Quantity and Composition of Liquid Products from Used Motorcycle

Tire Pyrolysis

Sitti Sahraeni, Ibnu Eka Rahayu and Helda

Department of Chemical Engineering, Polytechnic State of Samarinda, East Kalimantan, Indonesia

Keywords: Used Tires, Pyrolysis, Liquid Products, Yield, Temperature.

Abstract: Used tires are very difficult to degrade naturally. So far, the handling of used motorcycle tires has only been

hoarding or burning directly in the open air. This is less able to reduce used tires because it will

cause

problems with pollutant gases resulting from burning used materials that can pollute the

environment. The

pyrolysis process is one way to minimize waste restrictions. The purpose of this study is to determine the

effect of the temperature of the pyrolysis of used motor vehicle tires on the yield of liquid products and to

determine the composition of the liquid product at the highest yield. The pyrolysis process of used tires was

carried out for 2 hours and 1000 grams of raw material. Pyrolysis was carried out at

various operating

temperatures, namely 450 ° C, 500 ° C, 550 ° C, 600 ° C, and 650 ° C without using a

catalyst. The yield

of liquid products produced at operating temperatures were 450 ° C, 500 ° C, 550 ° C,

600 ° C, and 650 °

C respectively 41.31%, 55.07%, 51.49%, 41 , 99%, and 36.89%. The liquid product

composition test for

used motor vehicle tires at a temperature of 550 ° C was analyzed using GC-MS (Gas Chromathography-

Mass Spectrometer), the hydrocarbon chains were obtained as follows: (C5-C12) as much as 95.12% and

(C13-C20) as much as 4, 88%.

1 INTRODUCTION

Used tires are very difficult to degrade

naturally by

nature. So far, the handling of used motorcycle tires

has only been carried

out by hoarding or burning

directly in the

open air. This is less able to reduce

used tires, because it will cause problems with

pollutant gases resulting from burning used tires that

can pollute the environment

.

Another way to process

used tires is by processing them into handicraft

products. Handling used tires is

usually done using

the already popular method, namely 3R (Reuse,

Reduce, Recycle), but that method has weaknesses. A

better alternative for dealing with waste or used

tires is to convert them into other

forms, namely

liquid fuels as alternative

energy. Rubber-based tires

are one of the

synthetic polymers (polystyrene).

Polystyrene is derived from petroleum so the

best

solution at this time is to return to the

form of oil.

Polystyrine cracking is a way of reducing this

waste. Cracking is the process of breaking polymer

chains into compounds

with lower molecular

weights. Although this method is included in

recycling, the results of recycling do not return to the

form of tires or rubber. This used tire cracking uses

the

pyrolysis method (Handono, M. R. T., 2017). The

tire composition

consists of Styrene-butadiene

rubber (SBR) 62.1%, Carbon black 31%, Extender

Oil 1.9%, Zinc Oxide 1.9%, Stearic Acid 1.2%,

Sulfur 1.1%, Accelerator 0 ,7% (Williams &

Besler,

1995). Where Styrene-butadiene

rubber (SBR) is a

synthetic rubber that will

be converted into another

form, namely

liquid fuel as an alternative energy.

Based on the results of research conducted by (Muis

et

al., 2019) it was found that the compounds

contained in the pyrolysis oil of used tires have the

following hydrocarbon chains: (C1- C5) as much as

0.33%, (C5-C12) as much as 88.96% and (C10-C28)

10.71%. The hydrocarbon compounds found in the

oil

from the pyrolysis of used tires contain a lot of

aromatic compounds, wherein the

aromatic

compounds are derivatives of petroleum

hydrocarbon compounds which function as fuel

components. Many researches on pyrolysis using

used motor vehicle tires have been carried out, one

of which was conducted by Muis et al., (2019) This

researcher used used tires as raw materials with

variations in catalyst mass. Pyrolysis was carried out

at a temperature of 400⁰C within 3 hours, the oil

conversion obtained increased with increasing

1142

Sahraeni, S., Eka Rahayu, I. and Helda, .

Quantity and Composition of Liquid Products from Used Motorcycle Tire Pyrolysis.

DOI: 10.5220/0010961000003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1142-1145

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

catalyst

mass. The highest yield was found in the

180 gram catalyst weight of 41.073%. Dumilah &

Kholidah, (2019) conducted a

study using used two-

wheeled motorcycle

tires as raw materials with a

temperature

variation of 200⁰C – 300⁰C in an

operating time of 3 hours and using a zeolite catalyst.

The best results obtained were 58.6030% at

a

temperature of 300⁰C. To get maximum and

efficient results, the pyrolysis process is

carried out

without the use of a catalyst, this aims to avoid the

activation of the catalyst

which is quite long so that

it can shorten the

time used for the pyrolysis process.

Research on the effect of pyrolysis

temperature

without a catalyst using bicycle tire waste raw

materials with

temperature variations of 450 C, 500

C, 550 C, 550 C, and 650 C. The percent yield of

the liquid product produced was 49.6% with

the

optimum temperature of 600 C with a

reaction time

of 39 minutes.

The percent yield generated on research

Debalaxmi is higher as many as 49.5% compared to

the research conducted by Muis., Et al (2019), which

is

only about 41.07%, this is because the

higher

the temperature the more more liquid

product is

produced and can reduce the

reaction time required.

Therefore, the

pyrolysis process of used motorcycle

tires without using a catalyst in temperature

variations is carried out at medium to high

temperatures, it is hoped that it can produce

a

maximum and faster percent. The purpose of this

study was to

determine the effect of the pyrolysis

temperature of used motor vehicle tires on the yield

of liquid products and to determine the composition

contained in the liquid

products at the highest yields.

2 METODHOLOGY

This study uses quantitative and qualitative

analysis.

used motorcycle tires are pyrolyzed in a reactor with

variations in temperature. Quantitative analysis is

carried out by weighing the resulting product. Used

motorcycle tires are cleaned and dried and then

reduced in size by 2 cm. A total of 1000 grams were

put into the pyrolysis apparatus

and the process was

run for 2 hours with

variations in pyrolysis time

(450, 500, 550, 600, 650) °C. The resulting liquid

product is

then weighed and its composition

analyzed using GC-MS

3 RESULT AND DISCUSSION

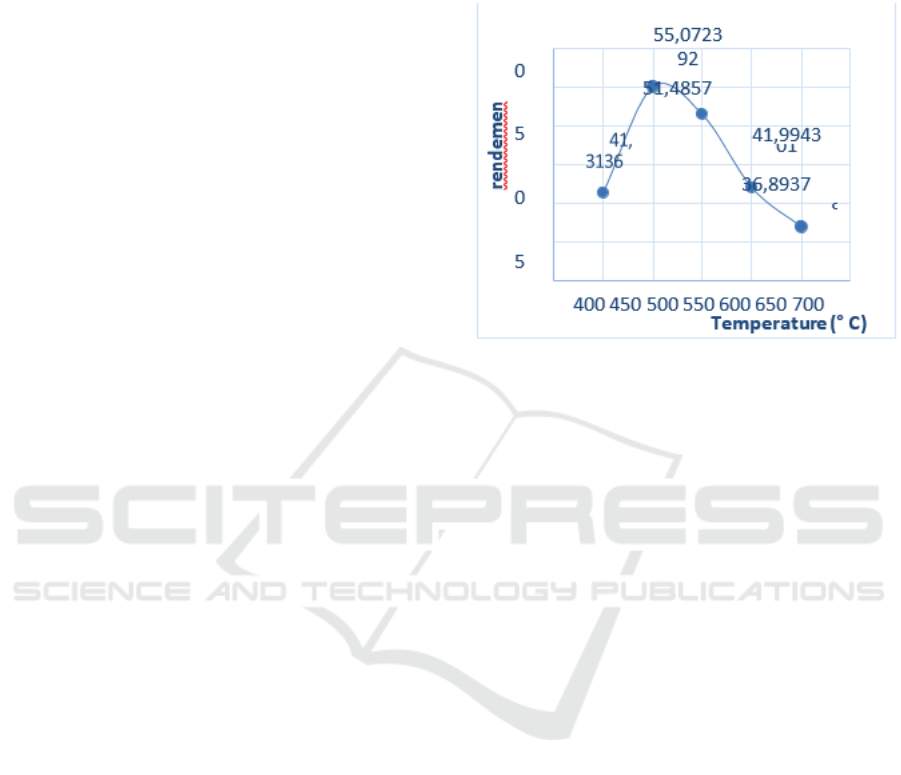

The relationship between temperature and the yield

of liquid products

can be seen in Figure 1

Figure 1: The Effect of Temperature

Relationship on the

Yield of Liquid Products.

Figure 1. shows that when the pyrolysis

process

is carried out, the percent yield

increases from a

temperature of 450 °C to

500 °C, this is because at

high temperatures the carbon chain will be more

easily cracked than at low temperatures so that the

yield of liquid products produced will be more and

more (Kholidah , 2018). The yield

percentage

increased with the initial increase

in temperature and

after the temperature of 550oC the percentage yield

decreased. Jung et al., (2013) explained this

phenomenon

that after reaching the optimal

temperature, several secondary reactions such as

polyaromatic formation reactions are

initiated during

the pyrolysis of used tires which reduce the yield

of liquid products. This is also in accordance with

research conducted by Udyani et al (2018), where the

yield produced will decrease with increasing

temperature from pyrolysis. This is because

the

higher the temperature, the more used tires break

down into non-condensable gases (CO, CO2, CH4,

etc.) so that less liquid is

produced. Based on Figure

1 shows that the

temperature of 500 °C is the optimal

temperature because it reaches the highest

yield of

55.07% which when the temperature

is increased to

550 °C the liquid product

decreases to 51.49% with

a pyrolysis

process time of 2 hours, while in the

research conducted by Dumilah and Kholidah

(2019), using temperature

variations where at the

highest temperature

of 300 °C added using a 400

gram catalyst

produced a liquid product of 58.60%,

and in

the research conducted by Muis et al.,

Quantity and Composition of Liquid Products from Used Motorcycle Tire Pyrolysis

1143

(2019) using The variation of the weight of the

catalyst which had previously been activated for 10

hours and the pyrolysis

process for 3 hours at a

temperature of 400°C resulted in the highest

percentage yield,

which was around 41.07%.

From the yield obtained, it shows that the

percent yield obtained between the pyrolysis

of used

tires using a catalyst and the

pyrolysis of used tires

without the use of a

catalyst is only a difference of

about 3.53% when compared to the results of

research conducted by Dumilah and Kholidah (2019),

and higher when compared to with research

conducted by Muis et al., (2019). The results of the

pyrolysis of used motor vehicle tires without using

a catalyst obtained a higher percent yield because

during the process it

uses a higher temperature so

that the

cracking process of used tires becomes faster

and at the optimum temperature produces more liquid

products.

The results of the pyrolysis of used motor

vehicle tires which have the highest percent

yield at

a temperature of 500 °C were

analyzed using GC-

MS (Gas Chromatoghraphy-Mass Spectrometry).

Based on Table 4.2, it shows that the

characteristics of the liquid fuel obtained have the

following hydrocarbon chains: (C5 - C12) as much

as 95.12% and (C13 - C20¬) as much as 4.88%. This

is similar to the

experiment conducted by Andry et

al., (2020) where the results of the GC-MS analysis

showed the highest hydrocarbon compounds (C5 -

C12) and included the

gasoline fraction.

Figure 2: Spectra of GC-MS Pyrolysis Oil of Used Tires.

Table 1: GC-MS analysis at a

temperature of 500 °C.

No %

Area

Molecular

Formula

Compoun

d

1.

95,12

%

C

5

- C

12

1H-Azepine,

hexahydro;

2H-

Azepine-2-One,

hexahydro;

cyclobutene,

1,2,3,4- tetramethyl;

Hexanoic acid, 6- amino

2. 4,88

%

C

13

- C

20

9-Octadecenal, (Z)

Based on research conducted by Muis., et al

(2019), the results of pyrolysis

analyzed using GC-

MS are the results of pyrolysis that have the highest

conversion,

namely 41.073% at a temperature of 400

°C. The analysis results obtained have the

highest

hydrocarbon chain (C5 - C12) as much as 88.96%.

This shows that the

pyrolysis process using a catalyst

carried out

by Muis., et al (2019) produced the

same

fraction as the study without using a catalyst

but the operating temperature used was lower at

400 °C compared to the pyrolysis

experiment

without using a catalyst, which was 500 °C. . This

is due to the presence of a

catalyst so that in the

Muis., et al. (2019) experiment, the process of

breaking or breaking long chain hydrocarbons is

faster.

4 CONCLUSIONS

1. The higher the temperature, the

lower the

liquid product yield and the percent yield

obtained. The

temperature of 500 °C is the

optimal temperature where the

highest yield

percentage is 55.07%.

2. The results of the GC-MS analysis

show that

the composition of the

liquid product at a

temperature of 500 °C has the most

hydrocarbon chains (C5 - C12) as much as

95.12% which is included in the

gasoline

fraction (gasoline).

ACKNOWLEDGEMENTS

The author would like to acknowledge

the Center

for Research and Community

Service at Polytechnic

State of Samarinda

which has provided funding for

this research as well as to the Chemical Engineering

Laboratory of Polytechnic State of Samarinda as a

place for the research to be

carried out.

REFERENCES

Arahim, A. A., Widayat, dan Hadiyanto. (2020). Liquid

Fuel Production From

Motorized Vehicle

Tires

With

Pirolysis

Process. International

Coference on Science

and Applied Science,

https://doi.org/10.1063/5.0030380.

Arita, S., Assalami. A., Naibaho.D.I. (2015). Proses

Pembuatan Bahan Bakar Cair

Dengan Memanfaatkan

Limbah Ban Bekas Menggunakan Katalis Zeolit.

Teknik Universitas Sriwijaya

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1144

Damayanthi, Reska dan Martini, R. (2009). Proses

Pembuatan Bahan Bakar Cair

Dengan Memanfaatkan

Limbah Ban Bekas Menggunakan Katalis Zeolit Y

Dan Zsm-5. Institutional Repository, Diponegoro

University, 8.

Dumilah, T. R., & Kholidah, N. (2019). Pengaruh

Temperatur terhadap Hasil

Pirolisis Limbah Ban

menjadi Bahan Bakar Cair menggunakan Katalis

Zeolit.

Juma, M., Koreňová, Z., Markoš, J., Jelemensky, L., &

Bafrnec, M. (2007). Experimental study of pyrolysis

and combustion of scrap tire. Polymers for

Advanced

Technologies, 18(2), 144–148.

Miandad, R., Nizami, A. S., Rehan, M., Barakat, M. A.,

Khan, M. I., Mustafa, A., Murphy, J. D. (2016).

Influence of temperature and reaction time on the

conversion of polystyrene waste to

pyrolysis liquid oil.

Waste

Management.

https://doi.org/10.1016/j.wasman.2016.09.023

Muis, L., Prabasari, I. G., & Suyana, N. (2019). Pengaruh

Berat Katalis Zeolit

Alam terhadap Pencairan Limbah

Ban dalam Bekas Kendaraan Bermotor Roda Dua

Menjadi Bahan Bakar Cair. Jurnal Daur Lingkungan,

2(2), 63. https://doi.org/10.33087/daurling.v2i2.

29

Nisar, J., Ali, G., Shah, A., Iqbal, M., Ali, R., Anwar, F.,

Salim, M. (2019). Fuel

production from waste

polystyrene via

pyrolysis : Kinetics and product

distribution. Waste Management, 88, 236–247.

https://doi.org/10.1016/j.wasman.2019. 03.035

Onwudili, J. A., Insura, N., & Williams, P. T. (2009).

Composition of products

from the pyrolysis of

polyethylene and polystyrene in a closed batch reactor:

Effects of temperature and residence

time.

Journal of

Analytical

and Applied Pyrolysis, 86(2), 293–303.

https://doi.org/10.1016/j.jaap.2009.07. 008

Handono,M.R.T. (2017). Pembuatan Bahan Bakar Cair

Dengan Memanfaatkan

Limbah Ban Bekas

Menggunakan Katalis Limbah Bekas Perengkahan

Minyak Bumi PT. Pertamina RU III

Quantity and Composition of Liquid Products from Used Motorcycle Tire Pyrolysis

1145