Tribological Study of Biolubricant Made from Blend of

Waste Cooking Oil and Calophyllum Inophyllum Oil

Jassinnee Milano

1a

, A. S. Silitonga

2,3 b

, A. H. Sebayang

2,3 c

, Abd. Halim Shamsuddin

4

,

Bambang Sugiyanto

2,3 d

, Supriyanto

2,3

, Abdul Razak

2,3 e

and Isman Harianda

2,3

1

Department of Mechanical Engineering, College of Engineering, University Tenaga National, Kajang, Malaysia

2

Department of Mechanical Engineering, Politeknik Negeri Medan, 20155 Medan, Indonesia

3

Centre of Renewable Energy, Department of Mechanical Engineering, Politeknik Negeri Medan, 20155, Medan, Indonesia

4

Institute of Sustainable Energy, University Tenaga Nasional, Kajang, Malaysia

bambangsugiyanto@polmed.ac.id, supriyanto@polmed.ac.id, abdulrazak@polmed.ac.id, ismanharianda@polmed.ac.id

Keywords: Tribology, Lubricant Oil, Biodiesel, Waste Cooking Oil, Calophyllum Inophyllum Oil.

Abstract: Biodiesel is an alternative and renewable source of fuel that exhibits sustainable properties. It is eco-friendly

as its combustion does not lead to the emission of greenhouse gases, which is associated with conventional

diesel fuel. This study examined the tribological characteristics of biodiesel made from cooking oil waste and

Calophyllum inophyllum oil. An untreated cooking oil waste collected from fast-food chains and household

were used as feedstock to produce biodiesel via transesterification reaction. The biodiesel was produced at

room temperature using the Calophyllum inophyllum plant as feedstock, which contained a significant amount

of non-edible oil. This led to the formation of biolubricant at different blending ratios with the percentages of

biodiesel and biofuel in the range of (5% to 25%) and (95% to 75%), respectively. The tribological

investigation was conducted using a 4-ball tribotester following the ASTM D 4172 standard. The result

showed that the wear scar and composition of the biolubricant are similar to the actual bearings. Finally, the

B75 combinations indicated the best tribological characteristics, therefore, its usage is recommended for the

protection of engine parts.

1 INTRODUCTION

The utilization of biodiesel in an internal combustion

engine is becoming popular in recent years. This is

because they are derived from wastes and renewable

sources such as vegetable oils, animal fats, and

residual cooking oils. Furthemore biodiesel can be

utilized in compression ignition engines to replace

fossil fuels for power and energy generation (Zahan

and Kano, 2018).

The high cost of biodiesel production is related to

the raw materials ranging from 60 to 80% (Zahan and

Kano, 2018). Several studies analysed the use of non-

edible oils as raw materials derived from different

sources, such as vegetables, Calophyllum inophyllum,

a

https://orcid.org/0000-0001-7130-072X

b

https://orcid.org/0000-0002-0065-8203

c

https://orcid.org/0000-0002-0810-7625

d

https://orcid.org/0000-0003-3977-7047

e

https://orcid.org/0000-0002-7687-456X

jatropha, grease, and cooking wastes, to minimize the

use of food crops. These sources of oil have the ability

to reduce the production costs by approximately 60-

90%. Furthermore, the utilization of these non-edible

oil sources serves as waste recycling and management

techniques and mitigation to environmental pollution

associated with the oil sources.

The major limitation to biodiesel production from

non-edible oil is the availability of raw material in

large quantities. This limitation can be addressed by

blending non-edible with edible oils obtained from

esters, which tends to reduce the use of food sources

for biodiesel production. The production of biodiesel

from blends of edible and non-edible oils, such as

Jatropha curcas, Calophyllum inophyllum,

Milano, J., Silitonga, A., Sebayang, A., Halim Shamsuddin, A., Sugiyanto, B., Supriyanto, ., Razak, A. and Harianda, I.

Tribological Study of Biolubricant Made from Blend of Waste Cooking Oil and Calophyllum Inophyllum Oil.

DOI: 10.5220/0010958000003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 1011-1018

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

1011

Pongamia pinnata, Ceiba pentandra and waste

cooking oils have been investigated (Silitonga et al.,

2016). Furthermore, the use of residues from fast food

centers and restaurants tends to increase urban

biodiesel generation. This also has excellent

environmental benefits because it promotes a green

atmosphere.

According to Yilmaz et al. (2017) rising demand

for petro fuel does not only lead to increase in prices,

rather it creates adverse effects on the environment

such as biodiversity loss, climate change, and global

warming . Therefore, biodiesel is an ideal alternative

to reduce the dependency on fossil fuels and it is

produced from animal fats, vegetables, and recycled

or waste cooking oils. Furthermore, biodiesel is a

renewable, non-explosive, biodegradable, non-

flammable and non-toxic fuel and has similar

combustion characteristics with diesel fuel (Dharma

et al., 2017).

Nowadays, non-edible feedstocks are prioritized

over edible one due to the shortage of vegetable oil

consumed in the nutritional diet as an energy source.

Besides, its usage for biodiesel production causes

food insecurity across the globe (Cordero-Ravelo and

Schallenberg-Rodriguez, 2018).

Furthermore, waste cooking oils not suitable for

edible purposes serves as a substitute. This possibly

leads to a decrease in biodiesel cost, thereby making

it an economically viable option (Cordero-Ravelo and

Schallenberg-Rodriguez, 2018). Therefore, waste

cooking oil is an economical source of biofuel

production used for power generation (Khan et al.,

2021). However, a major problem emerged when

there was an increase in the market price of these

vegetable oils. This led to an increase in biodiesel

production costs, thereby making it uneconomical.

Silitonga et al. (2020) stated that the problem

associated with biodiesel production can be overcome

using less expensive materials such as vegetable and

non-edible oils as alternatives. Previous studies

carried out in 1990 were centred on the use of raw

vegetable oils in pure form or partially blended with

appreciable success in engine performance. These

studies, showed that clogging and cooking the

injectors after prolonged usage equally remained a

serious challenge. Therefore, conscious efforts have

been made to produce this fuel from various

feedstocks compatible with the diesel engine by

refining the oil (Adekunle et al., 2020). Ma et al.

(2021) stated that the propensity of the resultant

biodiesel for carbon deposition, is significantly

reduced in engines.

According to Silitonga et al. (2018) the use of

biodiesel in diesel engines reduces life cycle

emissions of volatile organic compounds (VOCs)

except NO

x

. In addition, a combination of biodiesel

with diesel fuel reduces environmental impact,

improves brake power and thermal efficiency, as well

as engine torque (Dharma et al., 2017).

Biodiesel is similar to the conventional fossil

diesel, produced from an increasingly diverse mix of

waste oil. However, the continous use of the

biodiesel-diesel blend causes the biofuel to slip into

the engine compartment, thereby causing damages to

cams, piston rings, cylinder liners, valve stem seal,

gaskets and contaminate the lubricating oil (Ge et al.,

2018). These damages increases wear in critical

components, thereby shortening their life span and

engine durability. Therefore, the frequent changing of

engine oil is one of the essential maintenance tasks.

Besides, regularly scheduled oil changes help keep

the engine clean and avoid the enterance of impurities

(Arumugam et al., 2014).

Engine oil is an important aspect that supports

engine performance and works as a seal to fill the

gaps between the piston and cylinder. Hence, it is

important because it acts as a lubricant, coolant and

silencer in machines to reduce wear due to friction

and high temperatures. Engine oil needs to be highly

viscous to protect the inner parts of an engine from

rust or corrosion, which is extremely relevant to

maintain its performance. Furthermore, it ensures all

the components of an engine flow at a lower

temperature. Several studies have investigated the oil

lubricant properties of biodiesel.

For instance, Zulkifli et al. (2013), carried out a

research, which investigated the wear prevention

characteristics of engines using palm oil-based

trimethylolpropane (TMP) and ester blended with

lubricating oil. The result showed that 3% of TMP

was able to withstand the maximum load (220 kg),

while 7% approximately reduced it by 50% . Mosarof

et al. (2016) carried out similar research on friction

and wear characteristics using Calophyllum

inophyllum (CIME 10%) and palm biodiesel (POME

20%). The research showed that the addition of diesel

fuels increased the frictional coefficient of pure

CIME and POME by 28.8% and 23.4%, respectively.

In addition, the PB20 compared to other tested fuels,

reduced the wear scar, thereby implying better

lubrication performance. These perliminary studies

clearly indicate that engine oil manufactured from

non-edible oil is suitable for lubricating engines.

This study produced biodiesel from biosources,

such as waste cooking and commercial engine oil

blended with Calophyllum inophyllum. The 4 Ball EP

test machine was used to investigate the wear test to

determine the frictional coefficient and lubrication

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1012

properties. This test was carried out based on D 4172

to investigate the wear preventative characteristics of

lubricity fluids. The effect of these fuels on wear and

frictional characteristics of lubricating oil was also

compared.

2 MATERIALS AND METHODS

2.1 Materials

The waste cooking and Calophyllum inophyllum (CI)

oils used to carry out this research were obtained from

the local market and supplied by Koperasi Jarak

Lestari, Kebumen, Central Java, Indonesia.

Furthermore, the chemicals and materials, such as

methanol (99.9% purity) and filter paper used were of

analytical grade. Furthermore, a chrome alloy steel

test ball, with a diameter of 12.7 mm (0.5 in.) and

grade 25 EP with Rockwell C hardness relatively 64

to 66, was purchased from SKF Malaysia Sdn Bhd.

Castrol Magnatec part synthetic 10W-40 lubricant oil

blended with waste cooking biodiesel, produced with

a hot plate magnetic stirrer reactor.

2.2 Experimental Set-up

During the experimental set-up, the manufactured

biodiesel had high viscosity and density due to the

presence of excess fatty acids in its molecular

structure. These fatty acids were converted into

monoalkyl esters by mixing one mole of triglyceride

with ethanol. Furthermore, the lipids obtained was

converted into ester when it reacted with methanol in

the presence of an acid catalyst. Moreover, the

collected waste cooking oil was purified with filter

paper to remove the solid impurities. Calophyllum

inophyllum and waste cooking oils were mixed in the

ratio of WC70CI30 (70 (v/v)% and 30 (v/v)%.

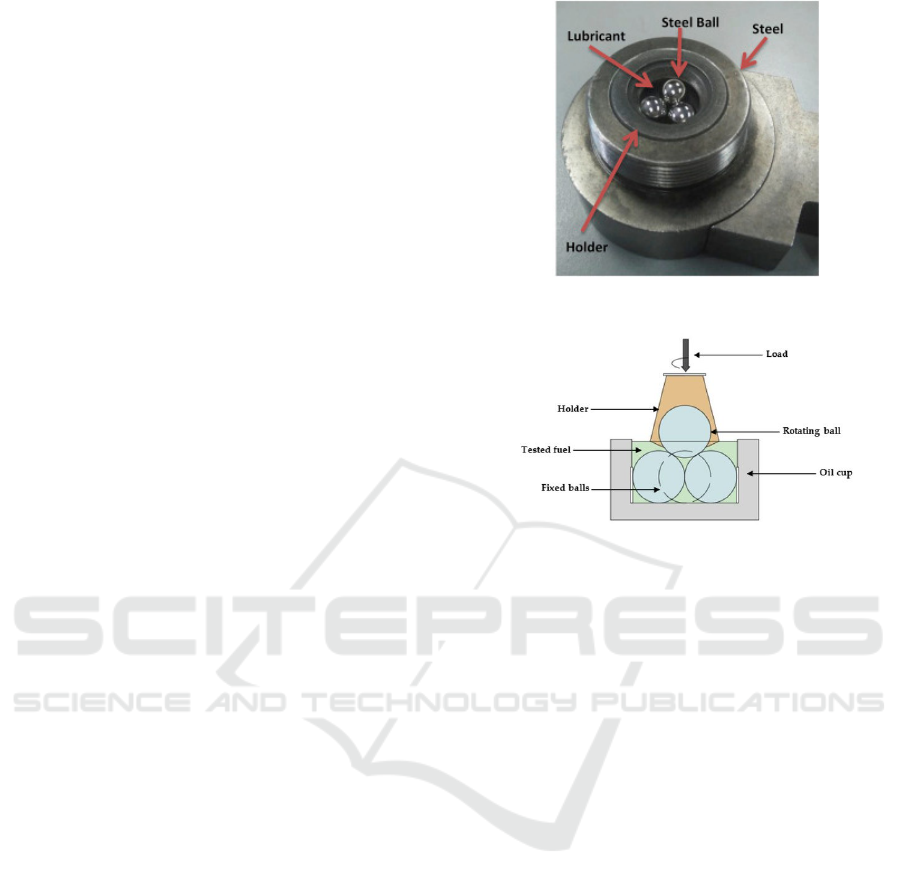

In addition, 3 cleaned steel balls were placed in

the test-lubricant cup and then locked with a nut at 68

± ƞm using a torque wrench shown in Figure 1.

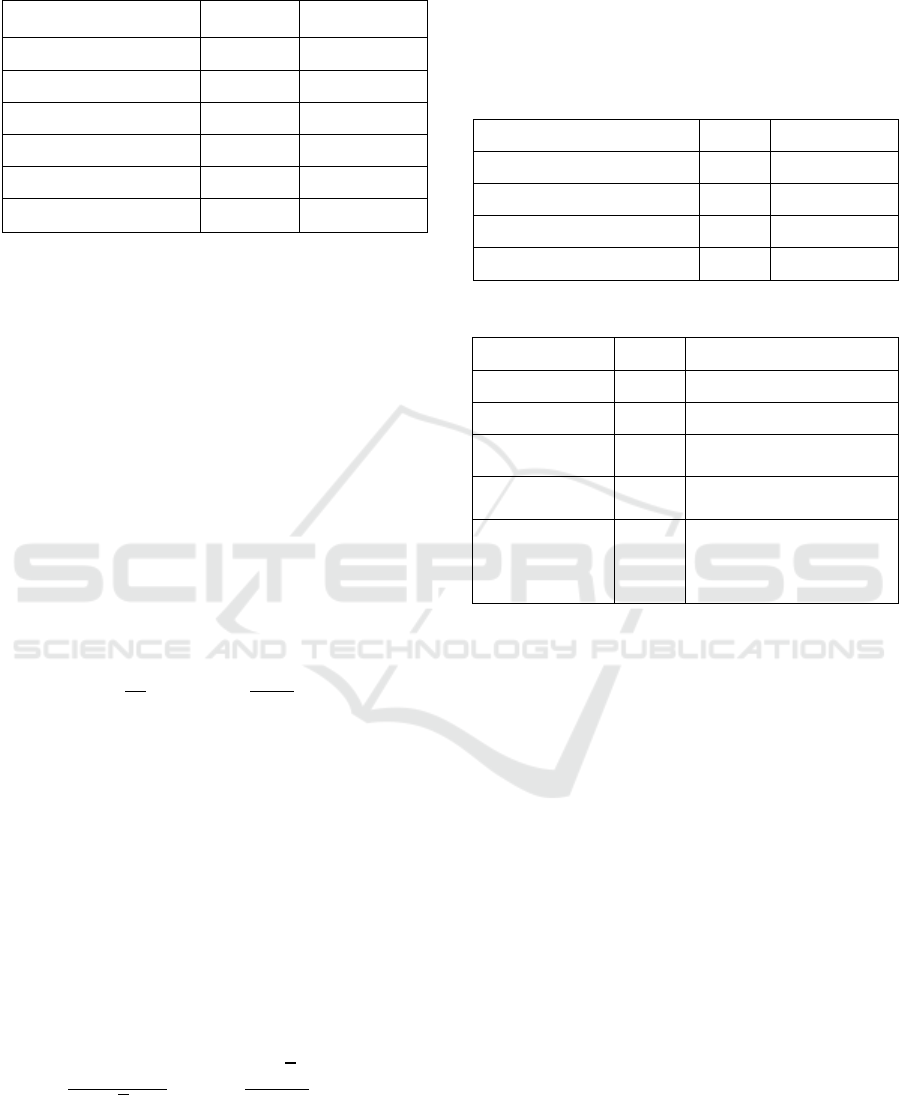

Subsequently, the Schematic diagram of the tribo-

tester cup is shown in Figure 2. The experiments were

carried out based on the wear preventive

characteristics of lubricating fluid (4-ball method)

according to ASTM D4172-94 with tests that lasted

for 1-hour, at a temperature of 75

o

C, with a spindle

speed of 1200 rpm and a 40 kg load.

Figure 1: Four ball tribo-tester cup.

Figure 2: Schematic diagram of the tribo-tester cup.

2.3 Biodiesel Production

The conversion efficiency of biodiesel production

depends on the molar ratio of alcohol to oil. The ratio

of methanol to 60% oil and 0.5 wt.% of H

2

SO

4

, was

made to react at 60° C for 1 hour. The crude oil is

highly acidic, therefore the esterification process

using a hot plate magnetic stirrer is required. In

addition, a completely dissolved methoxide solution

was obtained by dissolving 0.5 wt.% of potassium

hydroxide (KOH) in 60% of methanol and the

mixture was further added to the preheated waste

cooking oil at 65

o

C and a constant speed of 1000 rpm.

The entire process lasted for 60 min and after the

complete conversion, the extract was left overnight in

a separating funnel consisting of 3 layers. The

impurities and glycerine were found at the bottom

layer of the separating funnel, while the top consisted

of pure biodiesel. The middle layer is viscid and

needs to be separated. The methyl ester was further

dried using a vacuum rotary evaporator at 70

o

C for

45 min to remove the moisture content, while a

Whatman filter paper was used to extract any

insoluble material. Generally, 5% (L5), 10% (L10),

15% (L15), 20% (L20), and 25% (L25) of biodiesel

blended with lubricant were used to test the fluid.

Tribological Study of Biolubricant Made from Blend of Waste Cooking Oil and Calophyllum Inophyllum Oil

1013

Table 1: Composition of the various blending ratio (v/v)%

of lubricants with WC70CI30 biodiesel used in this study.

Biodiesel-Lubricant Lubricant

WC70CI30

b

iodiesel

BWCIL95 95 5

BWCIL90 90 10

BWCIL85 85 15

BWCIL80 80 20

BWCIL75 75 25

L100 100 -

2.4 Chemical and Physical Properties

with Fuel Characterization

The physicochemical properties of the biodiesel and

blended oil produced were determined using the

EN/ASTM standards. Furthermore, the automatic

density meter was used to measure the Kinematic

(Anton Paar) at 15

o

C and 40

o

C (Mettler Toledo). The

acid number was determined through the titration

method using a KOH-ethanol solution with the gas

chromatograph system equipped with an auto-

injector used to quantitatively analyze the samples.

The initial oven temperature of 150

o

C for 5 minutes

(60 m x 0.25 mm id., 0.25) was later increased to

250

o

C at a rate of 2

o

C for 17 minutes. The fatty acid

of methyl ester (FAME) yield is calculated using

equation (1).

𝑌𝑖𝑒𝑙𝑑% =

× 100% =

× 100% (1)

Where W

a

is the actual mass of FAME, and W

t

is the

theoretical mass. Meanwhile, Wester and Woil depict

the weight of fatty acid methyl ester (g) and oil used

(g) produced.

2.5 Test Procedure

2.5.1 Frictional and Wear Evaluation

Frictional and wear evaluation was performed using

a high-resolution optical microscope in accordance

with the ASTM D4172 standard. The friction of

coefficient (CoF) is expressed by Equation (2):

𝑇=

𝜇×3𝑊×𝑟

√

6

→ 𝜇 =

𝑇

√

6

3𝑊 × 𝑟

(2)

Where, μ= coefficient of friction, r = distance from

the centre of the contact surface on the lower balls to

the axis of rotation, which is 3.67 mm, T = frictional

torque in kg-mm, W = applied load in kg. Therefore,

the wear scar diameter (WSD) was measured and

analyzed using a DuCOM software with an installed

image acquisition system.

Table 2: Test parameter for the 4 ball wear tests.

Test parameter Unit Value

Fuel Temperature

o

C 75

Test duration S 3600

Applied load N 392

Rotation Rpm 1200

Table 3: Steel ball material.

Steel ball Unit Description

Diameter mm 12.7

Hardness HRc 62

Surface

roughness

um 0.1C.L.A

Materials

Carbon-chromium steel

(

SKF

)

Composition %

10.2% C; 0.45% Si;

0.12% P; 0.07% S; 1.46%

Cr; 0.42% Mn; 0.06% Ni;

2.15% Zn and 85.06% Fe

3 RESULT AND DISCUSSION

3.1 Properties of the Biodiesel and

Mixed Biodiesel

The thermophysical properties of WC and

WC70CI30 biodiesel, such as kinematic viscosity,

density, acid value and the flashpoint were

determined using the ASTM methods, as shown in

Table 4. WC70CI30 biodiesel had a lower kinematic

viscosity at 40 °C (4.72 mm

2

/s) than the WC (5.01

mm

2

/s). According to Blin et al. (2013) the

unsaturation factor is effectively applicable due to the

lower viscosity in the highly unsaturated oils in

glycerides carbon chains, which reduces the

compactness of triglycerides units. Furthermore, the

decrease in the mean molecular weight of the fatty

acids (shorter carbon chain length) was justified by

the lower kinematic viscosity (Wardana et al., 2018)

The densities of a moderate WC70CI30 and WC

biodiesel samples at 15 °C were 861.8 kg/m

3

and 862,

1 kg/m

3

respectively (Table 4) and is consistent with

ASTM D1298. Its value needs to be lower to have

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1014

proper fuel atomization in the injectors. Further,

lower density also reduces the smoke emission when

the engine operates at maximum power (Sharma

Dugala et al., 2021).

Acid value (AV) is a parameter that indicates the

amount of free fatty acid and residual catalyst

contained in the samples. Furthermore, the AV within

the ASTM D664 was placed in the middle of the

feedstock and used for biodiesel production. The

residual acid has the potential to produce corrosion

effects on the combustion engine as well as cause fuel

auto-oxidation. It also reduces the biodiesel shelf-life

due to the hydrolytic process, leading to the ester

bond's cleavage. An elevated biodiesel acid value is

able to increase the rate and level of its lubricant

degradation, thereby causing severe corrosion in the

engine systems (Haseeb et al., 2011). The acid value

of the WC70CI30 biodiesel is 0.46 mg KOH/g, which

is less than the permissible limit (0.5 mg KOH/g)

specified in the ASTM D6751 and EN 14214

standards, although higher than that of the WC (0.13

mg KOH/g).

In addition, Table 4 shows that the FAME

chemical compositions of the WC and WC70CI30

biodiesels produced are 97.45 (w/w)% and 98.84

(w/w)%., respectively. This indicates that the

WC70CI30 biodiesel has higher FAME content than

the WC. This fulfils the EN 14103:2011 standard test

method requirement, which stipulates that the FAME

content needs to be greater than 90 (w/w). The total

FAME content is not 100 (w/w)% for all methyl

esters due to an unidentifiable peak in the gas

chromatograms. This is due to the repeatability and

reproducibility limits of the gas chromatograph.

Calophyllum inophyllum biodiesel relatively had a

higher portion of unsaturated FAME compared to the

waste cooking oil. Moreover, the high content of

unsaturated fatty acid methyl esters was determined

at low temperatures. Consequently, a high degree of

unsaturation also causes the biodiesel to become more

susceptible to oxidation. In addition, the total (0.125

(w/w)%) and free glycerols (0.016 (w/w)%) fulfils

the specifications since its values are less than 0.25

(w/w)% and 0.02 (w/w)%, respectively. However, the

results of the total (0.205 (w/w)%) and free glycerols

(0.017 (w/w)%) are consistent with EN 14214.

Meanwhile, two final immiscible products (methyl

ester and glycerol) tend to become miscible because

of the soapy surfactant effect, reducing the reaction

yield. Furthermore, the glycerol was eliminated from

the methyl ester during the separation. The

WC70CI30 was discovered to have favourable

lubrication characteristics, while the biodiesel

properties were discussed in the following section.

3.2 Tribology Biodiesel of Lubricant Oil

The biodiesel and lubricant oil physicochemical

properties were further examined. These are essential

to investigate the compatibility of biodiesel blends

with automotive materials. The thermophysical

property study of the pure blended biodiesel with

lubricant is shown in Table 5. On the contrary, the

addition of lubricant oil to biodiesel is considered a

potential automotive fuel. Besides, the current

demand to carry out research related to engine fuel

wear and frictional characteristics becomes

imperative due to the frequent slippage of biodiesel

into the lubricant.

Table 4: Fuel characterization of waste cooking oil, Calophyllum inophyllum oil, blended WC70CI30 oil, WC biodiesel and

WC70CI30 biodiesel.

Property Unit WC raw oil CI raw oil WC70CI30 oil

WC

b

iodiesel

WC70CI30

b

iodiesel

Kinematic viscosity at 40 °C mm

2

/s 49.05 65.48 54.12 5.01 4.72

Density at 15 °C kg/m

3

904.4 929.2 912.2 862.1 861.8

Acid value mg KOH/g 2.19 63.25 19.75 0.13 0.46

Flashpoint

o

C — — —

154 160.5

FAME content (w/w) % — — —

97.45 98.94

Free glycerol (w/w)% — — — 0.017 0.016

Total glycerol (w/w)% — — — 0.205 0.125

Tribological Study of Biolubricant Made from Blend of Waste Cooking Oil and Calophyllum Inophyllum Oil

1015

Table 5: Kinematic viscosity and density of various

blending ratios of lubricants with WC70CI30 biodiesel

used in this study.

Name

Kinematic viscosity Density

40°C 100°C VI 15°C

BWCIL95 76.34 11.78 148.7 0.8689

BWCIL90 62.26 10.49 158.1 0.8696

BWCIL85 51.33 9.268 164.9 0.8702

BWCIL80 42.82 8.242 171 0.8707

BWCIL75 35.98 7.419 178.8 0.8713

L100 92.08 12.94 138.4 0.8685

A lubricant’s viscosity is its most important

property and is affected by temperature. The

lubricant’s formulation and quality tend to impact the

extent its viscosity drops with increasing temperature.

The change in oil’s viscosity due to an increase or

decrease in temperature is called viscosity index (VI).

This is important to discern whether the lubricant in

question meets the asset’s requirements based on the

operating temperature range. Therefore, adopting a

proactive approach to monitor the lubricant’s

viscosity makes a huge difference in machineries'

lives. The viscosity index was calculated using the

KV at 40

o

C and 100

o

C as stated in the ASTM

(American Standards for Testing Material) D2270

table, meanwhile the value obtained for the base oil

was 138.4.

The addition of lubricant to the waste cooking and

WC70CI30 biodiesel increases the viscosity index.

Subsequently, high viscosity results in good

lubrication properties asides from the hydrodynamic

condition. This simply means that they are subjected

to slight change in extreme temperatures and are

therefore considered to have stable viscosity. The

blends are regarded as ideal oils because they

maintain constant viscosity in all temperature

changes. An increase in the VI value for the different

blend proportions was also recorded. This complex

mixture of hydrocarbon molecules is relevant for the

classifications of products derived from crude oil and

biodiesel and is readily available in a great variety of

grades. It is a measure of a lubricant’s molecular

constitution from the hydrocarbon chain size

standpoint. Moreover, viscosity is determined by the

friction between individual molecules in a liquid, and

it is responsible for resistance to flow. Therefore, the

higher the intermolecular friction with longer

molecular chains, the greater the viscosity.

3.3 Anti-wear Behaviour

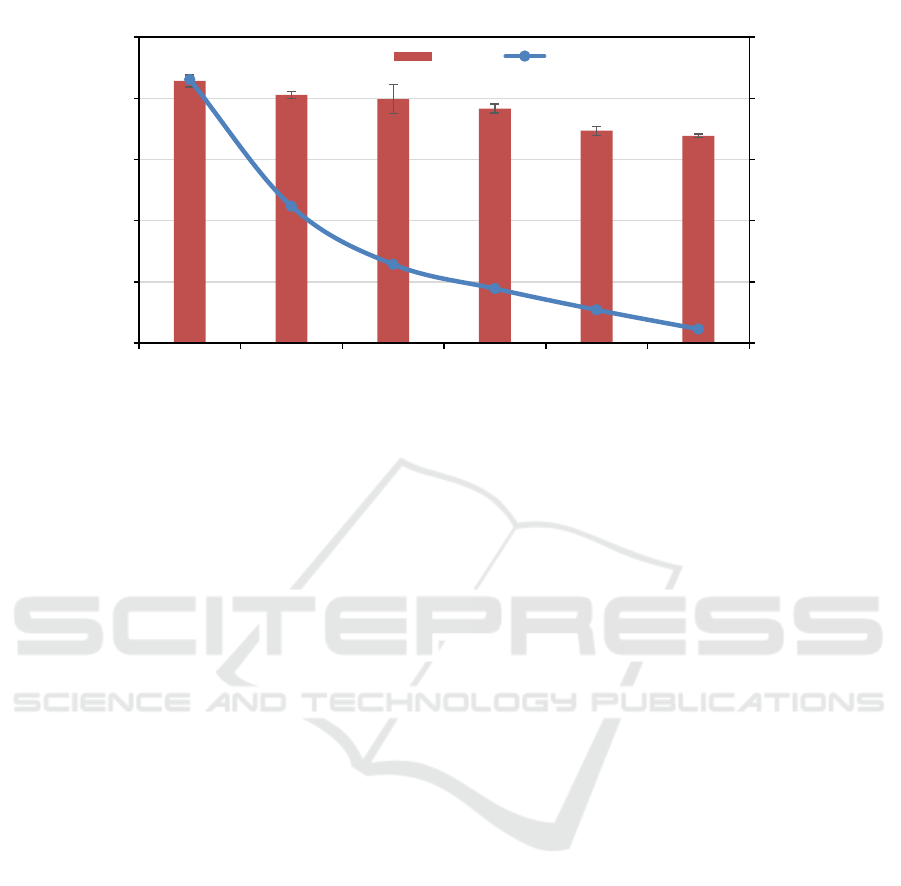

The wear tests were carried out using the WC70CI30

biodiesel blend with lubricant at various ratios, as

shown in Table . The CoF values were recorded

automatically during the tests. The wear preventive

tests were carried out with a constant load of 392 N

(40 kg) at an operating temperature of 75 °C and 1200

rpm rotational speed for 1 hr. Every experiment was

carried out thrice to obtain an average CoF value.

Furthermore, the stability and Wear Scar Diameter

(WSD) of the specimen was measured. The wear

behaviour of all considered oil and biodiesel is shown

in Figure 3.

It was observed that the duration of the run-in

phase is dependent on the physical, chemical, and

geometrical characteristics of the contact surfaces as

well as the ability of the lubricant to provide wear

protection. The CoF for all blended mixtures was

significantly improved. The WCIL75 biodiesel has

the least CoF (0.072) compared to other mixtures.

Moreover, the WSD obtained for WC70CI30

biodiesel with lubricant L95 is 405.92 µm. It was

observed that after the addition of biodiesel content in

the various stages from L95 to L75, there was a

reduction in the WSD.

Figure 3 shows the CoF and WSD realized from

the biodiesel-lubricant blend and lubricant. As

depicted in these figures, the CoF and WSD

decreased following the increase of biodiesel. The

CoF and WSD of BWCIL75 (0.072 and 338.73 µm)

was determined to be lower compared to the lubricant

(0.113077 and 428.64 µm). The WC70CI30 excellent

anti-wear efficiency was explained using these 2

factors. The WC70CI30 has a lower molecular

weight, are more active, easily decomposes and reacts

with metal surfaces. Therefore, the presence of an

unsaturated double bond in the molecule causes it to

become more polar and sensitive in terms of

adsorbing the newly exposed metal surface to assist

in tribochemical reactions. Biodiesel in lubricants

tend to improve the lubricity and reduces the WSD

additionally, it is used as a wear reducer. Zulkifli et

al. (2016) reported that the high concentration of the

unique fatty acid methyl ester could be responsible

for the lubricity-enhancing properties of biodiesel.

Calero et al. (2015) further reported that the

monoacylglycerides (MG) was proven to enhance

lubricity of biodiesel. The polarity of biodiesel and

vegetable oils has a chemical modification, which

improves the lubricity of steel balls metal surface.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1016

Figure 3: WSD and CoF for WC70CI30 biodiesel blend with lubricant (Conditions: Load: 392 N, Temperature: 75 °C,

Duration: 1 hr).

4 CONCLUSIONS

In conclusion, the tribological behavioural

characteristics of the lubricant and biodiesel blend

with lubricant were evaluated using a 4-ball tribo

tester with varying weight percentages. Furthermore,

biodiesel is a potential bio-lubricant for automotive

applications. It enhances mineral oils such as

lubricity, high viscosity, acts as a good anti-wear

property, and better frictional coefficient, low

emission of metal traces into the atmosphere and

rapid biodegradability. Moreover, its addition

reduces the lubricating oil's viscosity, thereby

investigating frictional and wear performances of the

blending oils and biodiesel. This reduces the

dependency on mineral oil-based lubricants by a few

percentage points. Biodiesel components, such as

fatty acid methyl esters, free fatty acids, and

monoglycerides, reportedly improve the lubricity of

biodiesel, thereby substantially reducing wear

tendencies. However, the lubricity of biodiesel at

higher temperatures is relatively decreased`. It can be

effect the biodiesel-lubricant combination shows a

much lower scar diameter than the blends.

Furthermore, it reduces WSD and CoF, and provides

an opportunity for industries to replace bio-fuel

production with lubricants that meet certain quality

standards. Furthermore, it reduces WSD and CoF,

and provides an opportunity for industries to replace

bio-fuel production with lubricants that meet certain

quality standards.

ACKNOWLEDGEMENTS

The authors are grateful to the Politeknik Negeri

Medan, Medan, Indonesia, for financially supporting

this research through the financial grant No.

B/189/PL5/TU.01.05/2021. The authors are also

grateful to the Institute of Sustainable Energy

UNITEN for their support.

REFERENCES

Adekunle, A.S., Oyekunle, J.A.O., Oduwale, A.I.,

Owootomo, Y., Obisesan, O.R., Elugoke, S.E.,

Durodola, S.S., Akintunde, S.B., Oluwafemi, O.S.

(2020). Biodiesel potential of used vegetable oils

transesterified with biological catalysts. Energy

Reports 6, 2861-2871.

Arumugam, S., Sriram, G., Ellappan, R. (2014). Bio-

lubricant-biodiesel combination of rapeseed oil: An

experimental investigation on engine oil tribology,

performance, and emissions of variable compression

engine. Energy 72, 618-627.

Blin, J., Brunschwig, C., Chapuis, A., Changotade, O.,

Sidibe, S., Noumi, E.S., Girard, P. (2013).

Characteristics of vegetable oils for use as fuel in

stationary diesel engines—Towards specifications for a

standard in West Africa. Renewable and Sustainable

Energy Reviews 22, 580-597.

Calero, J., Luna, D., Sancho, E.D., Luna, C., Bautista, F.M.,

Romero, A.A., Posadillo, A., Berbel, J., Verdugo-

Escamilla, C. (2015). An overview on glycerol-free

processes for the production of renewable liquid

0,07

0,08

0,09

0,1

0,11

0,12

0

100

200

300

400

500

L100 BWCIL95 BWCIL90 BWCIL85 BWCIL80 BWCIL75

CoF

WSD (µm)

Lubricant and W70CI30 biodiesel blend with lubricant

WSD CoF

Tribological Study of Biolubricant Made from Blend of Waste Cooking Oil and Calophyllum Inophyllum Oil

1017

biofuels, applicable in diesel engines. Renewable and

Sustainable Energy Reviews 42, 1437-1452.

Cordero-Ravelo, V., Schallenberg-Rodriguez, J. (2018).

Biodiesel production as a solution to waste cooking oil

(WCO) disposal. Will any type of WCO do for a

transesterification process? A quality assessment.

Journal of environmental management 228, 117-129.

Dharma, S., Hassan, M.H., Ong, H.C., Sebayang, A.H.,

Silitonga, A.S., Kusumo, F., Milano, J. (2017).

Experimental study and prediction of the performance

and exhaust emissions of mixed Jatropha curcas-Ceiba

pentandra biodiesel blends in diesel engine using

artificial neural networks. Journal of cleaner

production 164, 618-633.

Ge, J.C., Kim, H.Y., Yoon, S.K., Choi, N.J. (2018).

Reducing volatile organic compound emissions from

diesel engines using canola oil biodiesel fuel and

blends. Fuel 218, 266-274.

Haseeb, A.S.M.A., Fazal, M.A., Jahirul, M.I., Masjuki,

H.H. (2011). Compatibility of automotive materials in

biodiesel: A review. Fuel 90, 922-931.

Khan, H.M., Iqbal, T., Yasin, S., Irfan, M., Kazmi, M.,

Fayaz, H., Mujtaba, M., Ali, C.H., Kalam, M.,

Soudagar, M.E.M. (2021). Production and utilization

aspects of waste cooking oil based biodiesel in

Pakistan. Alexandria Engineering Journal 60, 5831-

5849.

Ma, Q., Zhang, Q., Liang, J., Yang, C. (2021). The

performance and emissions characteristics of

diesel/biodiesel/alcohol blends in a diesel engine.

Energy Reports 7, 1016-1024.

Mosarof, M.H., Kalam, M.A., Masjuki, H.H.,

Alabdulkarem, A., Habibullah, M., Arslan, A.,

Monirul, I.M. (2016). Assessment of friction and wear

characteristics of Calophyllum inophyllum and palm

biodiesel. Industrial Crops and Products 83, 470-483.

Sharma Dugala, N., Singh Goindi, G., Sharma, A. (2021).

Evaluation of physicochemical characteristics of

Mahua (Madhuca indica) and Jatropha (Jatropha

curcas) dual biodiesel blends with diesel. Journal of

King Saud University - Engineering Sciences 33, 424-

436.

Silitonga, A.S., Masjuki, H.H., Ong, H.C., Kusumo, F.,

Mahlia, T.M.I., Bahar, A.H. (2016). Pilot-scale

production and the physicochemical properties of palm

and Calophyllum inophyllum biodiesels and their

blends. Journal of Cleaner Production 126, 654-666.

Silitonga, A.S., Masjuki, H.H., Ong, H.C., Sebayang, A.H.,

Dharma, S., Kusumo, F., Siswantoro, J., Milano, J.,

Daud, K., Mahlia, T.M.I. (2018). Evaluation of the

engine performance and exhaust emissions of

biodiesel-bioethanol-diesel blends using kernel-based

extreme learning machine. Energy 159, 1075-1087.

Silitonga, A.S., Shamsuddin, A.H., Mahlia, T.M.I., Milano,

J., Kusumo, F., Siswantoro, J., Dharma, S., Sebayang,

A.H., Masjuki, H.H., Ong, H.C. (2020). Biodiesel

synthesis from Ceiba pentandra oil by microwave

irradiation-assisted transesterification: ELM modeling

and optimization. Renewable Energy 146, 1278-1291.

Wardana, I., Widodo, A., Wijayanti, W. (2018). Improving

vegetable oil properties by transforming fatty acid chain

length in jatropha oil and coconut oil blends. Energies

11, 394.

Yilmaz, N., Atmanli, A., Trujillo, M. (2017). Influence of

1-pentanol additive on the performance of a diesel

engine fueled with waste oil methyl ester and diesel

fuel. Fuel 207, 461-469.

Zahan, K.A., Kano, M. (2018). Biodiesel production from

palm oil, its by-products, and mill effluent: A review.

Energies 11, 2132.

Zulkifli, N.W.M., Azman, S.S.N., Kalam, M.A., Masjuki,

H.H., Yunus, R., Gulzar, M. (2016). Lubricity of bio-

based lubricant derived from different chemically

modified fatty acid methyl ester. Tribology

International 93, 555-562.

Zulkifli, N.W.M., Kalam, M., Masjuki, H.H., Shahabuddin,

M., Yunus, R. (2013). Wear prevention characteristics

of a palm oil-based TMP (trimethylolpropane) ester as

an engine lubricant. Energy 54, 167-173.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1018