Control System in Crusher and Sorting Nutmeg Seed Machine based

on Arduino Uno

Alfred Noufie Mekel

and Tineke Saroinsong

Dept. of Mechanical Engineering, Manado State Polytechnic, Manado, Indonesia

Keywords: Crusher, Sorting, Nutmeg, Arduino Uno.

Abstract: The aim of this research is to help the businessmen and exporters of nutmeg seeds by designing

and manufacturing control system on nutmeg crusher and sorting machine, so that they can

accelerate the process of nutmeg seed sorting. This research was conducted at the Production

Laboratory, Department of Mechanical Engineering, Manado State Polytechnic. The method used

in this research is design and manufacture, that

focused on the automatic control section. The design

of the nutmeg seed sorting tool uses a cmu pixy camera image sensor and an ultraviolet lamp that

serves to light up the color. The working system of this tool will be carried out automatically which

is controlled by an arduino uno AT Mega 328 microcontroller.

1 INTRODUCTION

Nutmeg is a medium-stemmed plant with a height of

18 m, has oval or oval leaves that are always green

throughout the year. Nutmeg can grow in the tropics

at an altitude below 700 m above sea level, humid and

hot climates, rainfall 2,000 - 3,500 mm without

experiencing a significant dry season period. The

major nutmeg producing regions in Indonesia are the

Maluku Islands, North Sulawesi, West Sumatra,

Nanggroe Aceh Darusalam, West Java and Papua

(Rismunandar, 1990). The development of nutmeg

planted areas throughout Indonesia until 2013 has

reached 140,000 ha with a production of 25,800 tons

of nutmeg (Directorate General of Indonesian

Plantation, 2014).

Nutmeg is known as a spice plant that has

economic and multipurpose value because every part

of the plant can be utilized in various industries.

Seeds, mace and nutmeg oil are export commodities

and are used in the food and beverage industry. Oils

derived from seeds, mace and leaves are widely used

in the pharmaceutical, perfume and cosmetics

industries. Yellow rounded nutmeg when old, fleshy

in white. The seeds are thin-skinned, rather hard,

brownish black, wrapped in a crimson colored mace.

The contents of the seeds are white, when dried to

dark brown with a distinctive aroma. Nutmeg consists

of flesh (77.8%), mace (4%), shell (5.1%), and seeds

(13.1%) (Rismunandar, 1990). Commercially nutmeg

and mace (mace) is the most important part of nutmeg

and can be made into various products including

essential oils and oleoresin. Another product that may

be made from nutmeg seeds is nutmeg which is

trimyristin which can be used for edible oils and the

cosmetics industry (Somaatmaja, 1984).

In the handling of agricultural products, division,

peeling and cutting are work that is always done from

harvesting until the product is ready for consumption

or further processing. For example, vegetables are cut

before cooking, tubers and bananas are sliced before

frying, pineapple sliced before canning, and grass is

cut before being given to cattle. The work of splitting,

peeling and cutting agricultural produce in small

quantities can be completed manually using a knife or

other cutting tool. However, if the amount is large

enough, such as stripping coconuts at harvest,

stripping manually requires considerable time and

labor. High capacity peeling machine is needed, so

the effectiveness and efficiency in this case is

absolutely necessary (Wiriaatmadja, 1995).

The division of the flesh of the fruit, seeds, and

mace is carried out after the ripe nutmegs are

collected, the fruit is split and between the flesh, mace

and seeds are separated. Each part of the nutmeg is

placed in a clean and dry container. The release of

mace from the seeds is carried out carefully, from the

tip towards the base, in order to obtain a complete

mace that is classified as high quality. The seeds

collected are sorted into 3 types, namely: fat and

Mekel, A. and Saroinsong, T.

Control System in Crusher and Sorting Nutmeg Seed Machine based on Arduino Uno.

DOI: 10.5220/0010966200003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1405-1409

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1405

intact, thin or wrinkled, and defective. (Directorate

General of Indonesian Plantation, 2012).

One way to increase the economic value of

nutmeg, especially for the export market, is by

sorting. The sorting process aims to determine the

classification of commodities based on similar quality

(Zain et al, 2005). Sorting is fraction sorting activity

based on physical characteristics (water content,

shape, weight, type, texture, color, foreign

matter/dirt), chemical (odor composition and

rancidity), and biological conditions (type of damage

by insects, microbial counts, and special growth for

seeds). In the process of sorting is done by examining

indicators such as intensity, color, size, shape, or

texture of the fruit (Arivazhagan et al, 2010). The

quality of nutmeg itself is determined by various

parameters including the parameters of maturity or

color index and size (Radityo et al, 2012).

The process of sorting fruits and seeds is still

using conventional methods, namely the use of

human labor (manual). This has the disadvantage that

human judgment is still subjective and inconsistent

with fruit objects and repetitive work can cause

burnout. For this reason, it is necessary to apply a

system that can carry out the sorting process

automatically (Febyan and Slamet, 2017).

In this study, we will try to combine a sorting

machine in the form of a conveyor using an image

sensor. This research was also developed based on

previous studies. Diah et al (2012) designed an

automation model based on color and size using

TCS3200 sensors and ultrasonic sensors. Al Amin et

al (2013) designed separators using laser and

photodiode detection sensors. Mochammad et al

(2017) implemented a sorting system based on color

and temperature using the NRF24L01 wireless

module.

The design of the nutmeg seed sorting tool uses a

cmu pixy camera image sensor and an ultraviolet

lamp that serves to light up the color. The working

system of this tool will be carried out automatically

which is controlled by an arduin uno AT Mega 328

microcontroller. With this system it is expected to be

able to increase efficiency and effectiveness in terms

of nutmeg sorting.

2 RESEARCH METHODS

2.1 Overview of the Nutmeg Sorter

Intelligent System

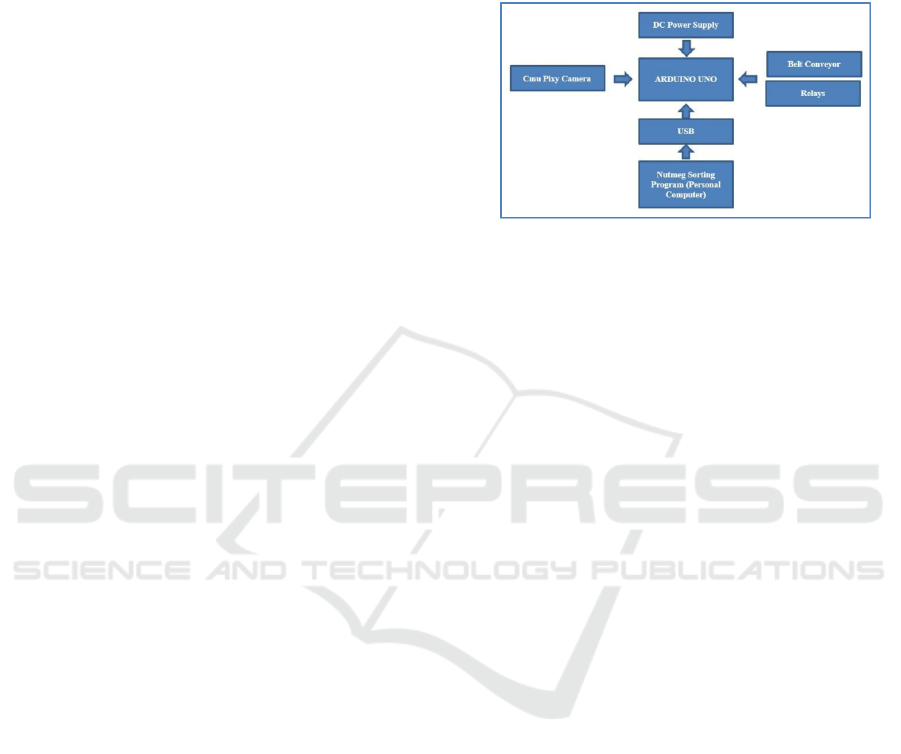

General description of this intelligent system consists

of input in the form of an image sensor with cmu pixy

camera, ultraviolet lights, and micro switch. After the

input detects the data will be sent to the Arduino uno

microcontroller and will give an output execution

command, where the DC motor will move the nutmeg

sorter bar. System block diagram shown in Figure 1.

Figure 1: Block Diagram of the System

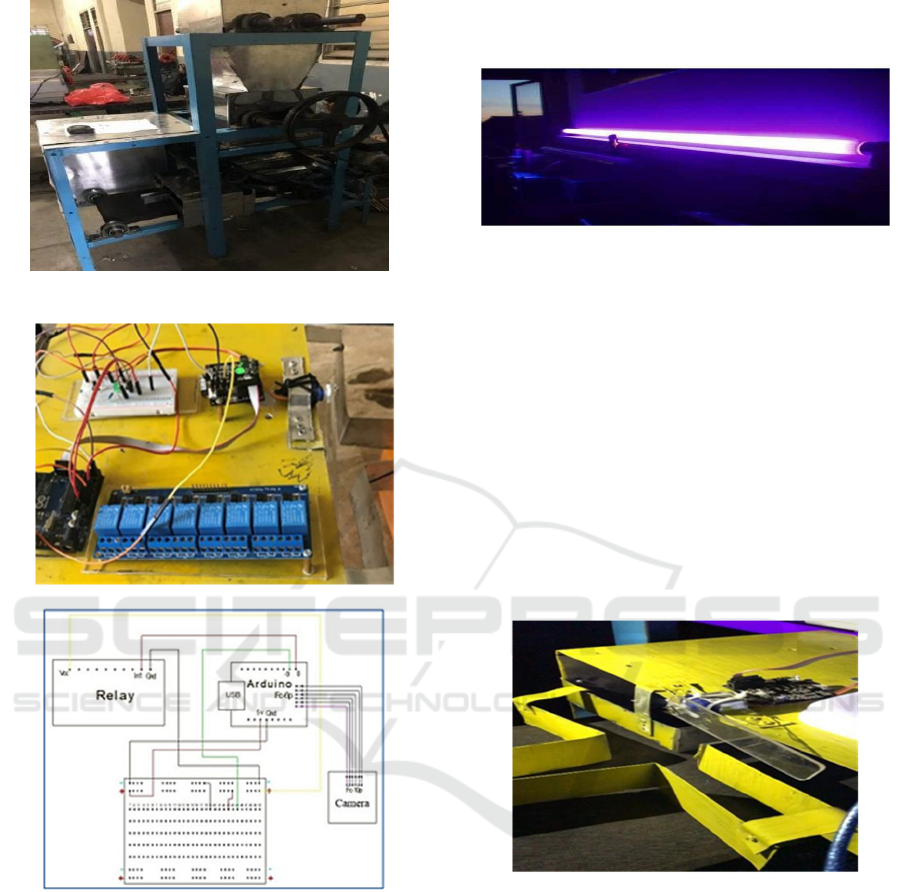

2.2 Mechanical Design

The design of mechanical design is shown in figure 2.

In mechanical design. This smart system considers

several important things, including:

1. The shape and size of the frame is kept to a

minimum in order to produce a system that

effective and efficient.

2. Circuits on electronic systems are kept to a

minimum to avoid error and excessive use of

jumper cables.

Conducting grouping of modules and other electronic

components to be more orderly and do not interfere

with other components.

2.3 Electrical Design

The design of the electrical design is shown in Figure

3. In the design of electrically intelligent systems

must consider several important things, including:

1. The DC source that will be used in this circuit is

12V, where the use of the Arduino Uno module

can work at 5V.

2. The microcontroller that will be used in this

study is Arduino Uno.

3. Control design to support this application using

some software.

The control system design uses C programming

language in Arduino IDE to acquire analogue and

digital data from the voltage sensor output.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1406

Figure 2: Mechanical Design.

(a) Real Display of Electrical Design

(b)

Figure 3: Electrical Design (a) Real Display (b) Circuit.

3 RESULT AND DISCUSSION

Result of Design and Manufacture

The main part of this intelligent nutmeg sorter system

model is the presence of an image sensor in the form

of a cmu pixy camera that is coupled with an arduino

uno microcontroller controller. After the broken

nutmeg seeds come out of the mechanical sorting

guide, the nutmeg seeds will enter the conveyors one

by one (in line). After that, nutmeg seeds will go into

a dark room with ultraviolet lights (Figure 4).

Figure 4: Ultraviolet Light.

If the nutmeg seeds are exposed to ultraviolet light

from the lamp, the nutmeg seeds will reflect white if

they contain toxins, and will remain dark if they do

not contain poisons. In this section the nutmeg will be

detected by a cmu pixy camera that functions as an

image sensor for the sorting process which will be

executed by the separator bar. The sorting indicator

itself is distinguished by white and colorless (dark). If

the nutmeg seeds that pass through the conveyor are

detected reflecting white then the separating bar is

active, conversely if a colorless nutmeg is detected by

the camera, the separating bar is not active. The

overall results of intelligent system design are shown

in Figure 5.

Figure 5: Prototype of Intelligent Nutmeg Sorter System.

Structural and Functional Test

At the structural test stage, testing is carried out aimed

at finding out whether the system designed is in

accordance with the previously designed concept.

This test is done by knowing whether the electronic

module is connected correctly so that the system can

function properly and has the performance and

function according to the design. The test results are

shown in table 1.

Control System in Crusher and Sorting Nutmeg Seed Machine based on Arduino Uno

1407

Table 1: Structural Test.

Component of the Syste

m

Connect to Description

Cmu pixy camera

Pin A0 connected

Arduino uno

Pin A1 connected

Out Pin A2

Se

p

aratin

g

bar

Pin A3 connected

At the functional testing stage, the test is aimed to

determine whether the voltage flowing in the circuit

is in accordance with what is needed. This test is done

by testing the output voltage of each component using

a multi meter or with a program.

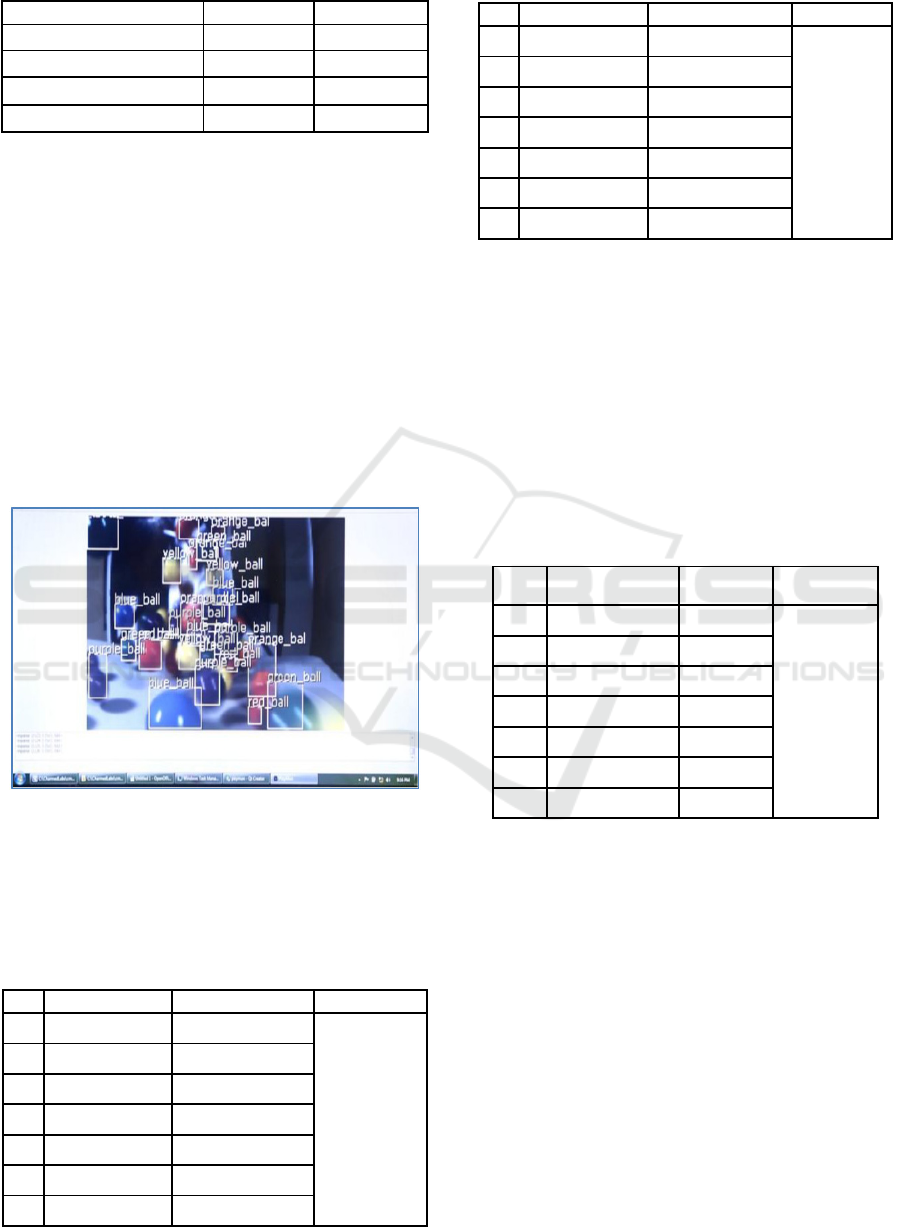

Validation Test

This stage is carried out with the aim to find out which

intelligent system has been working correctly or not.

Tests carried out by looking at the system output. The

output that is produced from the color input that

enters the microcontroller is processed with a

predetermined value so that it can sort the nutmeg

seeds according to the specified indicators.

Figure 6: An image captured from cmu pixy camera.

Furthermore, the control system testing is carried out.

At this stage, the intelligent system that is created will

be tested whether it is working properly or not.

Testing is done by looking at the system output.

Table 2: Example Testing I of Cracked Nutmeg.

No.

Separating Bar

Color of Nutme

g

Descri

p

tion

1

Opened

White

Succes

2

Opened

White

Succes

3

Opened

White

Succes

4

Closed

Black

Succes

5

Opened Black

Failed

6

Closed

Black

Succes

7

Closed

Black

Succes

Table 3: Example Testing II of Cracked Nutmeg.

No.

Separating Bar

Color of Nutme

g

Descri

p

tion

1

Opened

White

Succes

2

Opened

White

Succes

3

Opened

White

Succes

4

Closed

Black

Succes

5

Closed

Black

Succes

6

Opened

Black

Failed

7

Closed

Black

Succes

The output produced from the input of broken

nutmegs into a dark room equipped with an

ultraviolet light and a cmu camera, which then by the

microcontroller orders the mechanical system of the

dc motor to open or close the separating bar so that it

can sort out toxic and non-toxic nutmeg. The example

results of this test could be seen in Table 2 and Table

3 and Table 4. The process of this testing is performed

50 times with each using a variety of broken nutmeg.

Obtained successful trial data each of 45 times. The

success rate achieved is 90%.

Table 4: Example Testing III of Cracked Nutmeg.

No.

Separating Bar

Color of

Nutmeg

Description

1

Opened

White

Succes

2

Opened

White

Succes

3

Opened

White

Succes

4

Closed

Black

Succes

5

Closed

Black

Succes

6

Closed

Black

Succes

7

Closed

Black

Succes

The output produced from the input of broken

nutmegs into a dark room equipped with an

ultraviolet light and a cmu camera, which then by the

microcontroller orders the mechanical system of the

dc motor to open or close the separating bar so that it

can sort out toxic and non-toxic nutmeg. The example

results of this test could be seen in Table 2 and Table

3 and Table 4. The process of this testing is performed

50 times with each using a variety of broken nutmeg.

Obtained successful trial data each of 45 times. The

success rate achieved is 90%.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1408

4 CONCLUSIONS

This research produced a crushing and sorting

machine that can separate poisonous nutmegs and not

through a control system with an arduino uno and

cmu pixy camera. The result of the study is an

intelligent system which can increase the

effectiveness and efficiency of the nutmeg sorting

process because it can be done automatically and

continuously. The intelligent nutmeg seed sorter

system model based on the color produced through

ultraviolet lights by using a cmu pixy camera that

functions as an arduino uno based image sensor still

needs further development to get optimal results. This

system is expected to be applied and become a

recommendation for nutmeg entrepreneurs,

especially nutmeg exporters in North Sulawesi.

REFERENCES

Al Amin Putra, Krismadinata, & Irma Husnaini. (2013).

Design and manufacture of apples separator based on

size with microcontroller ATMega 8535. Thesis,

Department of Electrical Engineering, State University

of Padang, Padang.

Arivazhagan S., Shebiah R. Newlin., Nidhyanandhan S.

Selva, Ganesan L. (2010) Fruit Recognition using Color

and Texture Features. Journal of Emerging Trends in

Computing and Information Sciences, 1.

Diah Puji Astuti, Tjut Awaliah Zuraiyah, & Andi

Chairunnas. (2012). The Sorting Automation System

Model by Size and Color uses an Ultrasonic Sensor and

TCS3200 based on Arduino Uno. Computer Science

Study Program, Faculty of Mathematics and Natural

Sciences, Pakuan University, Bogor.

Directorate General of Plantation. 2014. Indonesian

Plantation Statistics 2009-2013 Nutmeg. Agriculture

department. Jakarta.

Directorate of Postharvest and Business Development.

Directorate General of Plantation. Ministry of

Agriculture. 2012. Technical Guidelines for Post-

Harvest Nutmeg Handling. Jakarta.

Febyan D. P. & Slamet Wibawanto. (2017). Design of

Automatic Tomato Fruit Sorting System Based on

Diameter Using Smart Relay SR2 B201JD.

Proceedings of the Elinvo National Seminar Volume 3

September, ISSN: 2477-2402, 125-132.

Radityo Dimas Rizki, Fadillah Muhammad Riyan,

Igwahyudi Quincy, & Dewanto Satrioh. (2012). Sorting

and checking fruit maturity using sensors. Journal of

Computer Engineering Vol 20 No. 2 Aug, 88-92.

Rismunandar. 1990. Nutmeg cultivation and commerce,

cet. II. PT.Penebar Swadaya. Jakarta.

Somaatmadja, D. 1984. Research and Development of

Nutmeg and mace. Communication No. 215. BBIHP.

Bogor. Page 12.

Wiriaatmadja, S. 1995. Agricultural Equipment and

Machinery. Slicers and Slicers. PT.Penebar Swadaya.

Jakarta.

Zain Sudaryanto, Dadi Rusedi, Syarifah Nurjanah. (2005).

Post Harvest Grain Processing Technology. Lecture

Module. Faculty of Agricultural Industrial Technology.

Padjadjaran University.

Control System in Crusher and Sorting Nutmeg Seed Machine based on Arduino Uno

1409