The Feasibility of Electrical Safety Grounding Tool for Medium

Voltage Distribution with A3CS Cables

I Wayan Jondra, I Nengah Sunaya and I Made Aryasa Wiryawan

Electrical Departmen, Politeknik Negeri Bali, Bukit Jimbaran, Badung, Indonesia

Keywords: Electrical, Grounding Tool, Work Safety.

Abstract: In this globalization Electrical energy has become like a primary need. Electrical energy consumption growth

has coherency with economic growth. The electricity supply system is designed to improve the reliability

without blackout. Reliability improvement can be done by construction, maintenance, repair and improvement

of the system. Construction, maintenance, repair and improvement of the distribution system must be

guaranteed work safety and health. In Australia, electrical safety and health are very tightly regulated, because

it very dangerous if the equipment is not grounded properly. The preparation of electrical safety grounding

for medium voltage distribution with A3CS cables is very important, because now only available for A3C

cables. This research is quantitative research through statistical and mathematical data processing. This study

examines the feasibility of electrical ground safety assembled for medium voltage distribution with A3CS

cables. The results found that electrical safety grounding tools is feasible to use in construction, maintenance,

repair and improvement of over head medium voltage distribution system with A3CS and A3C cable. This

grounding tools has an insulation resistance more than 100 mega ohms, a leakage current smaller than 1 milli

amperes, and the distance of workers to the active part is more than 0.9 meters.

1 INTRODUCTION

1.1 Problems Background

The electricity is very important in this globalization

era, the electricity has become like a primary need.

So many economic activity need electrical power.

Electrical energy consumption had a positive impact

and there was bidirectional causality with economic

growth (Yılmaz Bayar and Hasan Alp Özel, 2014).

The growth of energy consumption will be followed

by increase electricity consumption as a result of

economic growth (Zhenya Liu, 2016). An electrical

energy consumption increased during the economic

growth.

So many economic activities need electrical

energy. In Aceh Province of Indonesian the empirical

evidences indicate that the long-run bidirectional

relationship exists between, commercial electricity

consumption and economic growth and, in the short-

run bidirectional relationship between economic

growth and all of the sectoral electricity consumption

(Fahrul Rizal, 2014). That so very vital the electrical

energy, the engineer did some experimental to build,

maintenance and repair the system for a safe and

reliable electrical energy distribution(Math H Bollen,

2000).

This reliability system is designed to guarantee

the electricity supply quality that meets to the

standards. The quality of electricity supply aims to

protect consumer rights and so the State Electricity

Company’s (PLN’s) advantages. So that all parts of

the electrical energy supply system must meet the

standards of reliability and security. The hope to

electricity distribution by PT.PLN must not be

interrupted for 24 hours. Routine maintenance such

as a vegetation management program can reduce

unnecessary tripping especially during excess

channel situations (Chan F.C., 2008). These steps can

minimize the external interference. Thus, the

maintenance, repair and improvement of the

distribution system is an important action.

Maintenance, repair and improvement of the

distribution system must be safety and healthy work

processed. The work process must follow to standard

operational procedures with available standards tools.

In Australia, occupational safety and health in

working electricity is very tightly regulated, because

accidents to burns or falling from a height site, thus

the equipment must be earthed properly (Alex Ward,

Jondra, I., Sunaya, I. and Wiryawan, I.

The Feasibility of Electrical Safety Grounding Tool for Medium Voltage Distribution with A3CS Cables.

DOI: 10.5220/0010965200003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1345-1351

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1345

1982). My assembled that grounding tool for

electrical work safety at A3CS cable on medium

voltage distribution, will protect the workers from

electric shock and lightning strikes. There are many

people are not aware of the threat electricity danger,

so this awareness is very important, and safety and

healthy tools are prepared (Saba et. al., 2014).

A good grounding system if the equipment is well

connected to the earth. Electrical Working safety if

the whole system equipment bended and connected to

the ground. The quality of earthing is the basic

protection against AC interference (Mohamed, 2018).

The source of interference is lightning, switching, or

an error in the distribution system. To do this bending

and grounding must be done with adequate tools to a

good connection between the equipment and the

earth. The problem now is that are the overhead

medium voltage distribution in Indonesia, has been

replaced by an insulated cable like all alloy aluminum

conductor sheated (A3CS). This will be an obstacle

for bending and grounding conductor to earth,

because the current grounding equipment is properly

to A3C conductors.

This research is very important to get a model of

earthing tool for electrical work safety in over head

medium voltage system, that can grounded whole

equipment with properly to the earth, due

construction work, maintenance, repair and

improvement of over head medium voltage electrical

distribution system. This paper to explore how to

assembly dan tested the grounding tool for electrical

work safety at A3CS cable on medium voltage

distribution..

1.2 Problem

How the feasibility Of Electrical Safety Grounding

Tool For Medium Voltage Distribution With A3CS

Cables?.

2 RESEARCH METHOD

2.1 Research Approaches and

Concepts

To analyses that problems, this study was designed as

a qualitative approach study. The problems will be

discussed by the data from measurement dan tested,

ware calculation to obtain the good insulation for

medium voltage work safety handle, and all of

component connected. This research tested is done in

the Politeknik Negeri Bali Workshop and PLN UP2D

laboratory, and the test results statistically and

mathematically analyse to obtain the feasibility of

electrical safety grounding tool assembly, comparing

to the electrical work safety roles, and than taken

conclusions and recommendations. This grounding

tool is assembled by plastic pipe, rubber rings, life

line connector, and flexible copper cable. This

grounding tool is an innovation assembly for

electrical work safety tool. This grounding tools is

properly applied at medium voltage distribution with

all alloy aluminium conductors (A3C) and all alloy

aluminium conductors Sheeted (A3CS), but the other

only for A3C.

2.2 Total Sample

This research was conducted by tested three samples

“Electrical Safety Grounding Tool For Medium

Voltage Distribution With A3CS Cables” that was

taken from a product assembly.

2.3 Variable Operational Definition

In this study, we observed magnitude of the

connection, leakage current an insulation test,

dielectric strength and clearance distance. The

connection test is applied between connection head of

grounding tool and the medium voltage distribution

circuit. The test voltage is the amount of voltage

applied to the sample through the high voltage tester.

Leakage current is the amount of current flowing in

to the test sample, due to given test voltage. Dielectric

and clearance distance measured by ruler meter.

2.4 Tested

The connection test is tested by ohm meter, where the

good connection is indicated by resistance value at

about zero ohm. Electrical test voltage against

minimal insulation resistance is tested with a voltage

equal to the operating voltage. For testing a minimum

20 kV system equipment is tested with a voltage tester

at 20 kV. Tests are carried out using electronic high

voltage tank, volt meters and ampere meters. All

equipment connected with grounding system. Tested

are made between phase and ground.

For the connection tested, each sample

(connection head) is connected and screwed until the

pin piercing to the A3CS insulation. The connection

head is connected with red probe and the A3CS

conductor connected with black probe of ohm meter.

Selector switch of AVO meter was turned around to

1x of ohm meter. That connection tested process have

been done in three time reply.

For Current leakage tested, each test sample

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1346

(grounding shaft) is placed between the connection

head and winding electrode at the handle. The

connection head is given a 0.2 Hz AC voltage and the

winding electrode is grounded trough ampere meter.

The voltage given to the samples is increased step by

step, with each step is 5 kV, starting from 5 kV to 30

KV. In every voltage step, the current leakage flow

was measured with ampere meter. This current

leakage tested was processed three time at dry and

wet conditions of grounding shaft. Voltage detector is

applied to ensure the level of voltage leakage trough

current leakage from the head connection to the

grounding shaft.

2.5 Data Analysis

Data obtained from the test results are processed

quantitatively. Data is processed mathematically by

the process of multiplication and divide. The data is

also processed statistically by finding the smallest

value from all of data if the limit is minimum such as

insulation resistance, dielectric strength, space

clearance, and finding for the biggest value from all

of data if the limit is maximum such as at leakage

current condition.

3 RESULT AND DISCUSSION

The result of this research described by figure and

table. The analyses of the feasibility of a grounding

shaft was carried out is to guarantee the work safety.

Grounding tools must have good ground resistance

and the insulated shaft to ensure work safety in the

construction, maintenance, repair and improvement

of the medium voltage distribution. However, there is

no perfect shaft material, therefore the research on

this assembled shaft so important. This earthing shaft

constructed by polypropylene pipe, which has good

electrical characteristics because the coefficient of

resistivity volume is 8.5x10

14

Ohm-cm. Safety

grounding shaft was designed like as shown in Figure

1 below.

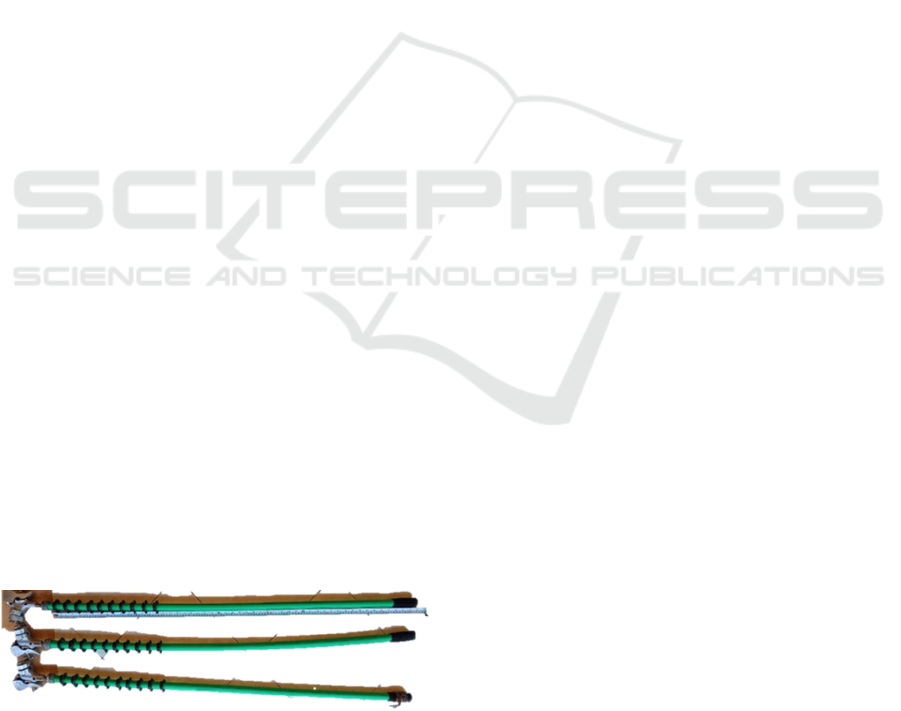

Figure 1: Safety grounding shaft.

In accordance to the safety grounding shaft

function is insulation. A perfect shaft insulating

material has an unlimited resistance, that currently

cannot obtained. There is a small leakage current that

flows in insulation material. The problem is the

resistance of insulating material is not unlimited. The

insulation resistance is according to Ohm's Law is

voltage divided by leakage current (Salman and

Muhammad, 2011) and can be shown as an equation

below.

V = I x R (1

)

R = V / I (2

)

where :

R = Insulating Resistance (Giga Ohm)

V = Voltage charge due the sample (Kilo Volt)

I = Leakage Current (micro Amperes )

The normal air dielectric strength coefficient is 30

kV/cm, the total dielectric strength is total distance

multiple with dielectric strength coefficient, as shown

in the formula below (Kumail et. al., 2018).

ℰ=ℰ

0

x d (3

)

where :

ℰ = Dielectric strength (KV)

ℰ

0

= Dielectric strength coefficient (KV/cm)

d = distance (cm)

3.1 Result

Conducting to the tested, insulation resistance after

the leakage current tested with the High Voltage VLF

Hi-pot Instruments Type: VLF4022, dielectric

strength, and safe distance between active voltage

equipment with workers. These four benchmark must

be considered to determining the feasibility of the

electrical work safety grounding shaft. The minimum

insulation for medium voltage is 100 Mega Ohms

(Sanjay et. al., 2018). The maximum leakage current

flow does not affect a shock to the human body is 1

milli amperes (Saba et. al., 2014). Total the dielectric

strength must exceed than the active voltage to avoid

the electric discharge (Saba et. al., 2014). The

minimum safe distance between workers and 15 Kilo

Volt active equipment is 90 cm (Manik et. al., 2015).

Conducting to the trial this safety grounding tools

connecting to the medium voltage distribution

network, occurred a good connection. Measurement

results of connections on A3CS and A3C cables is

limit to zero. Thus the head of the grounding shaft can

properly pierce the A3CS cable insulation and well

grip well on to A3C conductor.

Isolation resistance pretest was conducted at the

Electrical Engineering Workshop Bali State

Polytechnic, Before insulation resistance tested in the

UP2D Bali PLN laboratory. A pretest is carried out to

conduct an early detection of the insulation resistance

The Feasibility of Electrical Safety Grounding Tool for Medium Voltage Distribution with A3CS Cables

1347

Figure 2: Electrical safety grounding on the trial.

quality this electrical work safety grounding shaft.

The pretest is carried out by applying a voltage of

5,000 volts and 10,000 volts to the terminal head and

handle connected by grounding trough coil electrode

as shown in the following figure 3. Insulation

resistance pretest is done in dry and wet condition

three times for each sample, the wet condition testing

as shown at figure 4.

Figure 3: Dry insulation resistance pretest with megger

10,000 volt.

The pretest is very important because it is not easy

to get permission to do it again at PLN UP2D Bali.

Pretest is done using 10,000 Volt meggers. the results

of the insulation resistance pretest using megger are

analyzed to obtain leakage currents, such as the

calculation below.

Leakage current analysis, sample 1 at 1

st

step

Voltage tested: 5,000 Volt DC

Insulation resistance : 250,000 Mega Ohm

The leakage current calculation:

Figure 4: Wet insulation resistance pretest with megger

10,000 volt.

I = V/R

= 5,000/250,000,000,000

= 0.02x10-6 amperes

= 0.02 micro amperes

Through the same calculation, the leakage current as

displayed in table 1 at below.

Table 1: Leakage current analysis grounding shaft with

Megger 10 kV.

Sam

ple

Step of

testing and

condition

R Iso.

at 5 KV

(Giga

Ohm)

R Iso.

at 10 KV

(Giga

Ohm)

Leakage

current at

5 KV

(micro

am

p

e

r

es

)

Leakage

current at

10 KV

(micro

am

p

e

r

es

)

1

1 dr

y

250 500 0.0200 0.0200

2 dr

y

200 400 0.0250 0.0250

3 dr

y

225 450 0.0222 0.0222

1 wet 78 156 0.0641 0.0641

2 wet 80 160 0.0625 0.0625

3 wet 80 160 0.0625 0.0625

2

1 dr

y

220 440 0.0227 0.0227

2 dr

y

300 600 0.0167 0.0167

3 dr

y

250 500 0.0200 0.0200

1 wet 40 80 0.1250 0.1250

2 wet 45 90 0.1111 0.1111

3 wet 45 90 0.1111 0.1111

3

1 dr

y

300 600 0.0167 0.0167

2 dr

y

250 500 0.0200 0.0200

3 dr

y

275 550 0.0182 0.0182

1 wet 38 76 0.1316 0.1316

2 wet 40 80 0.1250 0.1250

3 wet 40 80 0.1250 0.1250

I leakage max. 0.1316 0.1316

R Iso min. 38 76

The insulation resistance tested with High Voltage

VLF Hi-pot Instruments like shown in figure 3 below

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1348

is done at PN UP2D Bali Laboratory. High voltage

VLF hi-pot instruments are high voltage test

equipment with low frequency. This measuring

instrument changes the voltage 220 Volt 50 Hz, into

a DC voltage, then converted back into low frequency

AC high voltage. The output of High Voltage VLF

Hi-pot Instruments test equipment Type: VLF 4022 is

40 KV AC with a frequency of 0.2 Hz.

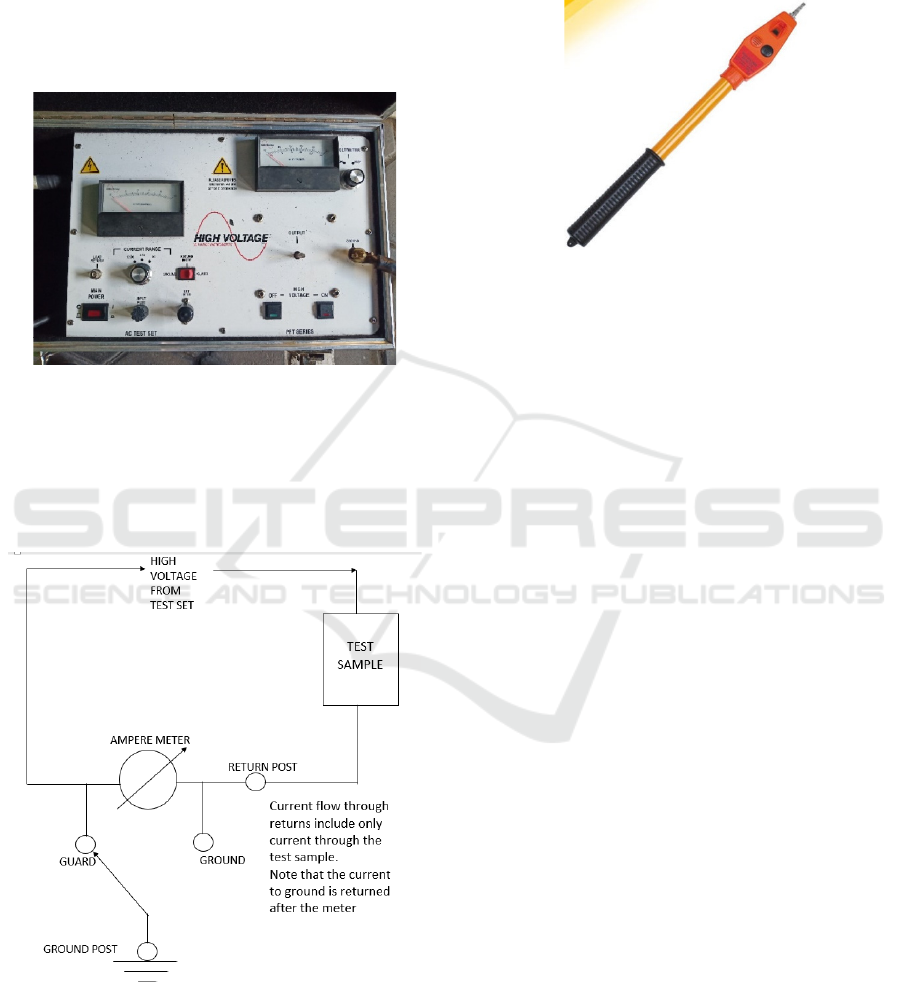

Figure 5: High voltage VLF hi-pot instruments.

The leakage current testing circuit is carried out by

connecting the sample in series with a measuring

instrument. The test equipment is solidly grounded

for safety in the testing process. the return switch is

positioned on the guard as shown in figure 6.

Figure 6: Test diagram.

This leakage current tested start at a voltage test

of 5 kV, then increased by 5 kV per step up to 30 kV.

When testing a leakage current, also detecting a

leakage voltage using a voltage detector, which starts

working with a voltage of 2.7kV and above like

shown on figure 7. Tests were carried out on three

ground stick samples that had been assembled, with

dry and wet conditions.

Figure 7: Voltage detector.

Leakage current tested for dry test samples first.

After six voltage step dry test is finished the test

equipment is turned off, followed by making artificial

rain from the spryer, placed on top of test sample with

an angle of 30 degrees. After being wet, the test

sample was given a voltage from 5 kV to 30 kV, noted

the leakage current and the dielectric discharge

voltage was detected by voltage detector.

The analyses the insulation resistance tested with

High Voltage VLF Hi-pot Instruments, using the ohm

formula. Insulation resistance is equal to the tested

voltage given divided by the leakage current. The

calculation of insulation resistance to sample 1 tested

step 1 as described below.

Tested result:

Voltage tested : 5,000 Volt AC

Leakage current : 1 micro ampere

The calculation of insulation resistant:

R = V/I = 5,000/(1 x 10-6)

= 5 x10

9

Ohm = 5 Giga Ohm

In the same calculation process, the insulation

resistance for other step is as displayed in the table 2.

To determine the safe electrical work distancing

there are two conditions must be discussed for the

grounding shaft, that are the total distancing dielectric

strength and the distancing between the potential life

voltage equipment with the worker when to

connecting the “electrical safety grounding tool for

medium voltage distribution with A3CS cables” to

the medium voltage equipment.

The angle of rain is expected to be a maximum of

30 degrees. The wet condition decrease the dielectric

strength. There are 10 pieces rubber ring like an

umbrella will protect the shaft from solidly wet. Part

of the shaft dry protected by the rubber ring to

maintain dielectric strength. Thus, the dielectric

The Feasibility of Electrical Safety Grounding Tool for Medium Voltage Distribution with A3CS Cables

1349

strength distance of “the electrical safety grounding

tool for medium voltage distribution with A3CS

cables” can be calculated as described below.

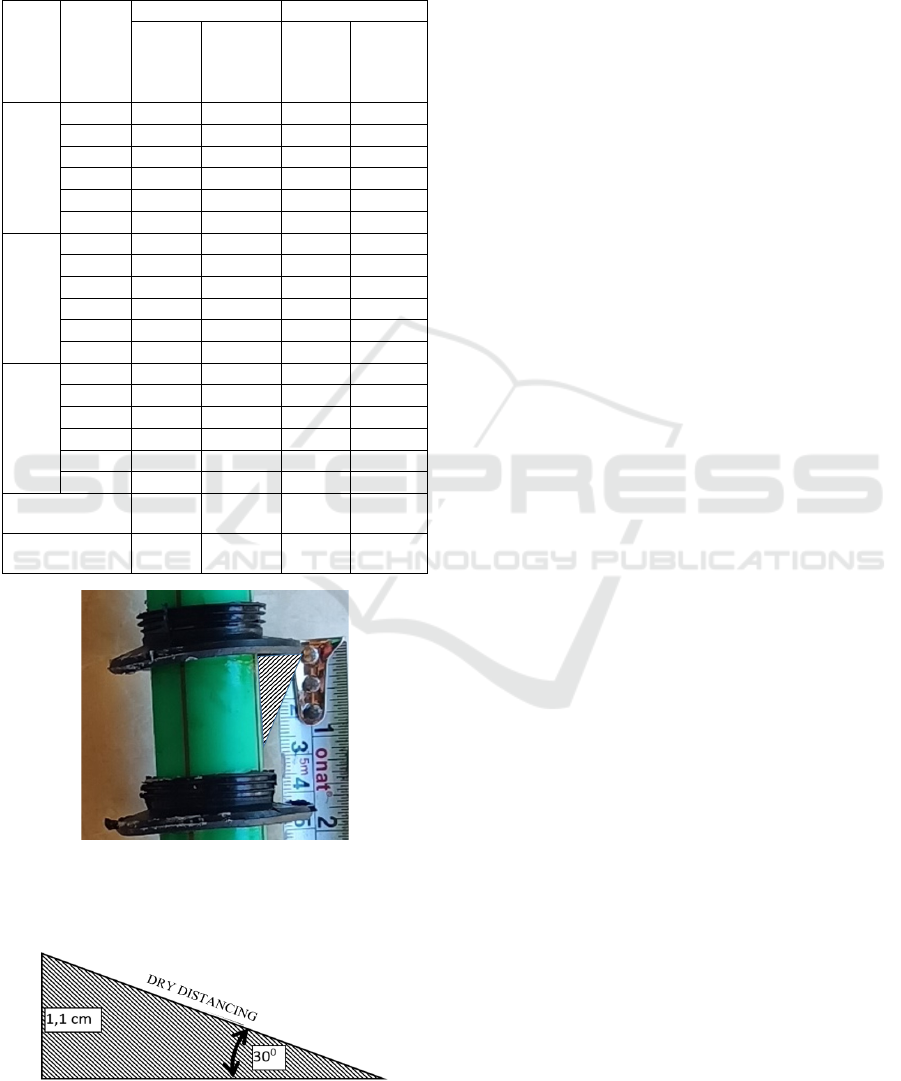

Table 2: Leakage current analysis grounding shaft with

Megger 10 kV.

Sam

ple

Voltage

Tested

(KV)

Dry Wet

Leakage

current

(micro

ampere)

Insulation

Resistance

(Giga Ohm

)

Leakage

current

(micro

ampere)

Insulation

Resistance

(Giga

Ohm)

1

5 1.00 5.00 1.00 5.00

10 1.00 10.00 2.00 5.00

15 2.00 7.50 4.00 3.75

20 2.00 10.00 4.00 5.00

25 2.00 12.50 5.00 5.00

30 3.00 10.00 4.00 7.50

2

5 1.00 5.00 3.00 1.67

10 2.00 5.00 4.00 2.50

15 2.00 7.50 4.00 3.75

20 3.00 6.67 5.00 4.00

25 4.00 6.25 6.00 4.17

30 4.00 7.50 5.00 6.00

3

5 1.00 5.00 1.00 5.00

10 1.00 10.00 2.00 5.00

15 2.00 7.50 3.00 5.00

20 2.00 10.00 4.00 5.00

25 3.00 8.33 5.00 5.00

30 3.00 10.00 4.00 7.50

Lowest insulation

resistance

5.00 1.67

Biggest leakage

curren

t

4.00 6.00

Figure 8: Rubber Ring on The Safety Grounding Shaft.

If the black-shaded triangle in figure 8 to copy and

pasted it will be obtained as shown in Figure 9 below.

Figure 9: Distancing angle.

Dry distancing calculation

Sin Q = Y/Z

Dry Distancing = 11/sin 300

= 1.1/0.5 = 2.2 cm

Total Dry Distancing = 10 x 2.2 cm = 22 cm

The normal air dielectric strength is 30 kV/cm

(Saba et. al., 2014). The total dielectric strength of

grounding shaft with 10 pieces rubber ring is:

ℰ=ℰ0 x d

= 30 x 22 = 660 KV

The total dielectric strength the shaft of “electrical

safety grounding for medium voltage distribution

with A3CS cables” with mathematic calculation is

660 kV. The result of voltage indicator tested at 30

kV AC given, 3 pieces rubber ring is lost dielectric in

wet condition.

Like as shown di Figure 1, the length of the shaft

is variability, that out of the three shaft, one stalk has

the smallest length of 123.5 cm. Thus the grounding

shaft is qualified to keep the distance between the

worker and the active part of the 15 kV phase to the

ground with a distance of 90 cm (Manik et. al., 2015).

Medium voltage distribution system in Indonesia

more lower only 11.6 KV from phase to ground.

3.2 Discussion

Based on the trial results it can be observed that work

safety grounding for medium voltage distribution

systems with A3CS cable, has been able to pierce

A3CS cable insulation to make a contact between the

clamp head and A3CS cable. Clamp heads also have

been trial to installed on A3C conductors. when

installed on the A3C conductor and A3CS cable AVO

Meter pointing to limit zero number.

Based on table 1 can be seen the maximum value

of leakage current is not more than 1 ampere and

minimum insulation resistance of grounding shaft is

not less than 100 Mega Ohm. The discussion can

proceed to the data shown in table 2. Based on table

2 can be seen the maximum value of leakage current

and minimum insulation resistance of grounding

shaft. Table 2 shows the minimum insulation

resistance occurs when the wet condition of shaft is

1.67 Giga Ohms and that the maximum value of

leakage current is 6 micro amperes. The benchmark

of minimum insulation for medium voltage is 100

Mega Ohms (Sanjay et. al., 2018). The benchmark of

maximum leakage current flow does not affect a

shock to the human body is 1 milli amperes (Kumail

et. al., 2018).

Based on the results of the analysis of safe

distance obtained two values to assessment the

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1350

feasibility of the safety grounding shaft, namely: the

value of the dielectric strength and the distance of the

worker with an active part with potential voltage

discharge. The analysis founded that the safety

grounding shaft has dielectric strength of 660 kV, and

provides safe distance between the worker and the

active part of 123.5 cm. The benchmark of total the

dielectric strength must exceed than the active voltage

to avoid the electric discharge (Kumail et. al., 2018).

The benchmark of the minimum safe distance

between workers and 15 kV active equipment is 90

cm (Manik et. al., 2015)

4 CONCLUSIONS AND

SUGGESTIONS

4.1 Conclusions

Based on the results of the research and discussion,

conclusions can be drawn as described. Safety

grounding tools for medium voltage distribution

systems with A3CS cables is appropriate. This

eligibility are determined based on good connection

capability, leakage current, insulation resistance,

dielectric strength and safety distance. The results

show that it exceeds the requirements specified in the

benchmark. Its connection capability is limit to zero,

the insulation value is more than 100 Ohms, the

leakage current is a lower than 1 milliampere, with

dielectric strength more than 11.6 kV, and more than

90 cm of the distance of the workers to the active

parts, to make the system in safe condition.

4.2 Suggestions

Based on the results of this study, there are many

suggestions as describe: PLN must requires the

vendors to prepare this “electrical safety grounding

for medium voltage distribution with A3CS cables.

This is a very important thing to electric work safety

of the workers, which has an impact on providing

benefits to both PLN and the vendors. This research

is not finish yet. because this research was carried out

in an covid19 pandemic situation, so the research was

carried out not by measuring instruments that met

laboratory standards. The next researcher could

continue this research in the laboratory.

ACKNOWLEDGEMENTS

This research was funded by DIPA Politeknik Negeri

Bali on year 2020. We thank Director of Politeknik

Negeri Bali for his support to this research.

REFERENCES

Alex Ward (1982). Electrical safety: an australian

prespective, The Australian journal of physiotherapy,

Vol 28 No. 1 February.

Chan F.C..(2008). Encyclopedia of life support systems

(EOLSS), Electric power distribution systems electrical

engineering – Vol. III.

Fahrul Rizal. (2014). Electricity and economic growth In

Indonesia’s province of Aceh, Aceh International

Journal of Social Sciences, 3 (1): 14 – 25.

Kumail Hassan Kharal, Chang-Hwan Kim, Chulwon Park,

Jae-Hyun Lee, Chang-Gi Park, Se Hee Lee and Sang-

Bong Rhee. (2018). A study for the measurement of the

minimum clearance distance between the 500 kV DC

transmission line and vegetation, Energies, 11, 2606.

Manik C Ghosh, Raju Basak, Avik Ghosh, Writwik Balow,

and Ayan Dey. (2015). An article on electrical safety,

IJSRD, International Journal for Scientific Research &

Development, Vol. 3, Issue 10.

Math H Bollen. (2000). Understanding power quality

problems:voltage sags and interruptions (Newyork:

Wiley-IEEE Press, ISBN:9780470546840).

Mohamed EL-Shimy Mahmoud. (2018). Electrical earthing

(grounding) systems a technical report and a short

course, Research gate: Technical Report: February.

Saba, T. M., Tsado, J. PhD, Raymond, E. PhD, and Adamu,

M. J.. (2014). The level of awareness on electrical

hazards and safety measures among residential ele-

ctricity user’s in Minna Metropolis of Niger State,

Nigeria.

Salman Amin and Muhammad Amin. (2011).

Thermoplastic elastomeric (tpe) materials and their use

in outdoor electrical insulation, Semanticscholar,

Edition 29, 15-30.

Sanjay Gothwal, Kaustubh Dwivedi, and Priyanka

Maheshwari. (2018). Partial discharge characteristics

and insulation life with voltage waveform,

International Research Journal of Engineering and

Technology (IRJET), Volume: 05 Issue: 07 July.

Yılmaz Bayar and Hasan Alp Özel. (2014). Electricity

Consumption and Economic Growth in Emerging

Economies, Scientific Papers (www.scientificpaper

s.org), Journal of Knowledge Management, Economics

and Information Technology, Vol. IV, Issue 2.

Zhenya Liu. (2016). Global energy interconnection (Cam

bridge: Elsevier Inc. All, ISBN : 978-0-12-804405-6).

The Feasibility of Electrical Safety Grounding Tool for Medium Voltage Distribution with A3CS Cables

1351