The Effect of Air Flow Rate on the Production of Active Charcoal

from Palm Oil Shells with Partial Oxidation Method

Firman and Sitti Sahraeni

Department of Chemical Engeneering, Polytechnic State of Samarinda, East Kalimantan, Indonesia

Keywords: Activated Charcoal, Oil Palm Shell, Air Flow Rate, Partial Oxidation, Pyrolysis.

Abstract: Palm kernel shell is one of the palm oil processing wastes which is quite large, reaching 6.5% of 1 ton of

palm

oil. This shell can be used as an ingredient for making activated charcoal. Activated charcoal is widely

used as an adsorbent, gas purification, water purification and so on. The palm kernel shell (PKS) is the

hardest part of the components found in oil palm. Oil palm shell contains 26.6% cellulose and 27.7%

hemicellulose which are

good for making activated charcoal. This study aims to determine the effect of air

flow rate on activated charcoal

according to SNI No. 06-3730-1995. Carbonization and activation are

carried out using pyrolysis with the

principle of partial oxidation. The pyrolysis process was carried out at

air flow rates of 20, 25, 30, 35 and 40 L/ min for 5 hours. The best results were shown at an air flow rate of

35 L / min with a product yield of 20%, water content of 5.82%, ash content of 7.51%, volatile matter

content of 8,73%, fixed carbon 77,94%, and

absorption. iodine of 750,1403 mg / g. These results have met

the SNI 06-3703-1995 standards.

1 INTRODUCTION

Oil palm shells contain 26.6% cellulose and

27.7% hemicellulose which are good for making

activated charcoal. The average annual production of

oil palm fruit is 5.6 million tons, which means that

around 364,000 tons of shells are produced. This

number will continue to increase in line with the

increase in palm oil production. With the availability

of this waste, a further process is needed to convert

palm oil shell waste into a product that has high

economic value such as activated charcoal

(Yuliusman, 2015).

The development of industry is increasing

along with the development of science and

technology, so that industry is one of the important

sectors that supports the Indonesian economy.

However, there are several industries that are

developing slowly, in this case the charcoal and

activated charcoal manufacturing industry. Activated

charcoal is widely used as adsorbent, gas purification,

water purification and so on. Activated charcoal can

be made from all materials containing charcoal, both

organic and inorganic, provided that the material has

a porous structure.

Activated charcoal is a porous solid containing

85-95% carbon, produced from carbon-containing

materials by heating at high temperatures. Charcoal

is a porous solid material

which is the result of

combustion of materials

containing carbon

elements, while activated charcoal

is charcoal that

is activated by immersion in

chemicals or by

flowing hot steam into the material,

so that the

pores of the material become more open with a

surface area range from 300 to 2,000 m2/g. The

wider

surface of activated charcoal has an impact on the

higher absorption of gas or liquid materials. The

methodology used includes the process of preparing

activated charcoal, absorption and testing.

Research on the manufacture of activated

charcoal with the pyrolysis method conducted by

Hasan et al., 2020 which the study varied the addition

of the amount of N2 gas, namely without the addition

of nitrogen gas, the addition of nitrogen gas in

batches, and the addition of nitrogen gas continuously

with air flow rates of 0.5 L/min and 1 L/min. The best

pyrolysis conditions are with nitrogen gas flowing

continuously at 1 liter/minute. characteristics of

activated charcoal with a yield value of 42%, water

content 3.23%, ash content 2.73% volatile substances

28.37%, fixed carbon 66.16%. Research on the

pyrolysis mechanism namely the production of

pilot scale

activated charcoal from oil palm shells

1138

Firman, . and Sahraeni, S.

The Effect of Air Flow Rate on the Production of Active Charcoal from Palm Oil Shells with Partial Oxidation Method.

DOI: 10.5220/0010960900003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1138-1141

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

(cks), the study varied the pyrolysis time and

temperature. In this variation, the yield is 33-52%,

water content 2- 5%, volatile matter 20-70%, ash

content 2-10% and fixed carbon 22-70%.

Yuliusman, 2015 conducted research with the

title of making activated carbon from palm oil shells

with KOH and N2/CO2 as activating ingredients.

Chemical activation with KOH 75% and physical

activation at a temperature of 850°C using N2 gas for

1 hour followed by CO2 gas for 1 hour.

Characteristics produced by the activation process at

a temperature of 850°C have an iodine number of 884

mg/g with a water content of 13.6%, an ash content

of 9.4% and a concentration lost on heating of 23.1%.

In this study using the pyrolysis method with the

principle of partial oxidation with a pilot plant scale

with a raw material capacity of 5 kg/batch, physically

activated not using pure N2 gas and CO2 but utilizing

excess N2 gas in the air by limiting the air flow rate

which aims to increase the pores. so that activated

charcoal has a high absorption capacity. The

advantage of this method is to use internal heat or heat

generated from the oxidation reaction that arises by

limiting the air flow rate in the raw material

combustion process so that it can reduce combustion

efficiency. In addition, with the air flow rate, biomass

can create new porosity which can affect the

combustion process and the resulting liquid smoke.

The purpose of this study was to determine the

effect of air flow rate on activated charcoal using oil

palm shells with a pyrolysis process using the

principle of partial oxidation in a pilot plant scale with

a raw material capacity of 5 kg/batch, and to

determine the quality of charcoal produced by

pyrolysis of oil palm shells. One of the advantages of

making activated charcoal with the partial oxidation

method is that at the activation stage it does not use

chemicals but utilizes nitrogen gas in the air as an

activator by limiting oxygen entering through the air

flow rate.

2 METHODOLOGY

A total of 5 kg of PKS shells are dried and

cleaned then the pyrolysis process will be carried out

using a pyrolysis device which is assembled

consisting of a raw material sleeve, combustion

chamber, compressor and condenser. The pyrolysis

combustion process uses coals that are inserted

through the bottom hole of the pyrolysis and held for

± 10 minutes. Then the compressor is turned on and

adjusts the air flow rate on the flow meter according

to the air flow rate used. Cooling water is run in the

condenser section. The process runs for 5 hour. The

resulting charcoal is then analyzed for absorption

of

iodine by the SNI method No. 06-3730-1995

Calculate the absorption of activated charcoal against

iodine using the following formula:

Iodine NUmber 𝐼

=

10 −

𝑉

x 𝑁

𝑁

x126,9 x fp × N

W

Keterangan:

V

tio

=

Required volume

of sodium

thiosulfate

solution (ml)

N

tio

= Normality of sodium thiosulfate (N)

solution

N

iod

= Normality of I

2

solution

126,9 = Iodine atomic weight

W

= Sample mass (grams)

3 RESULT AND DISCUSSION

The yield of activated charcoal produced relatively

decreases as air is added or flowed into the

reactor

during the pyrolysis process.

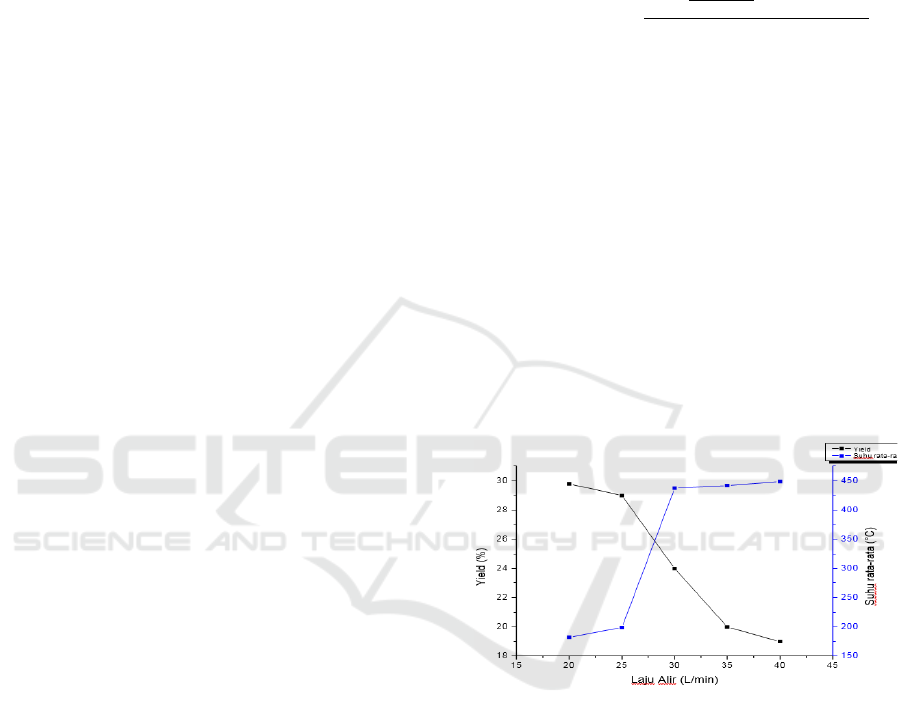

Figure 1: The relationship between the air flow rate and

the average temperature of pyrolysis with the yield of

activated charcoal produced.

In Figure 1 it can be seen that at a flow rate of 20

L/min the activated charcoal product produced is at

the maximum yield, which is 29.8%, while at a flow

rate of 40 L/min the minimum yield of activated

charcoal product is 19%. . It can be seen that the yield

continues to decrease along with the addition or flow

of air into the reactor, namely the more oxygen and

nitrogen gas that is circulated, the yield of activated

charcoal obtained is also relatively decreased (Hasan

et al., 2020). In addition, temperature is also very

influential on the pyrolysis process. The higher the

temperature, the better

the

decomposition/decomposition process, but the less

The Effect of Air Flow Rate on the Production of Active Charcoal from Palm Oil Shells with Partial Oxidation Method

1139

amount of charcoal obtained while the more liquid

and gas results, due to the large amount of

decomposed and evaporated substances. The

maximum yield was obtained at an average

temperature of 182.68 °C at 29.8% and the minimum

yield was obtained at a temperature of 448.98 °C at

19%, this is in accordance with the statement of Haji

et al., 2010 that due to the high temperature some

charcoal turns into ash and volatile gases, so the yield

tends to be low. It can be concluded that the oxygen

and nitrogen that are flowed into the reactor help the

pyrolysis process occur perfectly, the incoming

oxygen reacts with the activated charcoal to become

CO

2

which causes the amount of solids to decrease.

The function of oxygen here is to oxidize the material

while nitrogen is a physical activating agent. The

absorption of iodine (iod adsorption) indicates the

ability of activated carbon to adsorb components with

low molecular weight. Activated carbon with high

Iodine absorption microstructure and pores.

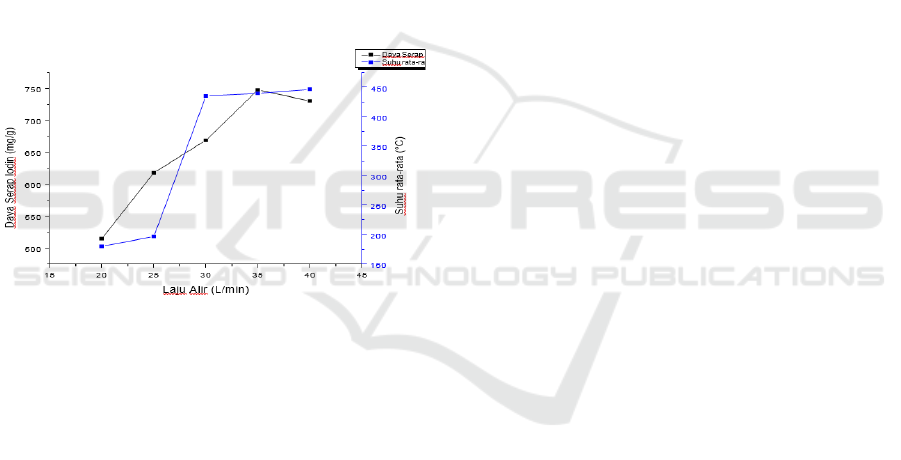

Figure 2: The relationship between the air flow rate

and the

average temperature of pyrolysis on the

absorption of

iodine in activated charcoal.

The absorption of iodine (iod adsorption)

indicates the ability of activated carbon to adsorb

components with low molecular weight. Activated

carbon with high

Iodine absorption means it has a

larger surface area

and also has a larger

microstructure and pores.

Figure 2. It can be seen that the higher the air flow

rate used in the pyrolysis process, the higher the

temperature rise and the higher the iodine absorption.

This is because the higher the air flow rate used will

reduce volatile substances and increase the amount of

fixed carbon in activated charcoal, the more iodine

will be adsorbed so that the greater the reduction in

the concentration of iodine solution which causes the

higher the absorption of iodine. From Figure 2. the air

flow rates are 20 L/min, 25 L/min, and 30 L/min with

an average temperature of 182.68 °C, 199.12 °C,

437.50 °C, the results of absorption analysis are

obtained. Iodine of 517,0282 mg/g, 620,1861 mg/g,

and 671,1982 mg/g that have not yet entered the

standard, this is due to the oxygen and nitrogen

entering the pyrolysis process has not been

maximized which causes the pyrolysis process to not

run properly. The best results for the absorption of

iodine by activated charcoal in this study were shown

at the air flow rate of 35 L/min of 750.1403 mg/g,

these results met the quality standard of activated

charcoal according to the SNI 06-3703-1955

standard, which was 750 mg /g.

4 CONCLUSIONS

1. The air flow rate reaches the optimum

condition at a speed of 35 L/min. At the above

optimum conditions, the activated charcoal

has already experienced a saturation point.

2. The best results are shown at the air flow rate

an iodine absorption capacity of 750.1403

mg/g. This result has met the standard of SNI

06-3703-1995.

ACKNOWLEDGEMENTS

The author would like to acknowledge the Center for

Research and Community Service at Polytechnic

State of Samarinda which has provided funding for

this research as well as to the Chemical Engineering

Laboratory of Polytechnic State of Samarinda as a

place for the research to be carried out.

REFERENCES

Ridhuan, K., Irawan, D., Zanaria, Y., & Adi, N. (2018).

Pengaruh Cara Pembakaran Pirolisis Terhadap

Karakteristik Dan Efisiensi Arang Dan Asap Cair

Yang Dihasilkan. Sntt, 141– 150.

Sudradjat, R., & Pari, G. (2011). Arang Aktif :

Teknologi Pengolahan dan Masa Depannya. In Badan

Penelitian dan Pengembangan Kehutanan (pertama).

Badan Penelitian dan Pengembangan Kehutanan.

Turmuzi, M., Tua, A. O. S., & Fatimah. (2015). Pengaruh

Temperatur Dalam Pembuatan Karbon Aktif Dari

Kulit Salak ( Salacca

Sumatrana ) Dengan Aktifator.

Jurnal Teknik

Kimia USU, 4(2), 59–64.

Wahyuni, I., & Fathoni, R. (2019). Pembuatan

Karbon

Aktif Dari Cangkang Kelapa Sawit

Dengan Variasi

Waktu Aktivasi. Jurnal

Chemurgy, 3(1), 11.

https://doi.org/10.30872/cmg.v3i1.2776

Wang, P., Zhang, J., Shao, Q., & Wang, G. (2018).

Physicochemical properties evolution of chars from

palm kernel shell pyrolysis. Journal of

Thermal

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1140

Analysis and Calorimetry, 133(3), 1271–1280.

https://doi.org/10.1007/s10973-018-7185-z

Yek, P. N. Y., Liew, R. K., Osman, M. S., Lee, C. L.,

Chuah, J. H., Park, Y. K., & Lam, S. S. (2019).

Microwave steam activation, an innovative

pyrolysis

approach to convert waste palm shell into highly

microporous activated carbon. Journal of

Environmental Management, 236(August 2018), 245–

253. https://doi.org/10.1016/j.jenvman.2019.01.010

Yuliusman. (2015). Pembuatan karbon aktif dari

tempurung kelapa sawit dengan bahan

pengaktif KOH

dan gas N

2

/CO

2

. Seminar Teknologi Dan Rekayasa

(SENTRA), 978–979.

Yuliyanti. (2016). Pembuatan arang aktif dari sekam padi

dengan menggunakan aktivator asam phospat.

Politeknik Negeri Samarinda.

The Effect of Air Flow Rate on the Production of Active Charcoal from Palm Oil Shells with Partial Oxidation Method

1141