Improving the Quality of Fishery Products by Maintaining Ideal

Composition of Seaweed Caragenan: Kappaphycus Alvarezii

Siti Hajar

1

and Herlina

2

1

Fishery Technology Politeknik Negeri Nunukan, Nunukan, Indonesia

2

Business Administration Politeknik Negeri Nunukan, Nunukan, Indonesia

Keywords: Carrageenan, Mackerel, Meatball.

Abstract

:

This study aim is to determine the ideal composition of good carrageenan as a natural preservative for

improving the quality of fishery products. Other aim is to analyze the quality of fishery products by

maintaining of seaweed carrageenan (Kappaphycus alvarezii). This research was conducted for 4 (four)

months at the Laboratory of the Fishery Products Processing Technology Study Program Nunukan, Indonesia.

Nunukan. Data were collected based on observations of organoleptic tests which consist of color, taste, texture,

and aroma. The method used is an experiment with treatment A0 (meatballs without the

addition of

carrageenan) as a control, treatment A1 (meatballs with the addition of carrageenan 2.5%), treatment A2

(meatballs with the addition of carrageenan 5%), treatment A3 (meatballs with the addition of carrageenan 7,

5%). The composition ideal of carrageenan flour with a concentration of 2.5% could led the

best effect on the

elasticity quality of mackerel fish balls. The organoleptic value with the hedonic test of mackerel fish balls

with the extra of carrageenan flour of 2.5% has an appearance parameter value IS 3.76 (neutral to like). The

color parameter value is3.87 (neutral to like), and aroma parameter value is 3.87 (neutral to like). The taste

parameter is 4.69 (like to very like) and the value of the texture parameter is 4.34 (like). Other material such

water content is 66.04%, and protein content is 11.87%, while fat content is

1.13%. The essential material

such as carbohydrate content is 8.59%, crude fiber content is 9.61%, and ash content is 1.53%.

1 INTRODUCTION

Most of Indonesia's territory is waters that have

the

potential to produce quite large marine products.

One

of them is seaweed which has high economic

value

because it can produce carrageenan (Dewi, et

al,

2015).

Carrageenan is a polysaccharide extracted from

several species of seaweed or red algae

(rhodophyceae). Carrageenan is a hydrophilic linear

sulfated galactan. These polymers are repeating

disaccharide units. These sulfated galactans are

classified according to the presence of the 3,6-

anhydro galactose (DA) unit and the position of the

sulfate group (Distantina, et al, 2010). Carrageenan

functions as a thickener, emulsifier, suspending

agent, preservative and stabilizing factor.

Carrageenan is also used in the food industry to

improve the appearance of coffee products,

meatballs, sausages, nuggets, salads, ice cream,

condensed milk, chocolate and jelly. (Ega, et al,

2016).

Fishery products have different durability and it

depending on the nature of the food itself. Its usually

handling during processing and storage. One of the

main causes of damage to fishery products is

contamination by microbes from outside or naturally

present in these foodstuffs. To extend the shelf life of

foodstuffs can be done in various ways, one of which

is the extra of chemicals as preservatives.

Preservatives in fishery products have become an

inseparable part, especially since the times they have

demanded products that are practical, durable, and it

also have an attractive appearance. The solution

should be taken by the industry is to add preservatives

for increasing product quality and make it last longer.

One of the preservatives that often used is chemicals,

but if it used in excess, so it can cause endanger

health. It can be stated that carrageenan is an

alternative as a natural food preservative and is safe

to use to improve the quality and quality of processed

fishery products, especially seaweed. So the author

took the title Improving the Quality and Quality of

Fishery Products by Adding the Ideal Composition of

Hajar, S. and Herlina, .

Improving the Quality of Fishery Products by Maintaining Ideal Composition of Seaweed Caragenan: Kappaphycus Alvarezii.

DOI: 10.5220/0010961200003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1153-1157

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1153

Seaweed Carrageenan (Kappapychus Alvarezii).

2 LITERATURE REVIEW

The high value of Indonesia's wealth, especially

the

fisheries sector which is supported by the vastness

of

Indonesia's oceans. It also provides its own points

for

increasing people's income.

A. Types of Processed Fishery Products

To meet the need for animal protein, it can be

obtained through the use of non-economical fish

bycatch products into products that have added some

values. One of the efforts to increase the

diversification of processed fishery products is by

developing fishery product processing technology

that can increase the selling value of these products

(Juminda, F, 2015).

Surimi is a semi-finished material made from

white meat, tasteless and odorless and it has high

gelling ability. The advantages of using surimi such

as (1) surimi can be used directly for processing food

products such as meatballs, sausages, nuggets,

kamaboko, burgers and others. (2) Surimi is odorless,

free of bones and thorns so that the processed product

is easier to consume by people of all ages. (3) The

supply and price are relatively stable because surimi

can be stored and this facilitates are the planning of

processed production. (4) The cost of storage,

distribution and transportation is cheaper because

surimi can be stored for a long time. (5) Save time and

labor because the handling is cheaper. (6) The

problems that arise due to waste disposal are smaller

(Peranginangin, et al, 1999).

The manufacture of surimi-based processed

products uses a variety of fillers and binders. These

fillers and binders can be distinguished according to

their protein and carbohydrate content. The filler is

usually a material that has a high carbohydrate

content and has little effect on the properties of the

emulsion. The binder is usually in the form of

vegetable or animal protein, with higher protein

content, and it can improve the properties of the

emulsion. Some of the processed surimi-based

products that use fillers and binders are as follows:

B. Fish Sausages (Sosis Ikan)

Sausage is meat or a mixture of several meats that

are

mashed and mixed with spices or herbs. The thing

that

needs to be considered in processed sausages is

the

binder. To get good quality sausage, so flour is

needed as a binder of good quality. The binder in

sausages serves to attract water, and it gives a

distinctive color, with form a dense texture, also it

improve the emulsion stability, and to reduce cooking

time shrinkage, improve taste and slice properties.

The binder will bind with water to form a mass,

strengthening the emulsifier ability of the meat. It

leads the emulsion more stable. Sausages on the

market are made from a mixture of meat, flour, and

STPP (sodium tripolyphosphat) as a binding material.

STPP is an inorganic compound in the form of white

crystals which is usually used for food preservatives

and texturizers, but it is currently the use of chemicals

in limited. For this reason, that why a natural STPP

substitute is still needed. The natural STPP is namely

carrageenan. Carrageenan is obtained from seaweed

extraction and it is an alternative to STPP.

C. Fish Meatball (Bakso Ikan)

Meatballs are foods that are favored by various

groups of people of all ages in all corners of

Indonesia. Fish ball is a processed fish product that is

round in shape, highly nutritious, tastes delicious. It

can be eaten under any circumstances and it is also

very easily accepted by anyone. Fish balls are made

by adding spices, salt, garlic, pepper, ice 20% and

flour 10-30% (Ministry of Fisheries and Marine

Affairs RI Agency for Research and Human

Resources for Marine and Fisheries. Fisheries

Training and Extension Center, 2016).

D. Fish Nugget (Nugget Ikan)

Fish nuggets are a food favored by the

community,

especially children. According to

Lukman et al

(2009), Evanuarini and Purnomo

(2011) in the

Ministry of Fisheries and Marine Affairs

RI Agency

for Research and Human Resources for

Marine and

Fisheries and Fisheries Training and

Extension

Center (2016) noticed that Nuggets are

restructured

meat products with dough and coating to

maintain

quality. In the manufacture of nuggets, the

filler and

basic ingredients determine the

characteristics of the

nuggets produced. It is usually

used as the main

ingredient in the form of fish as the main ingredient,

while the filler is in the form of

wheat flour, tapioca

and cornstarch.

3

RESEARCH METHODS

The design used in this study was a completely

randomized design (CRD) with 4 treatments and 3

replications. Variations in addition of carrageenan

concentration to the weight of the mackerel used are:

A.

Control without the addition of carrageenan

(sausage, nuggets and mackerel fish meatballs)

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1154

B.

Sausage, Nuggets and Mackerel Fish Meatballs

with the addition of 2.5% Carageenan flour

C.

Sausage, Nuggets and Mackerel Fish Meatballs

with the addition of 5% Carrageenan flour

Sausage, Nuggets and Mackerel Fish Meatballs

with the addition of 7.5% Carrageenan flour

4 RESULT AND DISCUSSION

A. Physical Characteristics of Mackerel Fish

Meatballs with the Addition of Carrageenan

The physical properties of a product greatly

determine the level of consumer acceptance of the

product. The physical properties of a product also

affect the quality of the product and the price of the

product. Making mackerel fish balls with various

variations of the addition of carrageenan flour may

cause changes in the physical properties of the

mackerel fish balls producing.

B. Gel Strength

Testing the hardness level of mackerel fish balls was

carried out with the Llyoid Instrument. The testing

technique is carried out by determining the maximum

force required to break (share force) the cooked

mackerel fish ball product. The maximum force (N)

here is the maximum force required to give the

formation of the meatball. This means that the higher

the force required to break with the same level of

damage.

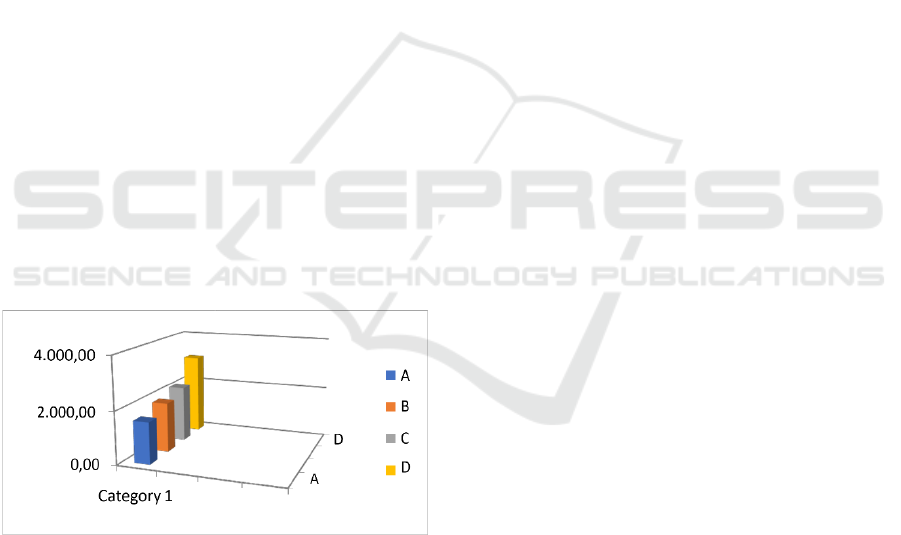

Figure 1: Gel Strength of Mackerel Meatballs with the

Extra

of Different Carrageenan Flour.

In Figure 1 it can be seen that the gel strength of

the mackerel fish ball increased with the increase in

the concentration of the addition of carrageenan flour.

The gel strength of the mackerel fish balls produced

ranged from 1,673.17 Blooms (A treatment) to

3,090.61 Blooms in D treatment.

The results of statistical analysis ANOVA test

showed that the addition of carrageenan flour had a

significant effect (α < 0.05) on the real gel strength (α:

0.05) with the extra of carrageenan flour as much as

7.5%. This shows that the extra of carrageenan flour

is directly proportional to the increasing in gel

strength of mackerel fish balls. The difference in gel

strength of the mackerel balls produced for each

treatment was caused by the extra of carrageenan

flour from the mackerel fish balls. The results showed

that the extra of carrageenan flour as much as 0%,

2.5% and 5% had a different effect on the addition of

carrageenan flour as much as 7.5%. This shows that

the addition of carrageenan flour is directly

proportional to the increasing in gel strength of

mackerel fish balls. The difference in gel strength of

the mackerel fish ball produced for each treatment

was caused by the extra of carrageenan flour.

The ability of meatballs to form a compact

structure is basically due to the ability of the meat to

bind together. This bonding process is caused by

heating. Carrageenan in fresh meat does not show a

tendency to bind to each other (Peranginangin, 1987

in Dwi, Wiwin. 2008).

Fish meat protein, especially myosin, is

responsible for the good or bad formation of gels and

emulsions in soft meat products. Small myosin

aggregates are thought to play a role in the formation

of fat emulsions. In addition, these aggregates have

the ability to expand when heated and bind all

components including water. It is determining the

consistency of the meatball product (Schut, 1976 in

Dwi, Wiwin. 2008).

The addition of salt also serves to increase the

ionic strength of the meat and dissolve the

actomyosin of the meat into cell forms which it if

heated for a certain time will form an elastic gel.

Starching can be viewed as a simple filler or binding

agent for protein gels. Gel formation is also

influenced by the addition of a thickening agent

added to the meatball which will react with starch to

form a structure.

C.

Test

1)

Bite Test

Elasticity affects a person's palatability to a

product.

The elasticity is based on the ease of

chewing time

without losing the proper tissue

properties.

Elasticity involves the easy initial

penetration of the

teeth into the meatball, the ease of

chewing into

smaller pieces and the amount of

residue left during

mastication (Lawrie, 2003 in

Sudrajat, G. 2007).

The results of the bite test on

mackerel fish balls

with the addition of different

carrageenan flours are

compact and sturdy, so the

texture of the meatballs

formed becomes chewy

(Fitrial et.al. 2005, in Dwi,

Wiwin. 2008). The bite

test of the mackerel fish balls

Improving the Quality of Fishery Products by Maintaining Ideal Composition of Seaweed Caragenan: Kappaphycus Alvarezii

1155

produced ranged from 2.69 (weak) to 5.79 (chewy

and acceptable).

Mackerel fish balls which have

chewy and acceptable

properties are the addition of

2.5% carrageenan flour.

(treatment B).

The results of the ANOVA test showed that the

addition of carrageenan flour had a significant effect

(α < 0.05) on the results of the bite test (elasticity) of

the mackerel fish balls produced. The results of

further tests with Duncan's DMRT as shown showed

that the addition of carrageenan flour had a

significantly different effect for all treatments on the

value of the bite test.

The addition of carrageenan flour can help the

formation of gels that can improve the elasticity

properties. The consistency of carrageenan gel

formation can be influenced by several factors,

including the type and concentration of carrageenan

and the presence of ions. Carrageenan can bind well

with water and protein and the meatballs also have the

strength to withstand external pressure and return to

their original shape after the pressure is removed.

This property is called ductility.

2)

Folding Test

The folding test is one of the tests on the quality

of

the meatball gel. The quality level used is on a scale of

1 to 9 (1 = completely cracked/cracked into pieces

when pressed with both fingers, up to 9 = not cracked

when folded in four). The value of the folding test

results obtained is 2.78 (cracked but still united when

folded in half) to 5.70 (slightly cracked when folded

in half to slightly cracked when folded in four).

The results of the folding test on mackerel fish

balls with the addition of different carrageenan flour

were directly related to the gel texture, especially the

gel strength. The higher folding test value, the better

the gel strength of the product. The higher

concentration of carrageenan flour is in the mackerel

fish ball product or it is higher the gel strength. The

results of the ANOVA test showed that the addition

of carrageenan flour had a significant effect (α < 0.05)

on the value of the folding test of mackerel fish balls

produced and the results of further tests with

Duncan's DMRT showed that the treatment of adding

carrageenan flour of 0% gave a significantly different

effect with treatment 2, 5%, 5% and 7.5%. The extra

of carrageenan flour treatment of 2.5% gave a

significantly different effect with the treatment of 5%

and 7.5%. However, the extra of carrageenan flour by

5% did not give a significantly different effect from

the 7.5% treatment.

3)

pH

The pH measurement aims to determine the

acidity

level of mackerel fish balls caused by

hydrogen

ions (H+). The final product that undergoes

cooking

and salting depends on the pH of the meat.

High temperatures increase the rate of pH

decrease while low temperatures inhibit the rate of pH

decrease (Suparno, 1998 in Sudrajat, G. 2007). The

average pH value of mackerel fish balls with the extra

of carrageenan flour is different. The pH of mackerel

fish balls ranged between 7.15 and 7.17, which means

that the acidity level of the mackerel fish balls which

produced in a neutral range. Based on the results of

the ANOVA test, it showed that the extra of

carrageenan flour had no significant effect (α > 0.05)

on the pH value of mackerel fish balls.

D.

Organoleptic Quality of Mackerel Fish Meatballs

with the Addition of Carrageenan

Sensory test conducted in this study is a preference

test which includes appearance, color, aroma, taste

and texture. In Table 1 it can be seen that the results

of the calculation of the average organoleptic value

could be done by the preference test (hedonic test) of

mackerel fish balls with the addition of carrageenan

flour.

Table 1: Results of the Hedonic Organoleptic Test on

mackerel fish balls with the addition of different

carrageenan flour.

No Parameter Treatment

AB C D

1. Visibilit

y

3.06 3.76 3.78 3.40

2. Colo

r

3.64 3.87 3.96 3.56

3. Aroma 3.77 3.87 4.48 3.76

4. Taste 3.96 4.69 4.56 3.76

5. Texture 3.27 4.34 4.15 3.48

Total 17.58 20.28 20.65 17.78

Average 3.58 4.09 4.17 3.59

Note: From 15 Panelis

The physical test results obtained were very

significant where the addition of carrageenan had a

significant effect (α < 0.05) on gel strength, fold-test

and bite-test values, but had no significant effect (α>

0.05) on the pH of mackerel fish balls. The hedonic

test results showed that the addition of carrageenan

flour had a significant effect (α < 0.05) on the

appearance, taste and texture parameters, but had no

significant effect (α > 0.05) on the color and aroma

parameters on consumer preferences for mackerel

fish balls.

The extra of carrageenan flour with a

concentration

of 2.5% gave the best effect on the

elasticity quality

of mackerel fish balls. The chemical

characteristics of

mackerel fish balls with the

addition of carrageenan

flour of 2.5% which has a

water content of 66.04%,

protein content of

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1156

11.87%, fat content of 1.13%,

carbohydrate content

of 8.59%, crude fiber content of

9.61%, ash content

of 1.53%,. The physical

characteristics of mackerel

fish balls with the addition

of carrageenan flour as

much as 2.5% are having a gel

strength of 3,090.61

Bloom, a pH of 7.17, a bite test

value of 5.79

(acceptable, slightly chewy), and a

folding test

value of 2. 78 (slightly cracked when

folded in

half). The organoleptic value with the

hedonic test

of mackerel fish balls with the addition

of

carrageenan flour of 2.5% and it has an appearance

parameter value of 3.76 (neutral to like), while the

color parameter value is 3.87 (neutral to like), and the

aroma parameter value is 3.87 ( neutral to like). Based

Table 1 result can be identified that the value of

the

taste parameter is 4.69 (like to very like) and the

value

of the texture parameter is 4.34 (like).

5 CONCLUSION

Based on the tes t which already done in previous, it

can be concluded that treatment A1 (meatballs with

the addition of carrageenan 2.5%), treatment A2

(meatballs with the addition of carrageenan 5%),

treatment A3 (meatballs with the addition of

carrageenan 7, 5%). The composition ideal of

carrageenan flour with a concentration of 2.5%

could

led the best effect on the elasticity quality of

mackerel

fish balls. The organoleptic value with the

hedonic

test of mackerel fish balls with the extra of

carrageenan flour of 2.5% has an appearance

parameter value IS 3.76 (neutral to like). The color

parameter value is3.87 (neutral to like), and aroma

parameter value is 3.87 (neutral to like). The taste

parameter is 4.69 (like to very like) and the value of

the texture parameter is 4.34 (like). Other material

such water content is 66.04%, and protein content is

11.87%, while fat content is 1.13%. The essential

material such as carbohydrate content is 8.59%,

crude

fiber content is 9.61%, and ash content is

1.53%.

ACKNOWLEDGEMENTS

There were many barriers in doing this research

both

essential matters and non-essential matters. For

fulfill

this research requirements, there are several

figures

need to be appreciated as follows:

1.

The Director of Politeknik Negeri Nunukan, who

already guided us for improving the essential

matters for this research.

2.

Vice Director 1 of Politeknik Negeri Nunukan,

who already motivated us in achieving the

research performance.

The Head Branch Office of Nunukan BNI, who

allowed us to make this research and also allowed

their customers to be our respondents.

REFERENCES

Anggadireja,et all. (2006). Rumput Laut (Pembudidayaan,

Pengolahan dan pemasaran) Komoditas

Perikanan

Potensial. Jakarta: Penebar

Swadaya.

Dewi Wulan, et all. (2015). Analisis Pengendalian Kualitas

Menggunakan Statistical Quality Control (SQC)

Produk Sepatu Pria Untuk Meminimumkan Produk

Cacat (Studi Kasus pada CV. Kabupaten Bandung:

Valentino Shoes, ISSN:2460-6545.

Distantina, S., Fadhilah, Rochmadi, Moh. Fahrurrozi, dan

Wiratni.(2010). Proses Ekstraksi Karagenan Dari Eu-

chema Cottonii. Seminar Rekayasa Kimia dan Proses.

Ega, L., C. G. C. Lopulalan, dan F. Meiyasa.(2016). Artikel

Penelitian Kajian Mutu Karaginan Rumput Laut

Euchema Cottonii Berdasarkan Sifat Fisiko- Kimia

pada Tingkat Konsentrasi Kalium Hidroksida (KOH)

yang Berbeda. Jurnal Teknologi Aplikasi Pangan. 5(2)

:38-44.

Erick, Satryo. (2016). Cara Mudah Mengenali Bakso Yang

Menggunakan Boraks.

http://www.kaskus.co.id.

Inglett, G. E. (Ed). (1974). Wheat: Production and

Utilization. Wesport, Connecticut: The AVI Publishing

Company, Inc.

Ministry of Fisheries and Marine Affairs RI Agency (2016).

Research and Human Resources for Marine and

Fisheries. Fisheries Training and Extension Center.

Ismanto, A dan Sumarna, D. (2016). Pengaruh Penambahan

Karagenan dengan Level Yang Berbeda Tehadap

Komposisi Kimia, Kualitas Fisik, Sensoris dan

Mikrostruktur Sosis Ayam. Buletin Peternakan. Vo.

40(1):58-65.

Juminda, Fitra (2015, Juni). Aneka Olahan Ikan. http//

www.slabance.blogspot.com./2015/aneka-olahan-ikan-

sektor-perikanan.html.

Kementerian Perikanan dan Kelautan RI Badan Riset dan

SumberDaya Manusia Kelautan dan Perikanan. (2016).

Balai Pelatihan dan Penyuluhan Perikanan. Bahan

Pengisi dan Bahan Pengikat Produk Olahan Berbahan

Surimi.

Parlina, Iin. (2009). Karagenan, produk olahan rumput laut

merah Indonesia yang sangat bermanfaat.

Peranginangin, R. S., Wibowo, dan Y. N. Easy. (1999).

Teknik Pengolahan Surimi, Balai Penyuluhan

Perikanan

Laut, Jakarta: Puslitbang Perikanan,

Rasyid,W M. (2015). Potensi Ekonomi Ikan Dan Produk

Perikanan Indonesia Dalam Lingkup

Masyarakat

Ekonomi ASEAN. Proceeding

SENDI_U.

R

etrieved

from

http://www.unisbank.ac.id/ojs/index .php/sendi_u/

article/view/3286.

Improving the Quality of Fishery Products by Maintaining Ideal Composition of Seaweed Caragenan: Kappaphycus Alvarezii

1157