The Effect of Rebar Tie Fiber as a Concrete Mixture Material on

Compressive and Tensile Strength

Joko Suryono

a

and Yudi Pranoto

b

Civil Engineering Department, Samarinda State Polytechnic, East Kalimantan, Indonesia

Keywords: Rebar Tie Fiber, Compressive Strength, Tensile Strength, Concrete Mixture.

Abstract: Concrete is one of the construction materials made of a homogeneous mixture between cement, coarse

aggregate, fine aggregate, and water. Concrete is widely used in construction, both on bridges, roads,

buildings, and other constructions. The purpose of this study is to determine the differences of compressive

and tensile strength between normal concrete and concrete with rebar tie fiber. The addition of tie wire fibers

with a length 8 cm. Variations in the addition of rebar tie fiber 0%, 0.2%, 0.4%, 0.6%, 0.8%, and 1% form

material total weight. Concrete was tested at the age of 28 days. From the test results, it was found that the

highest compressive strength is 29.48 MPa with the addition of 0.8% rebar tie fiber. The compressive strength

increase 13.5% from normal concrete. The highest tensile strength is 7.39 MPa with the addition 0.8% rebar

tie fiber. The tensile strength increase 17.3% from normal concrete.

1 INTRODUCTION

Concrete is one of the construction materials made of

a homogeneous mixture between cement, coarse

aggregate, fine aggregate, and water. Concrete is

widely used in construction, both on bridges, roads,

buildings, and other constructions.

Concrete also has the advantage of high

compressive strength, resistance to fire and weather,

concrete mortar is easy to transport and shape

according to needs, and maintenance costs are quite

low. In addition to having the advantages of concrete

also has weaknesses such as tensile strength that is

much smaller than the compressive strength so this

makes concrete requires special treatment to

overcome the weaknesses in concrete.

This can be improved by the addition of steel

reinforcement or fibers consisting of certain

materials. Fiber materials that can be used to correct

concrete weakness according to the American

Concrete Institute (ACI) Committee 544 (2002) one

of which is steel fiber (rebar tie fiber).

The purpose of the study was to find out and

analyze the additional influence of Rebar tie fiber on

compressive and tensile strength.

a

https://orcid.org/0000-0001-8281-6692

b

https://orcid.org/0000-0003-2997-7475

Studies about rebar tie fiber concrete has been

conducted by An M Shende et al., 2012; Juliansyah et

al., 2019; Kolawole et al., 2013; Komal Chawla and

Bharti Tekwani, 2013; Ngudiyono., 2012;

Rajarajeshwari et al., 2013; Wahyono and Agustinus.,

2013, Widodo and Aris., 2012. The result of these

studies obtained that fibers can improve the

mechanical properties of concrete such as

compressive strength, tensile strength, shear strength,

bending strength, ductility, and shock resistance.

2 CHARACTERISTICS OF

CONCRETE

2.1 Concrete Volume Weight

The weight of concrete volume is a comparison

between the concrete Weight divided by concrete

volume. The weight of concrete volume is influenced

by the aggregate shape, aggregate gradation because

the weight of the concrete volume depends on the

weight of the aggregate volume. The weight of the

concrete volume is in an air dry state. The weight of

the volume is calculated using the following formula:

Suryono, J. and Pranoto, Y.

The Effect of Rebar Tie Fiber as a Concrete Mixture Material on Compressive and Tensile Strength.

DOI: 10.5220/0010954200003260

In Proceedings of the 4th International Conference on Applied Science and Technology on Engineering Science (iCAST-ES 2021), pages 821-827

ISBN: 978-989-758-615-6; ISSN: 2975-8246

Copyright

c

2023 by SCITEPRESS – Science and Technology Publications, Lda. Under CC license (CC BY-NC-ND 4.0)

821

γc = W/V

Where:

γc = Concrete volume weight (kg/m

3

)

W = Weight of test object (kg)

V = Concrete volume (m

3

)

2.2 Concrete Compression Strength

Concrete Press is the magnitude of the load per unit

area, which causes the concrete test object to be

destroyed when weighed with a certain compressive

force, which is produced by the press machine. In the

testing of the strong concrete press, the test object can

be a cube and cylinder. The strength of the concrete

press is determined by material i.e. cement, coarse

aggregate, fine aggregate, and water. Strength

concrete press is the most important property of

concrete. Strength concrete press is usually related to

other properties, meaning when the concrete press is

high, the other properties are also good. According to

SNI 1974:2011 strong concrete press can be searched

with the following formula:

f’

C

= P/A

Information:

f’

C

= Strength concrete press (MPa)

P = Maximum compressive load (N)

A = Depressed cross-sectional area (mm2)

2.3 Concrete Tensile Strength

Tensile Strength tensile is one of the important

parameters in concrete strength. Tensile strength

values are obtained through laboratory press testing

by overloading each cylinder test object laterally to

Figure 1: Compression test.

its maximum strength. The test object used is a

cylindrical test object that is placed evenly in the

direction of diameter along with the test object. When

the tensile strength is reached then the test object will

be split in half (SNI 03-2491-2002). The tensile

strength can be calculated by the following formula:

f’

Ct

= 2P/LD

With:

f’

ct

= Concrete tensile strength (MPa)

P = Maximum load when the test object

is split (N)

L = Test object length (mm)

D = Diameter of the test object (mm)

Figure 2: Split Tensile Tes.

2.4 Use of Rebar Tie Fibers

Table 1: Requirement of Cube rebar Tie fibers test objects.

No

Rebar tie fibers (%) Re

q

uiremen

t

(g

r

)

One s

p

ecimen Five s

p

ecimen

1 0.2 19 95

2 0.4 38 190

3 0.6 57 285

4 0.8 76 380

5 1.0 95 475

Table 2: Requirement of Cylinder rebar tie fibers test objects.

No Rebar tie fibers (%) Re

q

uiremen

t

(g

r

)

One s

p

ecimen Five s

p

ecimen

1 0.2 10 50

2 0.4 20 100

3 0.6 30 150

4 0.8 40 200

5 1.0 50 250

Concrete

cylinder

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

822

Table 3: Number of test object.

Rebar tie fibers (%) 0 0.2 0.4 0.6 0.8 1 Total

Compressive Strength 5 5 5 5 5 5

60

Tensile Strength 5 5 5 5 5 5

Number of test object 10 10 10 10 10 10

2.5 Statistical Analysis

In this study, statistical analysis was conducted to

determine the accuracy of data obtained from the

research that has been done. There are two methods

used in this study are ANOVA and regression

analysis. The ANOVA method is an analysis that tests

the average difference between groups. The

hypothesis used in this study is H

0

= the absence of a

significant influence between the addition of

connective wire fibers with the value of compressive

strength and tensile strength of concrete and H

1

= the

presence of a significant influence between the

addition of rebar tie fibers and the value of

compressive strength with the tensile strength of

concrete. H

0

applies if F count < F table while H

1

applies if F count > F table.

Regression analysis is one method in statistics to

measure the influence of free variables (x) on bound

variables (y). In this study, the free variable (x) was the

percentage of the addition of connective wire fibers

(%) whereas variable bound (y) is the value of

compressive strength and tensile strength of concrete.

The regression analysis in this study was used to

determine the contribution of variable x (percentage of

addition of rebar tie fibers) to variable y (value of

compressive strength and tensile strength of concrete).

3 METHODOLOGY

3.1 Research Location

The research site was conducted in the Laboratory of

Civil Engineering Department, Samarinda State

Polytechnic.

3.2 General

The research was conducted using experimental

methods in the laboratory with several stages.

Starting from the preparation of equipment and

materials, material inspection, mixed planning is

continued with the manufacture of test objects. The

shape and size of the fibers of the rebar tie fibers with

a straight variation with a length 8 cm can be seen in

figure 3.

Figure 3: Cross-section of rebar tie fibers.

3.3 Dimensions of the Test Object

Pressure force test objects in the form of cubes size

15 cm x 15 cm x 15 cm and cylindrical tensile

strength test objects with a diameter of 10 cm and

height of 20 cm. In this study, the total number of test

objects made as many as 60 pieces consists of 30

pieces of press force test objects and 30 pieces such

as Table 1. Testing of compressive strength and

tensile strength of concrete is performed after the test

object is 28 days old.

3.4 Mixed Design

The mix design between cement, water, and

aggregates -essential to obtain the desired concrete

strength. In this study the composition of concrete

mixture design using SNI 03-2834-2000 with the

planned strength of K-250 and 20 MPa Of Normal

Concrete. The fiber of the connecting wire is straight

with a length of 8 cm and a diameter of 1 mm (Figure

3).

3.5 Addition of Rebar Tie Fibers

Sowing the fibers evenly into a mixing tub containing

ordinary concrete mortar. Sowing fiber is done

carefully and cultivated fibers are spread evenly in the

concrete mortar so that there is no clumping of fibers

that can affect the strength of concrete fibers. The

amount of fiber added corresponds to the percentage

of predetermined variations (Table 1 and Table 2).

3.6 Test Object

At this stage is carried out concrete compression

testing and concrete tensile strength at the age of 28

80 mm

Ø 1 m

m

The Effect of Rebar Tie Fiber as a Concrete Mixture Material on Compressive and Tensile Strength

823

days because concrete at the age of 28 days has

maximum compressive strength. The procedure of

testing strong press refers to (SNI 1974-2011) and

strong pull refers to (SNI 03-2491-2002).

Figure 4: Concrete Press Test Equipment.

Figure 5: Concrete Cube Test Objects.

Figure 6: Split Test Equipment.

Figure 7: Split Dance Test Objects.

Based on the values obtained from the inspection

of materials to achieve a concrete quality of 20 MPa

with FAS 0.60 it takes a mixture composition as in

Table 4 and Table 5.

4 RESULT AND DISCUSSION

4.1 Composition Concrete Mixture

Table 4: Composition of Cylindrical Concrete Mixture.

Source: Research Results

Table 5: Composition of Concrete Cube Mixture.

Composition of Concrete Cube Mixture

5 Cubes concrete mix volume

15x15x15 = 0,0194 m

3

0 % 0.2 % 0.4 % 0.6 % 0.8 % 1.0 %

Cement (k

g

) 6.3 6.17 6.05 5.92 5.79 5.67

Water (k

g

/ltr) 3.5 3.43 3.36 3.29 3.22 3.15

Coarse Aggregate ½ (kg) 12.4 12.15 11.90 11.65 11.41 11.16

Coarse A

gg

re

g

ate 2/3 (k

g

) 12.1 11.85 11.62 11.37 11.13 10.89

Fine Aggregate (kg)

13.1

12.84 12.58 12.31 12.05 11.79

Rebar tie fibers (k

g

) 0 0.095 0.190 0.285 0.380 0.475

Source: Research Results

Composition of C

y

lindrical Concrete Mixture

5 cylinders concrete mixture volume

ϕ 10 x 20 = 0,0102 m

3

0 % 0.2 % 0.4 % 0.6 % 0.8 % 1.0 %

Cement (k

g

) 3.32 3.25 3.19 3.12 3.05 2.98

Water (kg/ltr) 1.80 1.76 1.72 1.69 1.65 1.62

Rou

g

h A

gg

re

g

ate ½ (k

g

) 6.53 6.39 6.27 6.14 6.00 5.87

Rou

g

h A

gg

re

g

ate 2/3 (k

g

) 6.38 6.25 6.12 5.99 5.87 5.74

Fine Aggregate (kg) 6.91 6.77 6.63 6.49 6.36 6.22

Rebar tie fibers (k

g

) 0 0.05 0.10 0.15 0.20 0.25

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

824

4.2 Slump Test

The result of making concrete samples conducted

using cement water factor (fas) = 0.6 produces a

diverse slump value with intervals between 30-60

mm. Slump test results can be seen in the following

table 6:

Table 6: Slump Value For Cube Test Objects.

No.

Slump Value (mm)

%

Cylinder Test Objects

Cube Test

Objects

1 0 45 45

2 0,2 40 40

3 0,4 40 40

4 0,6 40 40

5 0,8 35 35

6 1 35 30

Figure 8: Concrete Slump Test.

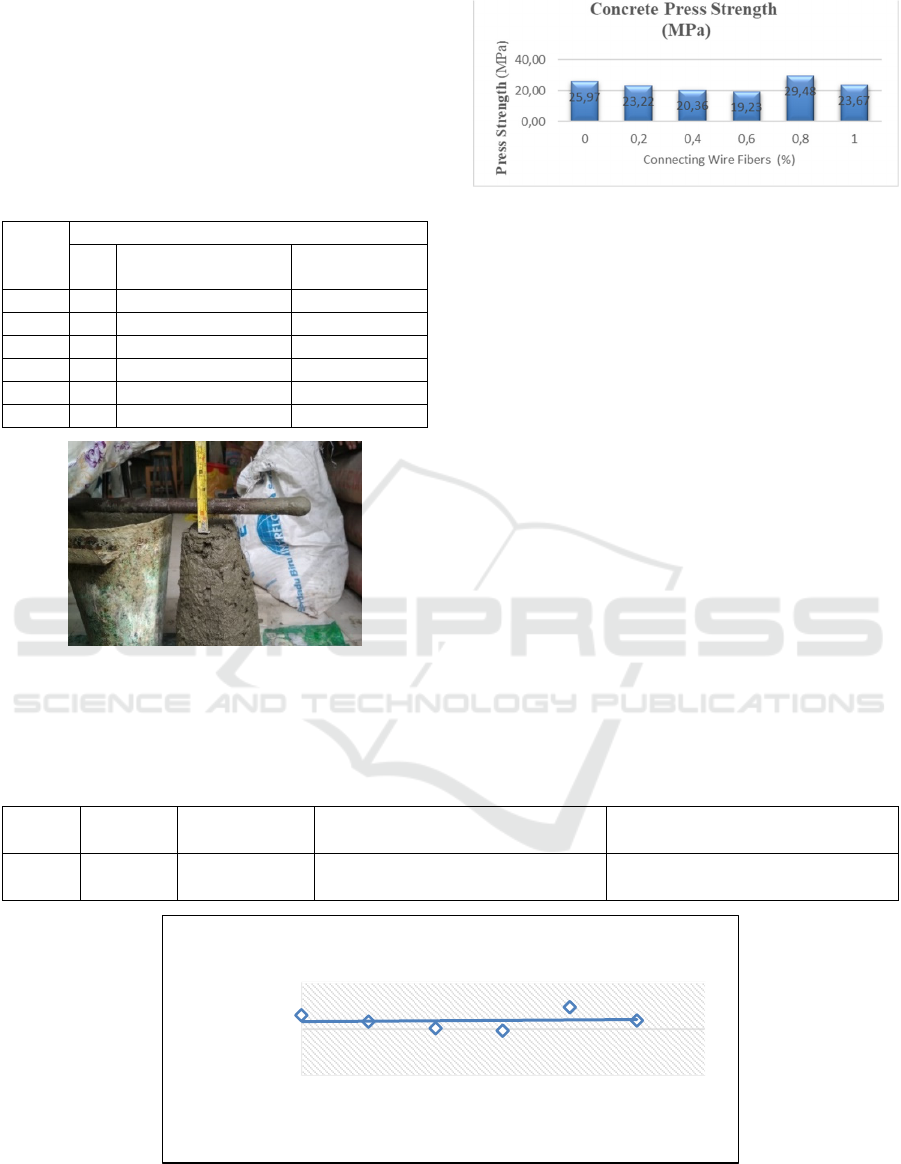

Based on Figure 9 of the test results obtained the

value of the compression strength at the percentage of

Figure 9: Concrete Press Strength Test.

the addition of rebar tie fibers 0% which is 25.97

MPa, then there was a decrease in the percentage of

the addition of rebar tie fibers 0.2% is 23.22. The

percentage of the addition of rebar tie fibers 0.4% is

20.36 MPa, the percentage of the addition of the

weight of rebar tie fibers 0.6% is 19.23 MPa. Then

the strong press increased at the percentage of the

addition of rebar tie fibers can be 0.8% is 29.48 MPa

and decreased again at the percentage of the addition

of rebar tie fibers 1% which is 23.67 MPa.

Based on Figure 10 R Square (R

2

) value of 0.008

means the amount of influence of the addition of rebar

tie fibers to the concrete press strength by 0.8%.

While the rest (100% - 0.8% = 99.2%) other variables

outside of research. Other variables in this study are

the lack of test objects, timeliness in the

manufacturing process, and temperature changes.

Based on Table 9 known value F count = 1,300

while F table = 7,709 which means F calculate < F

table then H0 received at signification level 0.05

means the addition of rebar tie fibers does not cause a

real change in the value of tensile strength.

Table 7: Average compressive strength analysis results.

N

o R R Square R Square Customize

d

Std. Estimation erro

r

1 0.88

a

0.008 -0.240 4.16463

Figure 10: Curve R Square Strength Press.

y = 0.8764x + 23.217

R² = 0.008

0,00

20,00

40,00

0 0,2 0,4 0,6 0,8 1 1,2

Compressive

Strength (MPa)

Connecting Wire Fibers (%)

The Effect of Rebar Tie Fiber as a Concrete Mixture Material on Compressive and Tensile Strength

825

Table 8: Compressive Strength Testing Analysis Results.

ANOVA

Variasi df

Kuadrat

Mean

F count F Table H0

Regression 0.540 1 0.540 0.031 7.709 receive

Residual 69.377 4 17.344

Total 69.917 5

4.4 Tensile Strength Test

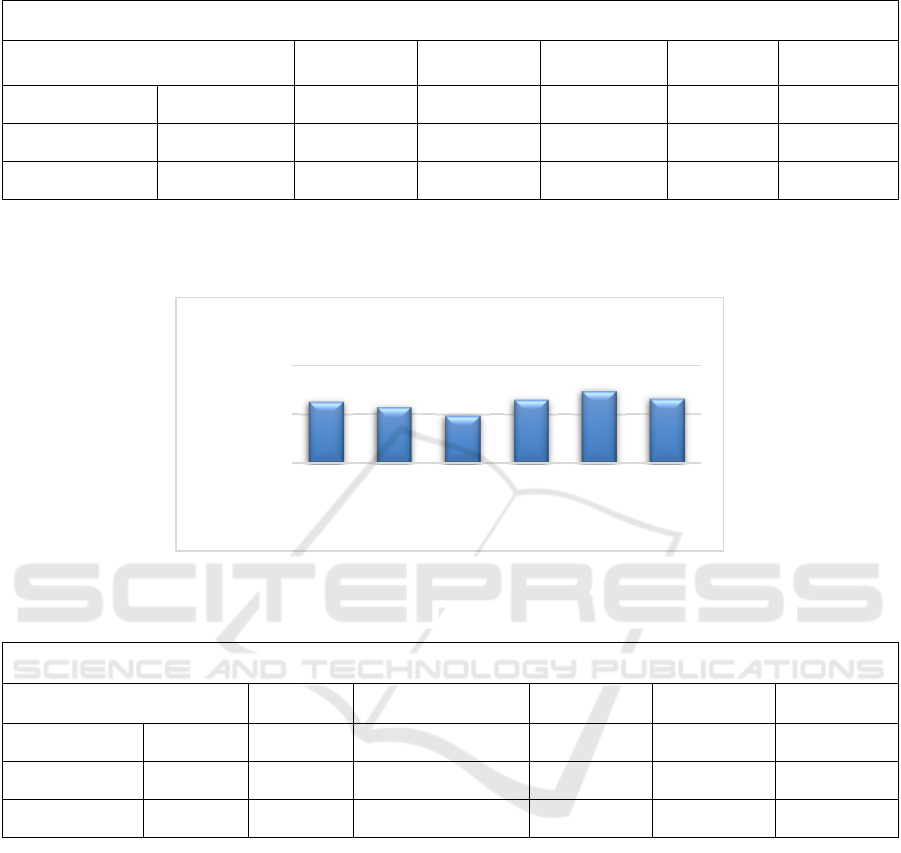

Figure 11: Concrete Tensile Strength Test.

Table 9: Tensile Strength Testing Analysis Results.

ANOVA

Variasi df Kuadrat Mean F count F Table H0

Regression 0.905 1 0.905 1.300 7.709 receive

Residual 2.786 4 0.697

Total 3.691 5

(source: SPSS)

Based on Figure 11 obtained the value of R Square

(R2) of 0.246 which means the magnitude of the

influence of the addition of connecting wire fibers to

the concrete press strength by 24.6%. While the rest

(100% - 24.6% = 74.4%) other variables outside of

research. Other variables in this study are the lack of

test objects, timeliness in the manufacturing process,

and temperature changes. Based on Table 10 known

value F count = 1.300 while F table = 7.709 which

means F calculate < F table then H0 received at

signification level 0.05 means the addition of rebar tie

fibers does not cause a change in the value of the pull

force in real.

5 CONCLUSIONS

From the results of research conducted on the

variation of connective wire fiber mixture 0%. 0.2%.

0.4%. 0.6%. 0.8% and 1% can be concluded as

follows:

• From the test result of concrete press

strength decrease occurred at 0.2% = 23.22

MPa. the addition of rebar tie fibers 0.4% =

20.36 MPa. the addition of rebar tie fibers

0.6% = 19.23 MPa then increased at the

addition of rebar tie fibers 0.8% = 29.48

MPa and decreased again at the addition of

6,30

5,68

4,86

6,49

7,39

6,54

0,00

5,00

10,00

0 0,2 0,4 0,6 0,8 1

Tensile Strength (MPa)

Connecting Wire Fibers (%)

Tensile Strength (MPa)

iCAST-ES 2021 - International Conference on Applied Science and Technology on Engineering Science

826

rebar tie fibers 1% = 23.67 MPa to normal

concrete of 25.97 MPa.

• From the test result of concrete tensile

strength the decrease occurred in the

addition of rebar tie fibers 0.2% = 5.68 MPa.

the addition of rebar tie fibers 0.4% = 4.86

MPa. then increased at 0.6% = 6.49 MPa.

increased the addition of rebar tie fibers

0.8% = 7.39 MPa and again decreased at the

addition of rebar tie fibers 1% = 6.54 MPa to

normal concrete with a tensile strength of

6.30 MPa.

• From the results of statistical analysis on

compressive strength obtained the value of

R Square (R2) = 0.008 and Anova obtained

H0 received then there is no significant

influence between the addition of rebar tie

fibers with the value of compressive

strength.

• From the results of statistical analysis on the

tensile strength of concrete tensile obtained

the value of R Square (R2) = 0.246 and

Anova obtained H0 received then there is no

significant influence between the addition of

rebar tie fibers with the value of I pull

concrete..

REFERENCES

ACI Committee 544. 2002. State of the Art Report on Fiber

Reinforced Concrete. Report:ACI 544.IR-96. American

Concrete Institute. Detroit. Michigan.

An M Shende.. A M Pande.. M Gulfam Pathan.. 2012.

Experimental Study on Steel Fiber Reinforced Concrete

for M-40 Grade. International Refereed Journal of

Engineering and Science (IRJES). Vol. 1 Issue 1. P.

043-048.

Juliansyah Astari Kawulusan. H. Manalip. Servie O. Dapas.

2019. Pemeriksaan Kuat Tarik Belah Beton Serat

Kawat Ikat Dengan Variasi Sudut Tekuk Pada Kedua

Ujungnya. Jurnal Sipil Statik. Vol. 7. No. 5 Mei 2019.

p. 513-525. ISSN : 2337-6732.

Kolawole Adisa Olanade. Adewale Donyinsola. Alake.

Abiola Gabriel. Morakinyo. 2013. Strength

Development and Crack Pattern of Coconut Fiber

Reinforced Concrete (CFRC). Civil Environment

Research. Vol. 4.

Komal Chawla. Bharti Tekwani. 2013. Studies of Glass

Fiber Reinforced Concrete Composite. International

Journal of Structural and Civil Engineering Research

ISSN 2319-6009 Vol. 2 No. 3.p. 176-182.

Ngudiyono.. 2012. Metode Perbaikan Tegangan Geser

Beton Dengan Fiber Kawat Ikat. Jurnal Teknik

REKAYASA. Vol. 13 No. 1. p. 44-54.

Rajarajeshwari B. Vibhuti.. Radhakrisna.. Aravind N..

2013. Mekanical Properties of Hybrid Fiber Reinforced

Concrete For Pavements. International Journal of

Research in Engineering and Technology. eISSN:

2319-1163. pISSN: 2321-7308.

The Effect of Rebar Tie Fiber as a Concrete Mixture Material on Compressive and Tensile Strength

827