

carried out using a free online Homer Powering

Health Tool and detailed analysis with different

tracking mechanisms using Homer Pro 3.13.

Figure 3: Mentawai Island, West Sumatra, Indonesia.

Figure 4: The average solar radiation of Mentawai Island.

4 RESULT AND DISCUSSION

The simulation results containing all of the system

configurations that meet the electrical needs of the

simulated health clinic are shown in Table 1. Where

D stands for Diesel, PV stand for photovoltaic and S

stands for Storage system. They are ranked in

ascending order with the lowest life-cycle cost at the

top.

Table 1: The capacity estimate of hybrid system installation.

Config

PV Diesel (D) Storage (S) Converte

r

(kW) (kW) (kW·h) (kW)

1. D/ PV /S 2 2 14 1

2. PV /S 7 — 11 2

3. D / S — 2 4 0

4. D — 2 — —

Design of Tracker based PV System for Health Care Facilities in Remote Islanded

1417

The simulation results for economic feasibility are

shown in Table 2.

Table 2: Economic feasibility result.

Configuration

Initial

Capital

TNPC

Operating

Cos

t

COE

($) ($) ($/yr) ($/kWh)

1. D / PV / S 8,073 11,415 191 0.314

2. PV / S 11,201 13,504 131 0.372

3. D / S 3,449 21,207 1,013 0.583

4. D 2,216 35,236 1,884 0.969

The optimum system design configuration with

minimum cost results, i.e., 0.314 $/kWh, can be

extracted from the first row of tables. Solar panels

require very little maintenance since there are no

moving parts and generally self cleaning, but in

mainly dry areas or where panel tilt is minimal, dust

and other substances such as bird droppings can

build up over time and impact on the amount

electricity generated by a module. Therefore, in this

study, the fixed cost for operation and maintenance

are chosen 1 % of the initial investment. The

degradation of the solar panel is also considered in

this study, and the PV system energy generated

decreases every year.

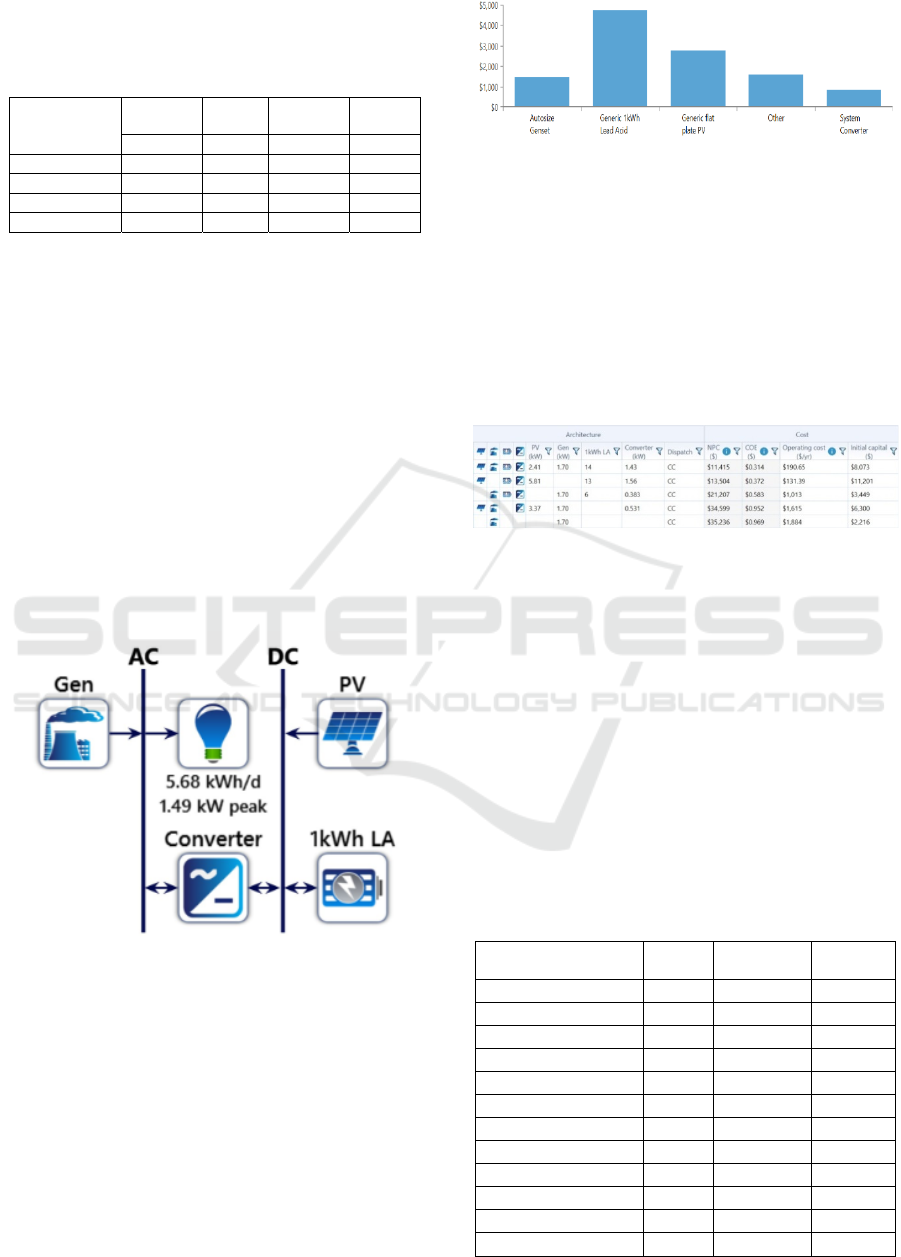

The schematic of the PV-Diesel and storage

system for further detail analysis is, as shown in

Figure 5.

Figure 5: Schematic of the PV-Diesel and storage system.

The 643 solutions were simulated with 473 were

feasible, and 170 were infeasible due to the capacity

storage constraint. 118 were omitted due to 33 for

lacking converter, 15 for having an unnecessary

converter, and 64 no source of power generation.

The detailed simulation result obtained, as shown in

Figure 6 for NPC result per component and the

categories optimization result shows in Table III.

Figure 6: Net present cost per components.

From Table 3, it is found that the optimal size of the

PV system is 2.41 kW, diesel generator 1.7 kW, and

14 units of lead-acid battery and a 1.43 kW power

converter. The payback period of PV installation for

household tariffs can also be calculated using

equation (3) based on Table III data. The payback

period from Homer Pro simulation is obtained three

years and four months.

Table 3: Categorized Optimization Result.

After the optimal configuration value is obtained,

then testing is done using a solar panel with a tracker

system. The three different PV structure installations

are fixed structures, single-axis tracking, and dual-

axis tracking mechanisms. The initial investment

cost for a single axis solar track is 10% -15% more,

and for a two-axis solar track is 25% more than a

fixed installation structure. Tracking settings require

periodic maintenance of rotating parts, and moving

parts may need to be changed from time to time.

Repairs and replacements can occur in the long run

with tracker settings. The optimum sizing and its

technical and economic parameter results are shown

in Table IV.

Table 4: The optimum sizing and its technical and

economic parameter results.

Parameter

without

Tracker

Tracker

(Single Axis)

Tracker

(Dual Axis)

P

V (kW) 2.41 2.43 2.25

D

iesel (kW) 1.7 1.7 1.7

B

a

t

tery 14 14 13

C

onverte

r

1.43 1.47 1.48

P

V Production (kWh/yr) 3341 3519 3931

R

enewable Fraction 90.9 91.0 89.8

F

uel 56.8 55.7 63

C

OE ($/kWh) 0.314 0.313 0.307

N

PC($) 11415 11363 11148

P

V Capital Cos

t

($) 2767 2784 2579

I

nitial Capital 8073 8107 7728

Simple payback (yr) 3.4 3.4 3.2

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1418

From the simulation results of Table 4, it is

obtained that the smallest PV capacity and the

number of batteries occurs in cases where a two-axis

tracker system is used. The two-axis tracker system

has good implications for the investment cost of PV

systems to be 2,579 $. The use of a two-axis tracker

system has increased electricity production from

solar energy sources from 3,341 to 3,931 kWh/yr.

Apart from the increase in energy production 0f, PV

systems with two-axis solar tracking will need fewer

PV modules and batteries to supply the same load,

hence requiring less space.

From the economic point of view, a PV system

with a two-axis Tracker is more economical because

it produces the lowest COE of 0.307 $/kWh as well

as the payback period of this system is faster around

0.2 years. The payback period for the flat and single-

axis tracker PV system is 3.4 years; however, by

using the two-axis tracker PV system to be 3.2 years.

The analysis of environmental influence needs to

be considered and needs to be taken into account by

knowing the amount of energy that can be generated

from the installation of the PV system. The factor of

greenhouse gasses (GHG), as mention in Ref, can be

known large emissions that can be reduced if using

photovoltaic as a source of electrical energy.

5 CONCLUSION

The technical and economic analysis of tracker

based solar power system for remoted islanded has

been presented. The potential of the energy of the

PV system can be generated 3,341 kWh/year. The

test result using three different PV structure

installations - fixed structures, single-axis tracking,

and dual-axis tracking mechanisms, shows that the

two-axis tracking system has more profitable in

terms of PV electricity production 3,931 kWh in a

year and had the lowest COE of 0,307 $/kWh. This

system requires less PV module and battery storage,

as well as lowest PV system, cost 2,579 $, and less

space needed for system installation. The analysis of

environmental influence needs to be considered for

future research in order to reduce CO

2

emission.

ACKNOWLEDGEMENTS

The authors gratefully acknowledge the assistance

rendered by DRPM KemRistek/BRIN for the

financial support under Penelitian Terapan Research

Grant 2020 (Contract No. 163/SP2H/AMD/LT/

DRPM/2020).

REFERENCES

Kepmen-ESDM-No.1567 K/21/MEM/2018. (2019).

RUPTL 2018-2027.

Syafii, A. B. Pulungan, Wati, and R. Fahreza. (2020).

Techno-Economic Analysis of Tracker Based Rooftop

PV System Installation Under Tropical Climate. Int. J.

Adv. Trends Comput. Sci. Eng., vol.9, no. 4, p. [In

Press].

Syafii and R. Nazir. (2016). Performance and energy

saving analysis of grid connected photovoltaic in West

Sumatera. Int. J. Power Electron. Drive Syst., vol.7,

no.4,

Kunaifi. (2011). Desain Pembangkit Listrik Hybrid ( Plts /

Diesel ) Untuk Meningkatkan Pelayanan Kesehatan.

vol. 10, no. 1, pp. 15–21.

L. Olatomiwa. (2016). Optimal configuration assessments

of hybrid renewable power supply for rural healthcare

facilities. Energy Reports, vol. 2, pp. 141–146.

[H. A. Kazem, H. A. S. Al-Badi, A. S. Al Busaidi, and M.

T. Chaichan. (2017). Optimum design and evaluation

of hybrid solar/wind/diesel power system for Masirah

Island. Environ. Dev. Sustain., vol. 19, no. 5, pp.

1761–1778.

H. A. Kazem, S. Q. Ali, A. H. A. Alwaeli, K. Mani, and

M. Tariq. (2013). Life-cycle cost analysis and

optimization of health clinic PV system for a rural area

in Oman. Lect. Notes Eng. Comput. Sci., vol. 2

LNECS, pp. 1052–1056.

NREL. (2020). HOMER Powering Health Tool. [Online].

Available: https://poweringhealth.homerenergy.com/.

A. Haghighat Mamaghani, S. A. Avella Escandon, B.

Najafi, A. Shirazi, and F. Rinaldi. (2016). Techno-

economic feasibility of photovoltaic, wind, diesel and

hybrid electrification systems for off-grid rural

electrification in Colombia. Renew. Energy, vol. 97,

pp. 293–305.

T. S. O. dan C. H. Thum. (2013). Net Present Value and

Payback Period for Building Integrated Photovoltaic

Projects in Malaysias. Int. J. Acad. Res. Bus. Soc. Sci.

R. G. J.Lee, B. Chang, C. Aktas. (2016). Economic

feasibility of campus-wide photovoltaic systems in

New England, Renewable Energy,” vol. 99, pp. 452–

464.

D. and F. D. K. Elieser Tarigan. (2014) .Economic

Simulation of a Grid-Connected PV System Design as

Specifically Applied to Residential in Surabaya,” in

Indonesia, The 3rd Indo-EBTKE ConEx.

Design of Tracker based PV System for Health Care Facilities in Remote Islanded

1419