Comparison of PI, PD, and PID Controller in Hydroponic Plant

Nutrient Concentration Control System

Nurmahaludin

1

, Gunawan Rudi Cahyono

2

and Joni Riadi

1

1

Dept. of Electrical Engineering, Politeknik Negeri Banjarmasin, Banjarmasin, Indonesia

2

Dept. of Mechanical Engineering, Universitas Lambung Mangkurat, Banjarmasin, Indonesia

Keywords: PID Controller, Nutrient Concentration, Hydroponics.

Abstract: Hydroponics is a plant cultivation technique by utilizing water media and emphasizing the need for nutrients

to grow. Each type of hydroponic plant requires a nutrient solution with different levels of concentration. If

the concentration is low, it will reduce the effectiveness of nutrients so that additional nutrients are needed.

Meanwhile, if it is excessive, the plant will wither and even die.

In this study, Proportional (P), Integral (I), dan Derivative (D) controller is used. PI, PD, and PID controllers

were designed, then tested on a nutrient concentration control system to get the best performance. If the error

is positive, it indicates the plant to approach the threshold of excess nutrients, so the controller will move the

servo motor to open the water valve. On the other hand, if the error value is negative, it indicates that the plant

to approach the nutrient deficiency threshold, so that the nutrient solution valve needs to be opened through

servo motor movement.

The observed variables are error rate and delta error. The test results show that the use of a PID controller

with Kp=0.5, Ki=1, and Kd=1 gives a fairly good performance with relatively small error rates and delta error,

namely 4.997 (0.83%) and 1.804.

1 INTRODUCTION

The hydroponic system is a method of growing plants

using a solution of mineral nutrients in water without

soil. Each type of hydroponic plant requires a solution

with a different level of nutrient concentration (Tallei,

Rumengan, & Adam, 2017). The level of

concentration of nutrients is measured in units of

particles per million (ppm) or by measuring the level

of conductivity. If the nutrient solution given

becomes too concentrated, it will cause the plant to

wither or die, so it is necessary to give water as a

diluent in order to reduce the concentration level

gradually. On the other hand, if the concentration of

the solution is low, then the plant will become

deficient in nutrients, so it needs to be added.

Monitoring to maintain the concentration value of

the nutrient solution for local hydroponic farmers is

still done manually using a TDS (Total Dissolved

Solids) measuring instrument at certain times. There

needs to be a regulatory system to control nutrient

concentrations automatically. Control algorithm is

needed to achieve the desired concentration

optimally. In this research, PI, PD, and PID

controllers will be designed for later analysis of the

resulting performance. The observed performance

parameters are the resulting error rate as well as

oscillations in the system response which are shown

through delta error observations.

There are a number of studies on monitoring

systems and nutrition for hydroponic plants,

including monitoring systems for pH and water

conductivity in hydroponic plants automatically

using sensors and microcontrollers (Gosavi, 2017)

(Umamaheswari, Preethi, Pravin, & Dhanusha,

2017). In this study, the control process is carried out

through a programmed microcontroller and is not

carried out remotely (wireless).

The next research development is the provision of

nutrition to hydroponic plants through remote

control, including Arduino which is connected to a

Wi-Fi module (P. Sihombing, Karina, Tarigan, &

Syarif, 2018), using an Arduino microcontroller

controlled via a smart phone (Poltak Sihombing,

Zarlis, & Herriyance, 2019), and based on IoT using

web technology (Crisnapati, Wardana, Aryanto, &

Hermawan, 2017). Although the control system as

mentioned above can be done wirelessly, in the

Nurmahaludin, ., Cahyono, G. and Riadi, J.

Comparison of PI, PD, and PID Controller in Hydroponic Plant Nutrient Concentration Control System.

DOI: 10.5220/0010955600003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 863-868

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

863

process of regulating the concentration of nutrients it

is still done on-off. Arduino will activate or deactivate

(on-off) the tank valve which contains water and

nutrients and then flows it to hydroponic plants.

The use of control algorithms in regulating the

NFT hydronic system, among others, uses fuzzy logic

(Mashumah, Rivai, & Irfansyah, 2018), with input in

the form of errors and water volume and output in the

form of valve openings. The results obtained are quite

good with an error rate of 8.9%. Another research is

the control of electrical conductivity (EC) with a PID

controller (Ikhlas, T, & Sc, 2018) . The control system

output is in the form of a solenoid valve to drain AB

mix nutrients or water. Observations were made on

the achievement of the predetermined EC set point.

In this research, PI, PD, and PID controllers will

be designed and applied to control nutrient solution

concentration. Then observations were made on the

three controllers to determine the method and

parameter values of Kp, Ki, and Kd which had the

best performance.

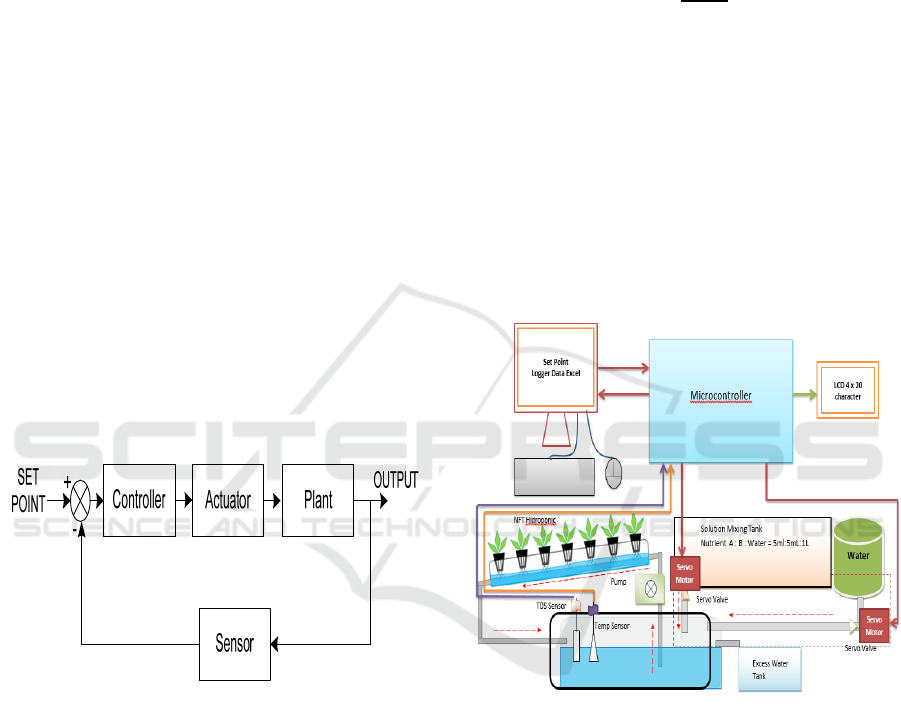

The control system is the process of setting one or

several variables so that they are at a certain price or

price range. Besides keeping the system output at the

desired price, the control system also aims to obtain

optimal performance. The closed loop control system

is shown in Figure 1.

Figure 1: Block diagram of closed loop control system.

The control system starts by assigning a set point

value. The system output is measured using sensors

and then compared with the set point to determine the

resulting error.

e(t) = SP

–

PV (1)

where e(t) is the error value at time t, SP is the set

point value, and PV (present value) is the sensor's

measured output value.

If there is an error, the controller will process it

using the programmed control algorithm. The PID

(Proportinal, Integral, Derivative) control algorithm

is defined as follows:

a. Proportional Controller (P):

=

()

(2

)

b. Integral Controller (I):

=

()

(3

)

c. Derivative Controller (D):

=

()

(4

)

2 METHODS

The design of the hydroponic plant nutrient

concentration control system is shown in Figure 2.

The nutrient solution bath contains a mixture of

nutrient A (5ml) and nutrient B (5ml), while the water

tank is used as a diluent for the solution. In the

circulation tub, adjustments are made to obtain the

nutrient concentration in accordance with the

reference value for each type of hydroponic plant.

Figure 2: Control system design for nutrient concentration.

To adjust the concentration, a control algorithm is

used which will adjust the opening of the servo valve

in the nutrient and the valve in the water tank as a

diluent. The control algorithms that are simulated are

PI, PD, and PID with parameter settings Kp, KI, and

Kd to determine the effect of each type of controller

and determine parameters that are considered to have

good enough performance. The process of adjusting

the concentration of the nutrient solution is shown in

a flow chart as shown in Figure 3. After the

concentration of the solution required by the plant is

reached, the nutrients are watered onto the

hydroponic plants.

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

864

If the error is smaller than zero, the water servo

valve will open at the calculated angle value. On the

other hand, if the error is greater than zero, the

nutrition servo valve will open. When the error

condition is equal to zero, the water servo valve and

the nutrition servo valve will be closed.

Figure 3: Control process flowchart.

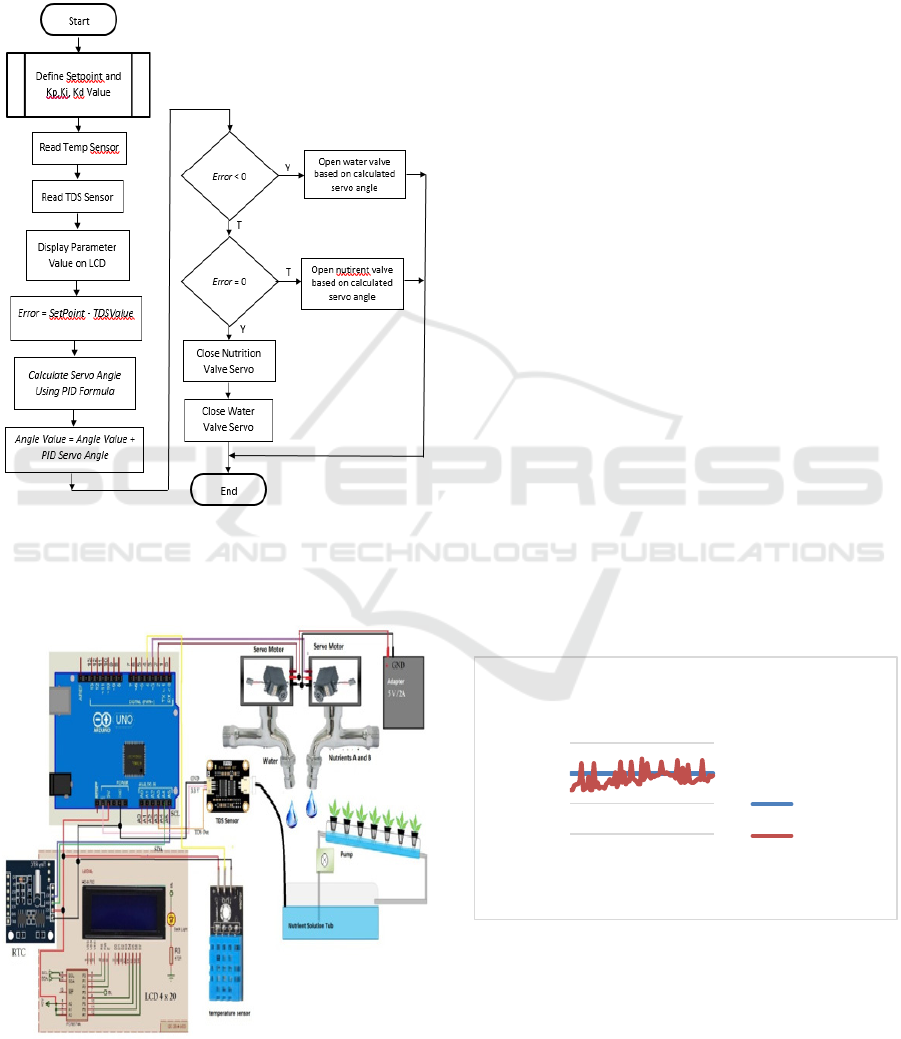

The electronic circuit used for system settings is

shown in Figure 4.

Figure 4: Electronic circuit.

The schematic of the circuit above has the

following pin out configuration:

1. The TDS sensor will be connected to pin A4 of the

Arduino microcontroller. The sensor probe is placed

in a tub of nutrient solution whose concentration will

be measured.

2. RTC and LCD use serial I2C, each for SDA data is

connected to an arduino microcontroller.

3. Temperature and humidity sensors are connected

to the D4 pin of the microcontroller

4. The servo motor is used to rotate the water and

nutrition valve connected to the D2 and D3 pins of the

Arduino microcontroller.

3 RESULT AND DISCUSSION

Tests were carried out on the PI, PD, and PID control

algorithms with variations in the values of Kp, Ki, Kd

and a set point of 600 ppm.

3.1 PI Controller

The proportional controller (P) and the integral

controller (I) are combined in a cascade and then

command the actuator in this case the servo motor to

drive the nutrient solution or water valve. The

movement of the valve is based on the servo motor

angle according to the given control signal.

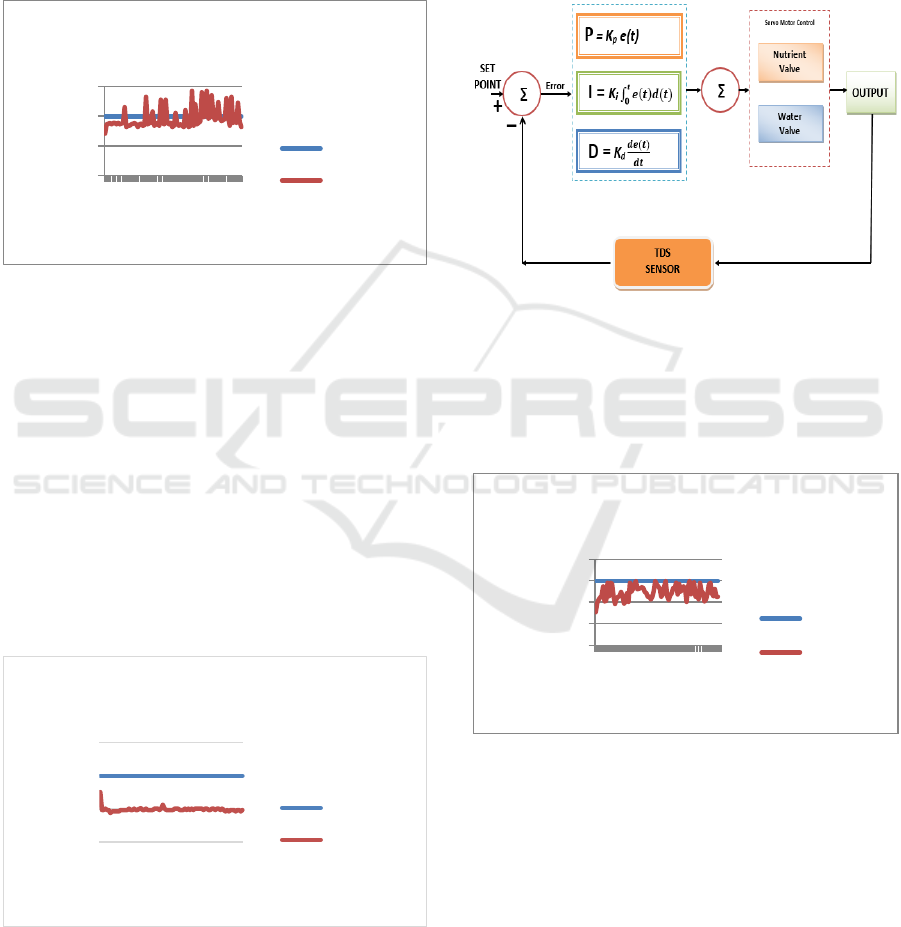

The results of the PI controller test with values of

Kp=0.5 and Ki=0.5 resulted in an error rate of 8.397

(1.4%) and an average delta error |dE| of 12,189. The

graph of the system response to the set point is shown

in Figure 5.

Figure 5: System response with Kp=0.5 and Ki=0.5.

The next test is by changing the PI controller

parameters where the Ki value is increased by 1,

while Kp remains at 0.5. The test results are given in

Table 5.2. The average error generated is 4,569

(0.76%) and the delta error is 16,194.

500

550

600

650

1 12233445566778

Concentration Value (ppm)

Time (s)

System Response Graph

Kp=0.5 and Ki=0.5

Set Point

TDS Value

Comparison of PI, PD, and PID Controller in Hydroponic Plant Nutrient Concentration Control System

865

When compared with the previous results, error

rate is relatively smaller, while the value of the delta

error is larger. This is influenced by controller

Integral which serves to minimize steady state error.

However, the increase in the value of Ki causes the

response to experience a slight increase in oscillations

which is indicated by a larger delta error. The graph

of the system response to the PI controller is shown

in Figure 6.

Figure 6: System response with Kp=0.5 and Ki=1.

3.2 PD Controller

The addition of a derivative controller (D) is intended

to reduce oscillations in the system response. The

results of the test using a PD controller with Kp=0.5

and Kd=1 indicate the error rate generated is larger,

namely 50,935 (8.49%). This means that the system

output does not succeed in approaching the specified

set point value of 600 ppm.

However, if we look at the average delta error |dE|

which became smaller by only 1,627, indicating the

system became more damped so that the oscillations

were successfully reduced. The system response

graph is shown in Figure 7.

Figure 7: System response with Kp=0.5 and Kd=1.

3.3 PID Controller

Based on the results of previous tests, the use of the

PI controller will reduce the error rate, while the PD

controller has succeeded in reducing oscillations and

overshoot. So that combining the three types of

controllers into a PID will result in better

performance. Block diagram of the PID controller can

be seen in Figure 8.

Figure 8: Block diagram of nutrient concentration control

using PID controller.

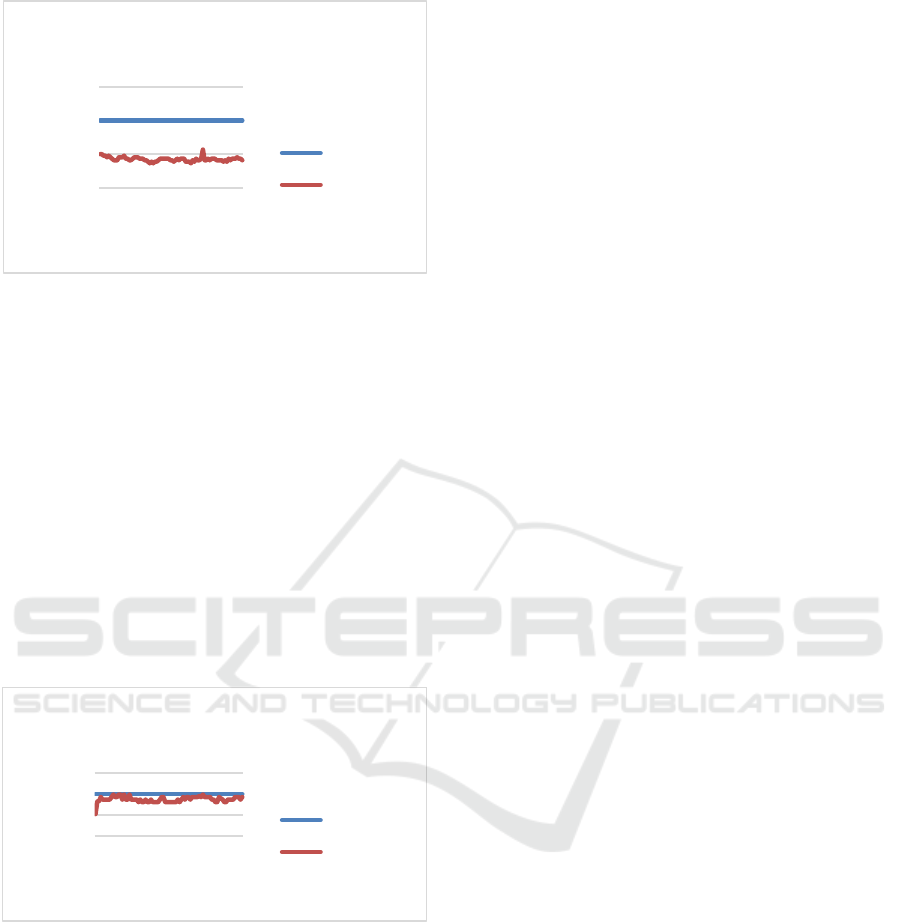

In the first test with values of Kp = 0.5, Ki = 0.5,

and Kd = 1, the error rate was 10,491 (1.75%) and

average delta error was 5.867. The system response

graph is given in Figure 9.

Figure 9: System response with Kp=0.5, Ki=0.5, and Kd=1.

To reduce the oscillations, the value of Kd is then

enlarged to 1.5, while the other parameters remain the

same. The test results show that the oscillation can be

reduced to only 1,798, but the resulting error rate is

57,661 (9.61%). Figure 10 shows a graph of the

system response for Kp=0.5, Ki=0.5, and Kd=1.5.

500

550

600

650

1 132537496173

Concentration Value (ppm)

Time (s)

System Response Graph

Kp=0.5 and Ki=1

Set Point

TDS Value

500

550

600

650

1 12233445566778

Concentration Value (ppm)

Time (s)

System Response Graph

Kp=0.5 and Kd=1

Set Point

TDS Value

540

560

580

600

620

1 1631466176

Concentration Value

(ppm)

Time (s)

System Response Graph

Kp=0.5; Ki=0.5; Kd=1

Set Point

TDS Value

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

866

Figure 10: System response with Kp=0.5, Ki=0.5, and

Kd=1.5.

Based on previous result, the Kd value should not

be too large, although it will provide stability to the

system response. To reduce the error rate that occurs,

the Ki parameter is enlarged to 1 and the Kd value is

returned to its original value to 1. So that the

controller parameters are now Kp=0.5, Ki=1, and

Kd=1.

From the test results, it can be seen that the average

error generated is 4,997 (0.83%), while the average

delta error is 1,804. So that there is a compromise

value between the control objectives to produce the

minimum possible error, with the minimum possible

oscillation impact. Figure 11 is a graph of the system

response using PID with Kp=0.5, Ki=1, and Kd=1.

Figure 11: System response with Kp=0.5, Ki=1, and Kd=1.

4 CONCLUSIONS

The control of nutrient concentration in hydroponic

plants in this study using PI, PD, and PID controllers

aims to observe the performance of each controller

and determine the parameters that have the best

performance.

There is a compromise in determining the

parameters of Kp, Ki, and Kd. By increasing the value

of Ki to produce a smaller error rate, it will increase

the oscillation and overshoot. Likewise, if increasing

the value of Kd in order to obtain a low level of

oscillation and overshoot, it will produce a greater

error rate.

In testing using a PID controller with Kp = 0.5,

Ki=1, and Ki=1, a satisfactory performance was

obtained, where the error rate and average delta error

produced were quite low, namely 4.997 (0.83%) and

1.804.

ACKNOWLEDGEMENTS

Many thanks to the Politeknik Negeri Banjarmasin

for providing funding so that this research can be

completed.

REFERENCES

Crisnapati, P. N., Wardana, I. N. K., Aryanto, I. K. A. A.,

& Hermawan, A. (2017). Hommons: Hydroponic

management and monitoring system for an IOT based

NFT farm using web technology. 2017 5th

International Conference on Cyber and IT Service

Management, CITSM 2017.

https://doi.org/10.1109/CITSM.2017.8089268

Gosavi, J. V. (2017). Water Monitoring System for

Hydroponics Agriculture. International Journal for

Research in Applied Science & Engineering

Technology (IJRASET), 887(Vii), 2321–9653.

Retrieved from www.ijraset.com

Ikhlas, M., T, I. S. S. M., & Sc, M. (2018). Perancangan

Kendali Nutrisi Pada Hidroponik Nft ( Nutrient Film

Technique ) Dengan Metode Pid Design of Controlling

Nutrient in Hydroponic ( Nutrient Film Technique )

Using Pid. E-Proceeding of Engineering, 5(1), 79–85.

Mashumah, S., Rivai, M., & Irfansyah, A. N. (2018).

Nutrient Film Technique based Hydroponic System

Using Fuzzy Logic Control. Proceeding - 2018

International Seminar on Intelligent Technology and Its

Application, ISITIA 2018, (1), 387–390.

https://doi.org/10.1109/ISITIA.2018.8711201

Sihombing, P., Karina, N. A., Tarigan, J. T., & Syarif, M. I.

(2018). Automated hydroponics nutrition plants

systems using arduino uno microcontroller based on

android. Journal of Physics: Conference Series, 978(1).

https://doi.org/10.1088/1742-6596/978/1/012014

Sihombing, Poltak, Zarlis, M., & Herriyance. (2019).

Automatic Nutrition Detection System (ANDES) for

Hydroponic Monitoring by using Micro controller and

Smartphone Android. Proceedings of 2019 4th

International Conference on Informatics and

Computing, ICIC 2019.

https://doi.org/10.1109/ICIC47613.2019.8985851

Tallei, T. E., Rumengan, I. F. M., & Adam, A. A. (2017).

Hidroponik untuk Pemula. In UNSRAT Press (Vol. 1).

500

550

600

650

1 12233445566778

Concentration Value (ppm)

Time (s)

System Response Graph

Kp=0.5; Ki=0.5; Kd=1.5

Set Point

TDS Value

560

580

600

620

1 12233445566778

Concentration Value (ppm)

Time (s)

System Response Graph

Kp=0.5; Ki=1; Kd=1

Set Point

TDS Value

Comparison of PI, PD, and PID Controller in Hydroponic Plant Nutrient Concentration Control System

867

Umamaheswari, S., Preethi, A., Pravin, E., & Dhanusha, R.

(2017). Integrating scheduled hydroponic system. 2016

IEEE International Conference on Advances in

Computer Applications, ICACA 2016, 333–337.

https://doi.org/10.1109/ICACA.2016.7887976

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

868