Development of 12 Volt Voltage Heating Element Model using Solar

Energy

Syahrul Bahari

1

, Muntasir

2

, Rosmiati

1

and Shadli Rolaskhi

3

1

Department of Mechanical Engineering, Kupang State Polytechnic, Jl. Adisucipto Penfui, Kupang,

East Nusa Tenggara, Indonesia

2

Public Health Study Program, Faculty of Public Health, University of Nusa Cendana, Jl. Adisucipto Penfui, Kupang,

East Nusa Tenggara, Indonesia

3

Department of Sociology, University of Muhammadiyah Kupang, East Nusa Tenggara, Indonesia

Keywords: Heating Element, 12 Volt Voltage, Solar Energy.

Abstract: Currently, solar energy conversion is widely used to generate heat and generate electricity. This paper

describes a heating element using solar energy as a low-voltage heating element model, focused on how to

plan and manufacture a low-voltage heating element using solar energy. The research method used is the

research and development method or Research & Development (R&D). The products resulting from this

research and development are. development of a low-voltage heating element model using solar energy. The

results of the analysis show that the research was conducted to test the heating element directly measuring the

resistance according to the length of the material. Measurements were made on the nickeline heating element

material, making the heating element model two samples, namely model one and model two. The heating

element can be interpreted as the desired amount of resistance equal to the planned amount of electrical power.

The wider the nickeline material, the greater the resistance, and the greater the electrical power, the smaller

the resistance, the smaller the power generated. The battery voltage using solar cells reaches the maximum

voltage peak during the day, the use of heating elements is adjusted at these times. The test is determined by

calculation only because the voltage and resistance are known. The amount of current is inversely proportional

to the resistance, so it can be measured as resistance, if the resistance is large, the current is small and the

resistance is small and the current is large.

1 INTRODUCTION

The development of technology is currently very

rapid from all fields, including heating element

devices of various models such as electric stoves, hair

dryers, incubators, space heaters and others. This

paper describes the process until the results of

research on the design and manufacture of heating

elements with a voltage of 12 volts using solar

energy. Heating elements on the market are mostly

high-voltage at least 110 volts, it is rare to find a

voltage of 12 volts using solar energy so that this is

the basis of this research, namely the absence of a

heating element using a 12 volt battery charged with

solar energy using energy-efficient solar cells. and

environmentally friendly. Based on this description,

answering the existing problems focused on how to

plan and make a 12 volt heating element using solar

energy. Judging from these problems, this paper aims

to develop a 12 volt low-voltage heating element that

is energy efficient and environmentally friendly. So

far, consumers only get a 12-volt heating element,

which must be converted from alternating current

(AC) electricity to direct current (DC) using an

inverter. Some supporting research, among others,

research on photovoltaic solar water heating

systems (Fanney and Dougherty, 1997) states that

using photovoltaic cells to produce electrical

energy is connected in several heating elements.

The microprocessor controller continuously selects

the appropriate heating element so that the resistive

load causes the photovoltaic array to operate at or

near maximum power. Photovoltaic solar thermal

systems eliminate the components most commonly

associated with solar thermal heating systems.

Although currently more expensive than solar

thermal heating systems, the continued decline in

photovoltaic cell prices is likely to put these

Bahari, S., Muntasir, ., Rosmiati, . and Rolaskhi, S.

Development of 12 Volt Voltage Heating Element Model using Solar Energy.

DOI: 10.5220/0010959600003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1091-1096

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1091

systems in competition with solar thermal hot water

systems in the next decade. and further describes the

system, discusses the advantages and disadvantages

relative to solar hot water heating systems, reviews

the various control strategies that have been

considered, and presents experimental results for two

full-scale prototype systems. A review of water

heating systems for solar energy applications

(Jamar, 2016) where solar energy is one of the

widely used renewable energies that can be

utilized either by obtaining energy directly from the

sun or indirectly. On the other hand, solar heating

system is one of the applications of solar energy

that has attracted the attention of many researchers

in this field. The solar collector, storage tank and heat

transfer fluid are the three core components in

solar heating and its applications.

This paper discusses the latest developments and

advances in heating elements using a voltage of 12

volts sourced from batteries using solar energy with

solar cells as conductors. The heating element

consists of a heating element plate wrapped with fire-

retardant lime material with resistance according to

design. The heating element plate is connected by

positive and negative wires.

Ohm's law states that current flows through a wire

at a constant temperature, proportional to the voltage

across its two ends. By inserting one form of Ohm's

law (Kavasoglu, 2011). The amount of heat

generated by the current flowing through the heat

resistance can also be used to calculate the

resistance of a circuit, which will be explained

further.

This paper is expected to solve the problem of

making 12 volt heating elements using solar energy

from solar cells, using renewable energy, saving

energy and not damaging the environment. The

world's energy demand is growing rapidly due to

population explosion and technological advances.

Therefore, it is important to plan and manufacture a

product that uses reliable, cost-effective and enduring

renewable energy sources for future energy demands.

It has become a tool for developing the economic

status of developing countries and for sustaining the

lives of many underprivileged people.

2 HEAT SOURCE PLATE

The plate can be a heating element in which heat is

generated by passing an electric current through it. If

we assume there is a steady state; that the material is

homogeneous. A journal describes the effect of

strain paths under heat transfer work (Davenport,

2000). Material models are often needed to facilitate

the development of new products. This is especially

true for hot rolled products, especially shaped parts.

Most material models assume that the behavior of a

material can be explained by reference to equivalent

plastic strain rate, temperature, and strain. The use

of the last

variable implies that the "strain path"

does not significantly affect the behavior of the

material. The review discusses previous

investigations of the effect of strain paths, mainly

carried out under cold working conditions.

The plate heat exchanger which has high

efficiency and small size is one of the most widely

used heat exchangers. Improvement of heat transfer

plate heat exchanger can be done by using

nanoparticles including working fluid. An

experimental study was carried out using infrared

thermovision to monitor the temperature distribution

over the plate-finned surface in a plate-finned tube

heat exchanger. The temperature differentiation

function was derived to determine the local

convective heat transfer coefficient in the tested fins,

using the local element centered conduction

equations including convective effects at the

boundary with experimental data.

It is disclosed that infrared thermography is

capable of rapidly detecting the location and extent of

transitions and separation regions of the boundary

layer over the entire surface of the tested model. By

comparing the test results on the in-line and staggered

regulatory areas, it is easier to understand or interpret

the detailed dynamic phenomena of the flow present

in the heat exchanger (Davenport, 2000).

2.1 Power and Energy

Power is the amount of work done per unit of time.

Power is equal to the amount of energy

consumed per unit time. Power is a scale quantity, the

integral of power over time defines the work done. As

a basic physics concept, power requires a change in

matter and a specific time when the change occurs.

While energy is a concept that can be transferred as a

potential to cause change or can be interpreted as a

work that can be done by certain forces such as

gravity, electromagnetic and others.

Electrical energy has become a very

important part of human life. Various equipment that

we use requires electrical energy, and to be able to use

electrical energy, we have to pay to the electricity

service provider. The available power is limited, and

overuse will stop the power supply. Cost savings that

must be paid can also be done by reducing the amount

of electricity consumption.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1092

2.2 Solar Energy

The territory of the State of Indonesia is a country that

is geographically traversed by the equator so that it

has great potential in terms of utilizing solar energy.

This is because the amount of solar radiation is

influenced by the latitude, atmospheric conditions,

and the position of the sun with respect to the equator.

According to NASA's Power Data Access Viewer in

2019, Indonesia had a relatively high average

radiation level of 4.8 kWh/m2/day. This is a big

advantage for Indonesia in terms of utilizing solar

energy into electrical energy through photovoltaic.

The use of solar energy is very important in reducing

greenhouse gas emissions. Although there have been

some advances in single solar power systems, the

efficiency and cost of these systems are not very

attractive. Utilization of solar energy, namely using

solar heat to replace heating elements to heat water,

air and space.

Global energy demand is currently growing

beyond the limits of installed generating capacity. To

efficiently meet future energy demands, energy

security and reliability must be improved and

alternative energy sources must be aggressively

investigated. Effective energy solutions must be able

to overcome long-term problems by utilizing

alternative and renewable energy sources. Of the

many renewable energy sources available, solar

energy is definitely a promising option because it is

widely available.

Solar energy, especially as it reaches a level that

is more competitive with other energy sources in

terms of cost, can serve to sustain the lives of millions

of people. Furthermore, solar energy devices can

benefit the environment and economies of developing

countries. The need for utilization of alternative

energy sources, evaluates the global scenario of

installed generation systems, reviews the technology

underlying various solar powered devices, and

discusses some of the applications and challenges in

this area. In addition, this paper discusses the

deployment, maintenance, and operating costs, as

well as the economic policies that drive the

installation of solar energy systems (Devabhaktuni,

2012).

3 RESEARCH METHOD

Action research simultaneously helps in solving

practical problems and expands scientific knowledge,

as well as increasing the competence of each actor, is

carried out collaboratively in direct situations using

data feedback in a cyclical process that aims to

increase understanding of a particular situation,

especially applies to understanding the process of

change in the system and carried out within a

mutually acceptable frame of reference (Hult, 1980).

The research method used is the research and

development method or Research & Development

(R&D). The research and development method is a

method used to produce a product and test the

effectiveness of the product in accordance with the

development objectives. The products resulting from

this research and development are. development of a

12 volt heating element model using solar energy.

The methods used include experimental methods and

action research methods. The experimental method is

a systematic and planned experiment of the truth to

prove the truth of a theory. The action research

method is the design approach stage, the tool-making

approach stage and the tool-testing stage.

Through the product evaluation and test process,

it is hoped that input can be obtained about the

advantages and disadvantages of the product using

the developed design model (Zhao, 2020). The

testing stage is measuring and analyzing, the stages

and processes of tool design and tool testing systems

which include measuring resistance (Ώ-ohms),

temperature (°C -degrees Celsius), and current (A

- amperes) with voltage (V - volts). ) . Measuring

instruments, which are used in the test to analyze

changes, use 1 multimeter which functions to

measure resistance, voltage and current, 1

automotive gauge to measure temperature. The

material used is 0.01mm thick Nickel (heating

element), 2.5 mm diameter cable. Observational

data in the form of measurement of resistance

measurements, in ohms, voltage in voltage and

temperature in degrees Celsius. The results of this

study are the amount of power from the calculation

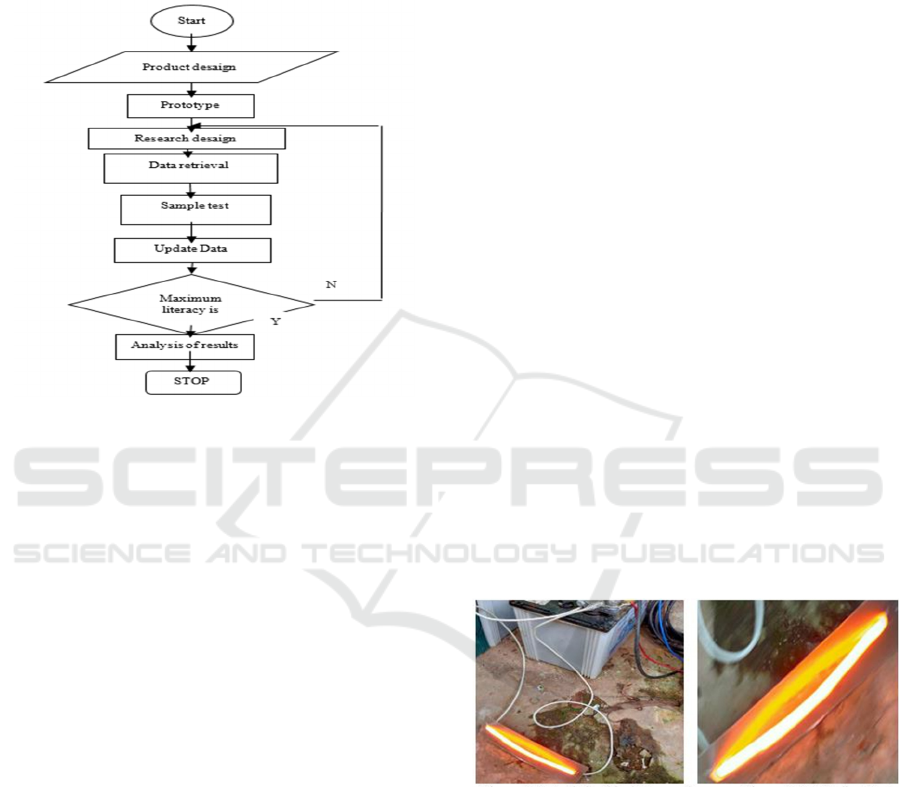

results. The research steps are presented in Figure 1

the following flow chart:

4 RESEARCH RESULTS

The research is carried out in stages starting from

planning to product making and sampling or testing.

Test material 1 consists of a heating element wire

with a flat size of 0.1 mm, a width of 10 mm and a

length of 100 mm. For the length of the test material

the length is varied to get the resistance varies as well.

The results of this study presented data on resistance

(Ώ-ohm), temperature (°C - degrees Celsius), and

current (A - amperes) with voltage (V - volts) from

the test results. Each - each is presented as follows:

Development of 12 Volt Voltage Heating Element Model using Solar Energy

1093

material 1. nickeline heating element wire, 0.1 mm

thick, 10 mm wide, 300 mm long. Material 2 nickelin

with a thickness of 0.4 mm, a width of 10 mm and a

length of 1000 mm. In this study, sample tests were

carried out, namely: the elongated model (HE1) and

the woven model (HE2).

Figure 1: Research flow chart.

In this study, a heating element test was

conducted to measure resistance directly according to

the length of the material. The heating element

model 1 (HE1) and the heating element model 2

(HE2) on the heating element where the desired

resistance is in accordance with the planned

electrical power. We conducted a test with a target

power of 50 watts, 100 watts, 200 watts, 300 watts

and 500 watts, the wider the heating element, the

greater the electrical power generated. This can be

proven by some of the tests we carried out which can

be seen as follows:

The voltage is set at 12 volts (V) DC, 0.1 mm

thick nickeline, 100 mm wide and 600 mm long,

producing a voltage of 0.8 Ohm so the power

generated is 180 watts. Then we tested again the

nickeline material, 0.1mm thick, 200mm long,

100mm wide, the results of the 0.3 Ohm voltage

measurement resulted in 480 watts of power. In the

third test also at the same voltage, 0.1 mm wide and

200 mm long measuring resistance 0.7 Ohm produces

206 watts of power, and so on, the length is varied

with the same thickness and width. The wider the

nickeline material, the greater the resistance and the

greater the electrical power.

Electric current (amperes) is the rate at which

electric charge flows through a point in a circuit. In

this test, the calculation is determined only, because

the voltage and resistance are known. Unless the

voltage is increased by 24 volts, 36 volts and so on.

The results of the calculation are as follows: it is

known that the amount of current is inversely

proportional to the resistance, then it can be obtained

for a resistance of 0.8 Ohms to produce a current of

15 amperes, if the resistance is 0.7, the current is 17

amperes and a resistance of 0.3 produces a current of

40 amperes and so on.

The HE1 model and the HE2 model can be stated

to have an effect on the amount of electric power

caused by the increase in the length of the nickeline

heating element. While the current source of solar

energy is used in the test as additional energy does not

decrease when the sun shines. Solar cell testing is

carried out starting at 08 - 16.00 by measuring the

voltage that goes into the battery. From the

measurement results, it was found that the highest

voltage at 9.04 hours reached a voltage of 14.47 volts

until 13.00 hours after that hour until 16.00 the

voltage became 13.39 volts. Next, the heating

element product was tested on refractory limestone,

measuring the starting point at a temperature of

32 F/5 minutes then 180 F and so on until the peak

point reached 220 F. The initial battery voltage was

14.47 volts and then decreased to a voltage of 10.99

so that the temperature also continued to decrease.

When it reaches the battery voltage of 10.0 volts then

the battery does not distribute heat anymore. Figure 2

is the connection between the heating element (HE1)

of the battery and the solar cell, while Figure 3 of the

heating element (HE1) radiates heat.

Figure 2: HE1

relationship, battery and

solar cell.

Figure 3: HE1 Radiant

Heat.

5 HEATING ELEMENT TEST

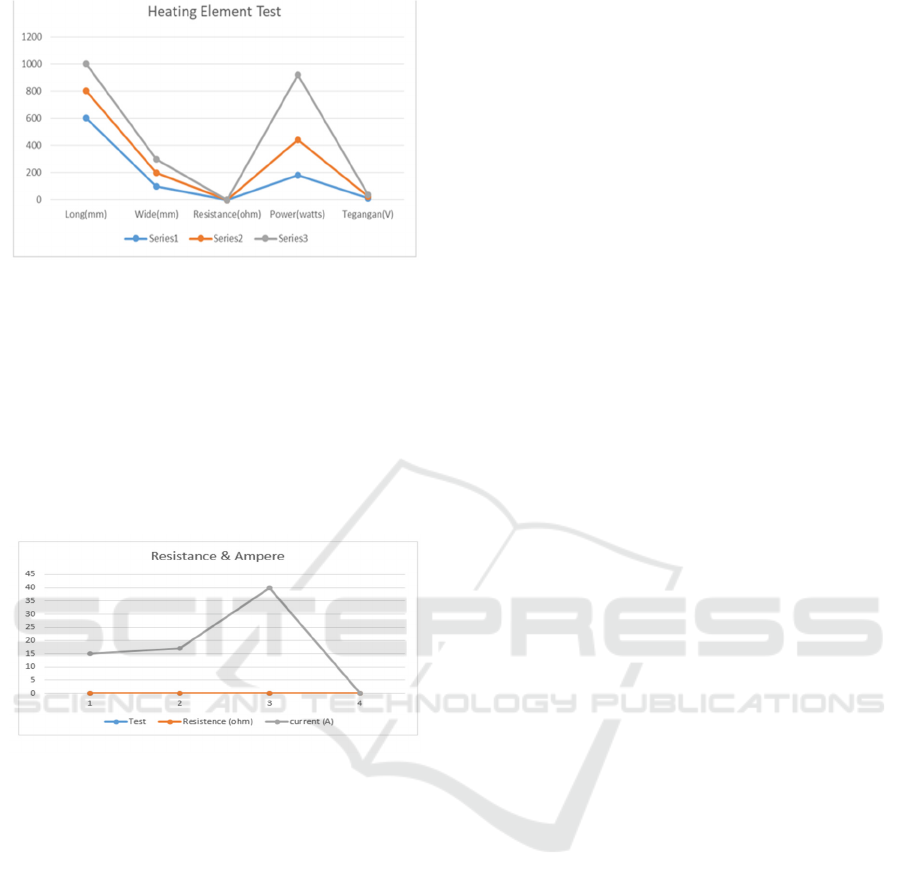

The test data obtained from the measurement and

testing results are presented in the following graph:

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1094

Figure 4: Test results of heating elements.

Figure 4 shows that electrical resistance has an effect

on the amount of power according to the test power.

The electrical resistance of 0.8 produces 180 watts of

power, the resistance of 0.7 produces 260 watts of

power, and the 0.3 resistance produces 480 watts of

power. So the smaller the electrical resistance, the

greater the electrical power generated. The following

is a comparison of electricity and electric current

presented in figure 5

Figure 5: Test results of resistance and ampere.

Figure 5 shows that the comparison between

electrical resistance and electric current in the heating

element material, where the smaller the electrical

resistance, the greater the electric current obtained.

The electrical resistance of 0.8 ohms is obtained by

an electric current of 15 amperes, an electrical

resistance of 0.7 produces an electric current of 17

amperes and 0.3ohm produces an electric current of

40 amperes. So when it is concluded that the size of

the electrical resistance is very influential on the size

of the electric power and electric current.

6 DISCUSSION

Based on the results of the research written in this

paper to answer the problems described above,

namely how the relationship between voltage (volts),

current (amperes) and electric power (watts). We

have often heard of this division, and how is it related.

The test results show that the nature of the heating

element where the greater the electric power

(wattage) affects the size of the voltage (volts) and

electric current (amperes) flowing, and the

relationship is as follows: The greater the voltage

(volts), the greater the power (watts) and the greater

the current (amperes), the greater the power (watts).

As the theory of George Simon Ohm found the

relationship between current, voltage, and resistance

in an electric circuit. He discovered, by experiment,

that pressure is equal to the product of current and

resistance; This relationship is known as Ohm's law

(Wells, 1987). This law is the practical basis on

which most electrical calculations are determined.

Formulas can be expressed in various forms and by

their use.

So in an electrical circuit, a larger voltage (volts)

will flow an amount of current (amperes) through a

smaller conductor (resistance) than is required to

force the same amount of current (amperages)

through a larger conductor (resistance). A smaller

conductor will allow less current (amperes) to pass

than a larger conductor if the same electrical pressure

(volts) is applied to each conductor for the same

period. Smaller conductors can only be considered to

offer greater resistance (ohms) than larger

conductors. Thus, we can define resistance as "a

property of a body that resists or limits the flow of

electricity through it." Resistance is measured in

ohms — a term similar to friction in a hose or pipe.

In many low power applications, solar cells are

used as an environmentally friendly power source. To

provide electricity also without solar radiation, we

invented a device that combines solar cells and

rechargeable batteries in one unit. The main

component is the p h o t o a c t i v e layer in the

charge storage layer. As such, this new device

represents an empty battery, which charges itself on

lighting (Hidayat, 2015). Charge and discharge

characteristics are presented with special

consideration of variations in light intensity and

ion concentration in the electrolyte. The relatively

high reverse reaction at the electrodes is still taking

place. A 1 hour charge under 1000 W/m2

illumination of the first sample yields 1.8 C/cm 2.

Batteries that use solar cells or solar panels. In

addition, this tool is a real action in fighting global

warming or what is commonly called global

warming. Thus, one way that can overcome or

minimize the impact of global warming is the use of

solar energy which can be used as an alternative

source of electricity. The solar energy can be used to

recharge the battery, so it is hoped that this tool with

Development of 12 Volt Voltage Heating Element Model using Solar Energy

1095

solar cells can reduce gas emissions that can cause

global warming (Hidayat, 2015). The battery is

needed as a support force or as an energy supply

in the use of electronic devices.

In certain circumstances, charging the battery from

the power grid is a difficult task, so that a battery

charger is needed without the need for an electricity

network, therefore solar or solar power is used for

that reason. The main components of this tool are

solar cells (as input by converting solar energy

into electrical energy), battery charger circuit (as

controller), LED indicator (as battery charging

indicator), and battery (12 volt voltage). This tool

works when there is a supply of energy from sunlight

which is converted into electrical energy through

solar cells.

The results of testing the maximum battery

voltage of 14.47 volts are at 9:00 to 13:00 and will

remain stable when not in use. The heat of the heating

element rises to its maximum peak at a temperature

of 220 C in 16 minutes when it is connected to the

battery, and when it is used continuously for 1-2

hours, the battery voltage drops to 11 volts and the

voltage is below 10 volts the heat emitted HE1 cannot

be used.

7 CONCLUSIONS

From the exposure of the research results and

discussion, it can be concluded as follows:

1. The form of the heating element design model is

divided into two, namely heating element 1

(HE1) straight model with an element length of

300 mm and a woven heating element model 2

(HE2) with an element length of 1000 mm.

While the average element thickness is 0.1 mm

and a width of 100 mm.

2. The wider the nickeline material, the greater the

resistance and the greater the electrical power. It

is proved by a resistance of 0.8 Ohm that

produces a current of 15 amperes, if the

resistance is 0.7, the current is 17 amperes and a

resistance of 0.3 produces a current of 40

amperes and so on. 180 watts of power, 205 and

480 watts of power, proportional to the current.

3. The smaller the resistance, the greater the power

generated and the battery voltage using solar

cells reaches its maximum voltage peak at 09.00

- 13.00, the use of heating elements is adjusted

at that time. This means that the input voltage is

equal to the output voltage, in this case the

amount of power of the heating element is small

from the input voltage through the solar cell.

ACKNOWLEDGEMENT

The author would like to thank for the assistance or

encouragement from various parties including the

work team that has assisted in this research activity,

the Head of the Kupang State Polytechnic and the

mechanical engineering department of the Kupang

State Polytechnic. The Ministry of Education and

Culture in particular the directorate general of higher

education which provides research grants so that this

research can be carried out.

REFERENCES

A. H. Fanney and B. P. Dougherty, “A photovoltaic solar

water heating system,” Journal of Solar Energy

Engineering, Transactions of the ASME, vol. 119, no.

2. pp. 126–133, 1997, doi: 10.1115/1.2887891.

A. Jamar, Z. A. A. Majid, W. H. Azmi, M. Norhafana, and

A. A. Razak, “A review of water heating system for

solar energy applications,” International

Communications in Heat and Mass Transfer, vol.

76. pp. 178–187, 2016, doi: 10.1016/j.ich

eatmasstransfer.2016.05.028.

N. Kavasoglu, A. Sertap Kavasoglu, O. Birgi, and S. Oktik,

“Intensity modulated short circuit current spectroscopy

for solar cells,” Solar Energy Materials and Solar

Cells, vol. 95, no. 2. pp. 727–730, 2011,

doi:10.1016/j.solmat.2010.10.012.

S. B. Davenport and R. L. Higginson, “Strain path effects

under hot working: An introduction,” Journal of

Materials Processing Technology, vol. 98, no. 3.

pp. 267–291, 2000, doi: 10.1016/S0924-

0136(99)00320-9.

V. Devabhaktuni, M. Alam, S. Shekara Sreenadh Reddy

Depuru, R. C. Green, D. Nims, and C. Near, “Solar

energy: Trends and enabling technologies,”

Renewable and Sustainable Energy Reviews, vol.

19. pp. 555–564, 2013, doi:

10.1016/j.rser.2012.11.024.

Hult . “Towards A Definition of Action Research_ A

Note and Bibliography - Hult - 1980 - Journal of

Management Studies - Wiley Online Library.” .

J. Zhao, Y. Dong, J. Fu, L. Zhao, and Y. Zhang,

“Design and experiment of energy-saving water

injection pump,” J. Pet. Explor. Prod. Technol., vol.

10, no. 5, pp. 2127–2135, 2020, doi:

10.1007/s13202-020-00860-1.

R. Wells, “Ohm’s law,” Electronics and Power, vol. 33,

no. 3. p. 172, 1987, doi: 10.1049/ep.1987.0114.

“Photovoltaically Self-Charging Battery-IOPscience.” .

S. Hidayat, “Portable Battery Charger Using Solar Cells,”

J. Energi Kelistrikan, vol. 7, no. 2, pp. 137–143, 2015.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1096