Effect of Nitrate-based Cetane Improver on Ternary Higher Alcohol

Biodiesel Blends and Diesel Engine Exhaust Emissions

H.KH. K. Imdadul

1

, A. H. Sebayang

2,3 a

, A. S. Silitonga

2,3 b

, H. H. Masjuki

1,4

, M. A. Kalam

1

,

Jassinnee Milano

5c

,

H. Ibrahim

2,3 d

and Abd. Halim Shamsuddin

6

1

Department of Mechanical Engineering, Faculty of Engineering, University of Malaya,50603, Kuala Lumpur, Malaysia

2

Department of Mechanical Engineering, Politeknik Negeri Medan, 20155 Medan, Indonesia

3

Centre of Renewable Energy, Department of Mechanical Engineering, Politeknik Negeri Medan, 20155, Medan, Indonesia

4

Department of Mechanical Engineering, Kulliyyah of Engineering International Islamic University Malaysia,

Kuala Lumpur, Malaysia

5

Department of Mechanical Engineering, College of Engineering, University Tenaga National, Kajang, Malaysia

6

Institute of Sustainable Energy, Universiti Tenaga Nasional, Kajang, Malaysia

jassinneemilano.jm@gmail.com, husinibrahim@yahoo.co.id, abdhalim@uniten.edu.my

Keywords: Biodiesel, Pentanol, Diesel-Biodiesel-Alcohol Blends, Nitrate-based Cetane Improver, Exhaust Emissions.

Abstract: Biofuels such as biodiesel and bioalcohols are promising alternative sources of renewable energy. However,

the lower cetane number of diesel-biodiesel-alcohol blends is a critical issue, resulting in higher noxious

engine pollutants. The objective of this study is to investigate the effects of blending diesel with 10 vol% of

palm biodiesel, 10 vol% of pentanol (long-chain alcohol), and 1 vol% of ethyl hexyl nitrate (EHN) on the fuel

properties and exhaust emissions of a single-cylinder, four-stroke, direct injection diesel engine. EHN was

added to improve the cetane number of the fuel blend. The engine tests were carried out at full throttle and

different engine speeds (1200–2400 rpm). The results show that the viscosity and density of the PB10PN10E1

blend (10 vol% of palm biodiesel + 10 vol% of pentanol + 1 vol% of EHN) are the lowest compared with

those for diesel, and PB10 (10 vol% of palm biodiesel), and PB10PN10 (10 vol% of palm biodiesel + 10 vol%

of pentanol), which improves fuel spray atomization. In addition, the cetane number, oxidation stability at

110 °C, and flash point are the highest for the PB10PN10E1 blend. The carbon monoxide and unburned

hydrocarbon emissions are the lowest for the PB10PN10 blend, though the values do not differ significantly

for the PB10PN10E1 blend. The smoke intensity values are the lowest for the PB10PN10E1 blend at all

engine speeds. Even though the NO

x

emissions are the lowest for diesel, the values do not differ significantly

from those for the biodiesel blends. The biodiesel blends tested in this study can be used directly in a diesel

engine without any modifications. Furthermore, cetane improvers of 20% ethyl hexyl nitrate oil can be a

potential alternative fuel for diesel engines and in line with other European Union rules and other global

adopted emission regulations.

1 INTRODUCTION

Energy plays a vital role in our daily life, and it is

widely used in various industries ranging from

agriculture and mining to construction and

transportation. Fossil fuels are the major fuel in the

transportation industry. Fossil fuel reserves account

a

https://orcid.org/0000-0002-0810-7625

b

https://orcid.org/0000-0002-0065-8203

c

https://orcid.org/0000-0001-7130-072X

d

https://orcid.org/0000-0002-7992-9618

for 26–27% of the total energy consumption and may

be entirely replaced by biofuels by 2050 (Imdadul et

al., 2015). Biodiesels produced from plant oils or

animal fats have garnered significant attention from

researchers as an alternative to fossil fuels owing to

their benefits: environmental friendliness,

sustainability, biodegradability, high flash points, and

Imdadul, H., Sebayang, A., Silitonga, A., Masjuki, H., Kalam, M., Milano, J., Ibrahim, H. and Shamsuddin, A.

Effect of Nitrate-based Cetane Improver on Ternary Higher Alcohol Biodiesel Blends and Diesel Engine Exhaust Emissions.

DOI: 10.5220/0010957800003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 995-1002

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

995

high cetane numbers (Murugesan et al., 2009).

Conversely, some biodiesels have poor

physicochemical properties such as high viscosities,

low volatilities, and poor cold flow properties, which

lead to problems in diesel engines. The poor

physicochemical properties lead to ignition delays

and large quantities of carbon deposits in the diesel

engine (Basha et al., 2009). For this reason, a small

concentration of biodiesel or bioalcohol (typically 10

vol%) is blended with diesel in order to improve the

physicochemical and cold flow properties, and the

fuels can be used directly in diesel engines without

any modifications (Atmanli et al., 2014). However,

lower carbon alcohols such as methanol and ethanol

are disadvantageous because microemulsion tends to

form at lower temperatures due to separation

(Atmanli et al., 2015). In addition, the poor lubricity,

low cetane numbers, and low heating values of lower

carbon alcohols prohibit the direct use of these fuels

in diesel engines (Campos-Fernandez et al., 2013).

The use of long-chain alcohols such as butanol and

pentanol blended with diesel has recently drawn

considerable attention from researchers due to their

higher miscibility with diesel (Atmanli et al., 2015;

Yilmaz et al., 2014). Imdadul et al. (2016) studied the

fuel properties, performance, emissions, and

combustion characteristics of a diesel engine fuelled

with pentanol-biodiesel-diesel blends. Lapuerta et al.

(2007) found that blending pentanol with diesel

improves the calorific value and cetane number of the

treated mixture (Lapuerta et al., 2007). Alcohol-based

mixtures have remarkably reduced the carbon

monoxide (CO) and unburned hydrocarbon (HC)

emissions as well as smoke intensity compared with

biodiesel-diesel blends. However, there was a slight

increase in the nitrogen oxide (NO

x

) and carbon

dioxide (CO

2

) emissions. Li et al. (2015b)

investigated the combustion and emission

characteristics of a diesel engine fuelled with diesel-

biodiesel-pentanol blends. They found that the

inherent nature of alcohols (lower viscosity and high

volatility) improves the atomization characteristics of

biodiesel blends (Kumar et al., 2013). In addition,

diesel-biodiesel-pentanol fuel blends resulted in low

soot and NO

x

emissions, especially at low and

intermediate engine loads. The CO emissions were

found to be greatly reduced owing to the presence of

oxygen in the fuel blends, and the HC emissions were

the lowest at low engine loads (Li et al., 2015b). Wei

et al. (2014) investigated the emissions of diesel-

pentanol fuel blends and they claimed that the best

volume ratio for pentanol-diesel fuel blends is 3:7.

The addition of pentanol improves the in-cylinder

combustion characteristics; however, this comes at

the expense of higher nitrogen dioxide (NO

2

)

emissions. (Li et al., 2015a) found that pentanol

improves premixed combustion and the resistance to

engine knocking compared with diesel; however, this

is negated by the lower cetane number of the fuel (Li

et al., 2015a). The benefits of using higher

concentrations of alcohol in diesel engines have

attracted the attention of many researchers, but many

claimed that fuel blends with higher alcohol

concentrations will result in higher exhaust emissions

at certain engine loads. The lower cetane number of

alcohol fuel blends can be solved by adding a cetane

improver additive. It is important to improve the

cetane number as this will promote the oxidizing

characteristics of the fuel blend (Li et al., 2014). To

date, there is a paucity of studies concerning the use

of ethyl hexyl nitrate (EHN) as a cetane improver

additive in pentanol-diesel-biodiesel blends. Hence,

the aim of this study is to investigate the effects of

blending diesel with 10 vol% of palm biodiesel, 10

vol% of pentanol, and 1 vol% of EHN on the fuel

properties and exhaust emissions of a single-cylinder,

four-stroke, direct injection diesel engine. It is

believed that the findings of this study will provide

insight on how the addition of pentanol and EHN

affects the fuel properties (viscosity at 40 °C, density

at 20 °C, calorific value, cetane number, and flash

point) as well as exhaust emissions (NO

x

, HC, and

CO emissions, and smoke intensity), which will be

useful to other researchers in this field.

2 METHODOLOGY

2.1 Materials

The palm oil was sourced from the Forest Research

Institute Malaysia. The chemicals used to produce the

palm biodiesel were anhydrous sodium sulphate

(NA

2

SO

4

), methanol (CH

3

OH), and potassium

hydroxide (KOH). Filter paper was used to filter the

biodiesel from foreign particles and impurities.

Pentanol and EHN were purchased from Nacalai

Tesque, Inc. and Sigma-Aldrich, respectively.

2.2 Biodiesel Properties

The biodiesel production process and

characterization of diesel, palm methyl ester (palm

biodiesel), and biodiesel blends were carried out at

the Tribology Laboratory, Department of Mechanical

Engineering, University of Malaya. Three fuel blends

were prepared in this study, namely, (1) PB10 (10

vol% of biodiesel), (2) PB10PN10 (10 vol% of

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

996

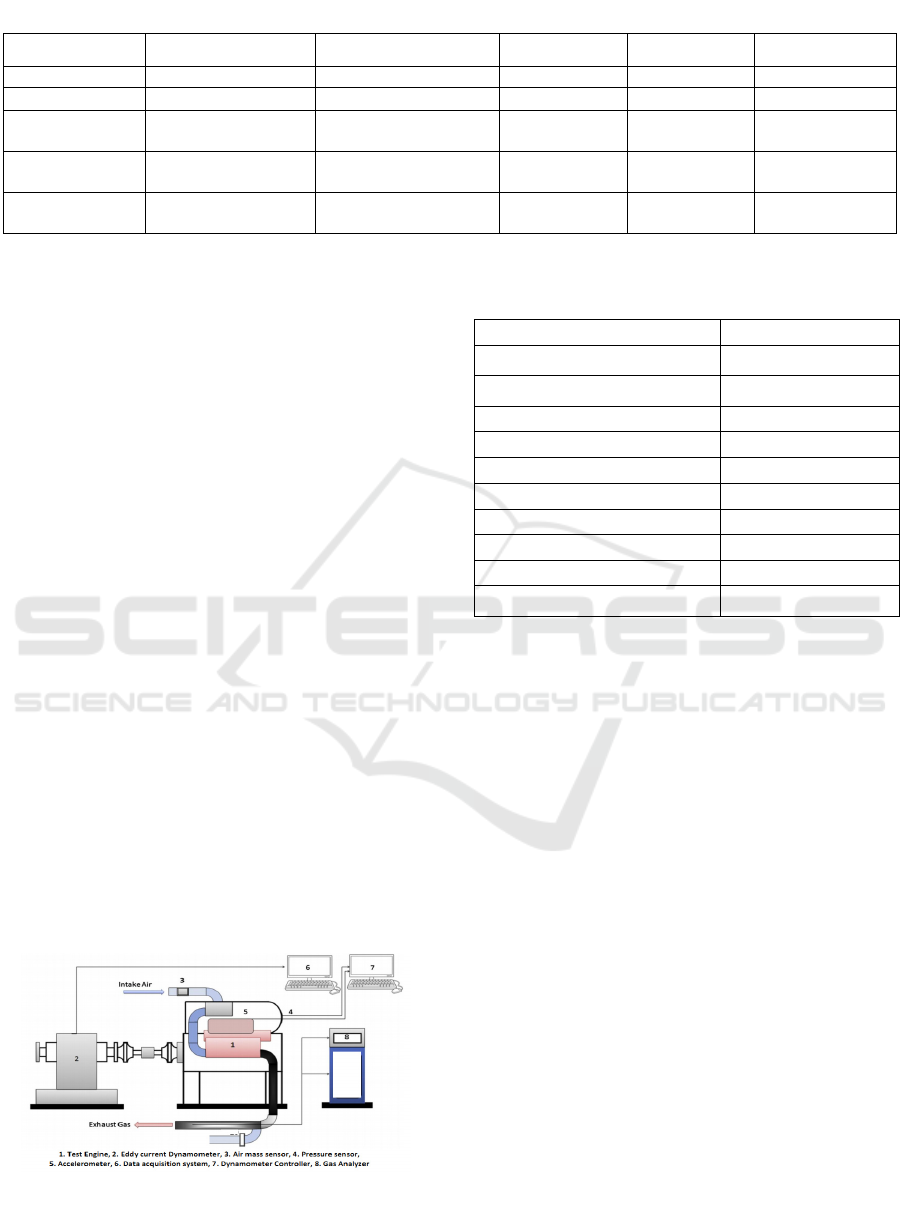

Table 1: List of instruments used to measure the properties of the test fuels.

Property Instrument Manufacturer Model Standard Accuracy

Viscosity Viscomete

r

Anton Paar, Austria SVM 3000 ASTM D445 ±0.1 mm

2

/s

Density Viscometer Anton Paar, Austria SVM 3000 ASTM D127 ±0.1 kg/m

3

Flash point

Pensky-Martens

flash point teste

r

Normalab, France NPM 440 ASTM D93 ±0.1 °C

Calorific value

Semi-automatic

b

omb calorimete

r

Perr, USA 6100EF ASTM D240

Up to 12000

calories/charge

Oxidation

stabilit

y

873 Rancimat Metrohm, Switzerland 873 Rancimat EN 14112 ±0.01h

biodiesel + 10 vol% of pentanol), and (3)

PB10PN10E1 (10 vol% of biodiesel + 10 vol% of

pentanol + and 1 vol% of EHN). The

physicochemical properties of the fuels used in this

study were examined in accordance with the ASTM

6751 and EN 14214 standards. The instruments used

to measure the properties of the fuels are presented in

Table 1.

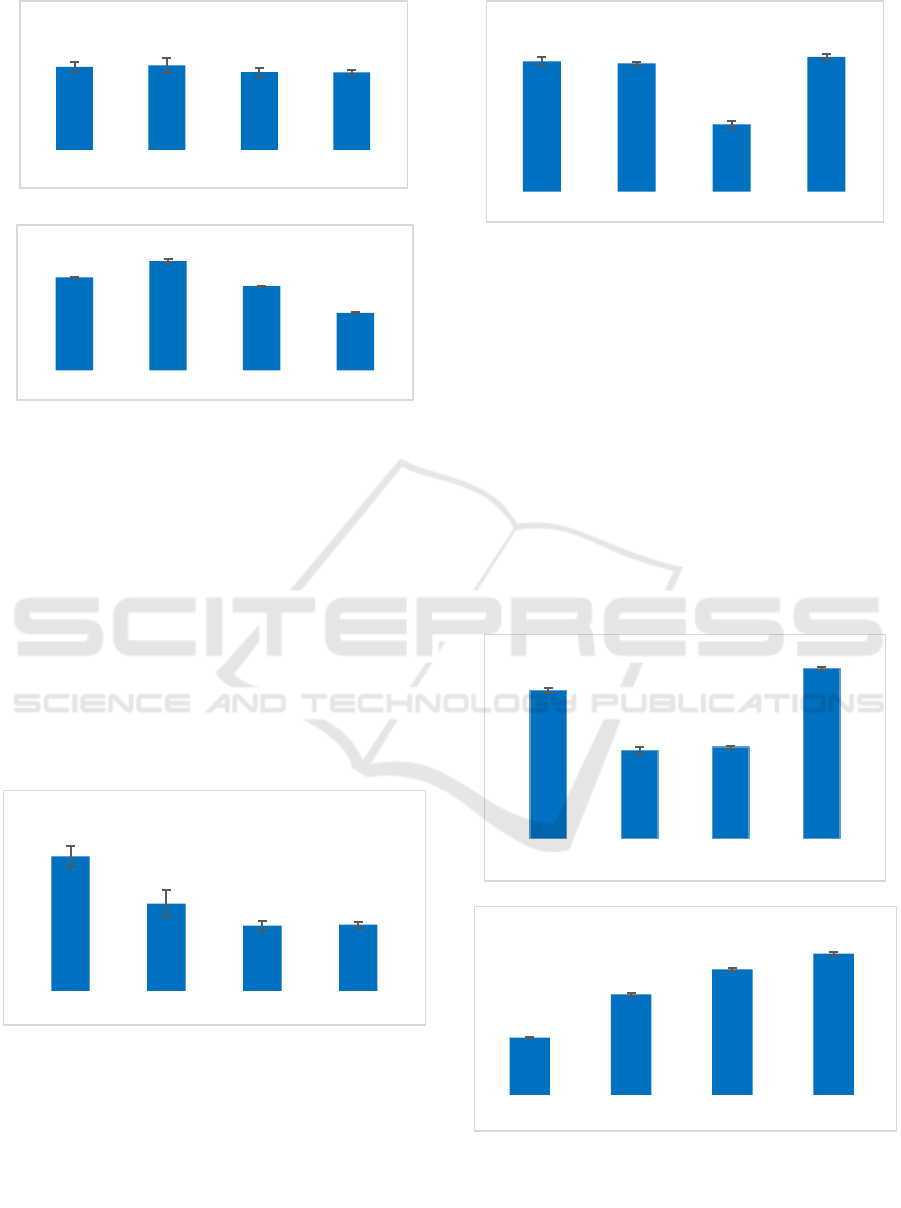

2.3 Test Engine

The exhaust emissions of a single-cylinder, four-

stroke, direct injection diesel engine were measured

at the Heat Engine Laboratory, Department of

Mechanical Engineering, University of Malaya. Fig.

1 shows the test engine set-up, and the specifications

of the test engine are listed in Table 2. The test engine

was connected to an eddy current dynamometer and

data acquisition system. The dynamometer was used

to measure and adjust the engine speed while the data

acquisition system was used to observe and record the

exhaust emissions using Dynomax 2000 software. K-

type thermocouples were used to measure the

temperature of the lubricating oil, water cooler,

exhaust gas, and inlet air. The fuel flow rate was

controlled by using Kobold ZOD positive-

displacement-type flow meter. There are two

separated fuel tanks; one was filled with diesel while

the other was filled with the fuel blend.

Figure 1: Schematic of the single-cylinder, four-stroke,

direct injection diesel engine test bed.

Table 2: Specifications of the single-cylinder, four-stroke,

direct injection diesel test engine.

Engine model Yanmar TF 120M

Number of cylinders Single

Bore × stroke 92 mm × 96 mm

Displacement 0.638 L

Compression ratio 17.7:1

Maximum power 7.7 kW

Maximum engine speed 2400 rpm

Cooling system Water cooling

Injection system Direct injection

Injection timing 17.0 BTDC

Injection pressure 200 kg/cm

2

3 RESULTS AND DISCUSSION

3.1 Fuel Properties

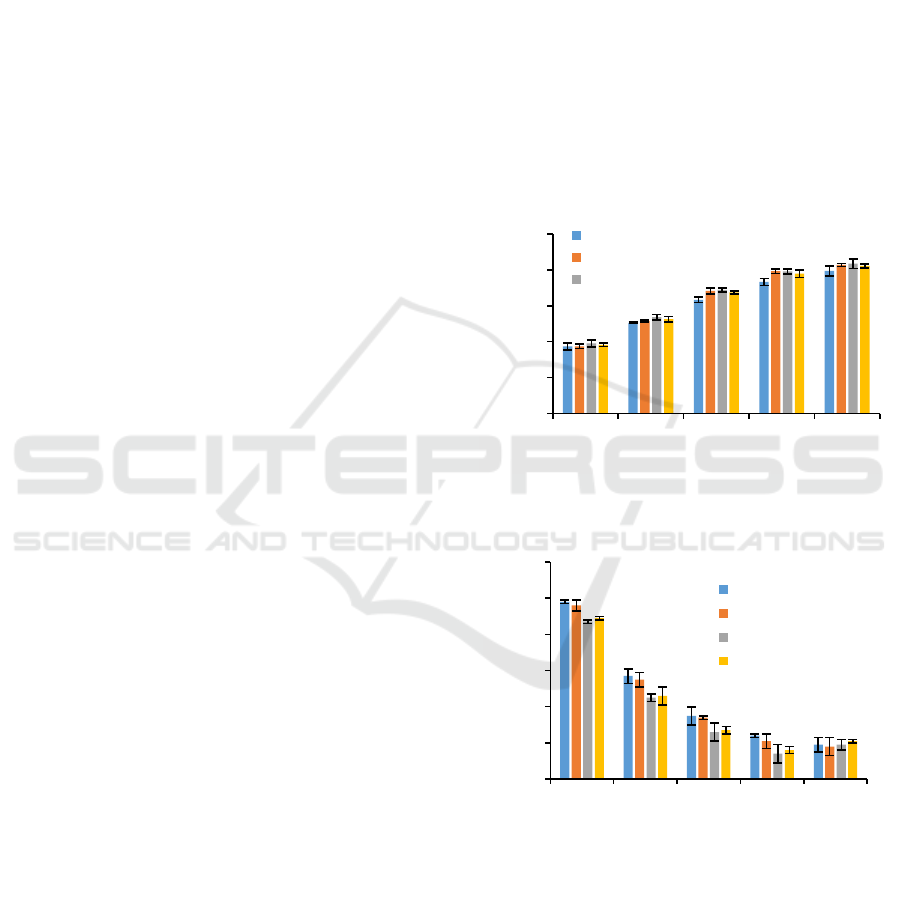

Variations in the fuel properties due to the addition of

pentanol and EHN are shown in Figs. 2–4. It can be

seen from Fig. 2 that although the PB10 blend has a

higher kinematic viscosity and density compared with

diesel, the addition of pentanol decreases the

kinematic viscosity and density for the PB10PN10

and PB10PN10E1 blends, which will promote the

atomization efficiency (Li et al., 2015b). The

kinematic viscosity decreases by 7.86 and 8.12% for

the PB10PN10 and PB10PN10E1 blends,

respectively, relative to that for the PB10 blend. The

density decreases by 0.26 and 0.52% for the

PB10PN10 and PB10PN10E1 blends, respectively,

relative to that for the PB10 blend. This indicates that

the addition of pentanol and EHN reduces the

kinematic viscosity at 40 °C and density at 20 °C.

Effect of Nitrate-based Cetane Improver on Ternary Higher Alcohol Biodiesel Blends and Diesel Engine Exhaust Emissions

997

(a)

(b)

Figure 2: (a) Kinematic viscosity at 40 °C and (b) density

at 20 °C of the test fuels.

The calorific value of alcohol is relatively lower,

and therefore, the calorific values of the PB10PN10

and PB10PN10E1 blends are lower by ~0.5% than

those of other test fuels, as shown in Fig. 3. The

addition of EHN results in a slight increase in the

calorific value. The cetane number of the PB10PN10

blend is lower than that of the PB10 blend by 5.2%.

However, the cetane number increases by 6% for the

PB10PN10 blend compared with that for the PB10

blend, indicating that the addition of EHN boosts the

cetane number of the diesel-biodiesel-alcohol fuel

blend.

(a)

(b)

Figure 3: (a) Calorific value and (b) cetane number of the

test fuels.

Fig. 4 shows the oxidation stability at 110 °C and

flash point of the test fuels. In general, the PB10 blend

has a lower oxidation stability than diesel. The

addition of pentanol increases the calorific value by

3.1%, as demonstrated by the results for the

PB10PN10 blend. The addition of EHN significantly

improves the oxidation stability by 9.44%, as

indicated by the result for the PB10PN10E1 blend.

The flash point increases as more constituents are

added into the palm biodiesel. The addition of

pentanol (PB10PN10) and EHN (PB10PN10E10)

increases the flash point by 5.05 and 3.03% relative

to that for PB10, respectively.

(a)

(b)

Figure 4: (a) Oxidation stability at 110 °C and (b) flash

point of the test fuels.

3,5

3,56

3,28

3,271

Diesel PB10 PB10PN10 PB10PN10E1

Viscosity @40

o

C (mm2/s)

829,71

832,30

828,33

824,10

Diesel PB10 PB10PN10 PB10PN10E1

Density @20

o

C (kg/m3)

44,34

43,87

43,65

43,66

Diesel PB10 PB10PN10 PB10PN10E1

Calorific value (MJ/kg)

54,0

53,9

51,1

54,2

Diesel PB10 PB10PN10 PB10PN10E1

Cetane number

38,00

22,60

23,43

43,66

Diesel PB10 PB10PN10 PB10PN10E1

Oxidation stability @ 110

o

C (h)

68,7

75,3

79,1

81,5

Diesel PB10 PB10PN10 PB10PN10E1

Flash point (

o

C)

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

998

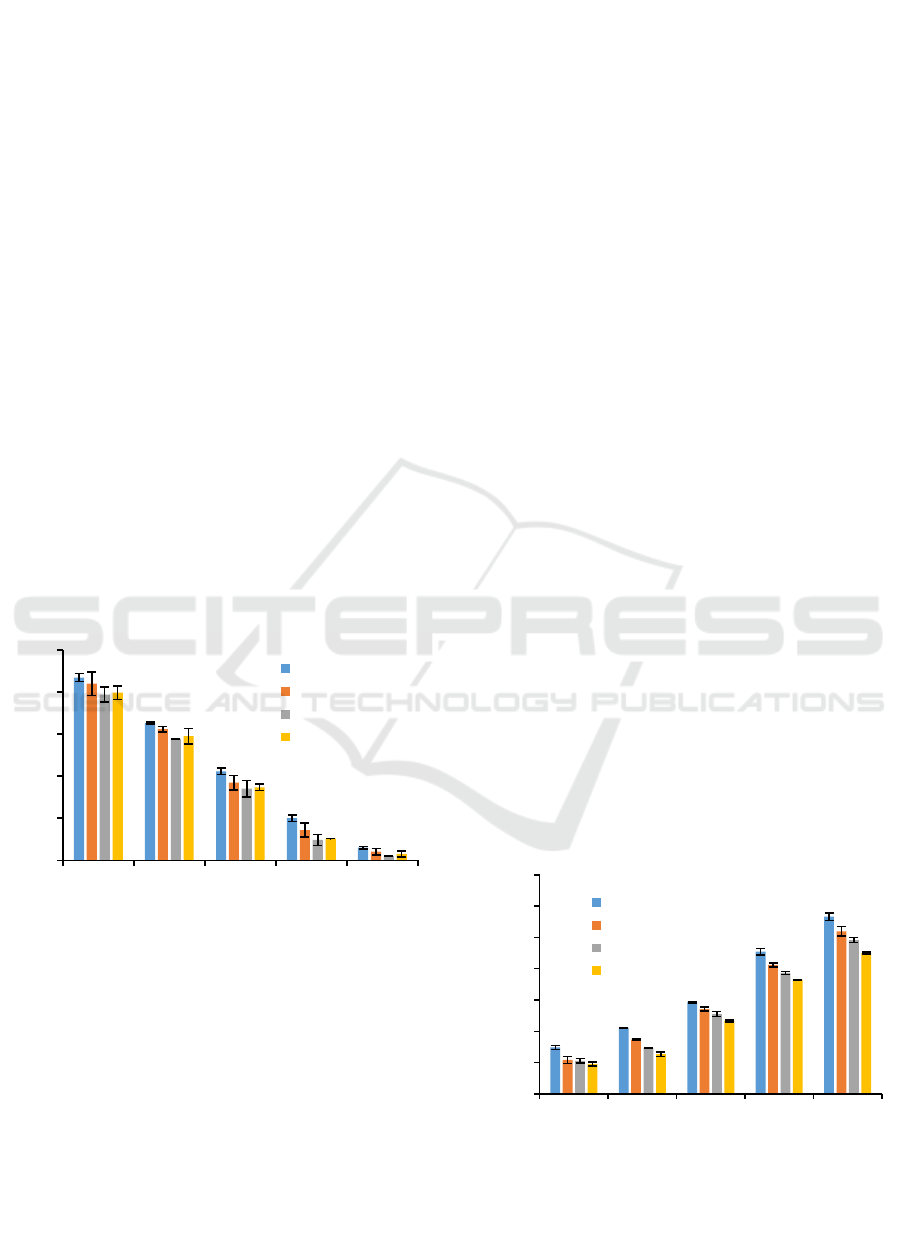

3.2 Exhaust Emissions

3.2.1 NO

x

Emissions

Fig. 5 shows the NO

x

emissions of the diesel engine

fuelled with the test fuels with respect to the engine

speed. Although the NO

x

emissions for the PB10 and

PB10PN10 blends are higher relative to those for

diesel, the addition of EHN slightly reduces the NO

x

emissions. The results show that the NO

x

emissions

increase by 1.60 and 6.74% for the PB10PN10 fuel

blend relative to those for PB10 and diesel,

respectively. When the palm biodiesel is blended with

pentanol, the NO

x

emissions are higher owing to the

presence of oxygen atoms in the fuel blend. The

properties of pentanol (low viscosity, low density,

and high volatility) enhance the combustion

characteristics, but this comes at the expense of

higher NO

x

emissions (Imdadul et al., 2016). In

contrast, the addition of EHN slightly reduces the

NO

x

emissions, as demonstrated by the results for the

PB10PN10E1 blend. The NO

x

emissions decrease by

1.9% for the PB10PN10 blend relative to that for the

PB10PN10 blend. Introducing EHN into the fuel

blend reduces the NO

x

emissions owing to changes in

the cylinder peak temperature as well as low heat

release rate (McCreath, 1971). EHN consists of

nitrogen atoms, which will react during combustion

and produce more NO

x

. The addition of EHN in the

fuel blend increases the cetane number, which

shortens ignition delay, and reduces the time for the

fuel to combust. The expansion phase during the

combustion process is higher for the test fuel with

higher cetane number. The combustion process is

more efficient for the test fuel with higher cetane

number, where the combustion takes place at a lower

combustion temperature, and this reduces the NO

x

emissions (Goldsborough et al., 2015; McCormick et

al., 2003). In addition, NO

x

emissions relatively

increase with the increase of biodiesel concentration

in the test fuel and a similar result was found by

Yesilyurt et al. (2018). The addition of pentanol does

not reduce the NO

x

emissions; however, the addition

of EHN gives a more favourable result. The NO

x

emissions are also dependent on the adiabatic flame

temperature and ignition period (Rami et al., 2021).

3.2.2 HC Emissions

Fig. 6 shows the HC emissions of the diesel engine

fuelled with different test fuels with respect to the

engine speed. It can be observed that the HC

emissions are lower for the PB10, PB10PN10, and

PB10PN10E1 test fuels compared with those for

diesel. The HC emissions of the PB10PN10 reduce by

26.92 and 18.03% relative to those for PB10 and

diesel, respectively. Biodiesels promote a more

complete combustion owing to their oxygenative

nature (Nayak et al., 2021). The addition of pentanol

further promotes combustion, which reduces the HC

emissions compared with the biodiesel blend.

However, the addition of EHN (PB10PN10E1)

slightly increases the HC emissions by 4.18%

compared with the PB10PN10 blend. The addition of

EHN reduces the temperature in the combustion

chamber due to its cooling effect. While the cetane

improver boosts the cetane number and ignition

quality (reduced time for fuel-air mixing), the cetane

improver slightly increases the production of HC as it

slows down the oxidation process (Li et al., 2014).

Figure 5: NO

x

emissions of the diesel engine fuelled with

different test fuels with respect to the engine speed.

Figure 6: HC emissions of the diesel engine fuelled with

different test fuels with respect to the engine speed.

3.2.3 CO Emissions

The CO emissions of the diesel engine fuelled with

different test fuels are shown in Fig. 7. It is evident

that the CO emissions decrease significantly with an

increase in the engine speed. In addition, the CO

emissions are the lowest for the PB10PN10 blend

0

200

400

600

800

1000

1200 1500 1800 2100 2400

NOx (ppm)

Engine Speed (rpm)

Diesel

PB10

PB10PN10

0

20

40

60

80

100

120

1200 1500 1800 2100 2400

HC (ppm)

Engine Speed (rpm)

Diesel

PB10

PB10PN10

PB10PN10E1

Effect of Nitrate-based Cetane Improver on Ternary Higher Alcohol Biodiesel Blends and Diesel Engine Exhaust Emissions

999

compared with those for the other test fuels. The CO

emissions for the PB10PN10 blend decrease by 9.5

and 17.2% compared with those for the PB10 and

diesel, respectively. The addition of pentanol

improves the combustion rate by reducing incomplete

combustion in the cylinder (Ma et al., 2021; Yesilyurt

et al., 2018). The addition of pentanol increases the

availability of oxygen atoms in the test fuel, which

promotes a more complete combustion. The biodiesel

blend with low carbon/hydrogen (C/H) ratio results in

lower CO emissions (Qi et al., 2014). The density of

pentanol is significantly lower compared with that of

diesel, and thus, the volatility of pentanol is much

higher, which reduces the length of spray

atomization. The fuel blend containing pentanol

converts into a gaseous state more quickly in the

engine cylinder, promoting a more complete

combustion, and reduces CO emissions (Yao et al.,

2010). However, the addition of EHN into the

PB10PN10 blend slightly increases the CO emissions

by 2.3%. The addition of EHN decreases the

hydroperoxyl (HO

2

) and hydrogen peroxide (H

2

O

2

),

and these molecules will negatively affect the

oxidation of hydroxyl (OH) group and CO. The EHN

results in a higher equivalence ratio, which disrupts

the stoichiometry of the combustion mixture (Rashed

et al., 2016).

Figure 7: CO emissions of the diesel engine fuelled with

different test fuels with respect to the engine speed.

3.2.4 Smoke Intensity

For a rich fuel-air mixture with a high equivalence

ratio (i.e., a high actual fuel-air ratio divided by the

stoichiometric fuel-air ratio), there is inadequate

oxygen to convert the fuel into CO

2

, resulting in the

formation of CO and smoke. The smoke intensity is

dependent on the type of fuel and engine operating

conditions such as the engine load and speed. Fig. 8

shows the smoke intensity of the diesel engine fuelled

with different test fuels with respect to the engine

speed. In general, the PB10PN10E1 blend has the

lowest smoke intensity, followed by the PB10PN10,

PB10, and diesel test fuels, regardless of the engine

speed. The PB10, PB10PN10, and PB10PN10E1

blends have a lower smoke intensity compared with

diesel due to the presence of oxygen atoms in the fuel-

rich zone during the early stage of the PC phase. This

eventually reduces the formation of smoke (Ozsezen

et al., 2008). The smoke intensity decreases if the

impurities of the biodiesel are in small quantities and

the sulphur content is low (Teoh et al., 2013). Pan et

al. (2019) and Sebayang et al. (2017) found that the

addition of pentanol decreases soot formation

compared with that for diesel and biodiesel blends

(Pan et al., 2019; Sebayang et al., 2017). The addition

of EHN further reduces the soot formation, as

evidenced by the results of the PB10PN10E1 blend.

The smoke intensity for the PB10PN10 blend

decreases by 19.60 and 17.18% relative to those for

the PB10 and diesel, respectively. The smoke

intensity for the PB10PN10E1 blend reduces by

8.24% relative to that for the PB10. In general, the

smoke intensity is lower at the initial stage of the

premixed combustion phase because the fuel-air

mixture is nearest to the stoichiometric state. The

oxygen content is significantly higher during the fuel-

rich state for the PB10, PB10PN10, and

PB10PN10E1 blends, which results in lower smoke

emissions compared with diesel. The higher cetane

number of the PB10PN10E1 blend promotes early

combustion, which gives sufficient time for soot

oxidation to occur and reduces smoke formation

(Imtenan et al., 2015). Moreover, blending the diesel

and biodiesel with pentanol and EHN reduces the

viscosity, which improves fuel atomization, and

reduces the smoke intensity (Rakopoulos et al.,

2007).

Figure 8: Smoke intensities of the diesel engine fuelled with

different test fuels with respect to the engine speed.

0

2

4

6

8

10

1200 1500 1800 2100 2400

CO (ppm)

Engine Speed (rpm)

Diesel

PB10

PB10PN10

PB10PN10E1

0

5

10

15

20

25

30

35

1200 1500 1800 2100 2400

Smoke Intensity (%)

Engine Speed (rpm)

Diesel

PB10

PB10PN10

PB10PN10E1

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1000

4 CONCLUSIONS

The objective of this study is to investigate the effects

of blending diesel with 10 vol% of palm biodiesel, 10

vol% of pentanol, and 1 vol% of EHN on the fuel

properties and exhaust emissions of a single-cylinder,

four-stroke, direct injection diesel engine. The engine

tests were carried out at full throttle and different

engine speeds. The results were compared with those

for neat diesel, and PB10 and PB10PN10 blends. It is

found that the viscosity and density are lower upon

the addition of pentanol, but these properties are

compensated for upon the addition of EHN. EHN is a

cetane improver, which improves the oxidation

stability of the PB10PN10E1 blend. The calorific

value is reduced for the PB10PN10 blend, but is

slightly increased for the PB10PN10E1 blend. The

NO

x

emissions are higher for the PB10PN10 blend,

but the NO

x

emissions are slightly reduced for the

PB10PN10E1 blend. The HC and CO emissions

exhibit a declining trend with an increase in engine

speed, with the lowest values obtained for the

PB10PN10 blend. However, the addition of EHN

results in a slight increase in the HC and CO

emissions, as evidenced by the results for the

PB10PN10E1 blend. The smoke intensities of the

PB10, PB10PN10, and PB10PN10E1 blends are also

lower compared with those for diesel.

ACKNOWLEDGEMENTS

The authors graciously acknowledge the financial

support provided by Politeknik Negeri Medan,

Medan, Indonesia (grant no.

B/185/PL5/TU.01.05/2021). The authors also wish to

express their greatest appreciation to Institute of

Sustainable Energy, Universiti Tenaga Nasional

(UNITEN) for supporting this research.

REFERENCES

Atmanli, A., İleri, E., Yüksel, B. (2014). Experimental

investigation of engine performance and exhaust

emissions of a diesel engine fueled with diesel–n-

butanol–vegetable oil blends. Energy Conversion and

Management 81, 312-321.

Atmanli, A., Ileri, E., Yuksel, B., Yilmaz, N. (2015).

Extensive analyses of diesel–vegetable oil–n-butanol

ternary blends in a diesel engine. Applied Energy 145,

155-162.

Basha, S.A., Gopal, K.R., Jebaraj, S. (2009). A review on

biodiesel production, combustion, emissions and

performance. Renewable and Sustainable Energy

Reviews 13, 1628-1634.

Campos-Fernandez, J., Arnal, J.M., Gomez, J., Lacalle, N.,

Dorado, M.P. (2013). Performance tests of a diesel

engine fueled with pentanol/diesel fuel blends. Fuel

107, 866-872.

Goldsborough, S., Johnson, M., Banyon, C., Pitz, W.,

McNenly, M. (2015). Experimental and modeling study

of fuel interactions with an alkyl nitrate cetane

enhancer, 2-ethyl-hexyl nitrate. Proceedings of the

Combustion Institute 35, 571-579.

Imdadul, H., Masjuki, H., Kalam, M.A., Zulkifli, N.,

Rashed, M., Rashedul, H., ISLAM, M.M., Mosarof, M.

(2015). A comprehensive review on the assessment of

fuel additives effects on combustion behavior in CI

engine fuelled with diesel biodiesel blends. RSC

Advances.

Imdadul, H.K., Masjuki, H.H., Kalam, M.A., Zulkifli,

N.W.M., Alabdulkarem, A., Rashed, M.M., Teoh,

Y.H., How, H.G. (2016). Higher alcohol–biodiesel–

diesel blends: An approach for improving the

performance, emission, and combustion of a light-duty

diesel engine. Energy Conversion and Management

111, 174-185.

Imtenan, S., Masjuki, H.H., Varman, M., Rizwanul Fattah,

I.M., Sajjad, H., Arbab, M.I. (2015). Effect of n-butanol

and diethyl ether as oxygenated additives on

combustion–emission-performance characteristics of a

multiple cylinder diesel engine fuelled with diesel–

jatropha biodiesel blend. Energy Conversion and

Management 94, 84-94.

Kumar, N., Bansal, S., Vibhanshu, V., Singh, A., 2013.

Utilization of Blends of Jatropha Oil and N-Butanol in

a Naturally Aspirated Compression Ignition Engine.

SAE Technical Paper.

Lapuerta, M., Armas, O., Garcia-Contreras, R. (2007).

Stability of diesel–bioethanol blends for use in diesel

engines. Fuel 86, 1351-1357.

Li, L., Wang, J., Wang, Z., Liu, H. (2015a). Combustion

and emissions of compression ignition in a direct

injection diesel engine fueled with pentanol. Energy 80,

575-581.

Li, L., Wang, J., Wang, Z., Xiao, J. (2015b). Combustion

and emission characteristics of diesel engine fueled

with diesel/biodiesel/pentanol fuel blends. Fuel 156,

211-218.

Li, R., Wang, Z., Ni, P., Zhao, Y., Li, M., Li, L. (2014).

Effects of cetane number improvers on the performance

of diesel engine fuelled with methanol/biodiesel blend.

Fuel 128, 180-187.

Ma, Q., Zhang, Q., Liang, J., Yang, C. (2021). The

performance and emissions characteristics of

diesel/biodiesel/alcohol blends in a diesel engine.

Energy Reports 7, 1016-1024.

McCormick, R., Alvarez, J., Graboski, M. (2003). NOx

solutions for biodiesel.

NREL Final Report, SR-510-

31465.

McCreath, C. (1971). The effect of fuel additives on the

exhaust emissions from diesel engines. Combustion and

Flame 17, 359-366.

Effect of Nitrate-based Cetane Improver on Ternary Higher Alcohol Biodiesel Blends and Diesel Engine Exhaust Emissions

1001

Murugesan, A., Umarani, C., Subramanian, R.,

Nedunchezhian, N. (2009). Bio-diesel as an alternative

fuel for diesel engines—A review. Renewable and

Sustainable Energy Reviews 13, 653-662.

Nayak, S.K., Hoang, A.T., Nayak, B., Mishra, P.C. (2021).

Influence of fish oil and waste cooking oil as post mixed

binary biodiesel blends on performance improvement

and emission reduction in diesel engine. Fuel 289,

119948.

Ozsezen, A.N., Canakci, M., Sayin, C. (2008). Effects of

Biodiesel from Used Frying Palm Oil on the Exhaust

Emissions of an Indirect Injection (IDI) Diesel Engine.

Energy & Fuels 22, 2796-2804.

Pan, M., Huang, R., Liao, J., Jia, C., Zhou, X., Huang, H.,

Huang, X. (2019). Experimental study of the spray,

combustion, and emission performance of a diesel

engine with high n-pentanol blending ratios. Energy

Conversion and Management 194, 1-10.

Qi, D.H., Lee, C.F., Jia, C.C., Wang, P.P., Wu, S.T. (2014).

Experimental investigations of combustion and

emission characteristics of rapeseed oil–diesel blends in

a two cylinder agricultural diesel engine. Energy

Conversion and Management 77, 227-232.

Rakopoulos, C.D., Antonopoulos, K.A., Rakopoulos, D.C.

(2007). Development and application of multi-zone

model for combustion and pollutants formation in direct

injection diesel engine running with vegetable oil or its

bio-diesel. Energy Conversion and Management 48,

1881-1901.

Rami, R.S., Murali, G., Ahamad Shaik, A., Dhana Raju, V.,

Sreekara Reddy, M.B.S. (2021). Experimental

evaluation of diesel engine powered with waste mango

seed biodiesel at different injection timings and EGR

rates. Fuel 285, 119047.

Rashed, M., Hasan, M.H., Kalam, M.A., Imdadul, H.,

Rashedul, H., Shahin, M., Habib, M.H. (2016). A

comprehensive study on the improvement of oxidation

stability and NOX emission levels by antioxidant

addition to biodiesel blends in a light-duty diesel

engine. RSC Advances.

Sebayang, A.H., Masjuki, H.H., Ong, H.C., Dharma, S.,

Silitonga, A.S., Kusumo, F., Milano, J. (2017).

Optimization of bioethanol production from sorghum

grains using artificial neural networks integrated with

ant colony. Industrial Crops and Products 97, 146-155.

Teoh, Y., Masjuki, H., Kalam, M., Amalina, M., How, H.,

2013. Impact of waste cooking oil biodiesel on

performance, exhaust emission and combustion

characteristics in a light-duty diesel engine. SAE

Technical Paper.

Wei, L., Cheung, C.S., Huang, Z. (2014). Effect of n-

pentanol addition on the combustion, performance

and emission characteristics of a direct-injection diesel

engine. Energy 70, 172-180.

Yao, M., Wang, H., Zheng, Z., Yue, Y. (2010).

Experimental study of n-butanol additive and multi-

injection on HD diesel engine performance and

emissions. Fuel 89, 2191-2201.

Yesilyurt, M.K., Eryilmaz, T., Arslan, M. (2018). A

comparative analysis of the engine performance,

exhaust emissions and combustion behaviors of a

compression ignition engine fuelled with

biodiesel/diesel/1-butanol (C4 alcohol) and

biodiesel/diesel/n-pentanol (C5 alcohol) fuel blends.

Energy 165, 1332-1351.

Yilmaz, N., Vigil, F.M., Benalil, K., Davis, S.M., Calva, A.

(2014). Effect of biodiesel–butanol fuel blends on

emissions and performance characteristics of a diesel

engine. Fuel 135, 46-50.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

1002