Utilization of Bottom Ash and Biogas Sludge into Carbon Briquette

as an Alternative Fuel

T. E. P. S. Rahayu

1a

, Rosita Dwityaningsih

1

, M. Nurhilal

2

and Dewi Hestyani

3

1

Teknik Pengendalian Pencemaran Lingkungan, Politeknik Negeri Cilacap, Jl. Dokter Soetomo No.1, Cilacap, Indonesia

2

Teknik Mesin, Politeknik Negeri Cilacap, Jl. Dokter Soetomo No.1, Cilacap, Indonesia

3

Departemen of General Affair and Community Relations, PT. Solusi Bangun Indonesia, Cilacap, Indonesia

Keywords: Bottom Ash, Biogas Sludge, Carbonization, Briquette, Calorific Value.

Abstract: Bottom ash is by-product of coal power plant that gain less attention to be utilized compared to fly ash whereas

the production of bottom ash will continue to increase due to increasing of energy demand particularly in

Indonesia where most of its power plant use coal as combustion material. Former researches commonly

proposed bottom ash as fertilizer or soil amendment and although the idea of utilization of bottom ash as fuel

had been identified years ago, study of bottom ash as fuel seems to be still limited. This research aims to

investigate potential utilization of bottom ash as fuel by mixing it with carbonized biogas sludge prior to

briquetting process to produce carbon briquette. The quality of briquette determined using parameters such

as moisture content, ash content, and calorific value. Result shows that adding biogas sludge carbon

significantly increase calorific value of bottom ash from 270.9141 Cal/g to as high as 2180.7976 Cal/g.

1 INTRODUCTION

Bottom ash and fly ash, two major by-product of coal

power plant, considered to be increased in years

ahead especially in Indonesia where most power plant

are still using coal as its fuel. It has made known that

electricity supply in this country is still constantly in

struggle to meet the domestic’s needs to this day

while on the other hand, the domestic energy demand

continuously increasing. This condition will cause

unavoidable increasing use of coal and aligned to that,

the increasing production of bottom ash and fly ash.

There are differences of properties of bottom and fly

ash, that results different potential utilization of both.

Many research concluded that utilization of fly ash

are preferable than bottom ash due to its properties

i.e. mineral content, important trace element (James

et al., 2012), and heavy metal contaminants (Khan,

A.; Jong, W.; Jansens, P.; Spliethoff, 2009). Other

issue is that research on utilization of fly ash are more

in number than of bottom ash that effective

management and potential utilization of bottom ash

still little known (James et al., 2012). Former studies

which have been conducted on bottom ash commonly

proposed its utilization as fertilizer and soil

a

https://orcid.org/0000-0001-8959-2759

amendment, in addition to that, papers and studies in

this field of research are still limited (James et al.,

2012).

It is also known from former researches that

bottom ash contains unburnt carbon due to inefficient

fuel use during combustion process. This unburnt

carbon content, however, can be a potential energy

resource to harvest. Unburnt carbon content act as

combustible matter which can be convert to heat

through combustion process. This fact strengthens

idea of utilization bottom ash as fuel, which had been

proposed by Batra et al. (Batra, V.; Urbonaite, S.;

Svensson, 2008). He stated that bottom ash can be

utilized as household fuel or gasifier feed after

briquetting or pelletizing, but according to James et

al. (James et al., 2012), there is no research of bottom

ash as fuel can be found to this day, that more

investigation still needed to conduct to have better

understanding of capturing this energy as fuel.

Biogas sludge, a left-over solid after anaerobic

digestion of organic substance to produce biogas, is

mixed with bottom ash to complement the properties

of briquette as fuel. Biogas or biofuel has been widely

known as promising future energy source due to its

economical, renewable, and clean energy

828

Rahayu, T., Dwityaningsih, R., Nurhilal, M. and Hestyani, D.

Utilization of Bottom Ash and Biogas Sludge into Carbon Briquette as an Alternative Fuel.

DOI: 10.5220/0010954400003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 828-832

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

characteristics whilst also has high calorific value.

Biogas global production in 2015 according to Scarlat

(Scarlat, N., Dallemand, J.F., Fahl, 2018) already

reach approximately 36 billion m

3

. Study on biogas is

still enchanting many researchers to this day in the

search of more effective and efficient method to

produce biogas as well as the higher purity one, yet

utilization of biogas residue somehow gains less

attention. Optimizing potential utilization of biogas

residue is worth to conduct considering its increasing

amount due to increasing biogas production.

According to Campo (del Campo et al., 2010), biogas

residue is common to be applied directly by spreading

it onto soil as soil fertilizer because it has undergone

maturation or composting process to form valuable

organic matter.

Former researches also had proposed several

methods of utilizing anaerobic digestion sludge. Fish

farm sludge can be used as agricultural fertilizer,

input factor in microalgae production, source of

combustion, and fish feed ingredients (del Campo et

al., 2010). Nusong and Puajindanetr proposed

utilization of beer industry wastewater sludge mixed

with biodiesel production waste as briquette fuel

(Nusong & Puajindanetr, 2018) and many other

researches has been conduct on utilization wastewater

treatment plant sludge as alternative energy

source

such as industrial fuel or combustion feed for

incineration, some of them are represented by Chiou

et al. (Chiou, I.-J., & Wu, 2014), Werle S. (Werle,

2015), and Jiang et al. (Jiang, L., Yuan, X., Xiao, Z.,

Liang, J., Li, H., Cao, L., ... Zeng, 2016). These

researches concluded the undoubtedly potential

utilization of organic substance sludge as alternative

energy.

This study proposed briquetted bottom ash mixed

with carbonized biogas sludge as an alternative fuel.

The sludge taken after anaerobic digestion of organic

mixture consist of cow manure, fish waste, and water

hyacinth. Cow manure has been proven of producing

high calorific value biogas and fish waste are also

considered to have high organic content that is

potential to produce high calorific value biogas, fish

waste can be found easily in coastal area of Cilacap,

Central Java since it has many fishing industries,

while water hyacinth added in order to increase C/N

ratio or carbon content in biogas sludge which will

increase calorific value of fuel briquette.

Carbonization conducted to convert organic

substance of biogas sludge into combustible matter

ready for energy capturing in the form of heat by

combustion. According to Kurniawan et al.

(Kurniawan et al., 2018), combustion is one among

many technologies to convert sludge into energy

source. Briquetting method is selected for practical

purpose of usage considering suggestion proposed by

Batra et al. (Batra, V.; Urbonaite, S.; Svensson,

2008). This research aims particularly to utilize the

potential of bottom ash as fuel by mixing it with

carbonized biogas sludge using briquetting method as

part of larger purpose of finding effective and

efficient method to optimally utilize bottom ash.

2 EXPERIMENTAL METHOD

2.1 Material

Bottom ash taken from Bunton Coal Power Plant,

Adipala, Cilacap, Central Java. Feed material for

anaerobic digestion is mixture of cow manure, fish

waste, and water hyacinth with ratio of weight 5:1:1.

Cow manure, fish waste, and water hyacinth

originally taken from around coastal area of Cilacap,

Central Java. Molasses used as mixture binder in

briquetting process are commercial molasses.

2.2 Testing Procedures

Biogas sludge collected after 28 days of anaerobic

digestion process. Sludge then dried under sunlight

for 5 days prior to carbonization process at 200-300

o

C for 2 hours in the furnace. Carbon from

carbonization process of sludge then mixed with

bottom ash (weight ratio of biogas sludge carbon,

BSC and bottom ash, BA presented in table 4) and

sieving with 200 mesh prior to pressing to form

briquette with molasses as binder with weight ratio of

solid and molasses 1 : 1.25. Briquette then dried up

and hardened by exposing under sunlight for 5 hours.

Parameters used in this research are calorific value,

moisture content and ash content , based on

Indonesian Standard Quality (SNI) 01-6235-2000 for

fuel briquette. Calorific analysis conducted in PT.

Solusi Bangun Indonesia’s alternative fuel and raw

material laboratory using Bomb Calorimeter to

determine calorific value, ash content and moisture

content by thermogravimetric analysis in Chemistry

Laboratorium, Environmental Pollution Control

Engineering Department, Politeknik Negeri Cilacap.

Utilization of Bottom Ash and Biogas Sludge into Carbon Briquette as an Alternative Fuel

829

3 RESULT AND ANALYSIS

3.1 Characteristics of Raw Material

Chemical composition/properties of coal combustion

bottom ash derived from literatures concised by

Priyadharshini et al. (Priyadharshini P, Dr. Santhi A

S, 2011) are presented in Table 1.

Table 1: Chemical Composition of Combustion Coal

Bottom Ash.

Major Element % Weight

SiO2 38.2-54.5

Al2 O3 15.1-21.3

C 6.52-10.10

Fe2O3 5.50-32.8

CaO 2.04-17.9

K2O 1.10-2.1

LOI 1.40-11.0

MgO 0.79-4.26

TiO2 0.70-1.3

Na2O 0.27-1.0

SO3 0.21-2.5

Properties of biogas sludge examined at 28

th

day

of anaerobic digestion process are presented in Table

2.

Table 2: Properties of Biogas Sludge.

Parameters Value

Moisture content (% w) 94.27

Volatile solid concentration (ppm) 10,400

Total solid concentration (ppm) 28,000

3.2 Briquette Experimental Result

Parameters examined in this study are moisture

content, ash content, and calorific value. These

parameters based on Indonesian Standard Quality

(SNI) 01-6235-2000 for fuel briquette (Table 3) and

the result provided in Table 4.

Figure 1: Bottom ash and biogas sludge briquette.

Table 3: Indonesian National Quality Standard for Quality

Briquette.

Parameters Value

Moisture content (%) <8

Ash content (%) <8

Carbon content (%) > 77

Calorific value (cal/g) > 5000

Badan Penelitian dan Pengembangan Kehutanan (1994) , Putri (2017) (Putri, 2017)

Variable of experiment is ratio of biogas sludge

carbon (BSC) and bottom ash (BA) which composed

fuel briquette. Experiment aims to find out ratio with

the best quality briquette in parameters of moisture

content, ash content, and calorific value. Result of

experiment provided in Table 4.

Table 4: Briquette Experimental Result.

Sample

(%w)

Moisture

Content

(%)

Ash

Content

(%)

Calorific

Value

(Cal/g)

BSC : BA= 0%:100% 1.55 83.96 270.9141

BSC : BA= 20%:80% 2.21 80.81 919.3231

BSC : BA= 40%:60% 3.00 71.41 1180.657

BSC : BA= 60%:40% 3.98 59.64 1497.1601

BSC : BA= 80%:20% 5.70 48.79 2180.7976

BSC : BA= 100%:0% 7.05 29.52 3226.7651

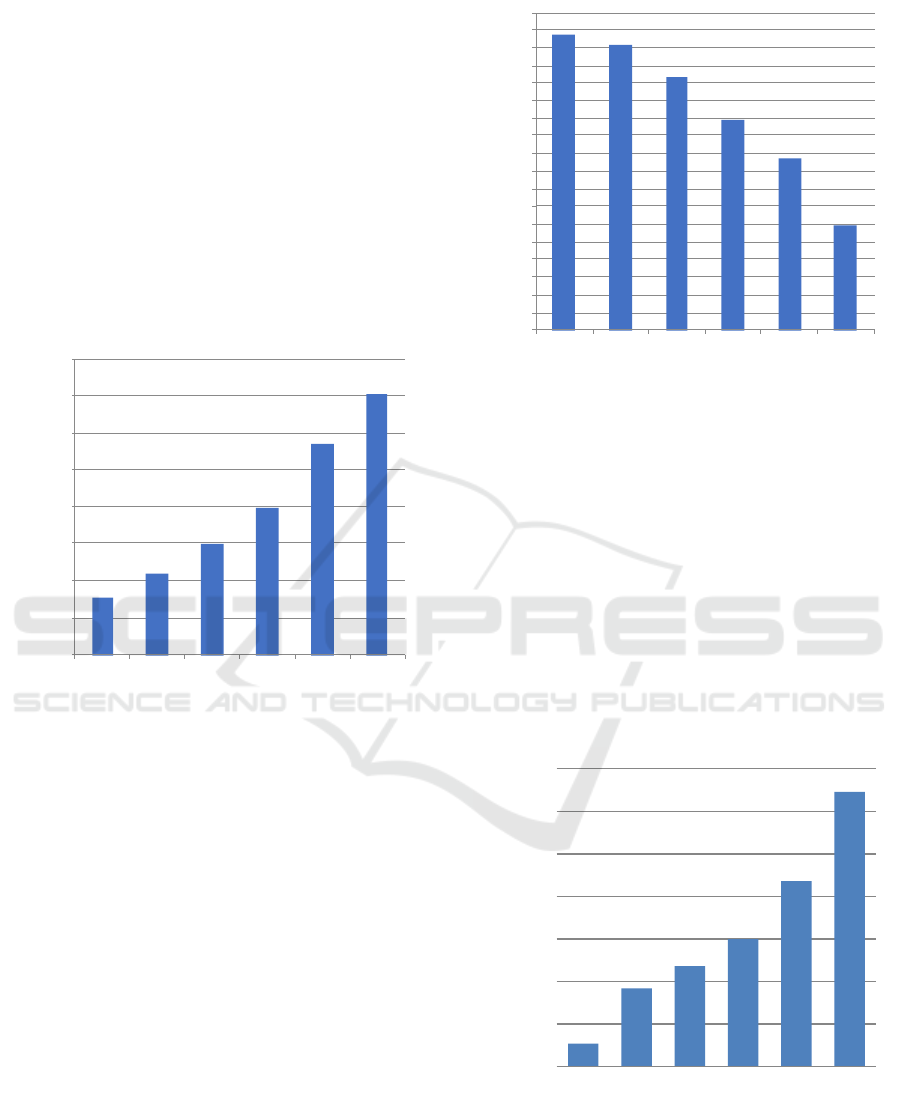

3.3 Moisture Content

Moisture content for each sample of briquette are

presented in Figure 2. It shows that moisture content

of briquette increase along with the increasing ratio

of biogas sludge to bottom ash increase. This is due

to hygroscopic nature of biogas sludge. The ability to

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

830

absorb water comes from carbon’s high surface area

and pores. Moisture content is a disadvantage in

capturing energy of fuel briquette because it inhibits

conversion of chemical potential energy into heat by

oxidation process (combustion) which is unwanted in

accordance with the purpose of research and the

higher the moisture content, the lower its ability of

burning and heating and briquette’s quality.

However, moisture content in all variants of

briquettes are below limit value of standard (< 8 %).

This also conclude that briquette of carbonized biogas

sludge and bottom ash typically has low moisture

content. This low moisture content is derived as result

of carbonization process of biogas sludge where most

of water vaporized during the process.

Figure 2: Moisture content of briquette.

3.4 Ash Content

Results of ash content are presented Figure 3. It

shows that increasing ratio of biogas sludge to bottom

ash on the contrary decrease ash content of briquette.

It is due to amount of bottom ash composed the

briquette. Ash is inorganic incombustible matter left

after combustion process of fuel and bottom ash is an

incombustible left over solid of coal combustion. Ash

content in a briquette prevent combustion gas free

movement to the core of briquette (James et al., 2012)

and inhibit energy conversion which is unwanted.

The higher the ash content, the lower the quality of

briquette. Ash content of all variant briquette are

above standard value (< 8%) which shows that the use

of bottom ash as fuel might be at cross purposes.

Figure 3: Ash content of briquette.

3.5 Calorific Value

Calorific value is the most important parameter of

fuel’s quality (Isa, 2012). The higher the calorific

value, the higher the quality of briquette as fuel. From

Figure 4. we may know that 100 % bottom ash

briquette has calorific value even though far below

SNI standard. Calorific value of 100% bottom ash

briquette shows that bottom ash still contain

combustible matter that is unburnt carbon (James et

al., 2012). Calorific value increase with the increasing

ratio of biogas sludge carbon. It extent from only

270.9141 Cal/g (100% bottom ash) to as high as

2180.7976 Cal/g (20% bottom ash).

Figure 4: Calorific value of briquette.

0,00

1,00

2,00

3,00

4,00

5,00

6,00

7,00

8,00

BSC: BA=

0%:100%

BSC: BA=

20%:80%

BSC:BA=

40%:60%

BSC:BA=

60%:40%

BSC:BA=

80%:20%

BSC:BA=

100%:0%

moisture content (%)

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

BSC: BA=

0%:100%

BSC: BA=

20%:80%

BSC: BA=

40%:60%

BSC: BA=

60%:40%

BSC: BA=

80%:20%

BSC: BA=

100%:0%

ash content (% )

0

500

1000

1500

2000

2500

3000

3500

BSC: BA=

0%:100%

BSC: BA=

20%:80%

BSC: BA=

40%:60%

BSC: BA=

60%:40%

BSC: BA=

80%:20%

BSC: BA=

100%:0%

calorific value (Cal/g)

Utilization of Bottom Ash and Biogas Sludge into Carbon Briquette as an Alternative Fuel

831

According to (Erikson, 2011), moisture content

and ash content influence calorific value of carbon

briquette. The higher moisture content and ash

content, the lower calorific value however results of

this research show that highest calorific value possess

by briquette with highest moisture content (20 %

bottom ash). This is due to drying process applied

prior to usage that removed moisture and increase

heating efficiency in briquette.

4 CONCLUSIONS

Result of experiments conducted in this research

draws conclusion that biogas sludge carbon added to

bottom ash proven to be successfully increased

calorific value of briquette from only 270.9141 Cal/g

(100% bottom ash) to as high as 2180.7976 Cal/g

(20% bottom ash) with low moisture content (below

8%) even though ash content is above standard value

of SNI 01-6235-2000, that it might open ways for

bottom ash not just ended at landfill, yet it still needs

further research to be optimally utilized as fuel. Other

organic substance to increase calorific value of

bottom ash might considerably conduct for the next

research.

ACKNOWLEDGEMENTS

Thanks to PT. Solusi Bangun Indonesia, Tbk for

supporting this research by providing its laboratory

and instrument to conduct calorific analysis.

REFERENCES

Batra, V.; Urbonaite, S.; Svensson, G. (2008).

Characterization of unburned carbon in bagasse fy ash.

Fuel, 87(13–14), 2972–2976.

https://doi.org/https://doi.org/10.1016/j.fuel.2008.04.0

10

Chiou, I.-J., & Wu, I.-T. (2014). Evaluating the

manufacturability and combustion behaviors of

sludge-derived fuel briquettes. Waste Management,

34(10), 1847–1852.

https://doi.org/https://doi.org/10.1016/j.wasman.201

4.05.013

del Campo, L. M., Ibarra, P., Gutierrez, X., & Takle, H.

(2010). Utilization of sludge from recirculation

aquaculture systems. In Rapport 9/2010 (Issue

March). www.nofima.no/filearchive/Rapport 09-

2010.pdf

Erikson, S. (2011). Studi Pemanfaatan Briket Kulit Jamu

Mente dan Tongkol Jagung Sebagai Bahan Bakar

Alternatif. Universitas Hasanudin.

Isa, I. (2012). Briket Arang Dan Arang Aktif Dari Limbah

Tongkol Jagung.

James, A. K., Thring, R. W., Helle, S., & Ghuman, H. S.

(2012). Ash management review-applications of

biomass bottom ash. Energies, 5(10), 3856–3873.

https://doi.org/10.3390/en5103856

Jiang, L., Yuan, X., Xiao, Z., Liang, J., Li, H., Cao, L., ...

Zeng, G. (2016). A comparative study of biomass

pellet and biomass-sludge mixed pellet: Energy input

and pellet properties. Energy Conversion and

Management, 126, 509–515.

https://doi.org/https://doi.org/10.1016/j.enconman.2

016.08.035

Khan, A.; Jong, W.; Jansens, P.; Spliethoff, H. (2009).

Biomass combustion in fluidized bed boilers:

Potential problems and remidies. Fuel Process.

Technol., 90(1), 21–50.

https://doi.org/https://doi.org/10.1016/j.fuproc.2008

.07.012

Kurniawan, T., Hakiki, R., & Sidjabat, F. M. (2018).

Wastewater Sludge As an Alternative Energy

Resource: a Review. Journal of Environmental

Engineering & Waste Management, 3(1), 1–12.

https://doi.org/10.33021/jenv.v3i1.396

Nusong, P., & Puajindanetr, S. (2018). Briquette fuel

production from wastewater sludge of beer industry

and biodiesel production wastes. IOP Conference

Series: Earth and Environmental Science, 133(1).

https://doi.org/10.1088/1755-1315/133/1/012022

Priyadharshini P, Dr. Santhi A S, D. M. G. G. (2011). A

review on the utilization of bottom ash. A Review on

the Utilization of Bottom Ash.

Putri, R. E. and A. (2017). Studi Mutu Briket Arang dengan

Bahan Baku Limbah Biomassa. Jurnal Teknologi

Pertanian Andalas, 21(2).

https://doi.org/https://doi.org/10.25077/jtpa.21.2.14

3-151.2017

Scarlat, N., Dallemand, J.F., Fahl, F. (2018). Biogas:

Developments and perspectives in Europe.

Renewable Energy, 129, 457–472.

https://doi.org/https://doi.org/10.1016/j.renene.2018

.03.006

Werle, S. (2015). Gasification of a Dried Sewage Sludge in

a Laboratory Scale Fixed Bed Reactor. Energy

Procedia, 8(8), 8562–8572.

https://doi.org/https://doi.org/10.3390/en8088562

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

832