Analysis of Impact Strength and Fracture Pattern of Hybrid

Composite Materials Reinforced with Lontar and Gebang Midrib

Fibers

Amros Alfonsius Tuati, Dedy Nataniel Ully and Edwin Pieter Hattu

Mechanical Engineering Department, State Polytechnic of Kupang, Adi Sucipto Street, Kupang, Indonesia

Keywords: Hybrid Composite, Volume Fraction, Impact Strength, Fault Pattern.

Abstract: The use of natural fibers as a filler in composite materials is starting to be widely used. One of the most

promising ones is hybrid composites. Hybrid composites are composites consisting of a combination of two

or more types of fiber as reinforcement in a single matrix. This study used Lontar Midrib Fiber (LMF) and

Gebang Midrib Fiber (GMF) as reinforcement and Polyester as binder. The method used is an experimental

method with hand lay up material printing. The results obtained that the highest impact energy value is owned

by hybrid composites with a volume fraction ratio of 70% Polyester, 20% LMF, 10% GMF (7,2,1) which is

20.8 Joule, with the highest impact value 0.1576 J/mm

2

and the lowest impact energy value was owned by a

composite with a volume fraction of 80% Polyester, 10% LMF, 10% GMF (8.1.1) which was 7.4667 Joule,

with a strength value of the lowest impact is 0.0566 J/mm

2

. The fracture pattern that occurs in the hybrid

composite material shows brittle fracture with fiber pull out.

1 INTRODUCTION

Lontar Tree (Borassus Flabellifer) and Gebang Tree

(Corypha Utan Lamarck) are tree species known as

the tree of life for people in East Nusa Tenggara

Province. In this plant, almost all parts are useful for

mankind, including as food, building, household

furniture, art and cultural goods. Various benefits can

be obtained from various parts of the lontar and

gebang tree or plant, among others, the stems are used

to support houses, the leaves are used to make mats,

sasando musical instruments, traditional hats, the sap

to make brown sugar, the fruit to make makeup and

the midrib is used as a fuel substitute for kerosene.

Based on the data reported that the area of natural

grazing areas on Timor Island is 24,382.04 ha and it

is estimated that around 5-10% of the area is covered

with gebang trees, while palm trees are commonly

found on the islands of Rote Ndoa, Sabu, Flores and

East Sumba with the area of palm trees in NTT.

20,555 Ha. So it can be said that the population of

palm trees and gebang trees is quite developed in

NTT. However, until now it can be said that the lontar

and gebang plants are still one of the flora of

Indonesia, especially in the East Nusa Tenggara

region that has not been used optimally. The

processing of parts of the lontar and gebang trees,

such as the base of the palm frond and the gebang

frond, has so far only been used as organic waste and

as a substitute for kerosene fuel for cooking. On the

other hand, the base of the lontar midrib and the

gebang frond are also used as a seat mat and a tool for

carrying water. This is because the gebang midrib and

lontar midrib have flexible properties and are not

easily broken.

Judging from the utilization of palm and gebang

trees and their mechanical properties, it is very good

if the fibers at the base of the palm and gebang

midribs are used as reinforcement for hybrid

composite materials. The reasons for choosing the

base fibers of the palm and gebang midribs as raw

materials for hybrid composites are that they have

flexible properties, are easy to obtain in large

quantities and provide opportunities for wood

substitute raw materials, which are decreasing in

availability due to utilization in all fields.

Hybrid composites are composites consisting of

a combination of two or more types of fiber as

reinforcement in a single matrix, either continuous or

discontinuous (Budinski,1995). Composite materials

are materials formed from a combination of two or

more constituent materials through an

1028

Tuati, A., Ully, D. and Hattu, E.

Analysis of Impact Strength and Fracture Pattern of Hybrid Composite Materials Reinforced with Lontar and Gebang Midrib Fibers.

DOI: 10.5220/0010958300003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1028-1033

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

inhomogeneous mixture, where the mechanical

properties of each constituent material are different

(Matthews and Bawlings,1993).

The advantages of hybrid composite materials

when compared to metals are that they have good

mechanical properties, are not easy to corrode, are

easily obtained raw materials at lower prices, and

have a lower density than mineral fibers. Natural fiber

composites have other advantages when compared to

synthetic fibers, natural fiber composites are more

environmentally friendly because they can be

degraded naturally and the price is cheaper than

synthetic fibers.

In Hybrid composite materials, there are several

factors that greatly affect its mechanical strength,

such as fiber volume fraction, fiber length, fiber type

variations. The larger the fiber volume fraction in the

matrix, the strength is increased. also increasing. This

is because the greater the length of the fiber in the

metric, the surface of the fiber that bears the load

given by the matrix becomes large, conversely the

shorter the fiber in the matrix, the surface of the fiber

that bears the load given by the matrix becomes

smaller, so that its strength is also getting stronger

low (Moto et al., 2018). Composites with natural

fibers have also been researched and developed

previously. Shomad et al., 2020, Researching the

Hybrid Composite Characterization Analysis on the

Matic Motorcycle Front Fender. The highest tensile

test results for the two types of fiber arrays with the

SR-SR-SK fiber arrangement of 47.67 MPa, while the

lowest tensile strength value for the SR-SF-SK

variation of the fiber array is 35.59 MPa. The highest

impact test result was 0.0141 J/mm

2

for the SR-SF-

SK variation, and the lowest impact strength for the

SF-SR-SK variation was 0.01226 J/mm

2

. Banowati et

al, 2020, Researching comparative analysis of hibrid

composite tensile strength pineapple leaf fiber

hybrid-E-glass/ epoxy bakalite EPR 174 and

pineapple leaf fiber hybrid -E-glass/Vinyl ester

repoxy R 80. Based on tensile test the average value

obtained by hybrid composite of pineapple fiber

fibers - e-glass / epoxy bakalite EPR 174 using hand

ly up method with unidirectional 0 ° direction of 114

N / mm2, bidirectional bidirectional direction of 90 °

22 N / mm2 and the direction of fiber ± 45 ° for 24 N

/ mm2. While the result of tensile test of the average

value obtained by hybrid composite of pineapple fiber

fiber - e-glass / vinyl ester repoxy R 802 using hand

ly up method with Unidirectional 0 ° array direction

of 86 N / mm2, bidirectional fiber direction direction

90 ° 66 N / mm2 and the direction of fiber ± 45 ° is

37 N / mm2.

Based on the reviews and references above, the

author was inspired to research the analysis of impact

strength and fracture patterns of hybrid composite

materials reinforced with lontar and gebang midrib

fibers. With the hope that we can find out how big the

effect of the volume fraction variation of the lontar

base fiber and the gebang midrib fiber is. to the

maximum value of mechanical strength (impact

strength) and fracture patterns on hybrid composite

materials.

2 RESEARCH METHODOLOGY

This research is an experimental research that aims to

determine the impact strength and fracture pattern of

a hybrid composite material reinforced with lontar

midrib fiber and gebang midrib fiber.

This research utilizes the base fiber of the lontar

midrib and the gebang midrib fiber as a composite

reinforcement material and polyester as a binder.

Previously the fibers were cleaned with pure water,

then treated by immersion in a 5% Alkali (NaOH)

solution per 1 liter of distilled water in order to

increase the adhesive properties so as to increase the

impact strength of the fiber composites it forms.

The fiber used has an average diameter of 0.7mm

for the gebang midrib fiber and an average diameter

of 2mm for the lontar midrib base fiber with the hand

lay up printing method and the fiber arrangement,

namely continuous fiber composite. This hybrid

composite test material will be impact tested to

determine the maximum impact energy value and

impact strength value.

The types of variables in this study:

• Independent Variables (unbound): are variables

that are determined before carrying out the

research.

• Volume Fraction Comparison: 80% Polyester, 10%

LMF, 10% GMF (8,1,1), 70% Polyester, 20%

LMF, 10% GMF (7,2,1), 70% Polyester,10% LMF,

20% GMF (7,1,2), 60% Polyester, 30% LMF, 10%

GMF (6.3, 1), 60% Polyester, 20% LMF, 20%

GMF (6,2,2), 60% Polyester, 10% LMF, 30% GMF

(6,1,3)

• Treatment of alkaline (NaOH) palm midrib fiber

5% per 1 liter of distilled water with an upset time

of 120 minutes.

• Dependent Variables are: Impact Strength

• Controlled Variables are:

• Methyl ethyl ketone peroxide (MEKP) / hardener

1%

• Resin : Polyester

Analysis of Impact Strength and Fracture Pattern of Hybrid Composite Materials Reinforced with Lontar and Gebang Midrib Fibers

1029

• Average fiber diameter (d) = 0.7 mm for midrib

fiber

• Average fiber diameter (d) = 2 mm for the fiber

at the base of the palm frond

• Fiber length L = 125 mm for Impact test

specimen

• Dried composite at room temperature until dry.

• Curing fiber at room temperature until dry.

Impact test specimens is made based on the

ASTM D6110 standar as the following picture.

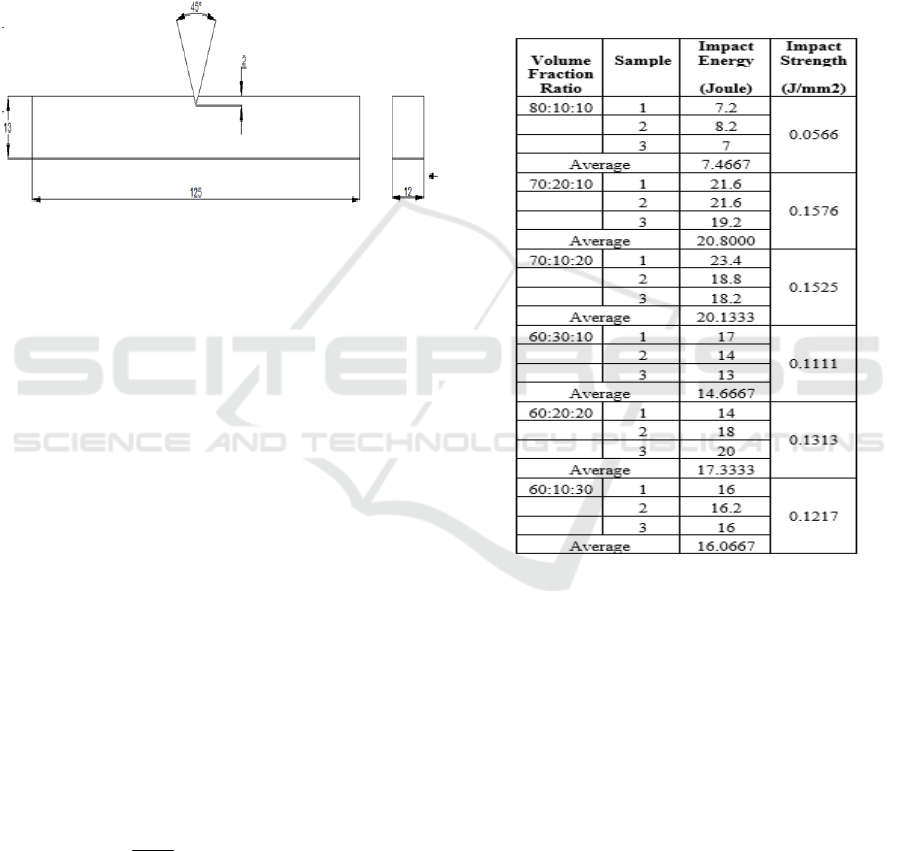

Figure 1: Impact Test Specimens ASTM D6110.

Impact strength is known by using a charpy impact

testing machine with ASTM D6110 specimen

standard, as shown in Figure. 1. To measure the

impact test data used the formulas as follows (Calister

and Retwisch, 2007):

E

absorption

= initial energy – remaining energy

= m.g.h – m.g.h’

= m.g.(R-R cos α) - m.g.(R-R cos β)

E

absorption

= m.g.R. (cos β – cos α)

with :

E

absorption

= Energy Absorption (J)

m = Pendulum Weight (kg)

g = Gravitational Acceleration (m/s

2

)

R = Sleeve Length (m)

α = The angle of the pendulum before swinging

(°)

β = Swing angle of the pendulum after breaking

the specimen (°)

The impact price can be calculated by:

o

srp

A

E

HI =

with :

HI = Impact’s price (J/mm

2

)

E

absorption

= Energy Absorption (J)

A

0

= Cross-sectional area (mm

2

)

3 RESULT AND DISCUSSION

3.1 Research Results

From the results of the research that has been carried

out, the value of the impact energy and the value of

the impact strength of the hybrid composite is

obtained from the comparison of each volume

fraction variation shown in table 1.

Table 1: Hybrid Composite Impact Strength Test Results

Data.

3.2 Discussion on the Impact Strength

of Hybrid Composite

Table 1 shows the impact energy data and the impact

strength of the hybrid composite shown in Figures 2

and 3.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1030

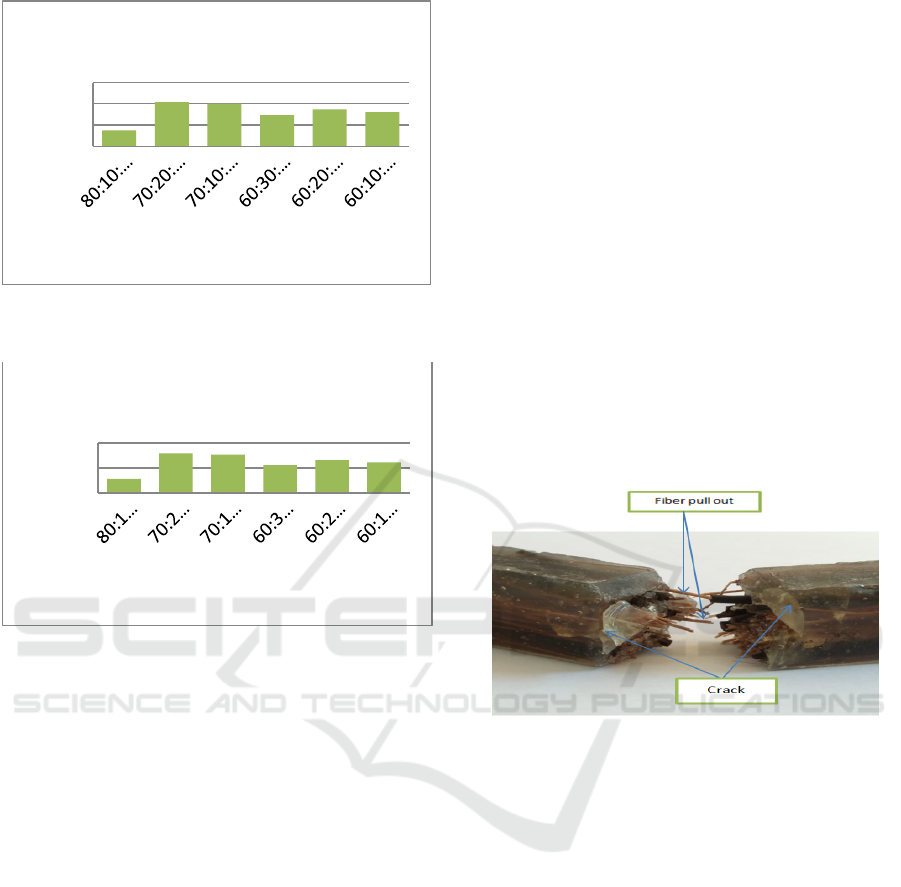

Figure 2: Graph of the correlation between Impact Energy

and Gebang Midrib Fiber.

Figure 3: Graph of Impact Strength vs. Volume Fraction

Comparison.

From Figures 2 and 3, the graph of the

relationship between the impact energy value and the

average impact strength with a comparison of the

volume fraction variation of the hybrid composite, it

is known that the highest average energy value

required to break the hybrid composite specimen is

20.8 joules, obtained from the comparison Volume

fraction variation is 70% polyester, 20% Pangkal

Midrib Lontar Fiber (SPPL), 10% Gebang Midrib

Fiber (SPG), and the lowest average energy value

required to break the hybrid composite test specimen

is 7.4667 Joules, obtained from the ratio of volume

fraction variation is 80% polyester, 10% Lontar

midrib fiber (SPPL), 10% Gebang midrib fiber

(SPG)). The highest average impact strength value is

0.1576 mm2, obtained from the ratio of the volume

fraction variation of 70% Polyester, 20% Lontar

Midrib Fiber (SPPL), 10% Gebang Midrib Fiber

(SPG), and the lowest impact strength is 0 ,0566

joules/mm2, obtained from the ratio of the volume

fraction of 80% Polyester, 10% Lontar midrib fiber

(SPPL), 10% Gebang midrib fiber (SPG). The

comparison of the variation of the volume fraction of

the matrix and the variation of the fiber type in the

composite material affects the value of the impact

energy and the value of the impact strength, where

there is a significant increase in impact energy and

impact strength along with the increase in the volume

fraction of fiber and matrix. The optimum volume

fraction ratio occurs at 70%. polyester, 20% midrib

fiber and 10% midrib fiber.

There are several other supporting factors that

influence the increase and decrease in the value of

impact energy and impact strength, namely the

adhesion between fiber and matrix, where a strong

bond between fiber and matrix will be able to

withstand the amount of energy transmitted from the

matrix when it gets a sudden load. On the other hand,

the weak bond between the matrix and the fiber, so

when it gets a sudden load, the absorption energy

received will decrease.

3.3 Macro Photo of Composite Fault

Surface

Figure 4: Hybrid Composite 80% Polyester, 10% LMF,

10% GMF.

From Figure 4 macro photos of composite material

fractures, it can be seen that there are cracks in some

parts of the specimen and there is a fiber pull out

mechanism in some parts of the composite material.

From Figure 5, it can also be seen that there is a fiber

pull out mechanism on the fracture surface of the

material, where there are several fibers that are

released from the matrix bond due to the adhesive

power that is not too strong. Then the arrangement of

fibers that are quite a lot and dense and evenly

distributed in all parts causes the material to be able

to absorb the energy given. The fracture pattern that

occurs is brittle fracture, this can be seen on the

fracture surface of the composite material which is

quite shiny in some parts.

7,4667

20,8

20,1333

14,6667

17,3333

16,0667

0

10

20

30

Energiy Absorption(J)

Volume Fraction Comparison (%)

(Polyester:Lontar Midrib Fiber:Gebang …

Energy Absorption Vs Volume Fraction

Comparison

0,0566

0,1576

0,1525

0,1111

0,1313

0,1217

0

0,1

0,2

Impact Strength (J/mm2)

Volume Fraction Comparison (%)

(Polyester:Lontar Midrib …

Impact Strength Vs Volume Fraction

Comparison

Analysis of Impact Strength and Fracture Pattern of Hybrid Composite Materials Reinforced with Lontar and Gebang Midrib Fibers

1031

Figure 5: Hybrid Composite 70% Polyester, 20% LMF,

10% GMF.

Figure 6: Hybrid Composite 70% Polyester, 10% LMF,

20% GMF.

From Figure 6, there are cracks in several parts

of the fracture surface of the composite specimen and

fiber pull out on the fracture surface. The fiber bonds

are evenly distributed in all parts and have good

adhesion. Then in Figure 7, cracks occur in the fibers

in the composite material and also experience fiber

pull out. The fracture pattern also tends to experience

brittle fracture on the fracture surface of composite

materials

Figure 7: Hybrid Composite 60% Polyester, 30% LMF,

10% GMF.

Figure 8: Hybrid Composite 60% Polyester, 20% LMF,

20% GMF.

From Figure 8, there are cracks on some parts of

the surface of the composite material and fiber pull

out also occurs on the fracture surface. The

composition of the fibers is quite evenly distributed

throughout the composite. From Figure 9, the fracture

pattern that occurs is brittle fracture and also the

occurrence of fiber pull out on the fracture surface of

the composite material.

Figure 9: Hybrid Composite 60% Polyester, 10% LMF,

30% GMF.

4 CONCLUSION

There are variations in the volume fraction of

polyester, palm stem base fiber and gebang midrib

fiber in hybrid composite materials, it will affect the

impact strength value. The maximum strength of the

hybrid composite material, which is 0.1576 J/mm2, is

in the volume fraction variation of 70% polyester,

20% SPPL, 10% SPG. The lowest composite material

strength is in the volume fraction variation of 80%

polyester, 10% SPPL, 10% SPG, which is 0.0566

J/mm2. The fracture pattern that occurs in the hybrid

composite material is brittle fracture.

REFERENCES

Budinski, K.G. (1995). Engineering Material Properties

and Selection,4th, Prentice Hall,Inc A Simon

andSchuster Company,USA

L,F. Matthews and D.B.,Bawlings. (1993). Composite

Materials Engineering and Science, Chapman & Hall,

London Glosgow, New York, Tokyo Melbourne,

Madras.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1032

Moto, M., Boimau, K., & Bale, J. (2018). Effect of Long

Fiber And Thick Polyester Composite Board With

Lontar Fiber And Gewang Fiber On Bending Strength.

LONTAR Journal of Mechanical Engineering Undana

(LJTMU ), 3(2), 21-30.

Shomad, A.N., Sofyan, Ady (2020). Hybrid Composite

Characterization Analysis on Motor Matic Front

Mudguards. Journal of Manufacturing Energy Engines

and Materials e-ISNN:2579-7433.

Banowati, L., Fauzan, F.A., Suprihanto, D. (2020).

Comparative Analysis of Hibrid Composite Tensile

Strength Pineapple Leaf Fiber hybrid-E-Glass/ Epoxy

Bakalite EPR 174 and Pineapple Leaf Fiber hybrid -E-

Glass/Vinyl Ester Repoxy R 80. ISSN 2087-9245,

Nurtanio University Bandung.

ASTM, D6110, “Standard Tes Method For Determing the

Izod Pendulum Impact Resistance of Plastic”.

Philadelphia, PA: American Society For Testing and

Materials.

D,W. Calister., and G.D. Rethwisch (2007). “Fundamental

of Materials Science and Engineering”, An Integrated

Approch Third Edition, Departement of Metallurgical

Engineering The University-Bozeman, Bozeman

Montana.

Analysis of Impact Strength and Fracture Pattern of Hybrid Composite Materials Reinforced with Lontar and Gebang Midrib Fibers

1033