Analysis of Precast Concrete Beam Type L Joint at Moment

Maximum

A. Rudi Hermawan

1

and Eka Sasmita Mulya

2

1

Teknik Sipil, Teknik Konstruksi Gedung, Politeknik Negeri Jakarta, Indonesia

2

Teknik Sipil, Konstruksi Gedung, Politeknik Negeri Jakarta, Indonesia

Keywords: Sikagrout 215, Concrete, Deflection.

Abstract: Cause of regarding many case was difficulted for adjusting between joint of elements, then this research was

described about joint of element precast with L shape. L shape that is mean, joint of element precast have

shape such as word of L and easier to adjusting. This research have molded two beam of conventional (K1,K2)

and two beam of precast (P1,P2). Purpose of this research was determined of deflection and maximum

moment occur at tension maximum. Just for question of this research was about deflection and moment

maximum occur at tension maximum if any load were applicated. Result of precast L shape concrete beam

P1 and P2 and conventional beam K1 and K2 were strength of flexural beam at ultimate and deflection of

beam at ultimate. Strength of flexural conventional beam K1 at ultimate was achieved 11,38 T at deflection

138 mm. Strength of flexural conventional beam K2 at ultimate was achieved 11,25 T at deflection 163,9

mm. Strength of flexural precast beam P1 at ultimate was achieved 11,21 T at deflection 28,44 mm and

strength of flexural precast beam P2 at ultimate was achieved 11,76 T at deflection 26,71 mm. Average

compressive strength of concrete beam was achieved 311,89 kg/cm2. Average compressive strength of sika

grout 215 was achieved 421,33 kg/cm2 at 9 day. Conclusion of this research about joint type L for precast

concrete beam is having good performance only less for ductility. Conventional beam K1 and K2 were showed

ductility du/dy behavior at least approximately 4,29 different with precast beam P1 and P2 was has less

behavior ductility du/dy at least approximately 1,17.

1 INTRODUCTION

Aim of research of precast concrete beam type L joint

was determined deflection and maximum load where

load was applicated at its beam. This type could be

easier to install or erection construction precast.

Compared with research previously, this research was

product joint where if it was erected so more

facilitate.

The benefit of using precast concrete beam type L

joint is more effective for construction than

conventional beam (cast in site) and minimize cost of

construction. Research of strength of flexural and

deflection between diversification of two materials

was investigated, Mario E. Rodríguez, Miguel

Torres-Matos (2013) was researched of joint between

beam to column with joint by embedded was

connected by rebar and was welded

Marco

Breccolotti et al. (2017) was researched of Wet-joint

techniques for the construction of precast concrete

pipe rack structures in remote seismic zones.

Contradiction with this research was a connection

between element used joint type L shape. L shape that

is mean, joint of element precast have shape such as

word of L.

For connecting between element of precast has

welded and used Sika grout 215 to cover its void. Sika

grout 215 was material for grouting between element

concrete has welded and casted.

Specification of material sika grout have

compressive strength for 3 days approximately 40,0

N/mm2 and for 7 days approximately 52,0 N/mm2.

For this research have compressive strength 42,13

N/mm2.

The question for this research is how about strength

of flexural precast concrete beam type L joint if any

load were applicated and how about deflection occur.

Eventually, aim of this research was determined of

strength of flexural precast concrete beam type L joint

beam P1,P2 and deflection occur if that was

Hermawan, A. and Mulya, E.

Analysis of Precast Concrete Beam Type L Joint at Moment Maximum.

DOI: 10.5220/0010957600003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 983-987

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

983

compared with deflection of conventional beam

K1,K2.

1.1 Tension Non-prestressed

Bonded between rebar and concrete were determined

for strength of flexure of conventional beam and

precast beam. Code of ACI 318-2011 and SNI 03-

2847-2019 was explained for bonded between them:

Where as :

fy = Strength of yield (Mpa)

β = Coating factor

α = Reinforcement location factor

λ = Ligthweigth aggregate concrete

factor

db = Nominal diameter tulangan

fc’ = Compressive strength (MPa)

T = Tension

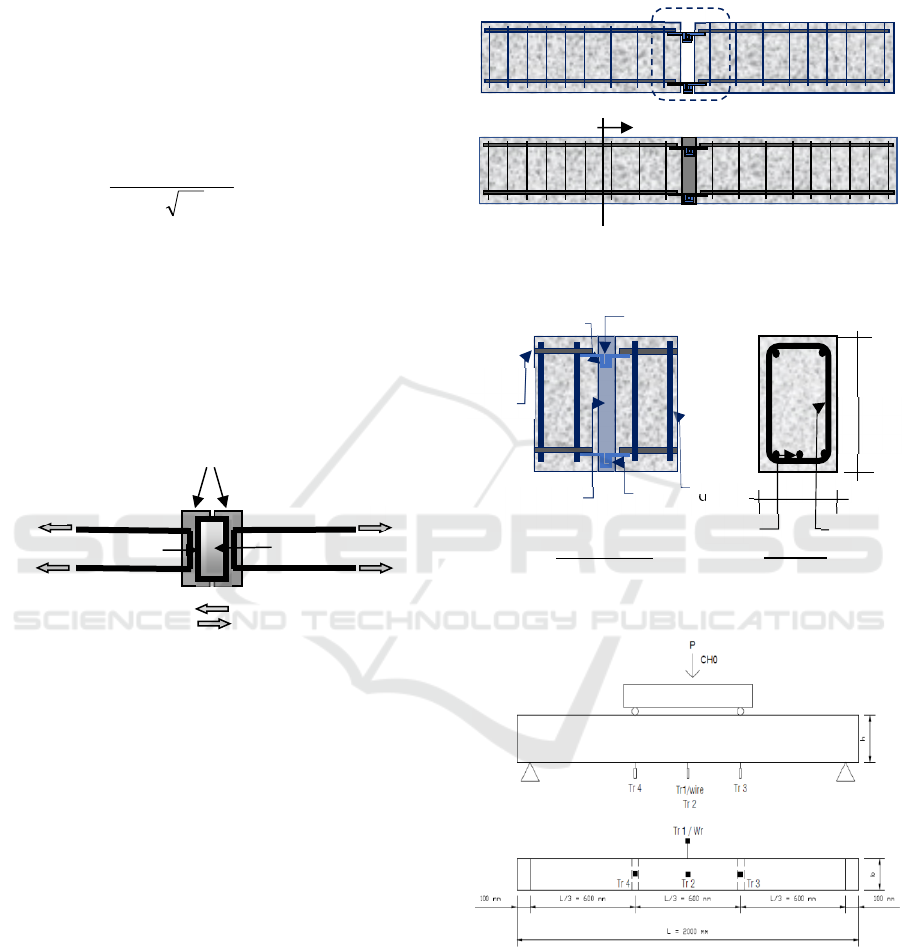

Figure 1: Joint L Shape.

2 RESEARCH METHOD

Element conventional concrete beam and precast

concrete beam were tested at Bina Teknik

Permukiman dan Perumahan Direktorat Jenderal

Cipta Karya Kementerian PUPR Jl. Panyaungan,

Cileunyi Wetan Kab. Bandung. This research have 2

samples of precast concrete beam type L joint (P1,P2)

and 2 samples precast conventional beam (K1,K2).

All of samples would be tested flexural tensile

strength. Reinforced bars used D12,59 mm. At below

describe Figure 1 was showing prototype element

joint embedded precast concrete beam type L shape.

Figure 2 was showing Prototype element precast type

L Joint concrete beam will be tested and Figure 3 was

showing detail and Section of element precast type L

Joint concrete beam also figure 4 was showing setting

up of Loading Test will be tested. Figure 5 was

showing element Universal Testing Machine (UTM)

and figure 6 was showing element precast beam was

under tested also figure 7 was showing element

precast beam has tested.

Figure 2: Prototype element precast type L Joint concrete

beam.

Figure 3: Detail and Section of element precast type L Joint

concrete beam.

Figure 4: Setting up of Loading Test.

Ld =

mm

fc

dbfy

300

'.25

.....18

>

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

λβα

(1)

A

A

20 cm

25 cm

D 13

d8

SEC - A

Plate 5 mm Plate 5 mm

D13

d8

embedde

d

Grouting

Sikagrout

DETAIL - A

T

T

T

T

T

Embeded

Plate

Welded

Ld

Ld

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

984

Figure 5: UTM machine.

Figure 6: Specimen precast beam was under tested.

Figure 7: Specimen of precast beam has tested.

3 RESULT AND DISCUSSION

Research of precast concrete beam type L joint for all

specimens were indicated that precast concrete beam

type L joint was capable for resistance under loading

until at least more than 11 T equal with specimens

conventional beam, accordingly all specimens were

indicated that strength of flexural and deflection was

not different respectively between specimens and will

be explained at below. For pattern of crack, all of

specimens have pattern of crack were not equal crack

due to moment, indicate that all specimen have

different behavior. Specimen precast type L joint

have embedded with long width enough at the below

then was extruded concrete at below of embedded and

cause of crack pattern was different by conventional

(figure 6,7). Average of compression strength of

specimens were 311,89 kg/cm2 and 421,33 kg/m2 for

sika grout 215 at 9 days.

Results of Strength of flexural precast beam P1 at

ultimate was achieved 11,21 T at deflection 28,44

mm. Strength of flexural precast beam P2 at ultimate

was achieved 11,76 T at deflection 26,71 mm and

strength of flexural conventional beam K1 at ultimate

was achieved 11,38 T at deflection 138 mm and

strength of flexural conventional beam K2 at ultimate

was achieved 11,25 T at deflection 163,9 mm. That

indicate, specimens precast type L have strength

ultimate better than specimens conventional

nevertheless have behavior less for ductility. Table 1

showing result of flexural test of loading test.

Table 1: Result of Flexural Test.

No Element

Load Deflection.

Ton m

m

1 K1 0,00-2,65

2,83-5,66

5,86-8,83

9,01-10,36

10,25-10,51

10,33-10,73

10,76-11,06

11,10-11,33

11,35-11,38

0,00-1,22

1,27-3,91

4,01-6,68

6,77-15,61

16,42-29,99

30,99-49,16

50,23-73,48

74,97-108,40

111,50-138,00

2 K2 0,00-2,65

2,85-7,26

7,53-9,86

9,88-10,28

10,33-10,28

10,21-10,88

10,95-11,18

11,18-11,25

0,00-1,18

1,33-4,50

4,59-8,11

8,44-20,48

22,49-46,91

48,21-80,77

86,67-132,90

135,50-163,90

3 P1 0,00-2,62

2,77-3,92

3,93-4,96

5,01-5,76

5,75-6,65

6,83-8,93

9,66-11,21

0,00-0,90

0,94-1,71

1,75-3,43

3,66-6,04

6,30-9,13

9,47-17,39

18,52-28,44

4 P2 0,00-2,13

2,23-3,72

3,87-5,46

5,55-7,53

7,71-19,55

9,60-11,65

11,70-11,76

0,00-1,2

1,27-2,83

2,92-6,42

6,58-12,23

12,48-17,73

17,81-15,14

25,40-26,71

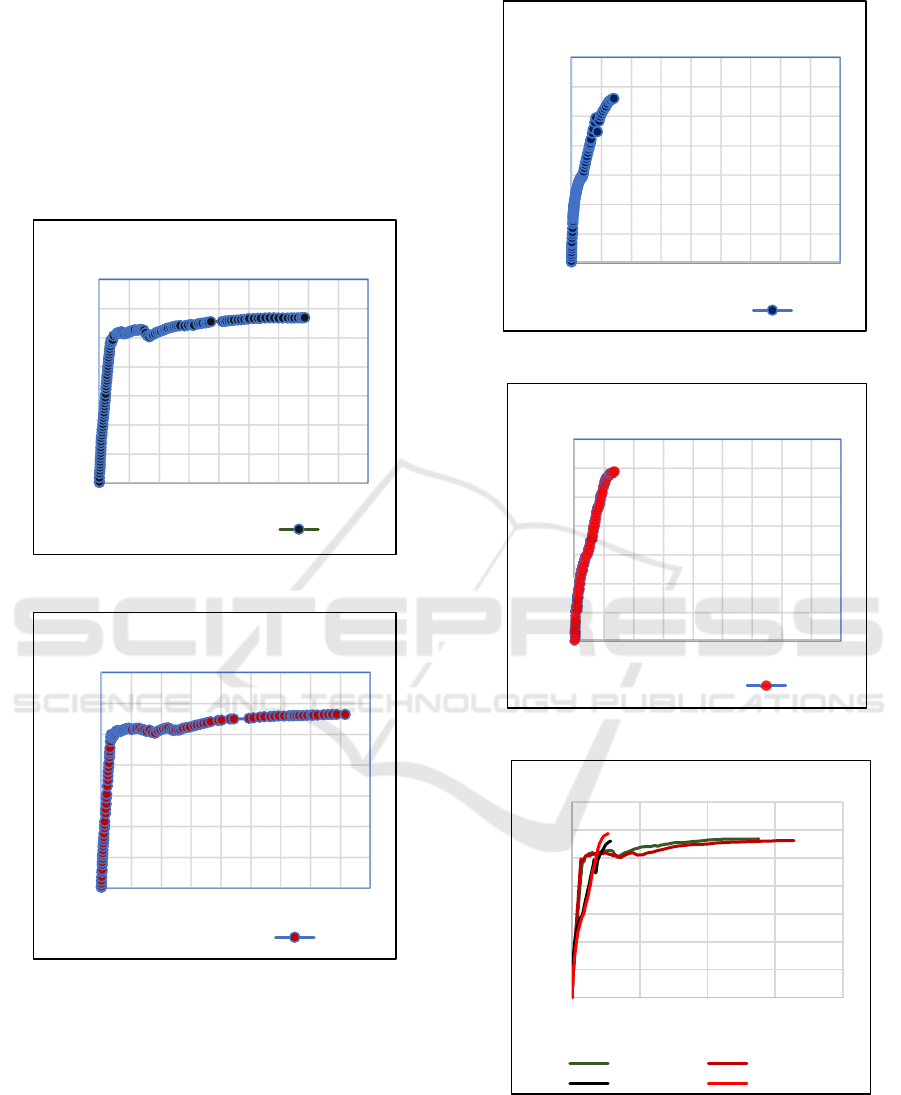

Figure 8 showing chart of result of loading versus

deflection of specimen beam K1. Figure 9 showing

chart of result of loading versus deflection of

specimen beam K2. Figure 10 showing chart of result

of loading versus deflection of specimen beam P1.

Analysis of Precast Concrete Beam Type L Joint at Moment Maximum

985

Figure 11 showing chart of result of loading versus

deflection of specimen beam P2. It is evidence that

result all of specimen indicate have equal

performance for ultimate strength nevertheless

different for behavior of pattern of failure, precast

concrete beam type L joint was behavior less for

ductility and conventional beam was behavior

sufficient for ductility. For further information could

be see chart at below.

Figure 8: Chart of Result Beam K1.

Figure 9: Chart of Result Beam K2.

For figure 12 showing of result of loading versus

deflection of specimen entirely beam K and P. If refer

to figure 12, showing indeed behavior of

conventional beam K1 and K2 were showed ductility

δu/δy behavior at least approximately 4,29 different

with precast beam P1 and P2 was has less behavior

ductility δu/δy at least approximately 1,17.

Figure 10: Chart of Result Beam P1.

Figure 11: Chart of Result Beam P2.

Figure 12: Chart of Result Beam K,P.

The benefit of precast concrete beam type L joint is

more effective for construction than conventional

beam (cast in site) and minimize cost of construction,

cost of all element will be cheaper and can be

0

2

4

6

8

10

12

14

0 20 40 60 80 100 120 140 160 180

Load, Ton

Deflection,mm

LOAD VS DEFLECTION BEAM

K1

Beam K1

0

2

4

6

8

10

12

14

0 20 40 60 80 100 120 140 160 180

Load, Ton

Deflection,mm

LOAD VS DEFLECTION BEAM

K2

Beam K2

0

2

4

6

8

10

12

14

0 20 40 60 80 100 120 140 160 180

Load, Ton

Deflection,mm

LOAD VS DEFLECTION BEAM

P2

Beam P2

0

2

4

6

8

10

12

14

0 50 100 150 200

Load,Ton

Deflection,mm

LOAD VS DEFLECTION

Beam K1 Beam K2

Beam P1 Beam P2

0

2

4

6

8

10

12

14

0 20 40 60 80 100 120 140 160 180

Load, Ton

Deflection,mm

LOAD VS DEFLECTION BEAM

P1

Beam P1

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

986

applicated at location with difficult to rotate and

difficult for availability of materials for mixing

concrete.

4 CONCLUSION

Result of precast concrete beam type L joint (P1,P2)

and conventional beam (K1,K2) were strength of

flexural beam at ultimate and deflection of beam at

ultimate. Strength of flexural precast concrete beam

type L joint P1 at ultimate was value 11,21 T at

deflection 28,44 mm. Strength of flexural precast

concrete beam type L joint P2 at ultimate was value

11,76 T at deflection 26,71 mm and strength of

flexural conventional beam K1 at ultimate was value

11,38 T at deflection 138 mm and strength of flexural

conventional beam K2 at ultimate was value 11,25 T

at deflection 163,9 mm. Result all of specimen

indicate have equal performance for ultimate strength

nevertheless different for behavior of pattern of

failure, precast concrete beam type L joint was

behavior less for ductility δu/δy at least

approximately 1,17 and conventional beam was

behavior sufficient for ductility δu/δy behavior at

least approximately 4,29. Result all of specimen

indicate have same as performance.

REFERENCES

ACI Committee 318, 2011, Building Code Requirments for

Structure and Commentary,American Concrete

Institute, Detroit

Rodríguez. dan Torres M, Summer 2013 , “Seismic

Behavior of type of welded precast concrete beam-

colum connection, PCI Journal Paper,Vol.58, Issue: 3,

Page number: 81-94.

Ameli,J dan Park,Joel E, March - April 2015,” Seismic

evaluation of grouted splice sleeve connections for

reinforced precast concrete column–to–cap beam joints

in accelerated bridge construction”, PCI Journal Paper,

Volume: 60 Issue: 2 Page number: 80 – 103

Nabi Goudarzi, Yasser Korany, March-April 2016,”

Characterization of the shear behavior of Z-shaped

steel plate connectors used in insulated concrete

panels”, PCI Journal Paper, Volume: 61,Issue: 2, Page

Number: 23-37

Elide Pantoli dan Tara C. Hutchinson, July-August 2016,”

Seismic-drift-compatible design of architectural

precast concrete cladding: Tieback connections and

corner joints”, PCI Journal Paper, Volume: 61, Issue:

4, Page Numbers: 38-52

Hatem M. Seliem dan Lining Ding, September-October

2016,” Use of a carbon-fiber-reinforced polymer grid

for precast concrete piles”, PCI Journal Paper,Volume:

61, Issue: 5, Page Number: 37-48

SNI 03-2847-2019,Standar Nasional Indonesia ,Tata Cara

Perhitungan Struktur Beton Untuk Bangunan Gedung,

Bandung, 2019

George Morcous and Raed Tawadrous, May -June 2020,”

Precast concrete deck-to-girder mechanical connection

for accelerated bridge construction”, Volume:

65,Issue: 3,Page Numbers: 37 – 52

Theresa C. Aragon, Yahya C. Kurama, and Donald F.

Meinheit, July - August 2020,” Behavior of ductile

short-grouted seismic reinforcing bar–to–foundation

connections under adverse construction conditions”,

Volume: 65,Issue: 4,Page Numbers: 33 – 50

Rafal Anay, Lateef Assi et.All, November - December

2020,” Development of a double-tee flange connection

using shape memory alloy rods’, Volume: 65,Issue:

6,Page Numbers: 81 - 96

Xiao Liang; Sritharan, Sri, May-Jun 2021,” Use of

unstressed strands for connections of precast concrete

members “ PCI Jurnal Paper, Volume 66, Issue: 3,

p49-66. 18p

Jae HyunKimaSeung-HoChoiaJin-HaHwang,et all, 2021,

Experimental study on lateral behavior of post-

tensioned precast beam-column joints, PCI Journal

Paper,Vol.33, Page number: 841-854

Analysis of Precast Concrete Beam Type L Joint at Moment Maximum

987